Corrosion-resistant steel tube for conveying industry fuel gas and preparation technology thereof

An industrial gas and preparation technology, applied to pipes, rigid pipes, anti-corrosion coatings, etc., can solve the problems of shortened service life and poor corrosion resistance of steel pipes, so as to prolong the service life, enhance the ability of blocking gas, and reduce the adhesion on The effect of the probability of the inner wall of the tube blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

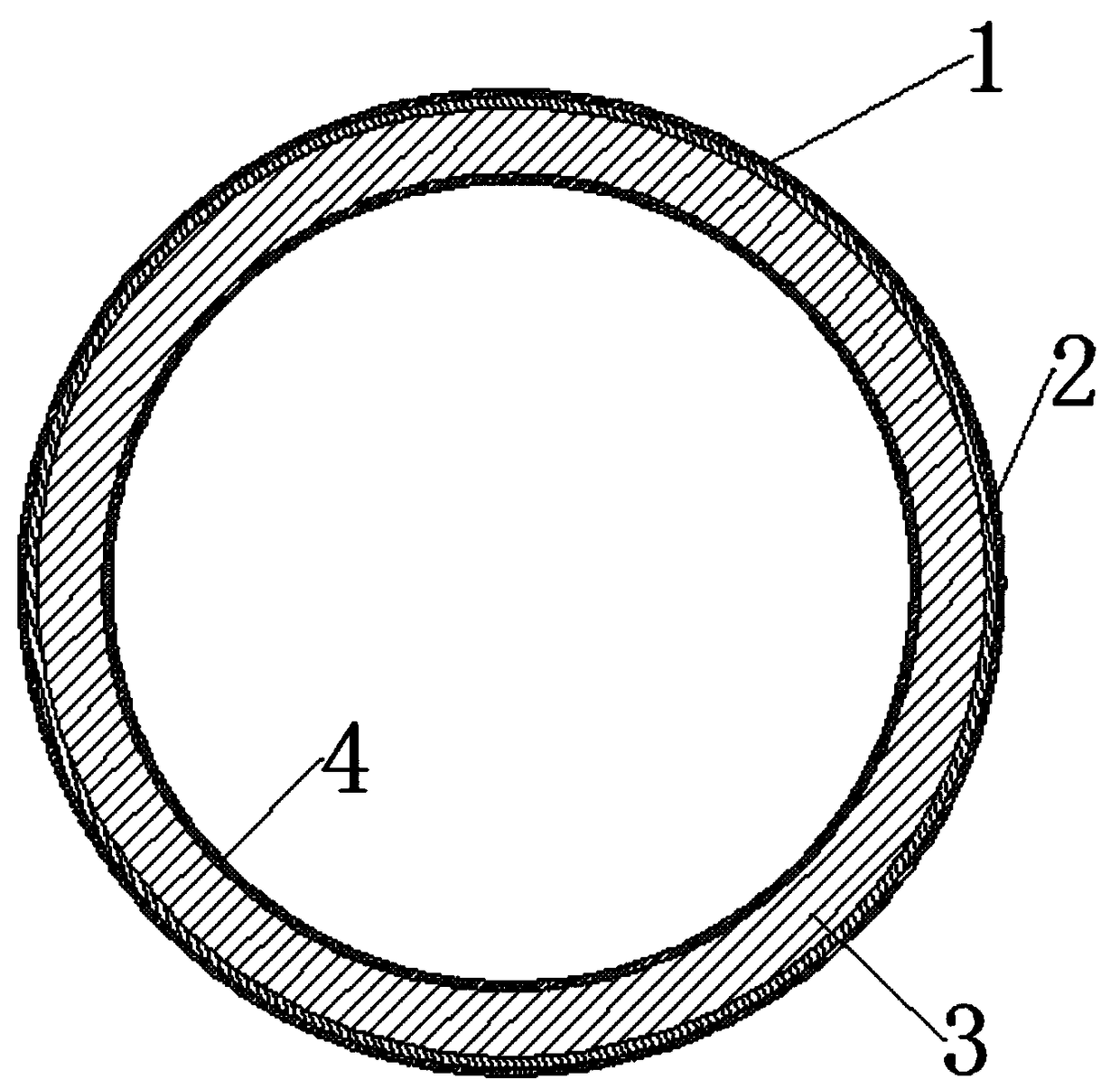

[0031] Such as figure 1 As shown, a corrosion-resistant steel pipe for transporting industrial gas, its structure includes an outer coating, an electroplating layer, a tube blank and an inner coating in sequence from the outside to the inside.

[0032] Preferably, the outer coating is composed of 40 parts of vinylidene chloride composite polymer emulsion, 7 parts of iron red, 10.5 parts of sodium ethylenediamine tetramethylene phosphate, and 13 parts of diethylene triamine pentacarboxylate in terms of weight ratio. 4 parts, 4 parts of gallic acid, 18 parts of toluene, 0.6 parts of emulsified silicone oil, 0.6 parts of carboxymethyl cellulose and 24 parts of deionized water; after mixing and stirring the above components, the outer coating is made by ultrasonic emulsification.

[0033] Preferably, the plating metals in the electroplating layer are Zn and Sn; and the mass ratio of Zn and Sn is 1.5:1.

[0034] Preferably, the tube blank is composed of the following components in...

Embodiment 2

[0044] Such as figure 1 As shown, a corrosion-resistant steel pipe for transporting industrial gas, its structure includes an outer coating, an electroplating layer, a tube blank and an inner coating in sequence from the outside to the inside.

[0045] Preferably, the outer coating is composed of 30 parts of vinylidene chloride composite polymer emulsion, 9 parts of iron red, 10 parts of sodium ethylenediamine tetramethylene phosphate, and 15 parts of diethylene triamine pentacarboxylate in weight ratio. 3 parts of gallic acid, 20 parts of toluene, 0.3 parts of emulsified silicone oil, 0.9 parts of carboxymethyl cellulose and 22 parts of deionized water; after mixing and stirring the above-mentioned components, the outer coating is made by ultrasonic emulsification.

[0046] Preferably, the plating metals in the electroplating layer are Zn and Sn; and the mass ratio of Zn and Sn is 2.0:1.

[0047] Preferably, the tube blank is composed of the following components in terms of ...

Embodiment 3

[0057] Such as figure 1 As shown, a corrosion-resistant steel pipe for transporting industrial gas, its structure includes an outer coating, an electroplating layer, a tube blank and an inner coating in sequence from the outside to the inside.

[0058] Preferably, the outer coating is composed of 60 parts of vinylidene chloride composite polymer emulsion, 12 parts of iron red, 12 parts of sodium ethylenediamine tetramethylene phosphate, and 17 parts of diethylene triamine pentacarboxylate in weight ratio. parts, 7 parts of gallic acid, 22 parts of toluene, 1.0 parts of emulsified silicone oil, 1.2 parts of carboxymethyl cellulose and 27 parts of deionized water; after mixing and stirring the above components, they are then ultrasonically emulsified to make the outer coating.

[0059] Preferably, the plating metals in the electroplating layer are Zn and Sn; and the mass ratio of Zn and Sn is 2.5:1.

[0060] Preferably, the tube blank is composed of the following components in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com