Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1205results about "Foundation repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

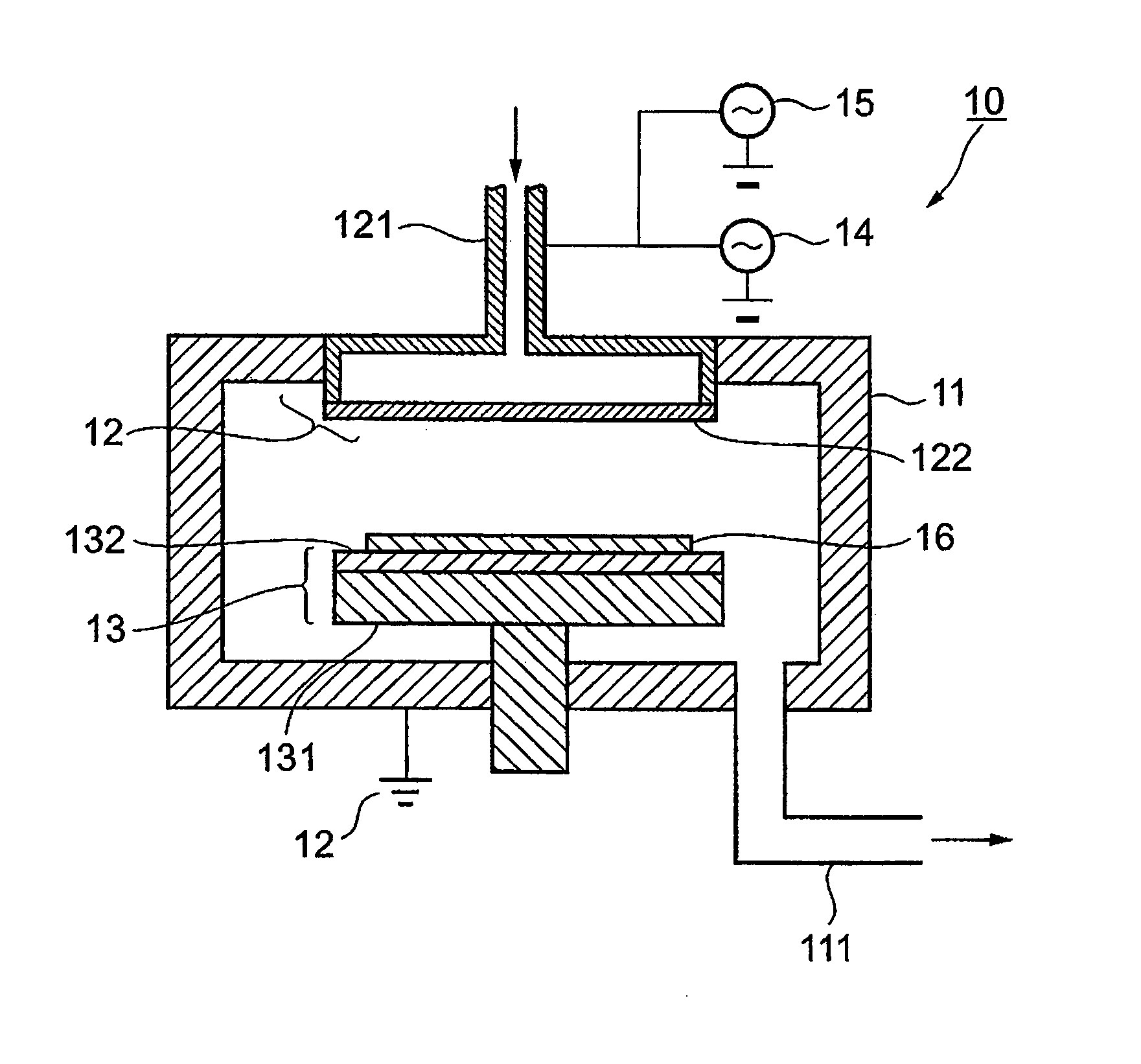

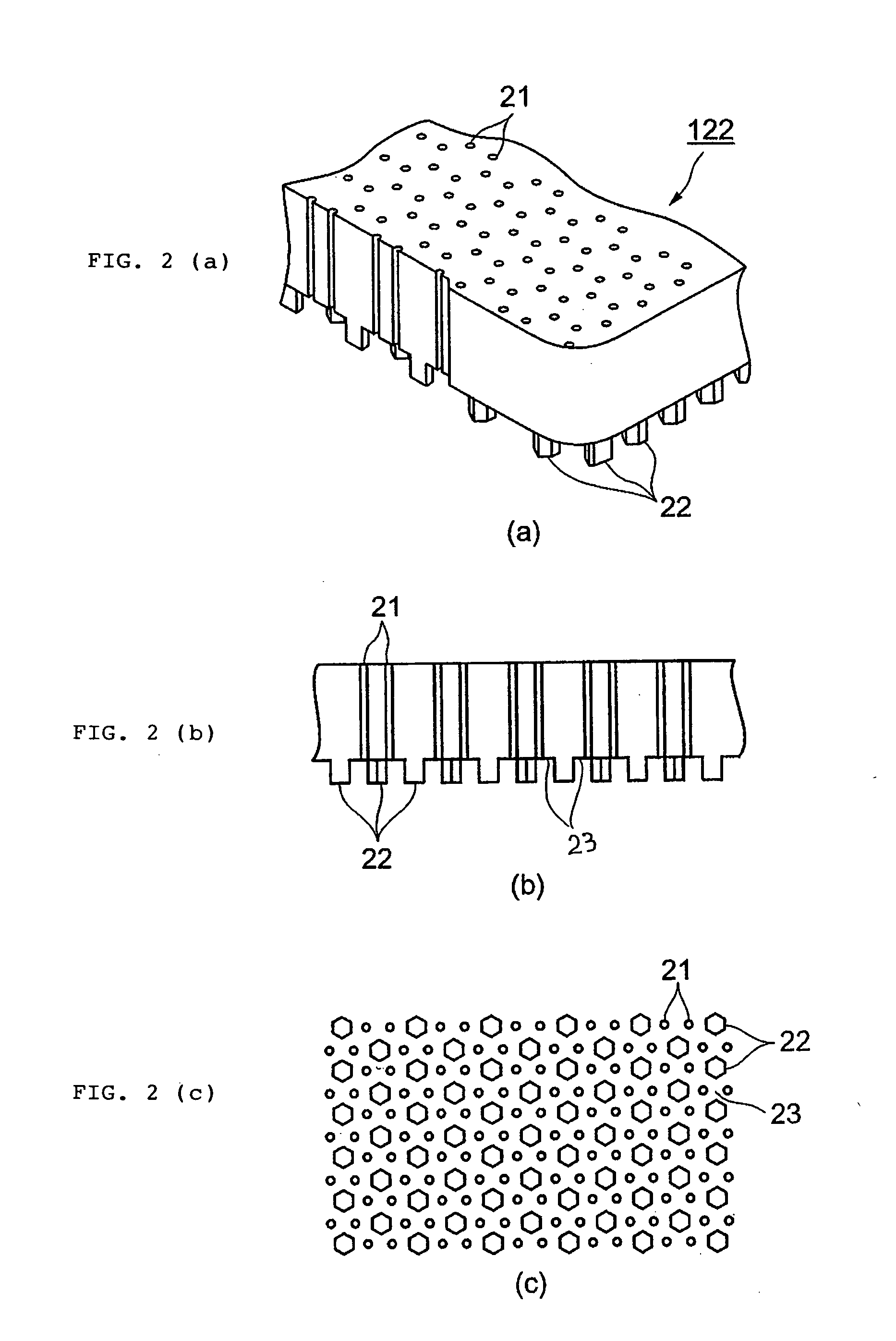

Shower plate having projections and plasma CVD apparatus using same

ActiveUS20050183666A1Improve controllabilityMaintain stable propertiesElectric discharge tubesSoil drainageEngineeringShower

A shower plate 122 has protrusions 22 formed on the front face used with a first electrode in a plasma CVD apparatus. A plane-surface portion 23 is left around apertures of gas inlet holes 21 formed in the shower plate 122. With protrusions 22 being formed, a surface area of the first electrode is increased.

Owner:ASM JAPAN

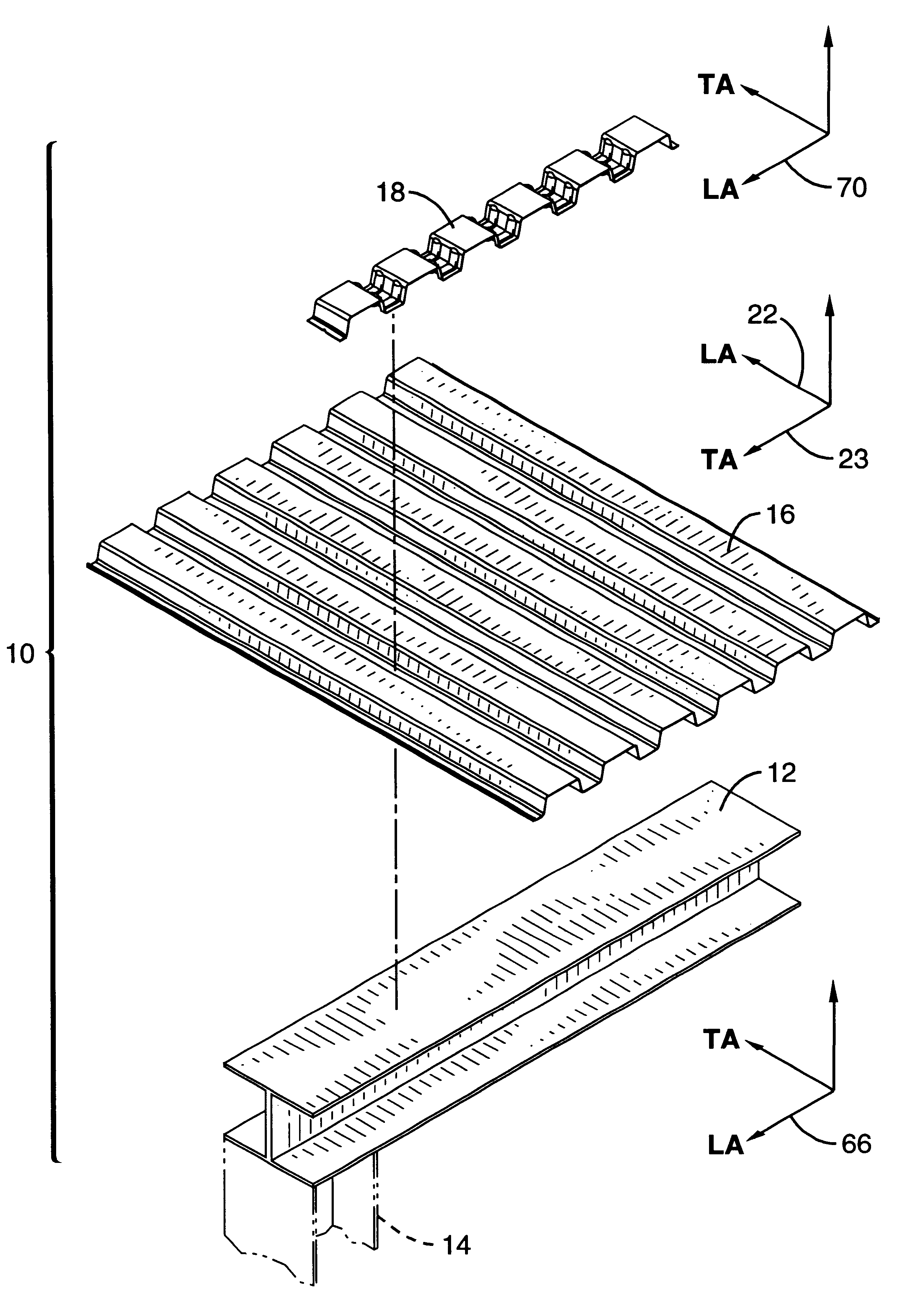

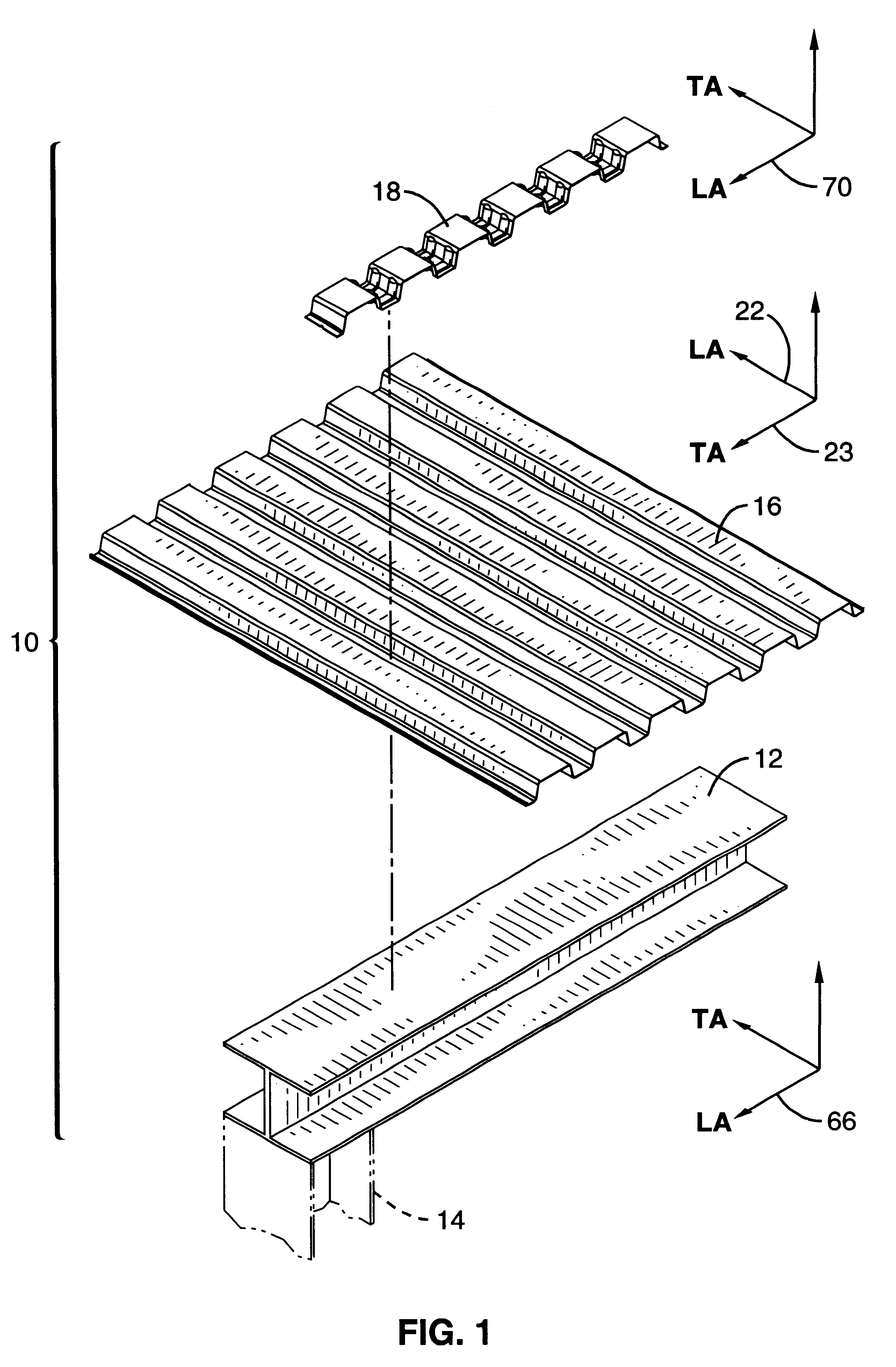

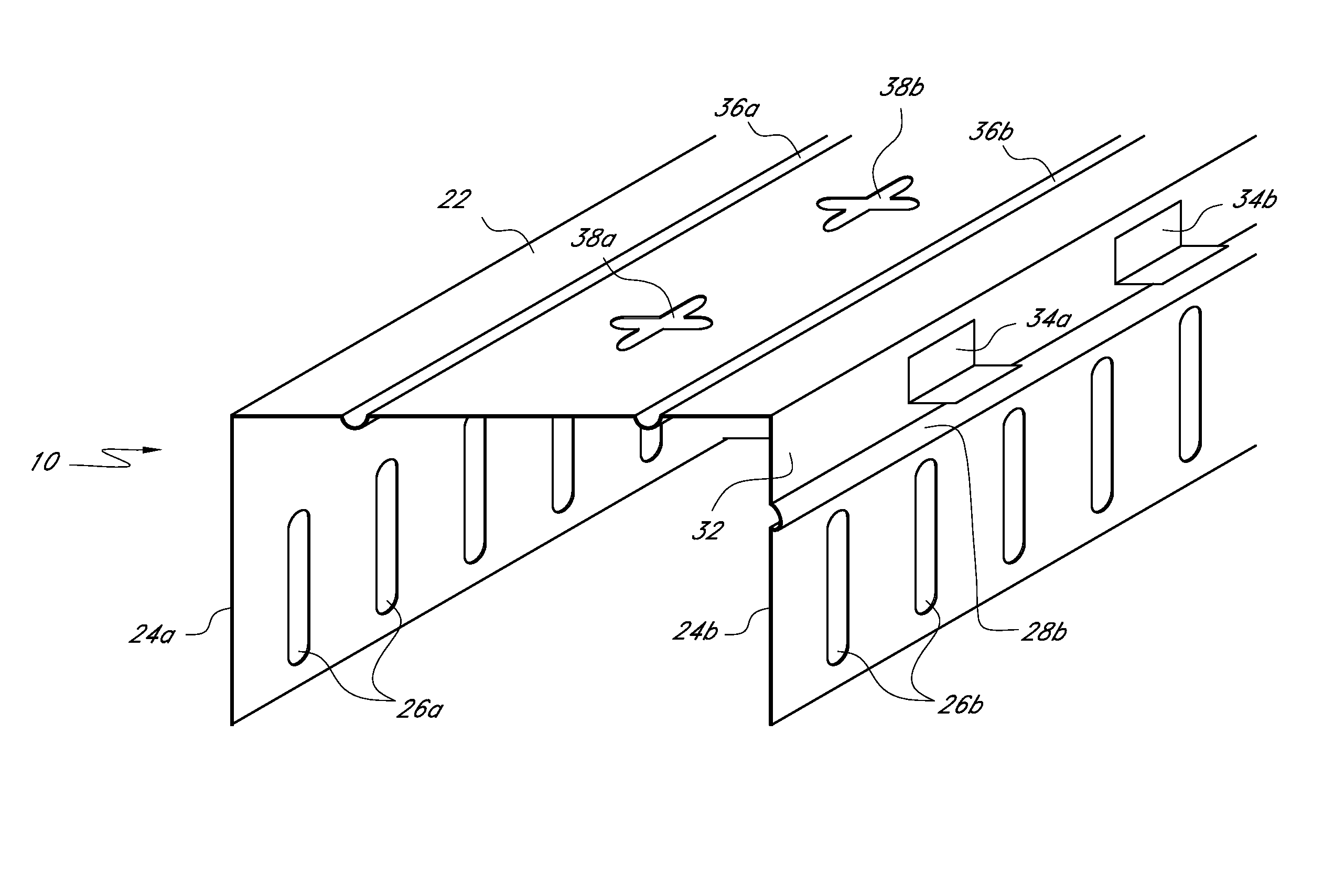

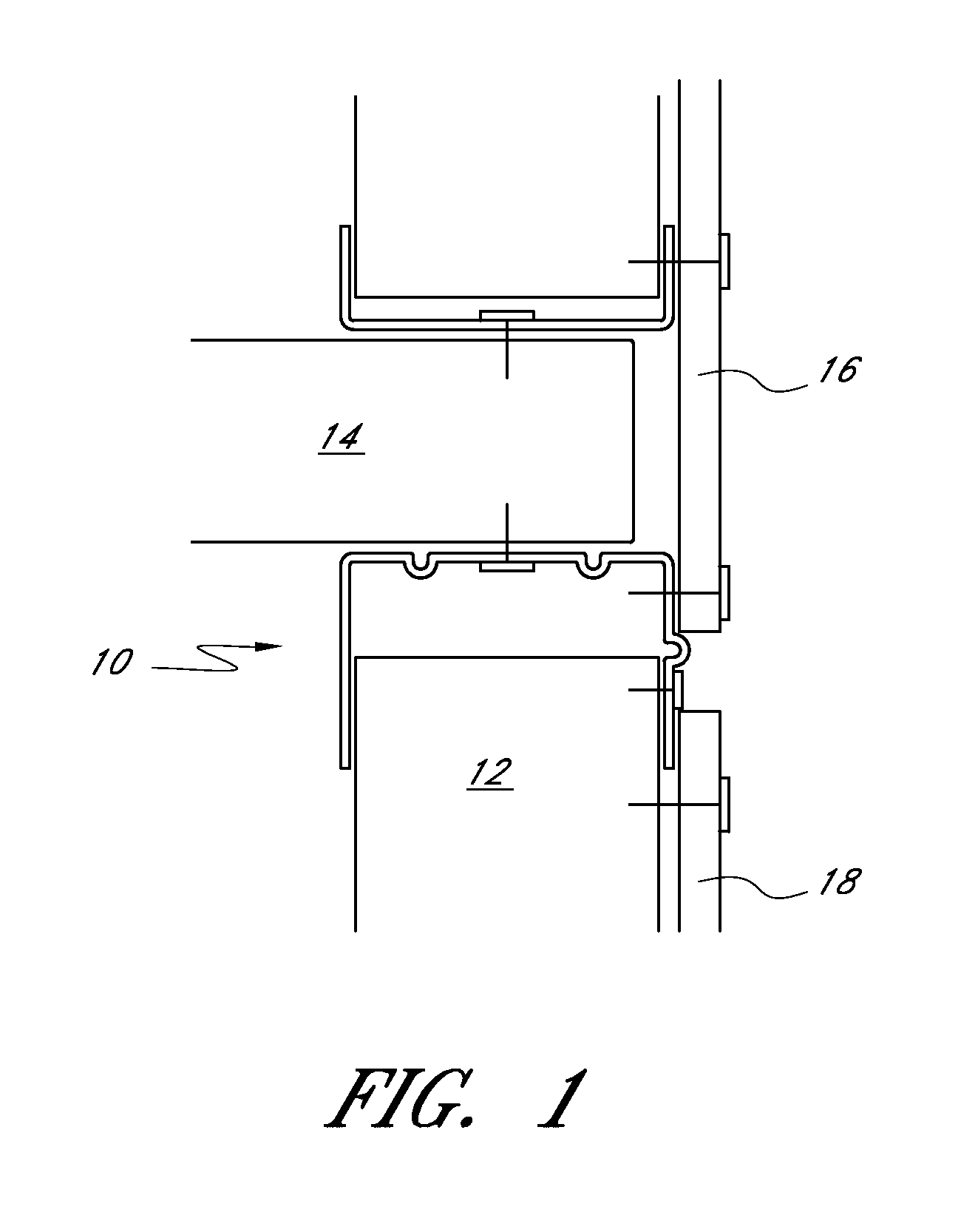

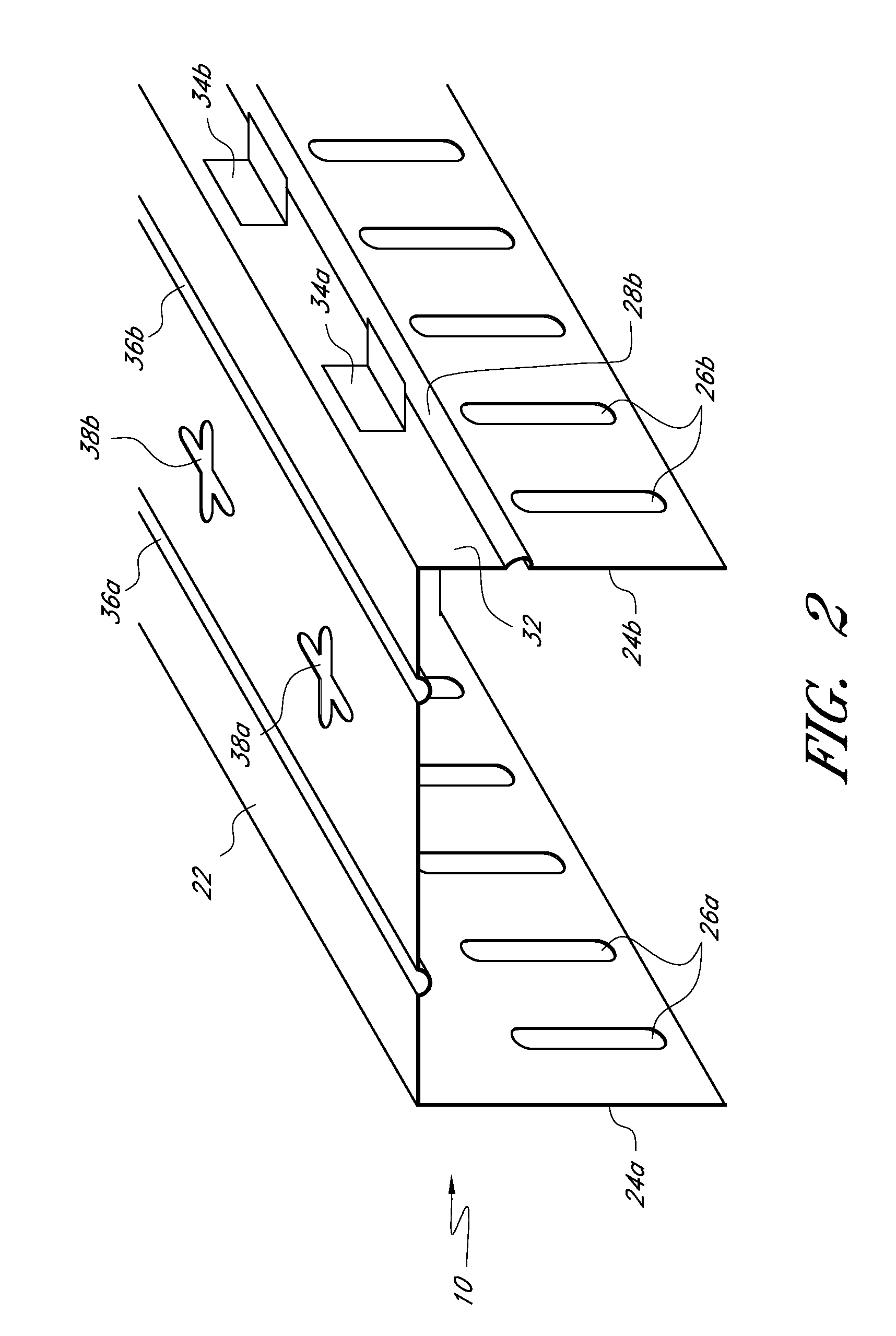

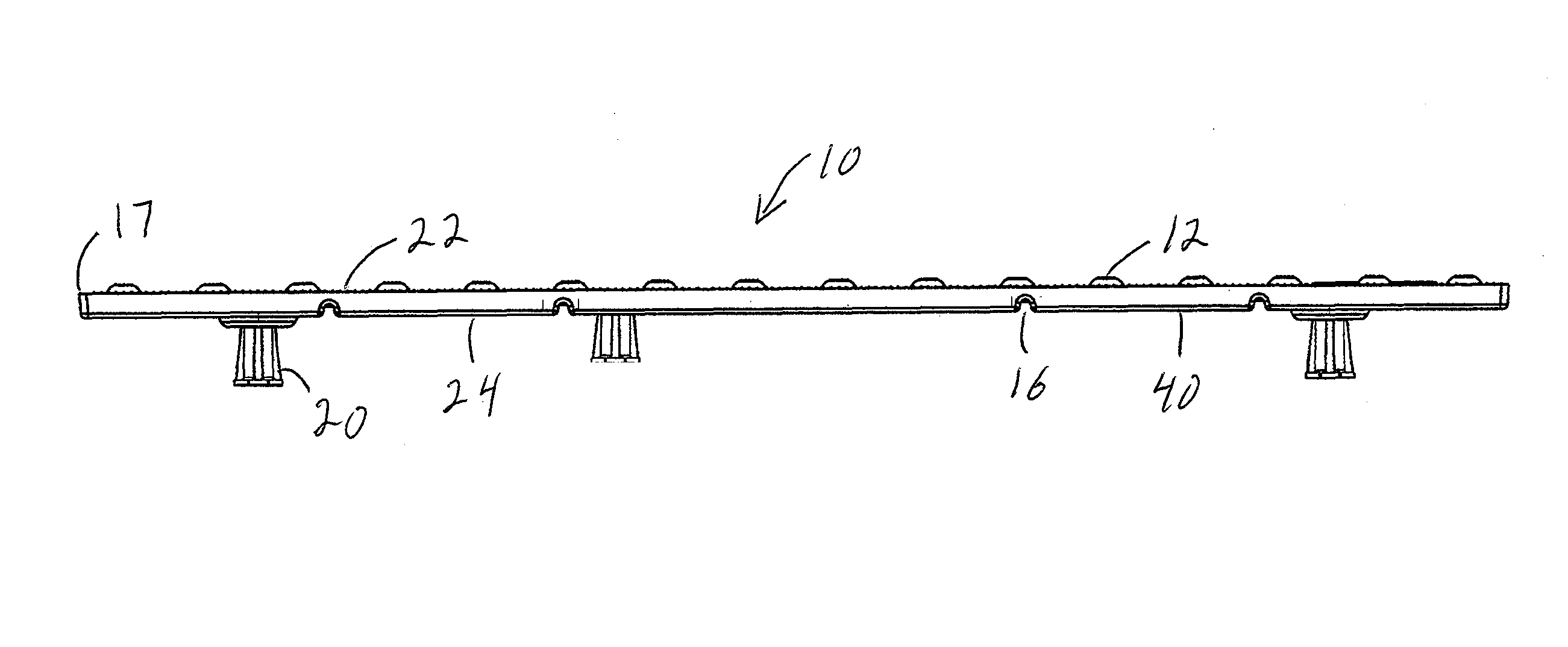

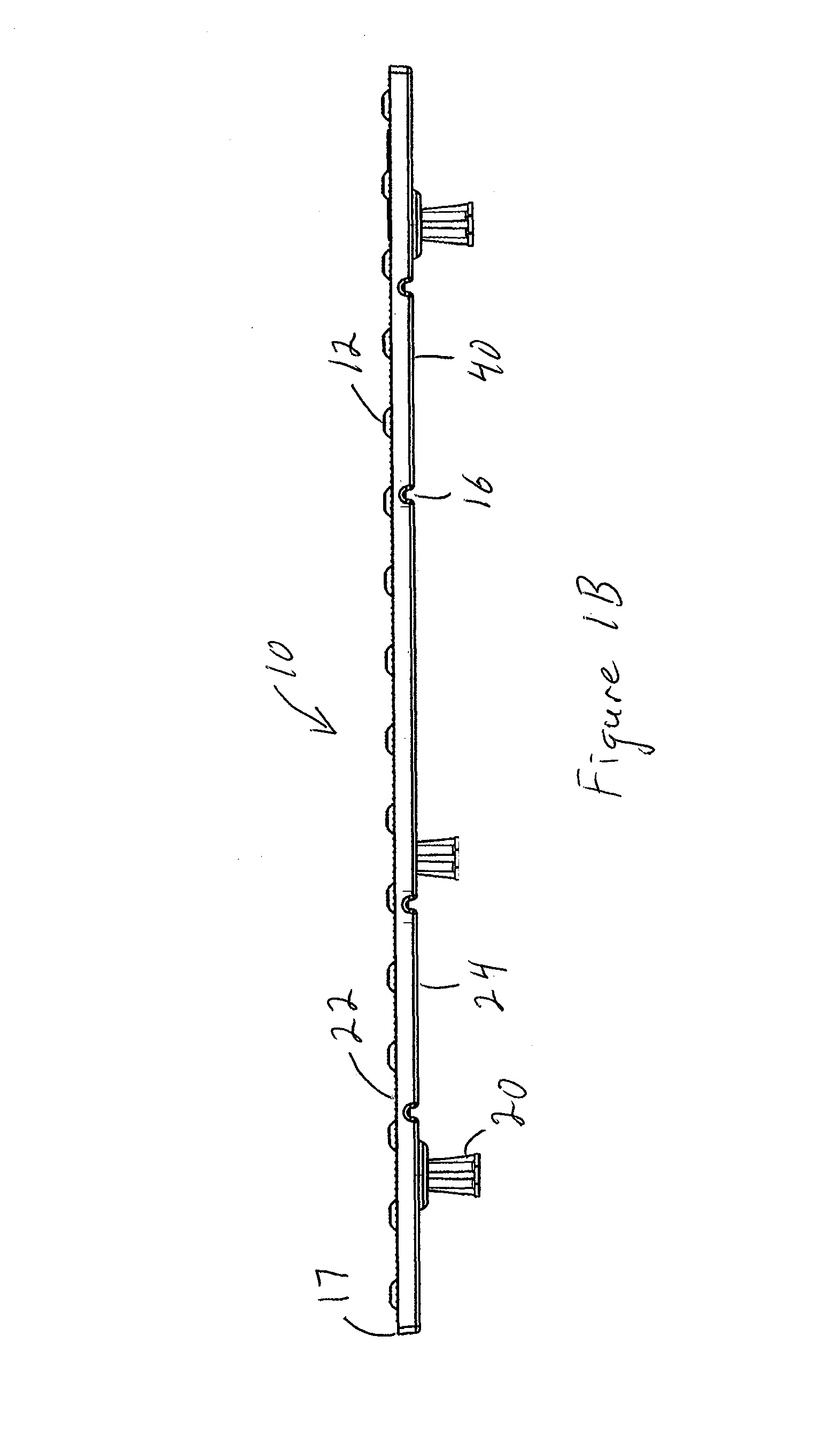

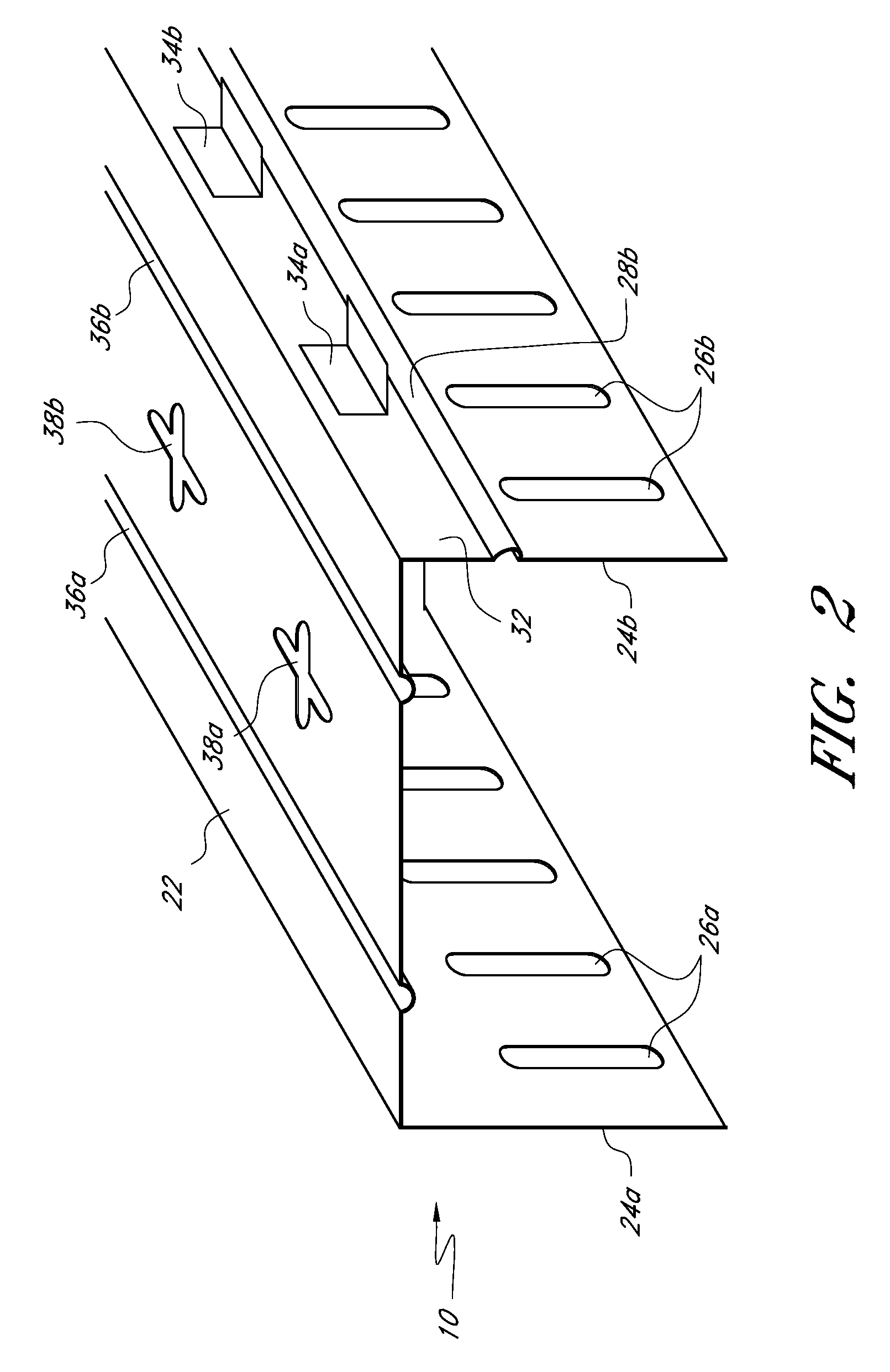

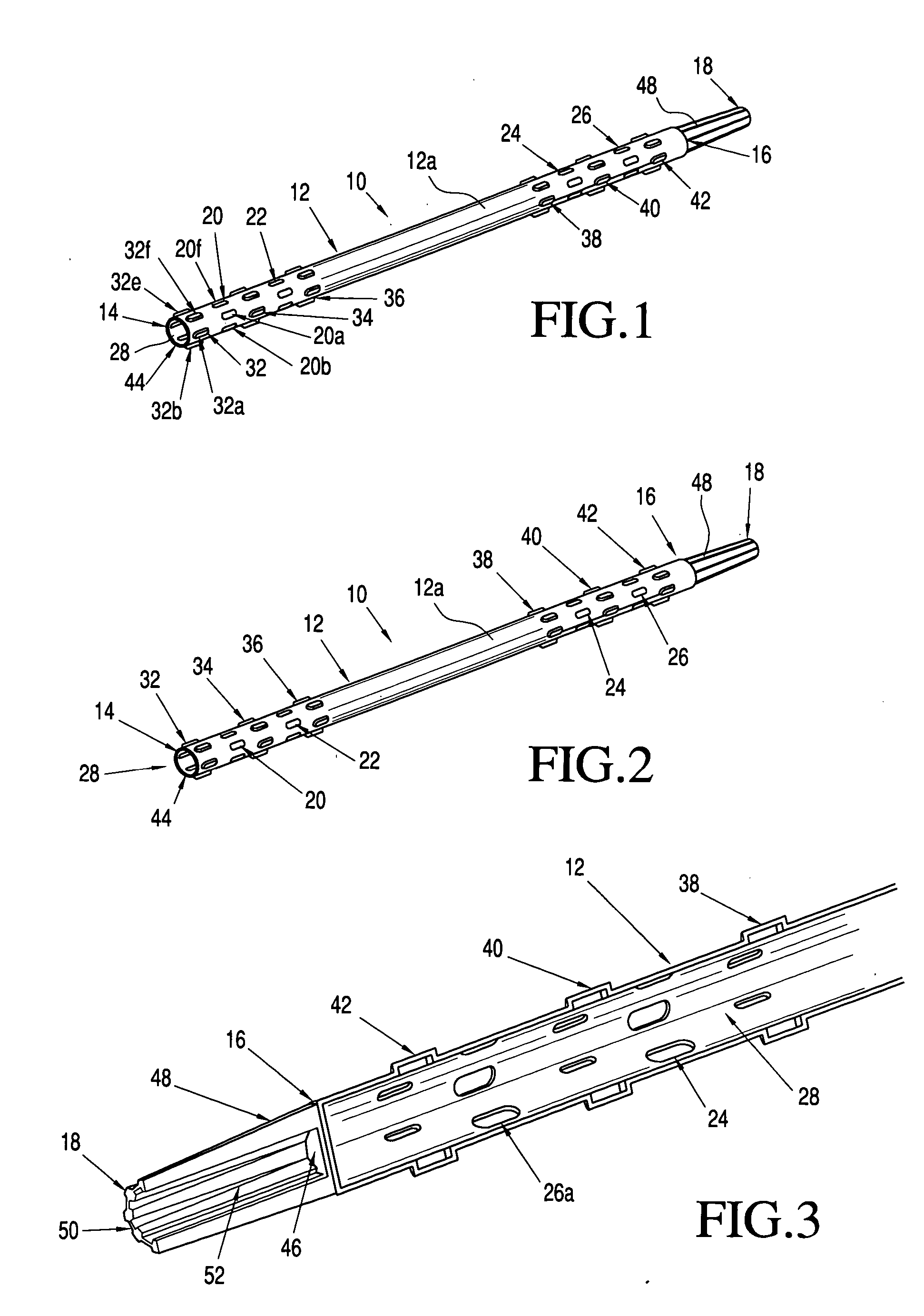

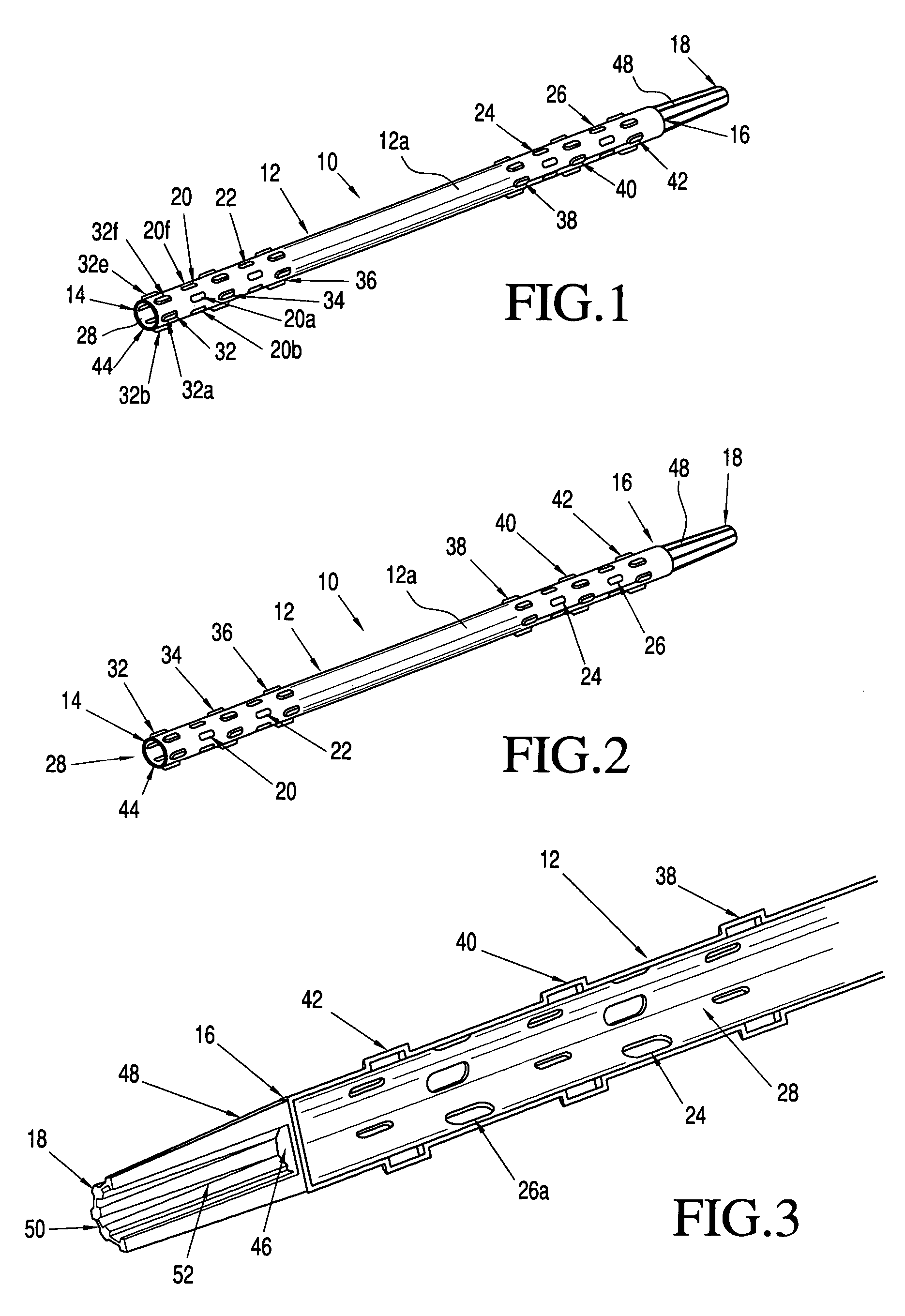

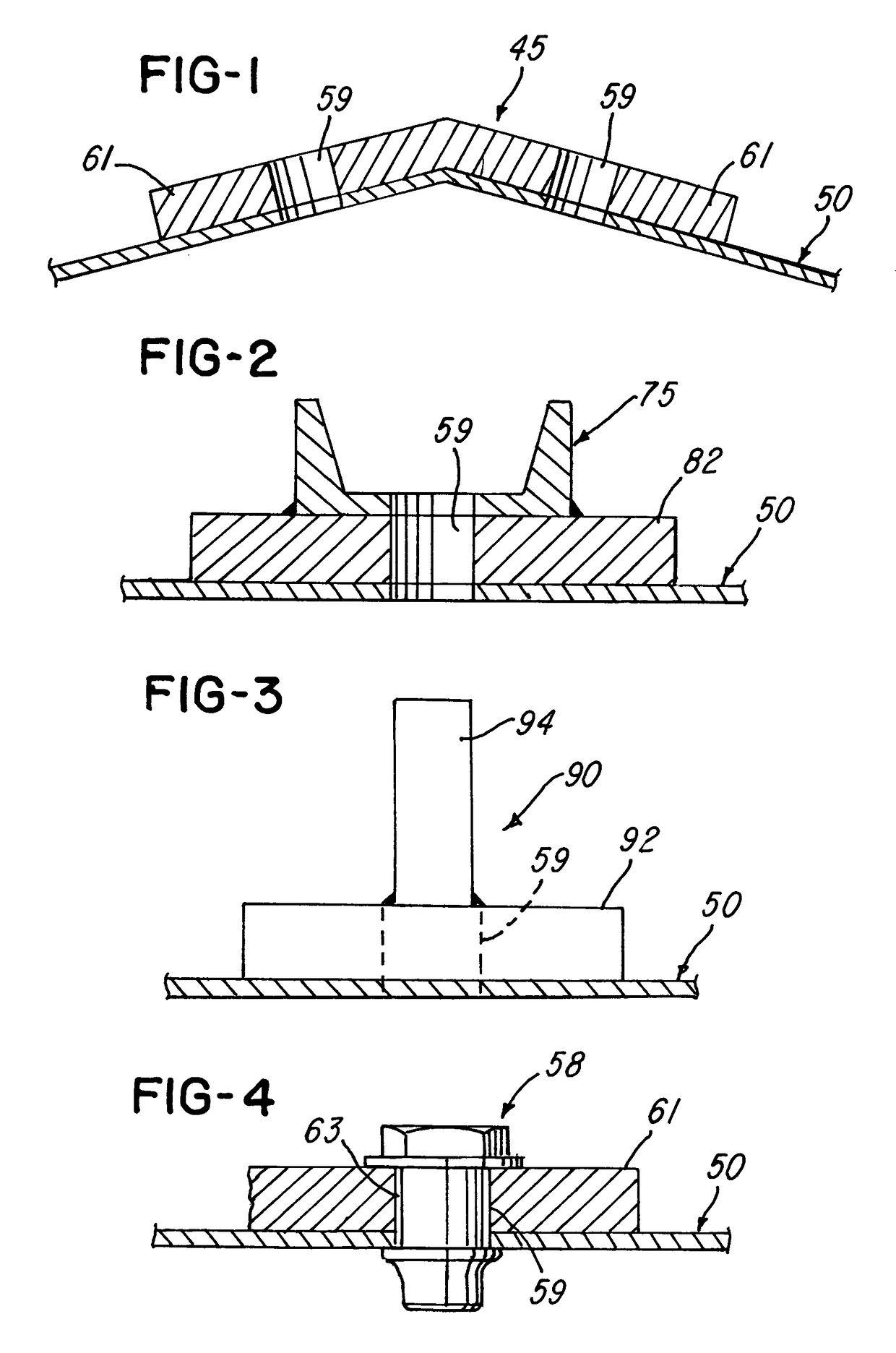

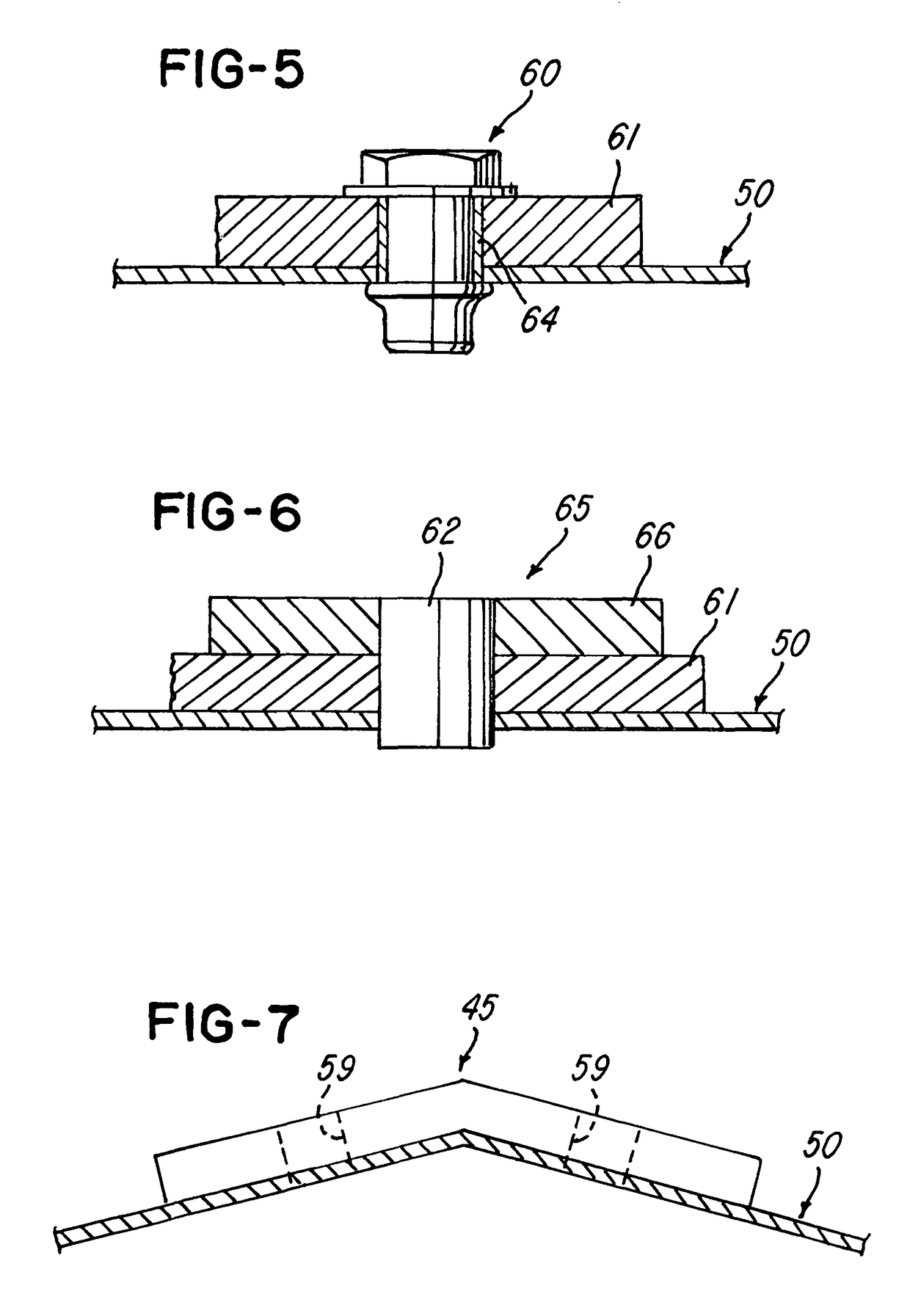

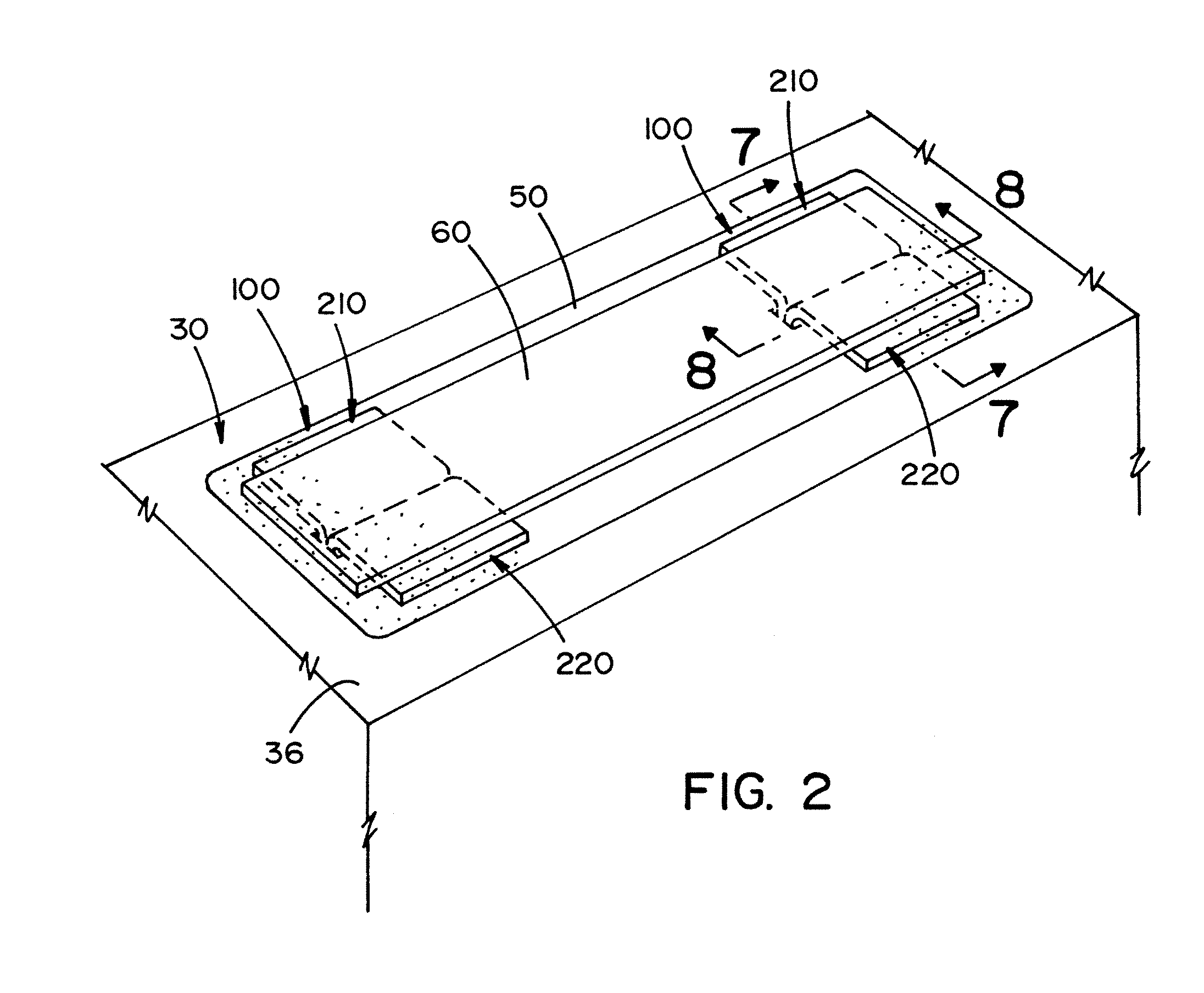

Corrugated stiffening member

InactiveUS6415581B1Easy and cost-effectiveLess-time-consuming fashionRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringFlange

A stiffening member, as well as a diaphragm of a building in which the stiffening member is used, is disclosed. The diaphragm includes a horizontal wide-flange beam, a corrugated deck, and a corrugated stiffening member. The stiffening member is an elongate, corrugated strip. The stiffening member's corrugations are formed by a series of U-shaped portions that alternate with, and are integrally connected to, a series of horizontal upper portions. Each U-shaped portion consists of three planar portions: two substantially vertical side portions and one horizontal floor portion. Each U-shaped portion is reinforced with two parallel raised ribs. In a second embodiment of the stiffening member, the U-shaped portion is reinforced with two parallel tab portions attached at the sides of the stiffening member. The stiffening member nestingly overlies the corrugated deck, and is attached to the deck and to the underlying horizontal beam with either welds or pins.

Owner:DECK WEST

Exterior wall construction product

Owner:CEMCO LLC

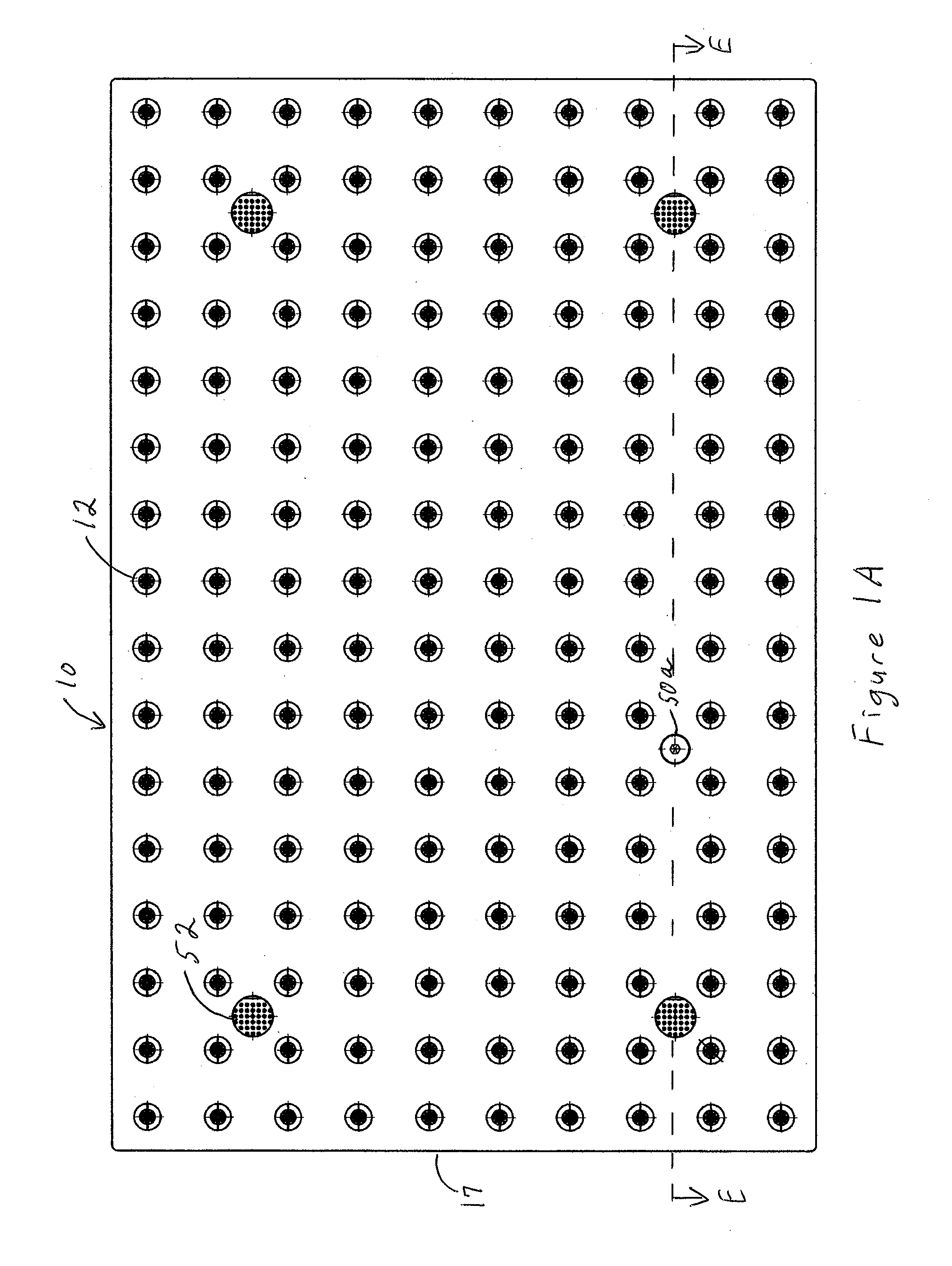

Replaceable wet-set tactile warning surface unit and method of installation and replacement

A replaceable, wet-set tactile warning surface unit having a body defining an upper surface and a lower surface, the body defining a series of raised projections on its upper surface, and defining a plurality of spaced through-holes from the top to the bottom surface, in which the raised projections are spaced from one another and the through-holes are located between projections. An anchor member such as a threaded insert is coupled to the bottom surface of the unit member directly below each of the through-holes by fasteners such as bolts that pass through the through-holes.

Owner:ADA SOLUTIONS

Exterior wall construction product

Owner:CEMCO LLC

Panelized wall system utilizing trough-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with trough-edge building panels. The trough-edge building panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE TECH LTD

Method of repairing concrete floors and system for same

A floor plug (40) is disclosed having an upper portion (41) with a top plate (44) and a neck (48), a lower portion (42) with a bottom plate (51), and post (32) which coupled the two portions together and draws them towards each other sandwiching the floor therebetween. The upper portion is positioned within the bore hole (20) and the lower portion is coupled to the post so as to be threadably drawn against the underside of the floor. Once the adhesive has cured a viscous smoothing compound or concrete floor leveler is poured over the floor plug upper portion and surrounding concrete floor area. If necessary, the concrete floor leveler material is smoothed to provide a generally smooth or level surface.

Owner:BARNES AUDREY

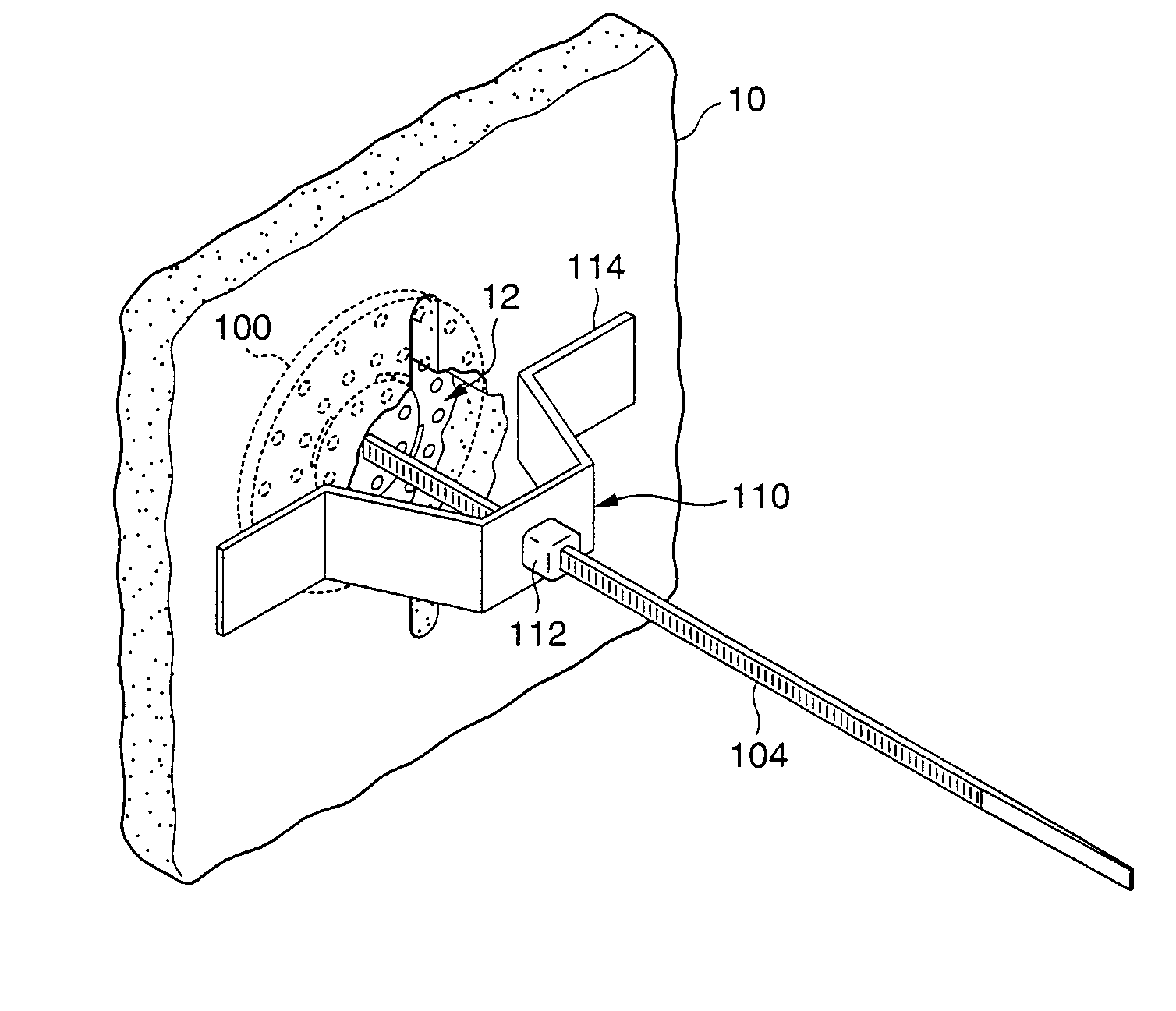

Masonry wall anchoring device, system, and anchoring method

InactiveUS20050097849A1Prolong lifeEarthquake proof and more resistant to damage and failureConstruction materialBuilding repairsEngineering

Owner:HAYES JOHN T

Solid polyurethane compositions, infrastucture repair and geo-stabilization processes

Owner:BAYER MATERIALSCIENCE AG

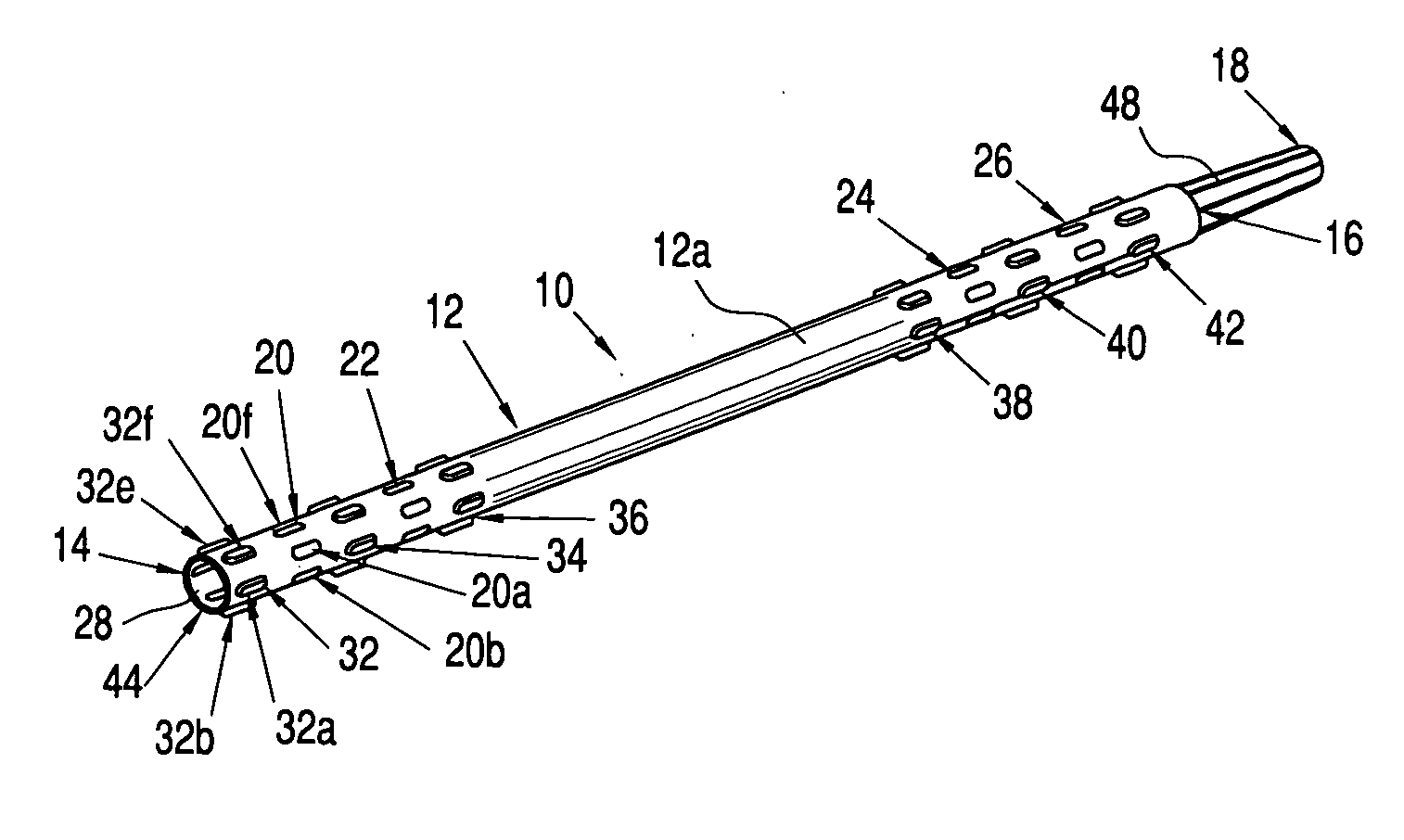

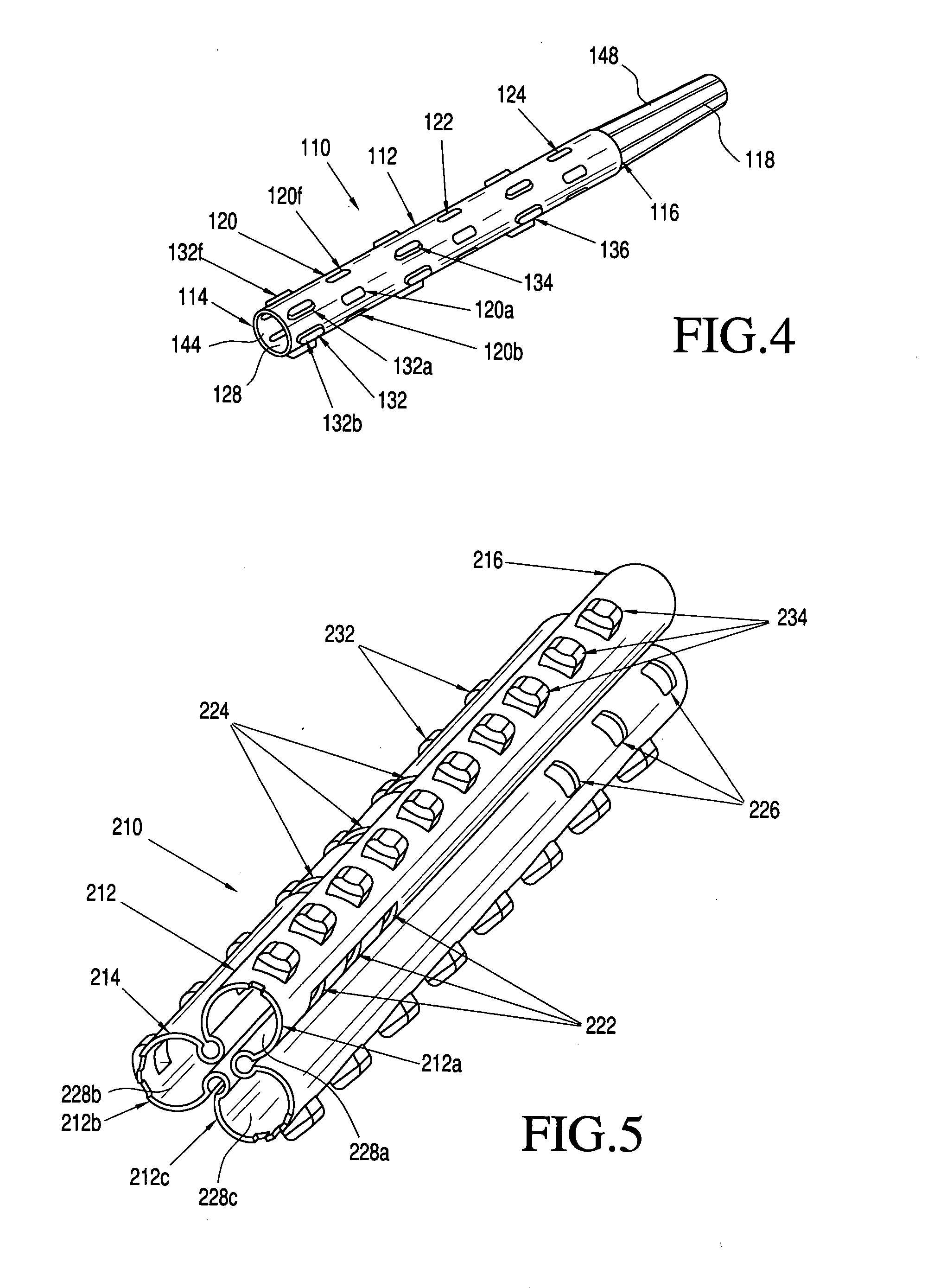

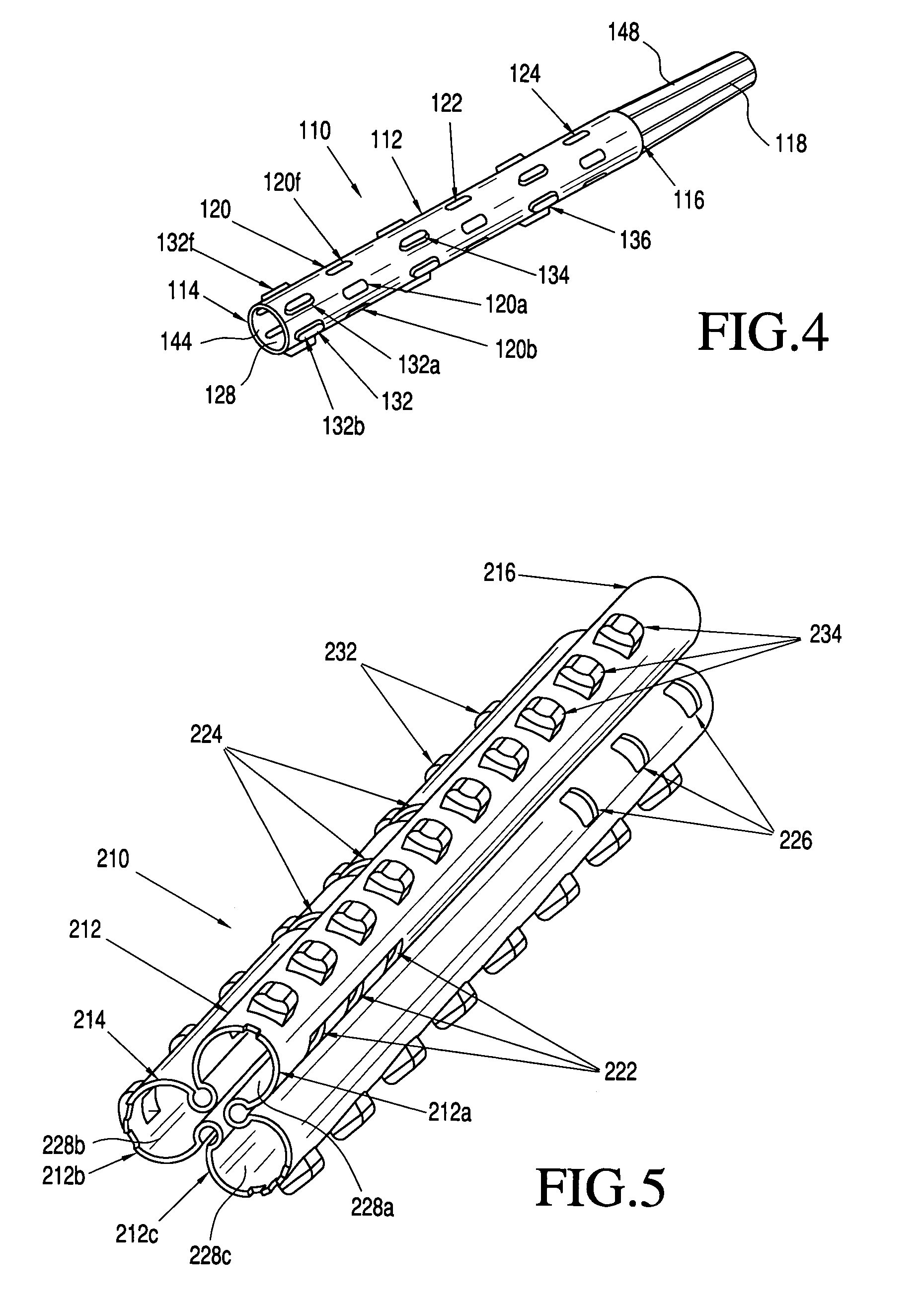

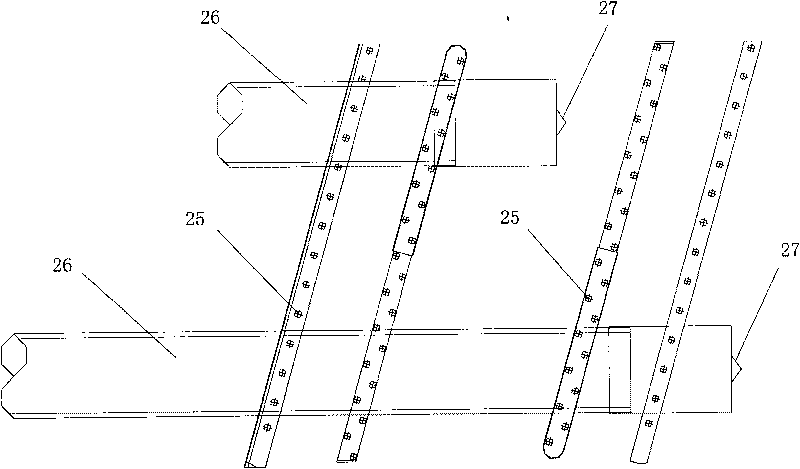

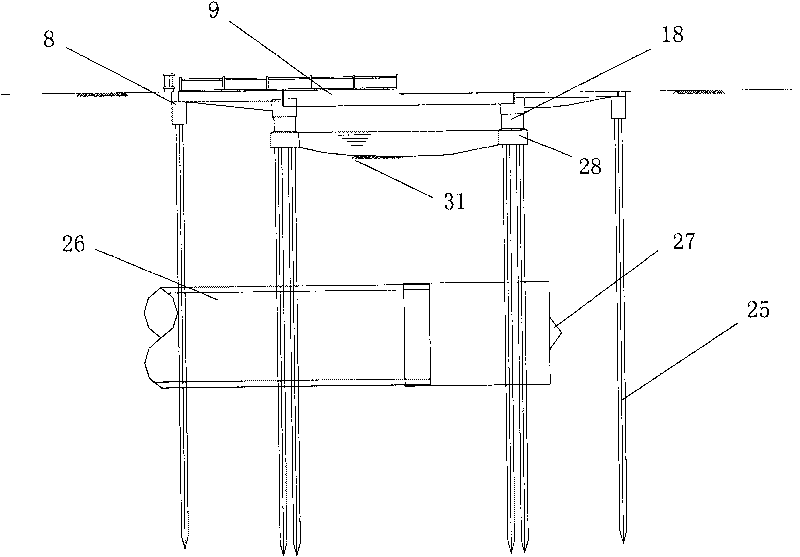

Drainage anchor rod, side slope protection engineering repairing and reinforcing structure and construction method

InactiveCN102155016AEfficient repairThe effect is long-lasting and stableFoundation repairExcavationsFiltrationStructural engineering

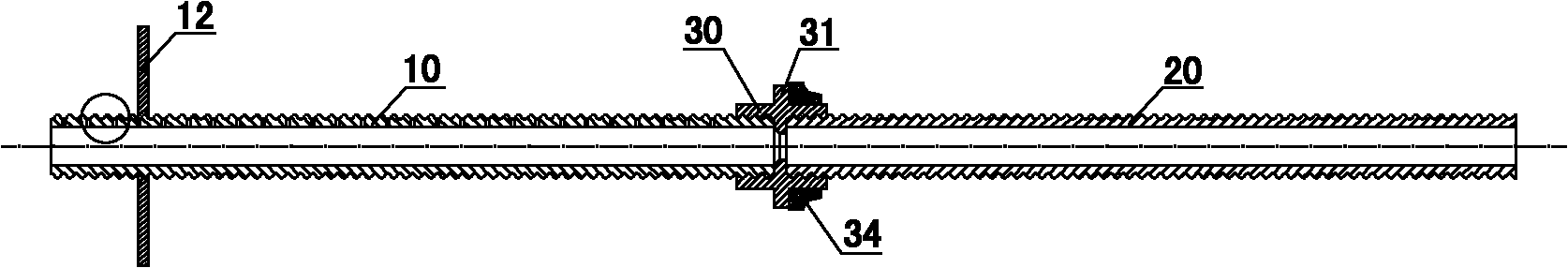

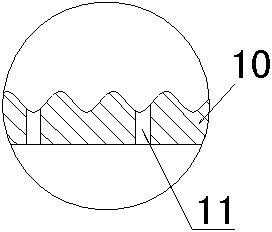

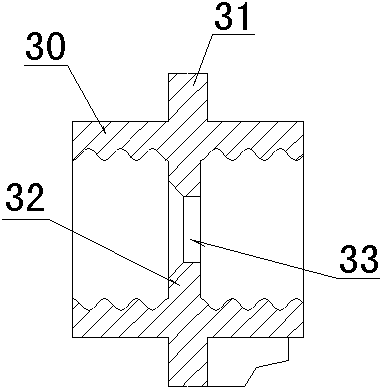

The invention discloses a drainage anchor rod, a side slope protection engineering repairing and reinforcing structure and a construction method; the side slope protection engineering repairing and reinforcing structure can reinforce the side slope protection engineering, also can effectively repair an inverted filtration system of the side slope protection engineering, obtains lasting and stable effect, has a simple structure and is easy to construct. The drainage anchor rod comprises a drain pipe (10) and an anchoring pipe (20), wherein the drain pipe (10) and the anchoring pipe can be axially detached or butted by a connecting member (30); small drain holes (11) are dispersedly arranged on the wall pipe of the drain pipe (10); and the external end part of the drain pipe (10) is connected with an external anchoring steel plate (12).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

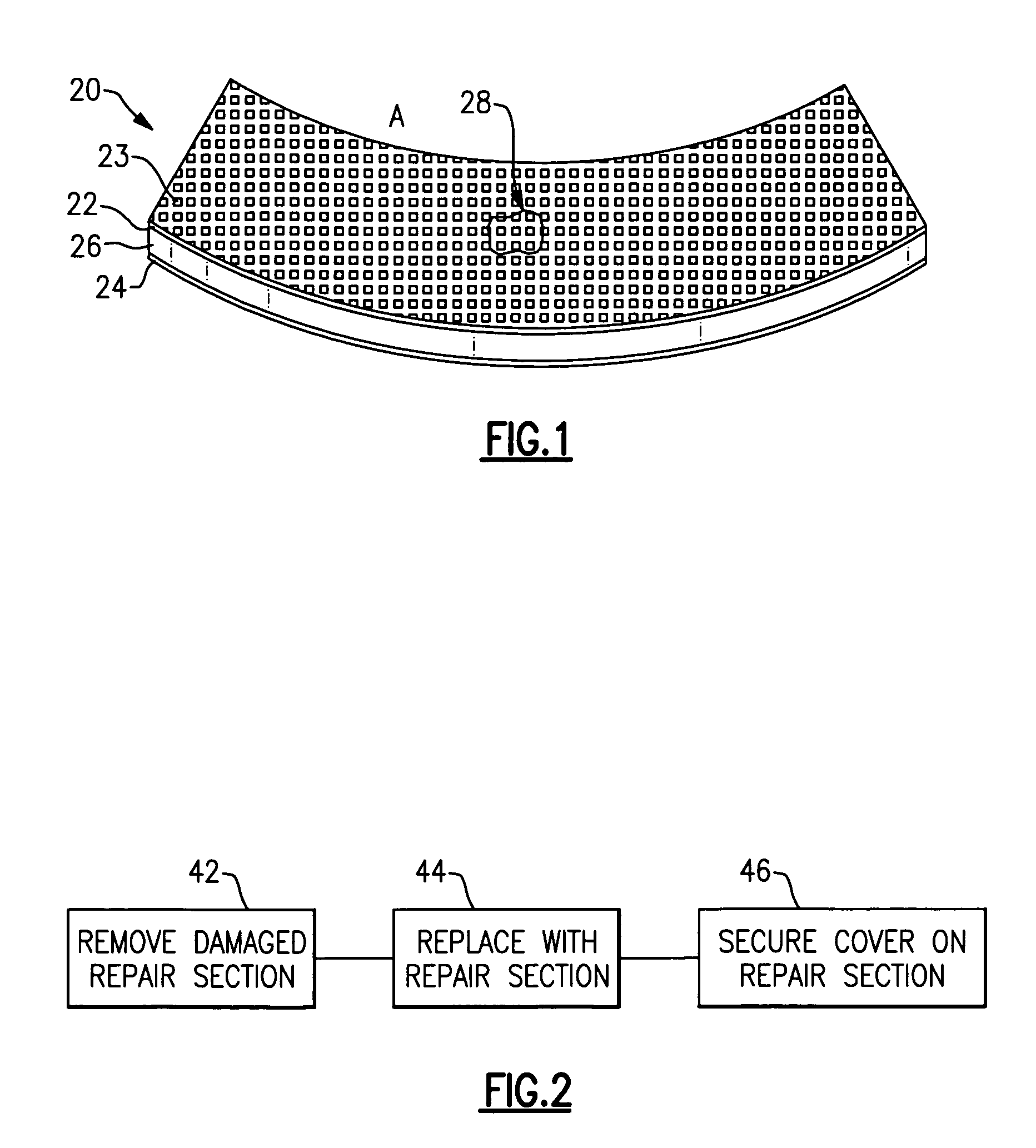

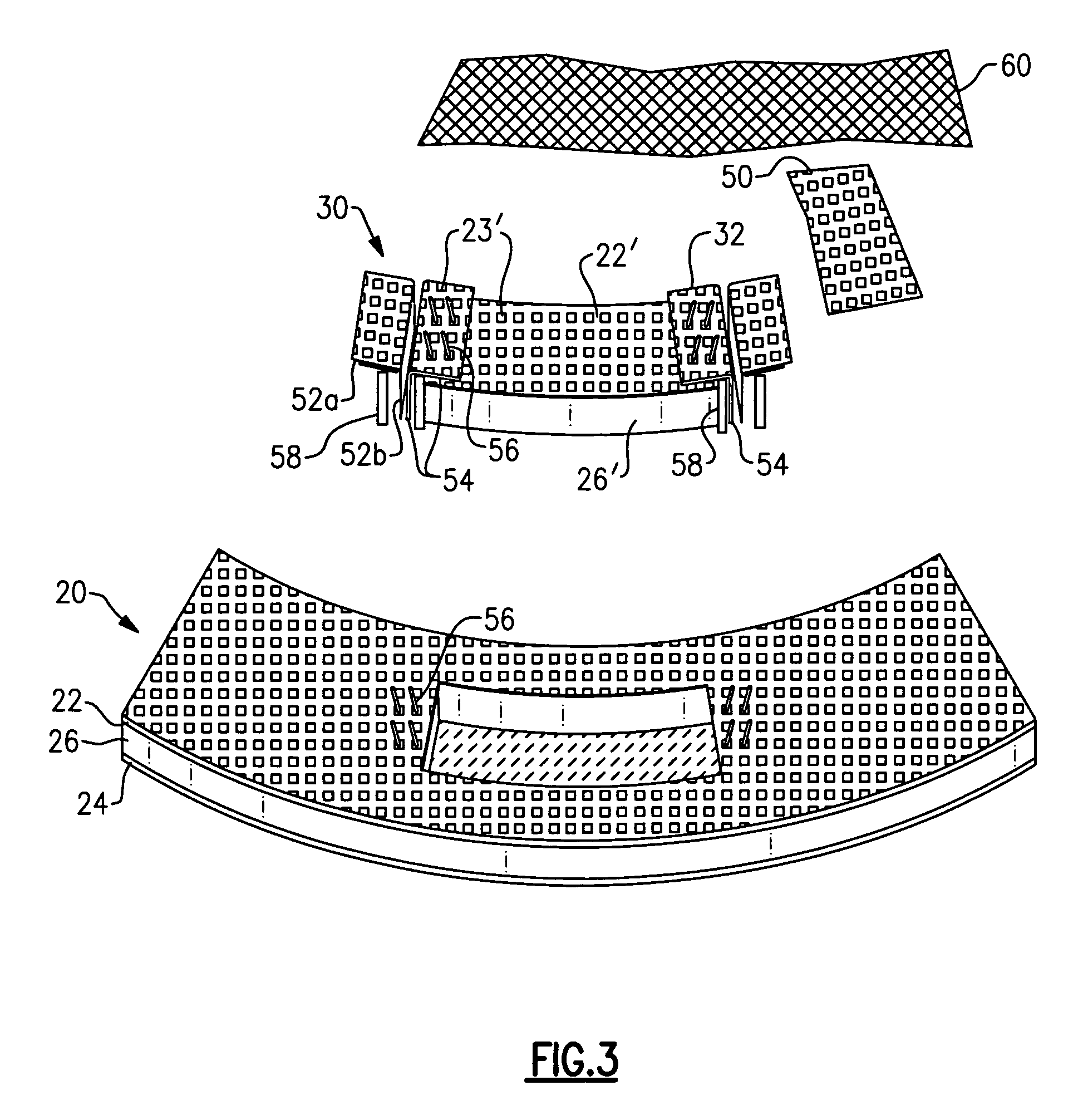

Repair of composite sandwich structures

A method of restoring a section of a composite includes the steps of removing an undesirable section of a composite and securing a repair section in the location of the removed undesirable section. One or more covers are secured on at least a portion the repair section to prevent or resist peeling of the repair section.

Owner:RTX CORP

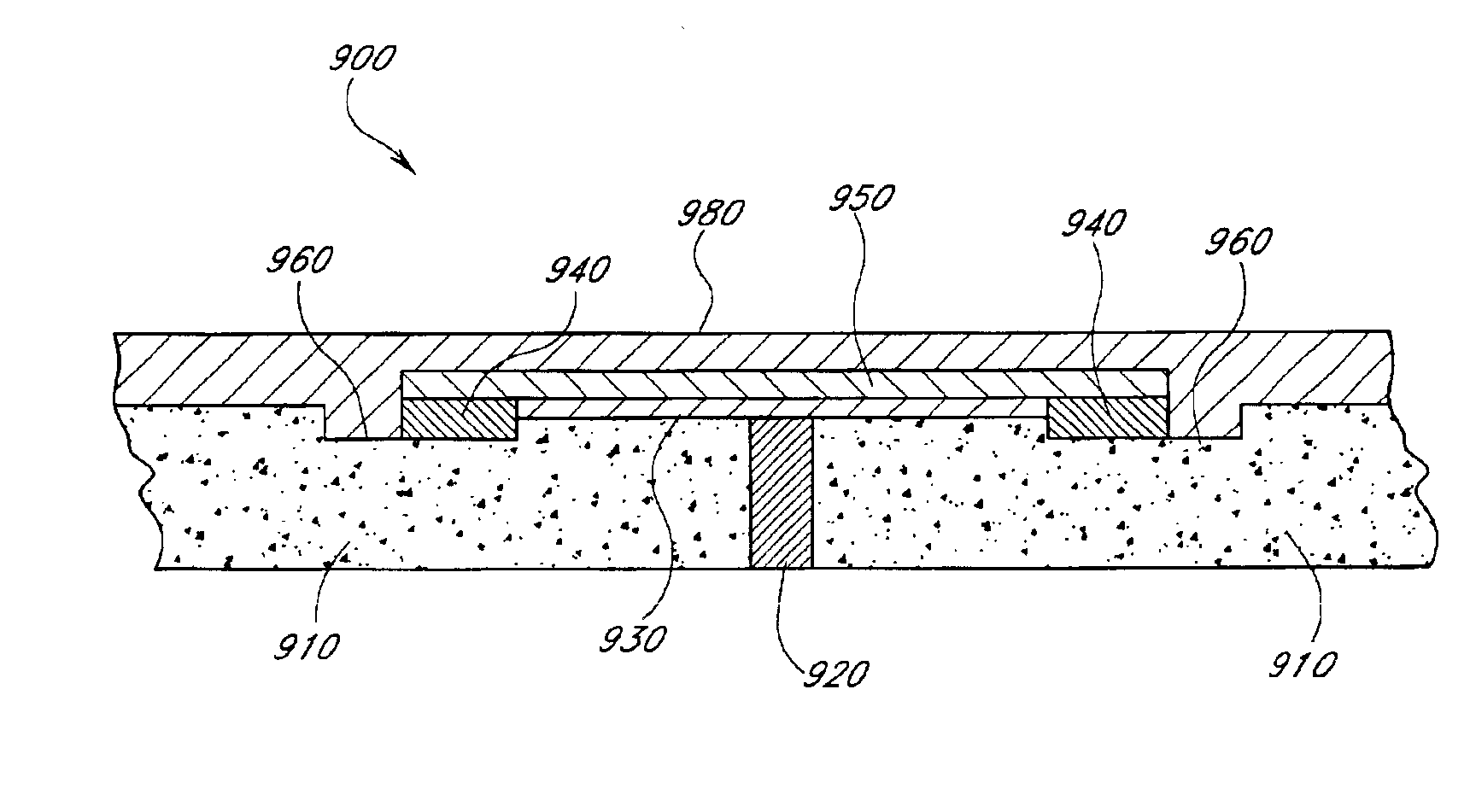

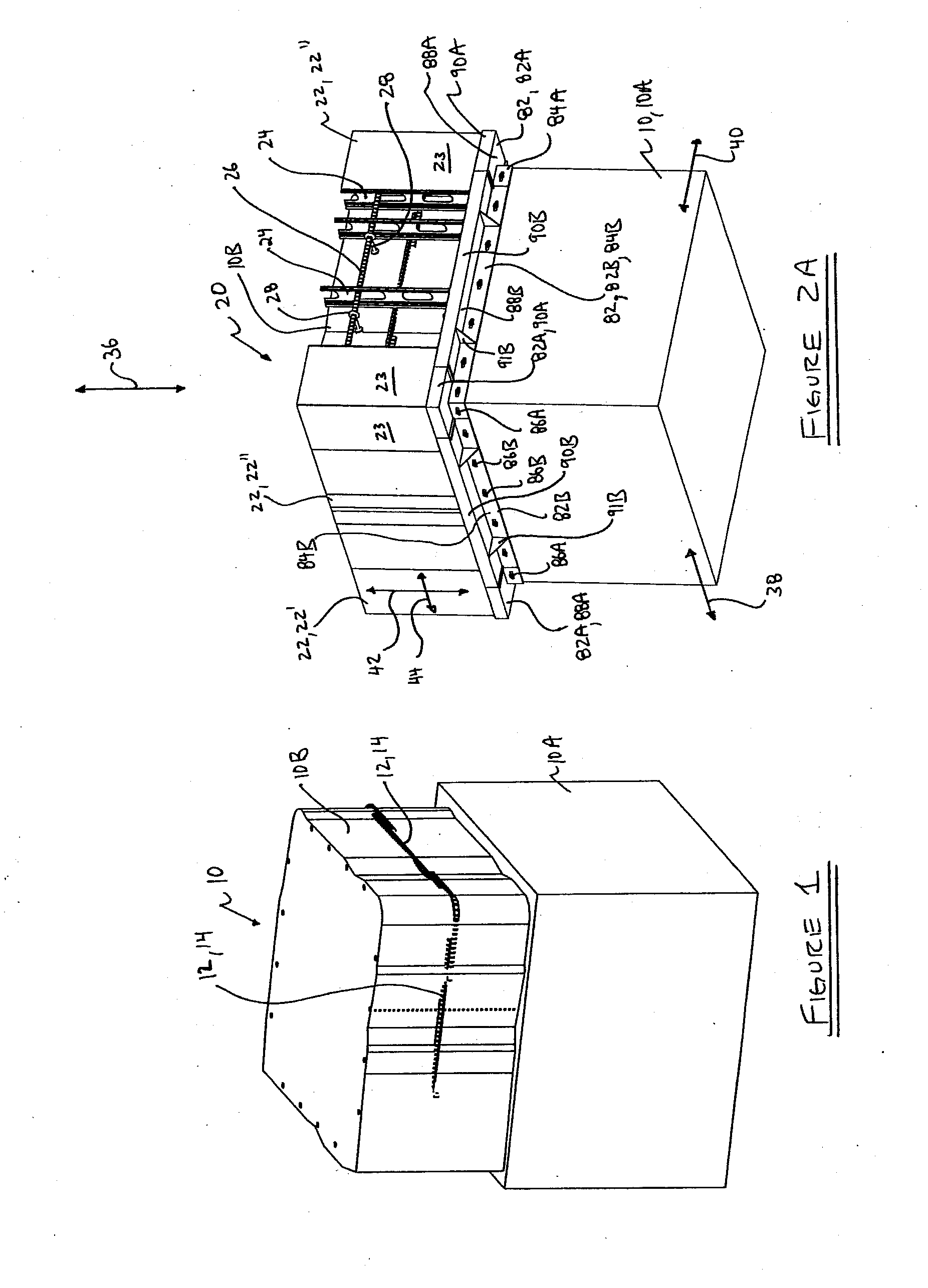

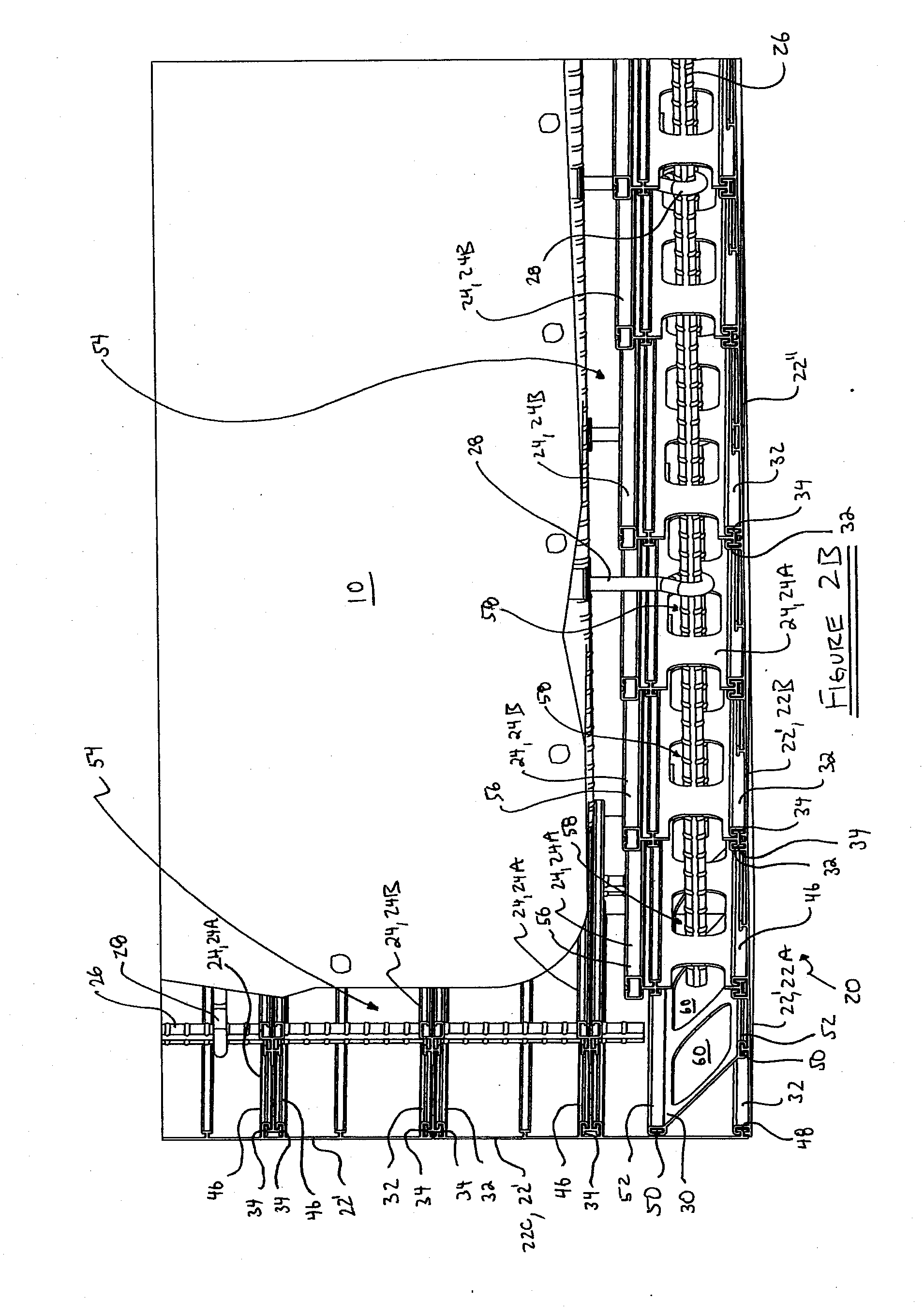

Methods and apparatus for restoring, repairing, reinforcing and/or protecting structures using concrete

Methods are provided for repairing an existing structure to cover at least a portion of the existing structure with a repair structure. Such methods comprise mounting one or more standoff retainers to the existing structure; coupling one or more standoffs to the standoff retainers such that the standoffs extend away from the existing structure; coupling one or more cladding panels to the standoffs such that the panels are spaced apart from the structure to provide a space therebetween; and introducing a curable material to the space between the panels and the existing structure, the panels acting as at least a portion of a formwork for containing the curable material until the curable material cures to provide a repair structure cladded, at least in part, by the panels. Corresponding apparatus for effecting such methods are also provided.

Owner:CFS CONCRETE FORMING SYST

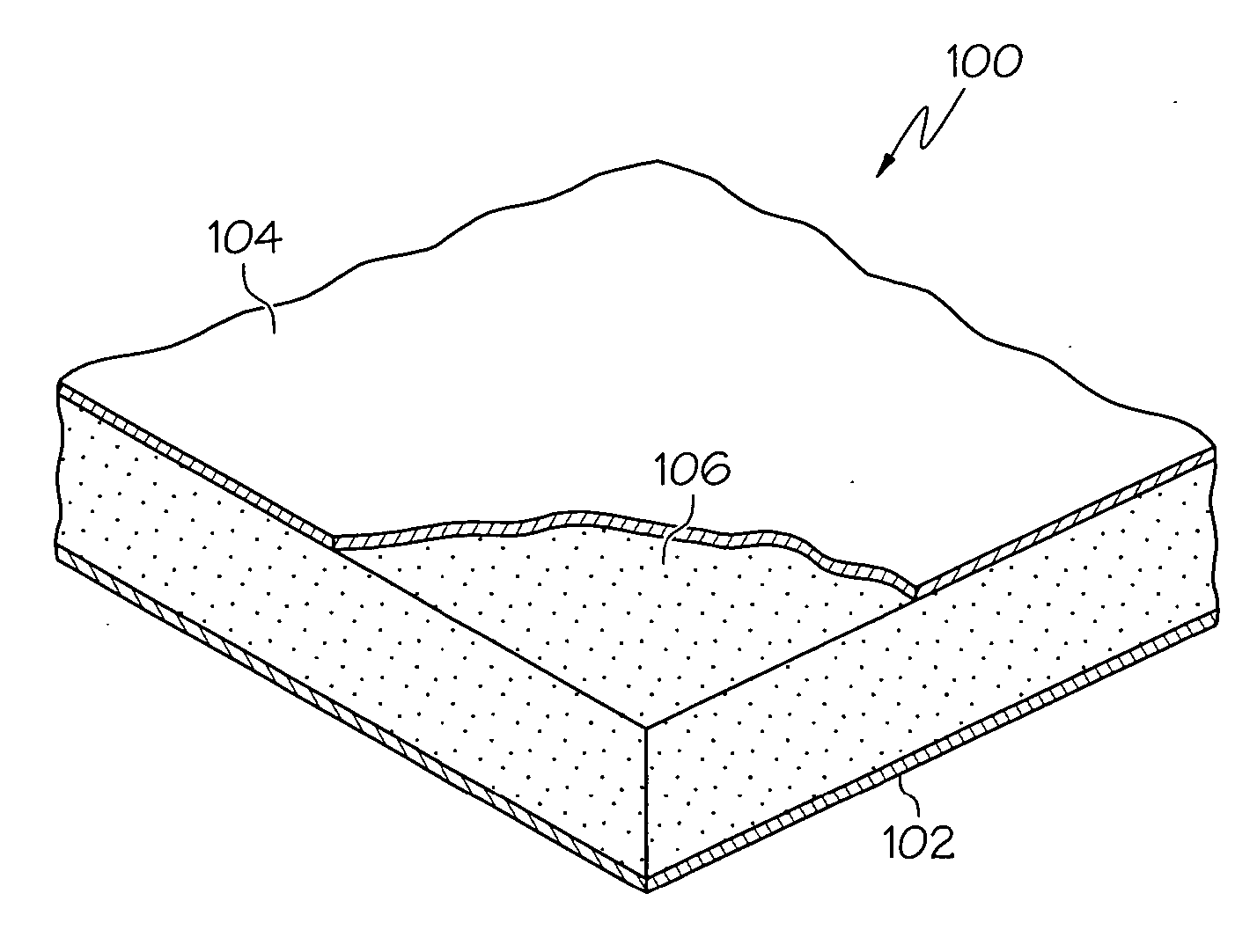

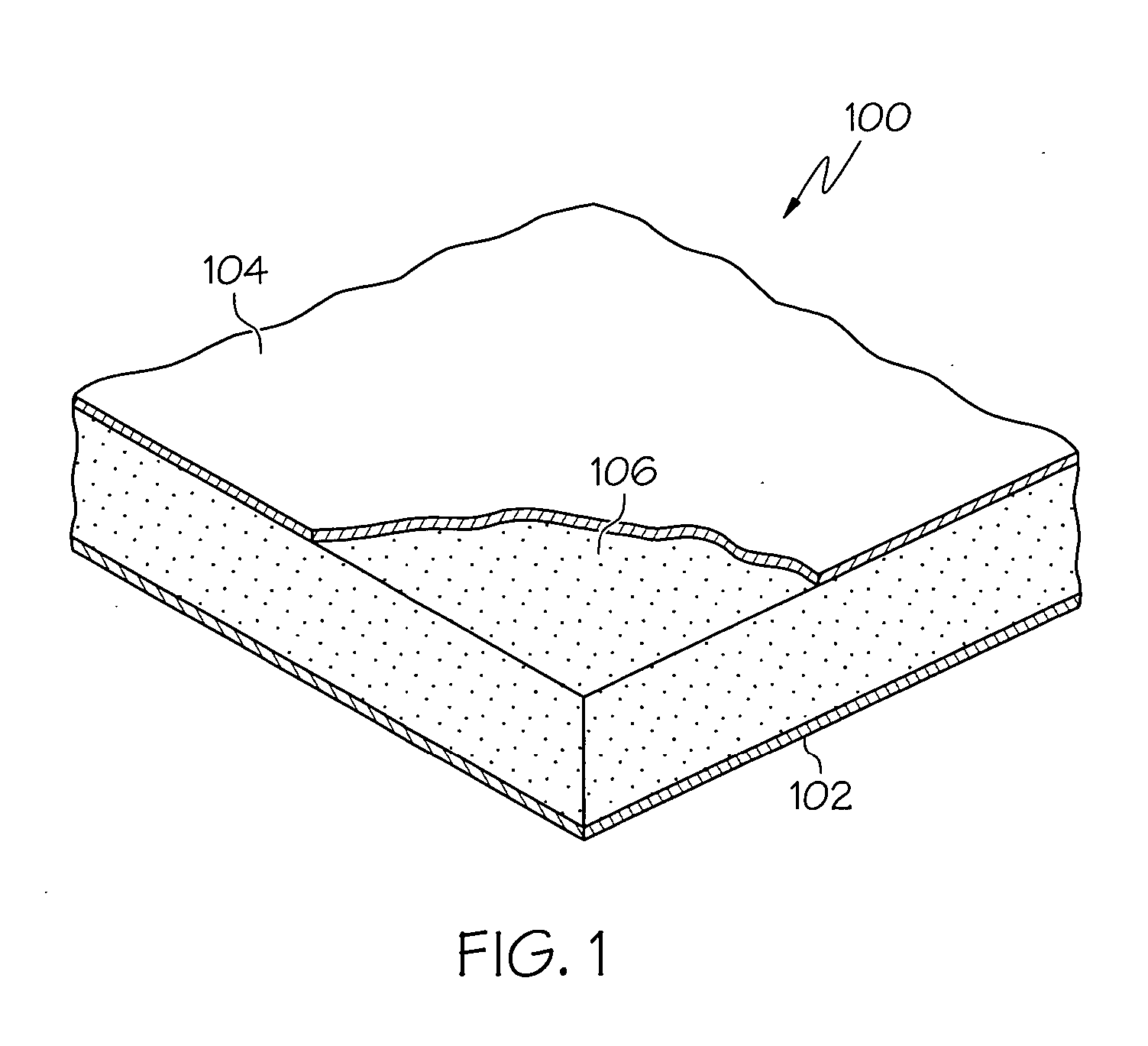

Repair method for noise suppression structure

A method is provided for repairing a defect in a noise suppression panel. The method may be used to repair defects in a panel that may occur during the manufacture of or normal use of the panel. The method includes the steps of removing the defect from the noise suppression panel to create a cavity therein, forming material comprised of a material having acoustic damping properties into an insert configured to mate with the cavity, and placing the insert into the cavity.

Owner:HONEYWELL INT INC

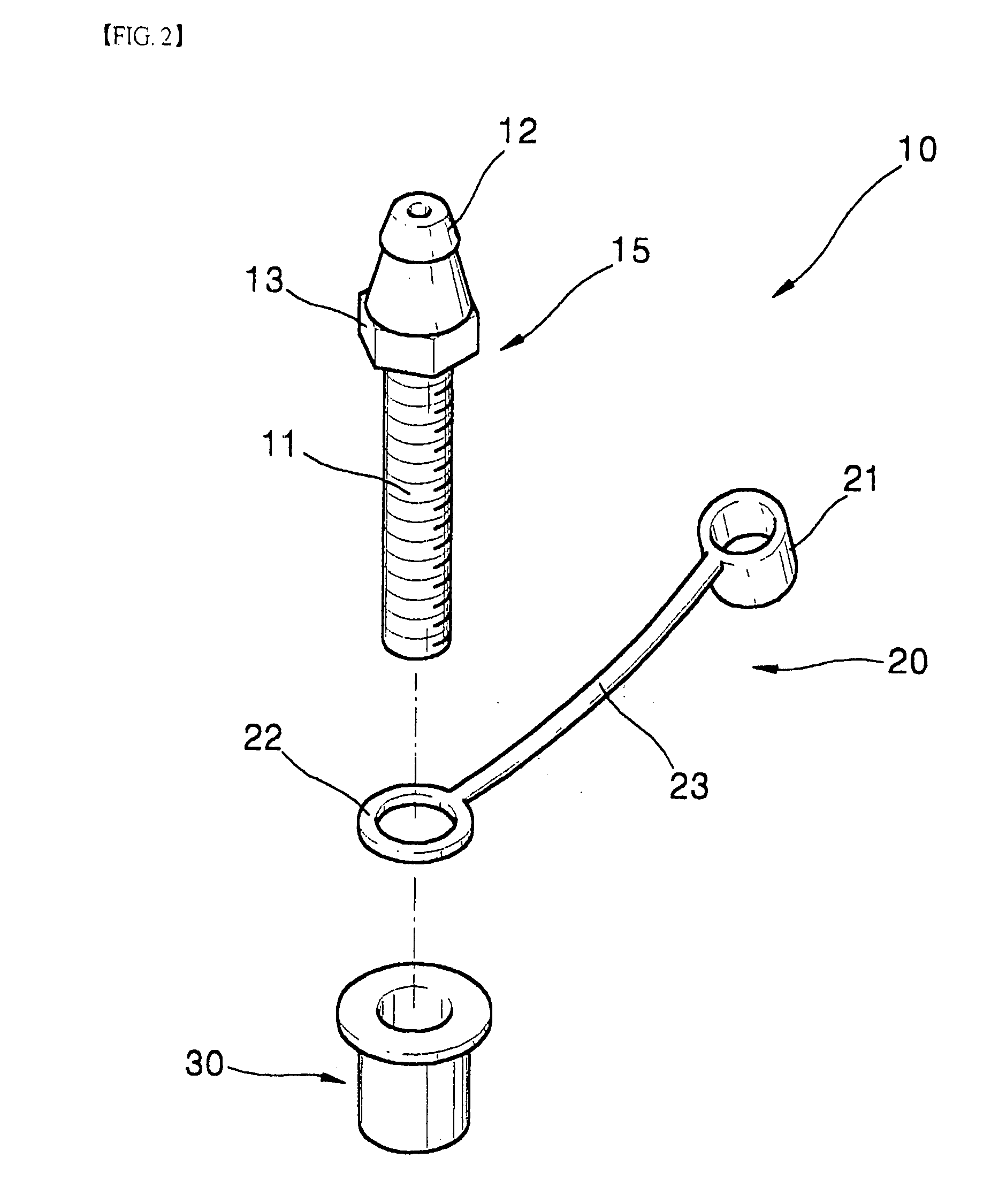

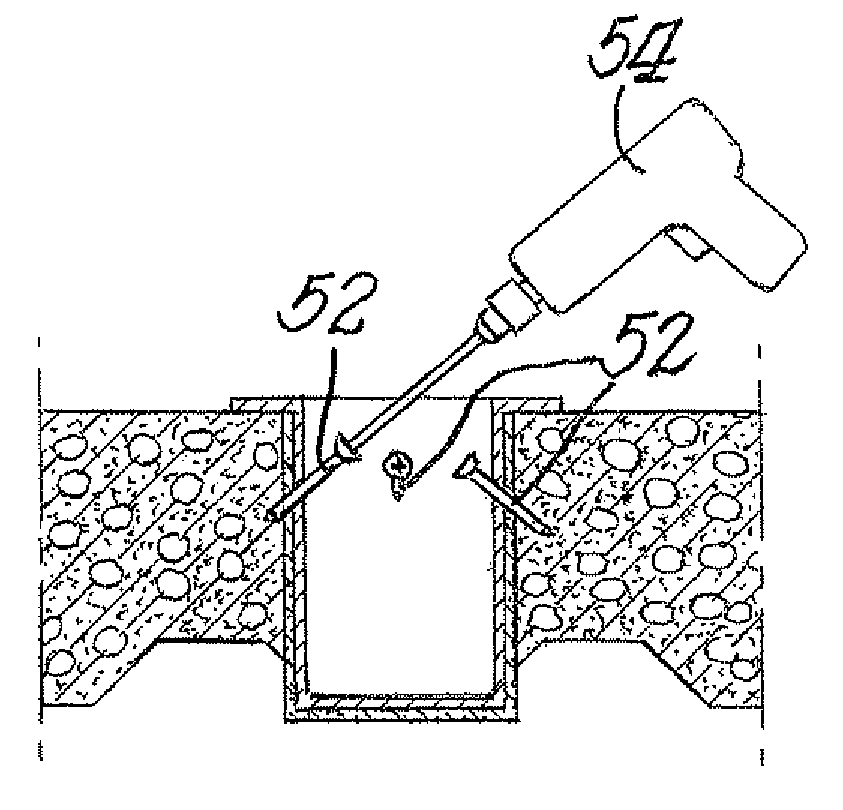

Plastic micro packer and construction method using it

InactiveUS20050120660A1Simple structureEasy constructionBuilding repairsFoundation repairCouplingEngineering

Disclosed are a plastic micro packer for repairing cracks of structure and a method for repairing middle or low pressure cracks using the plastic micro packer: The micro packer is connected to a hole formed in a crack to inject, repairing solution into the crack of a concrete structure, and includes: a hollow rubber sleeve having a screw portion formed on the inner surface thereof; a hollow packer body having a screw coupling portion screwed with the screw portion and a nozzle portion connected to a repairing solution injector; and a cove; member connected to the nozzle portion to prevent leakage of repairing solution. The screw portion of the rubber sleeve has a wide top and a narrow bottom, and thereby, is closely contacted to the hole while the lower portion of the screw portion is expanded in a radial direction when the screw: coupling portion is screwed with the screw portion. A flange portion is formed at the front end of the rubber sleeve to prevent excessive induction of the rubber sleeve into the hole.

Owner:SAMSUNG GROUP +1

Masonry wall anchoring system

InactiveUS7404274B2Prolong lifeEarthquake proof and more resistant to damage and failureConstruction materialBuilding repairsBrickStone wall

Owner:HAYES JOHN T

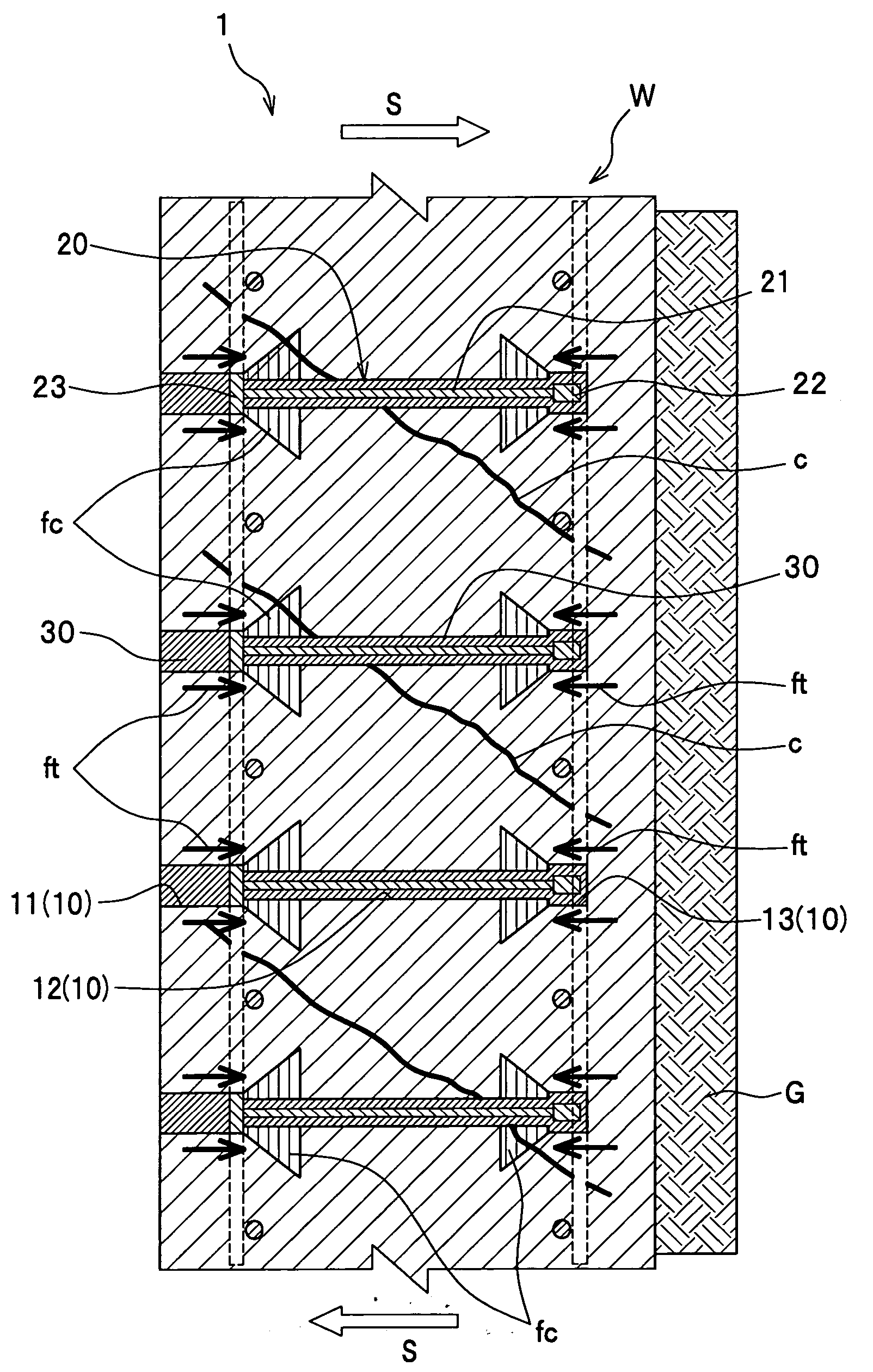

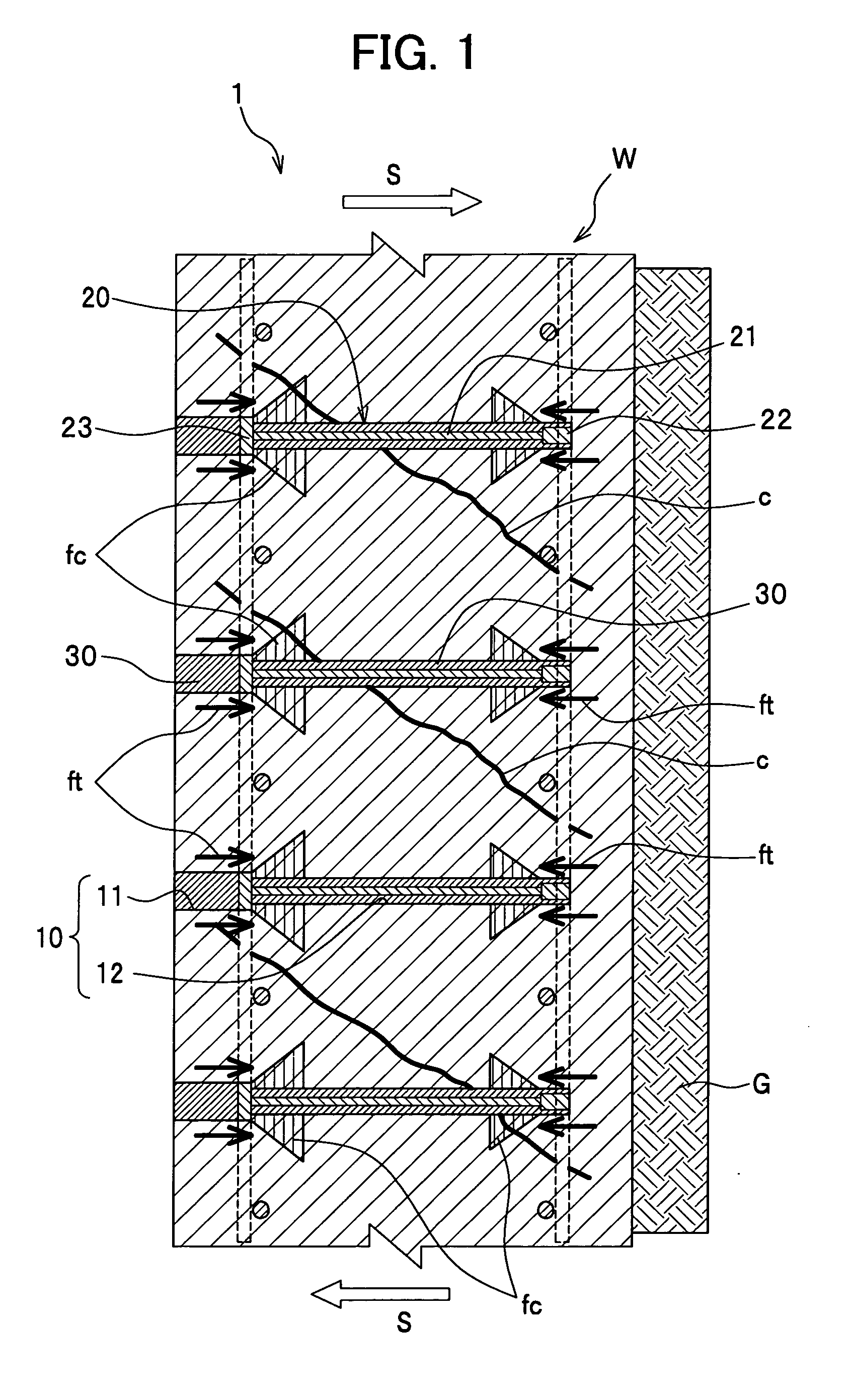

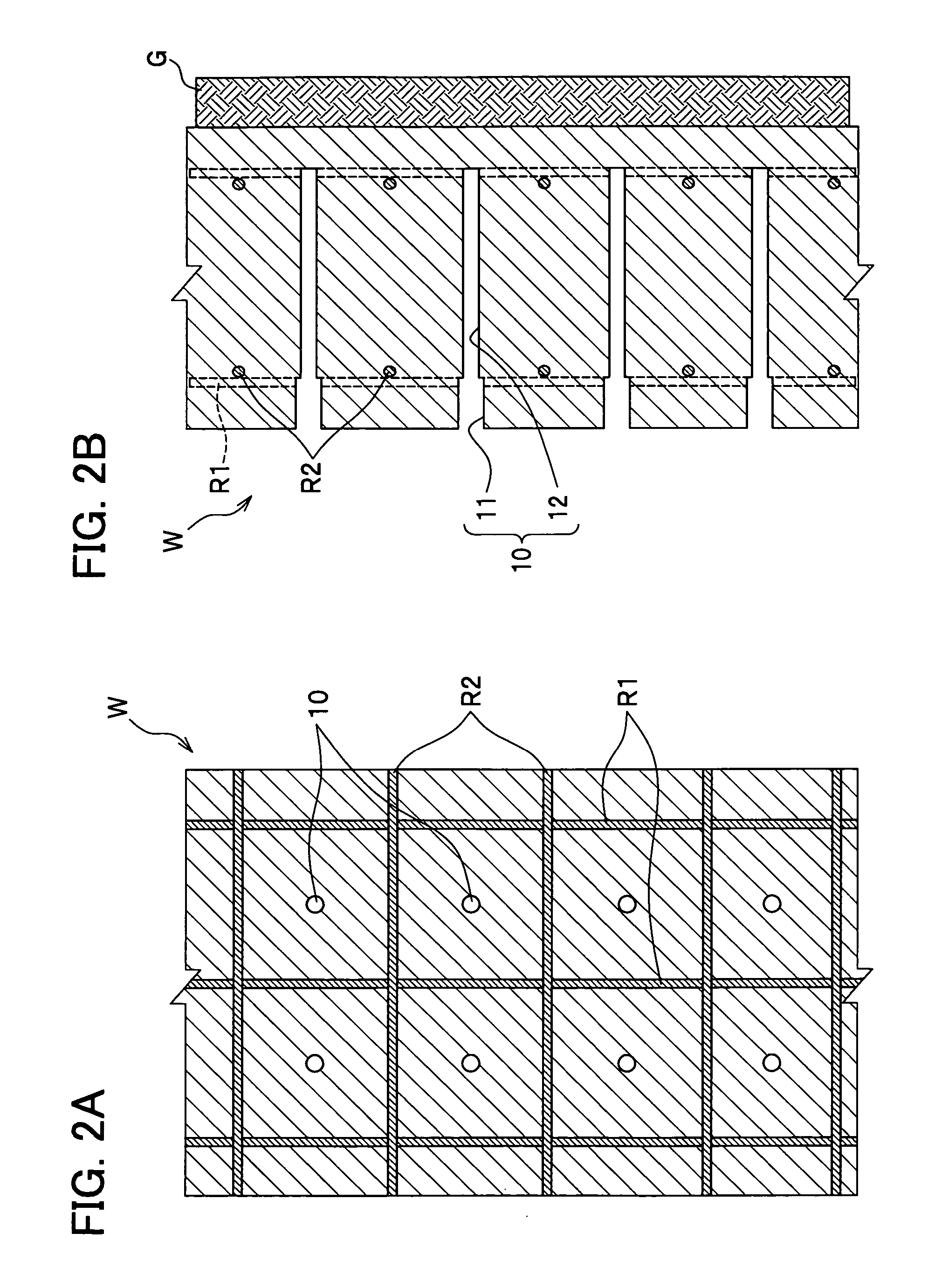

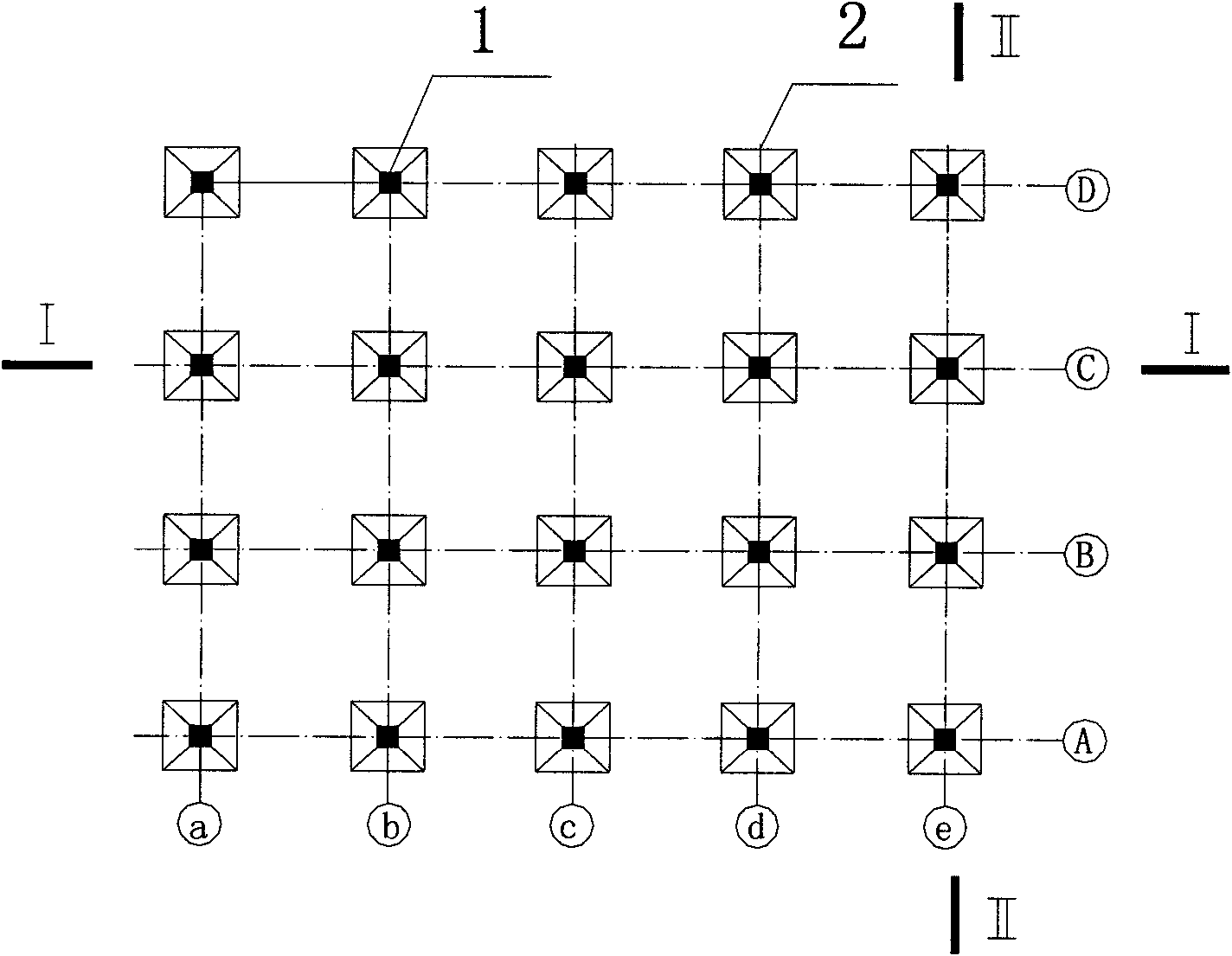

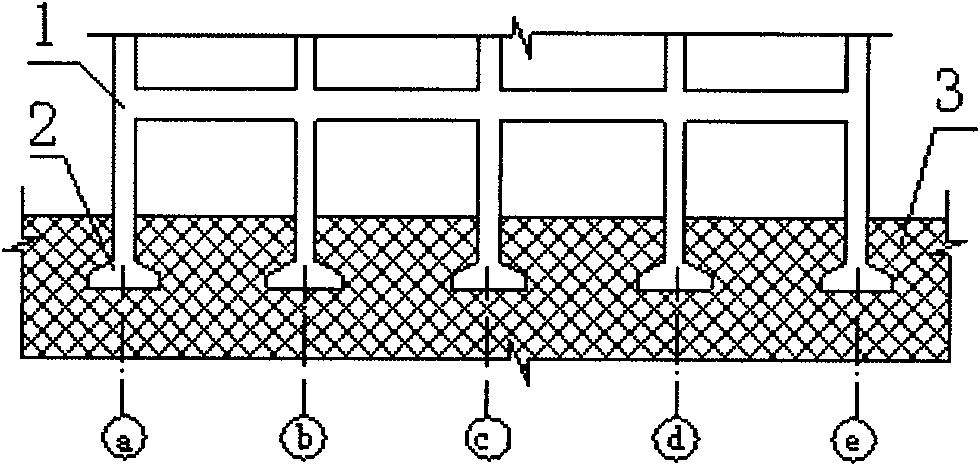

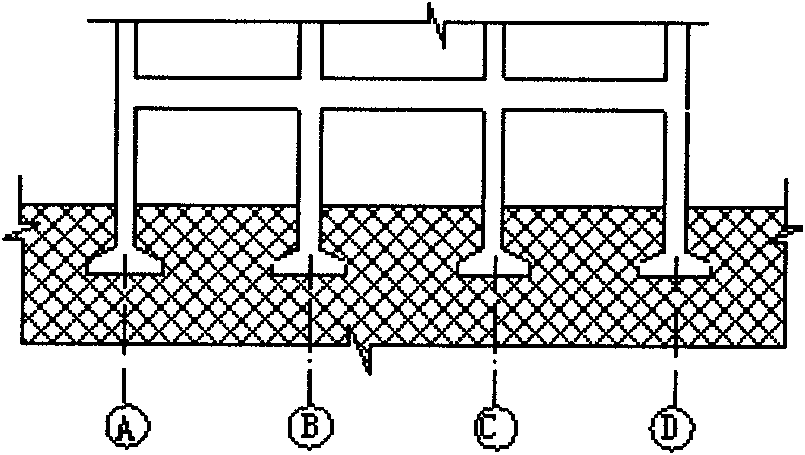

Shearing force reinforced structure and member

The purpose of the present invention is to provide a shearing force reinforced structure of an existing RC structure body that can simply and surely ensure a predetermined pulling-out rigidity. Then a shearing force reinforced structure (1) of the invention is configured with: a side wall (W) of an existing reinforced concrete structure; shearing force reinforced members (20) arranged inside reinforced member insertion holes (10) with bottoms formed in a direction intersecting a major reinforcing bar of the side wall (W); and fillers (30) filled in the holes (10), wherein each of the shearing force reinforced members (20) is configured with a shearing force reinforcing bar (21), a plate head 23 and a ring head (22) respectively fixed at a base end and top end of the reinforcing bar (21); each of the holes (10) is formed at a general part (12) having an inner diameter larger than a reinforcing bar diameter of the reinforcing bar (21) and smaller than a width of the head (23), and a base end width broadening part (11) formed at a base end of the hole 10 and having a diameter larger than the width of the head (23). In accordance with such a shearing force reinforced structure and a shearing force reinforced member, it is enabled to simply and surely ensure a predetermined pulling-out rigidity.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

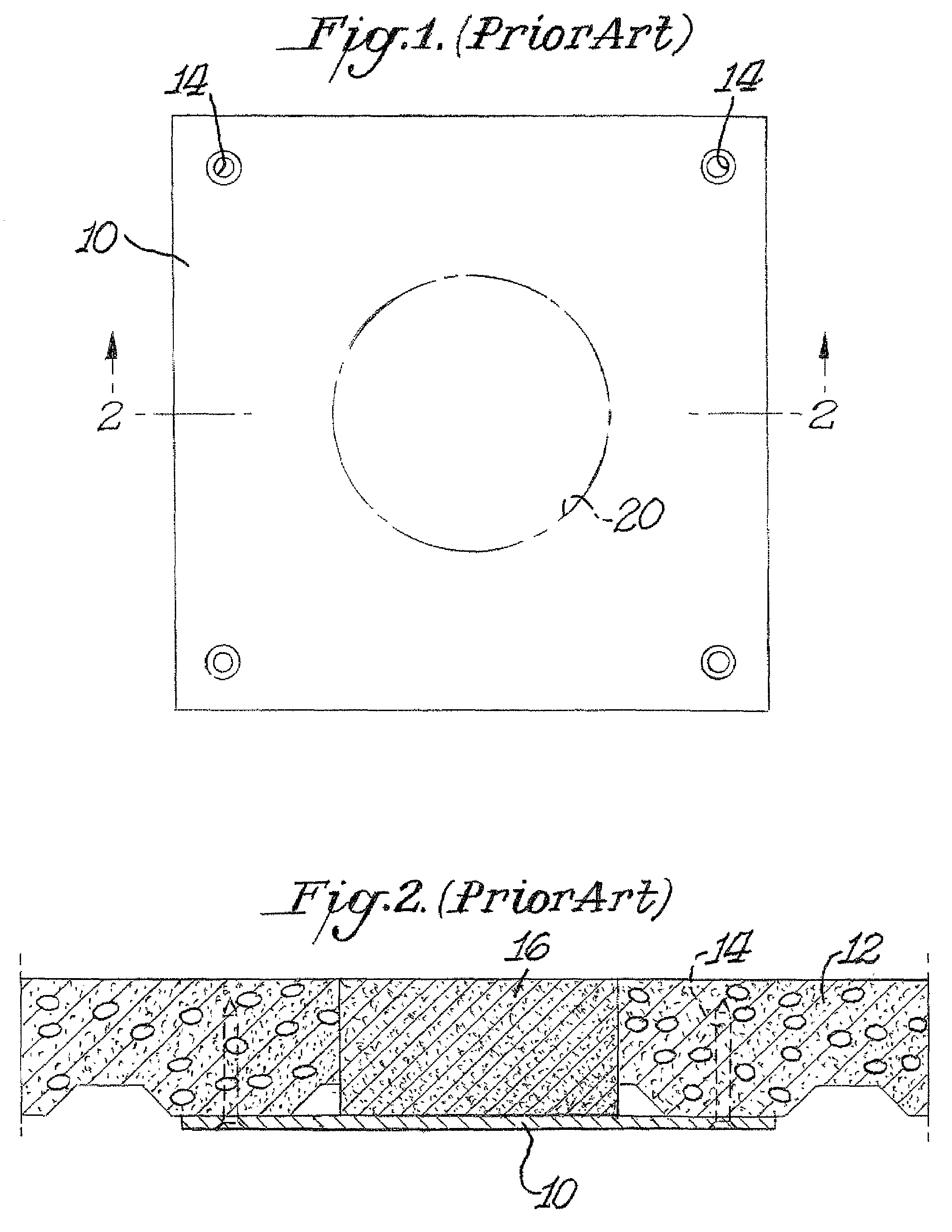

Wallboard repair clip, method of repairing wallboard, and kit for repairing wallboard

InactiveUS6209277B1Shorten the timeReduce the amount of wasteCovering/liningsBuilding repairsBiomedical engineeringWall plate

Owner:MELCHER JEFFREY S

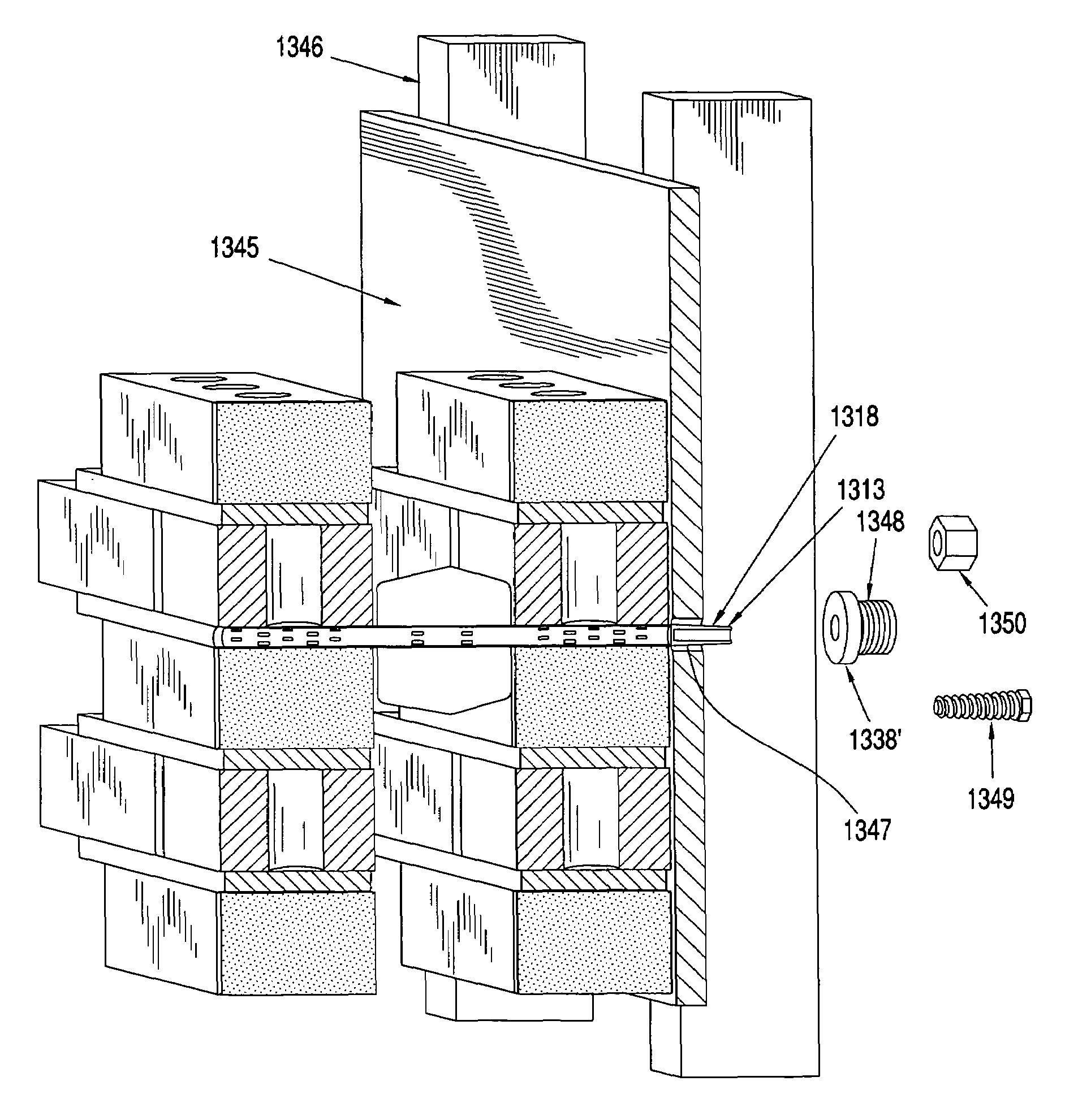

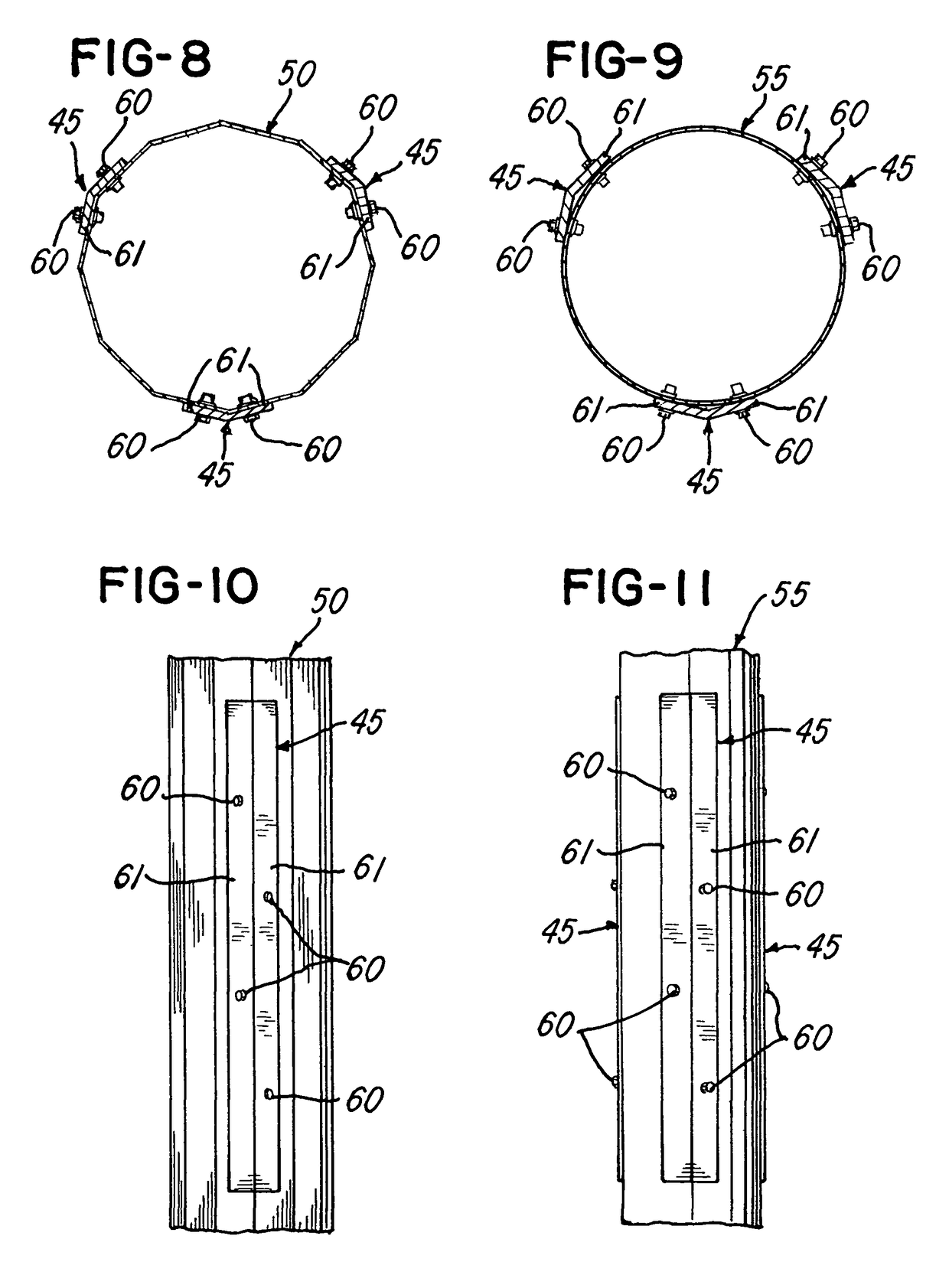

Reinforcing systems to strengthen monopole towers

InactiveUS7905069B1Optimize vertical distanceOptimize spaceBuilding repairsFoundation repairEngineeringTower

An existing vertical monopole tower is reinforced by a plurality of vertically extending metal reinforcing members in the form of elongated channel members or angle plate members or ribbed plate members. The reinforcing members have longitudinally spaced holes which align with vertically spaced holes in the tower wall, and blind fasteners extend through the aligned holes to secure the reinforcing members to the tower. The fasteners provide for transferring only tensile forces or tensile and shear forces to the reinforcing members. Vertically aligned reinforcing members have adjacent end portions spliced together by splice plates and blind fasteners, and the splice plates are fastened to the web portions of the channel members or the ribs of the rib plate members or the wing portions of the angle plate members. Shear plates and pin assemblies may also be used to transfer shear forces and in splicing vertically aligned reinforcing members.

Owner:AERO SOLUTIONS

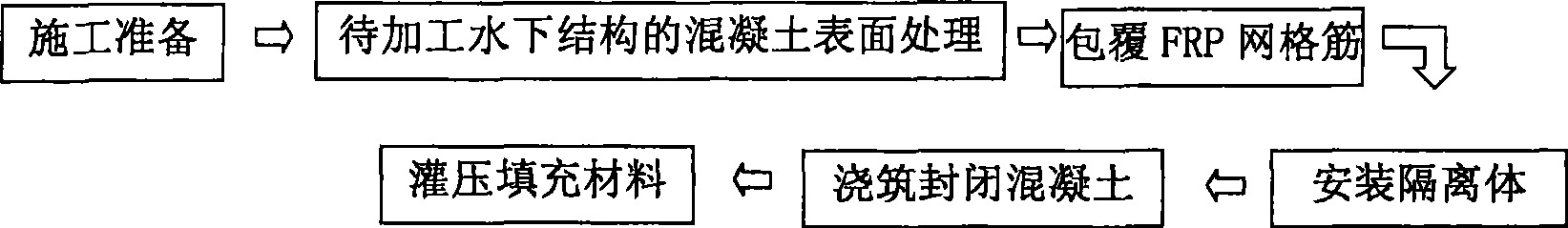

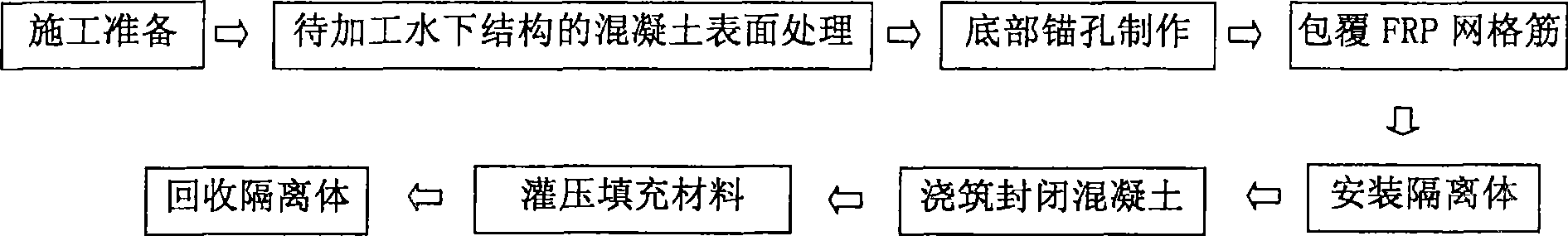

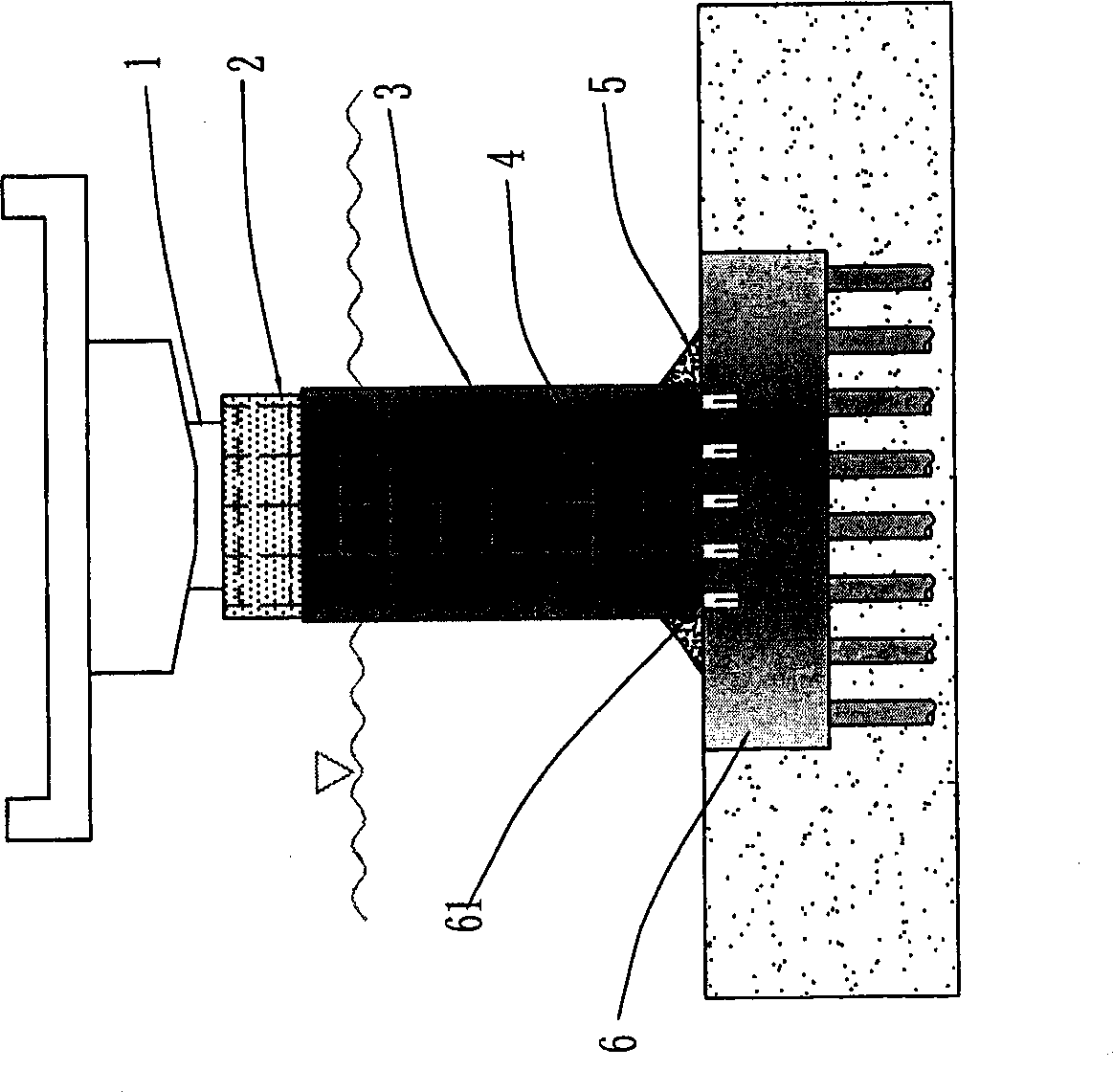

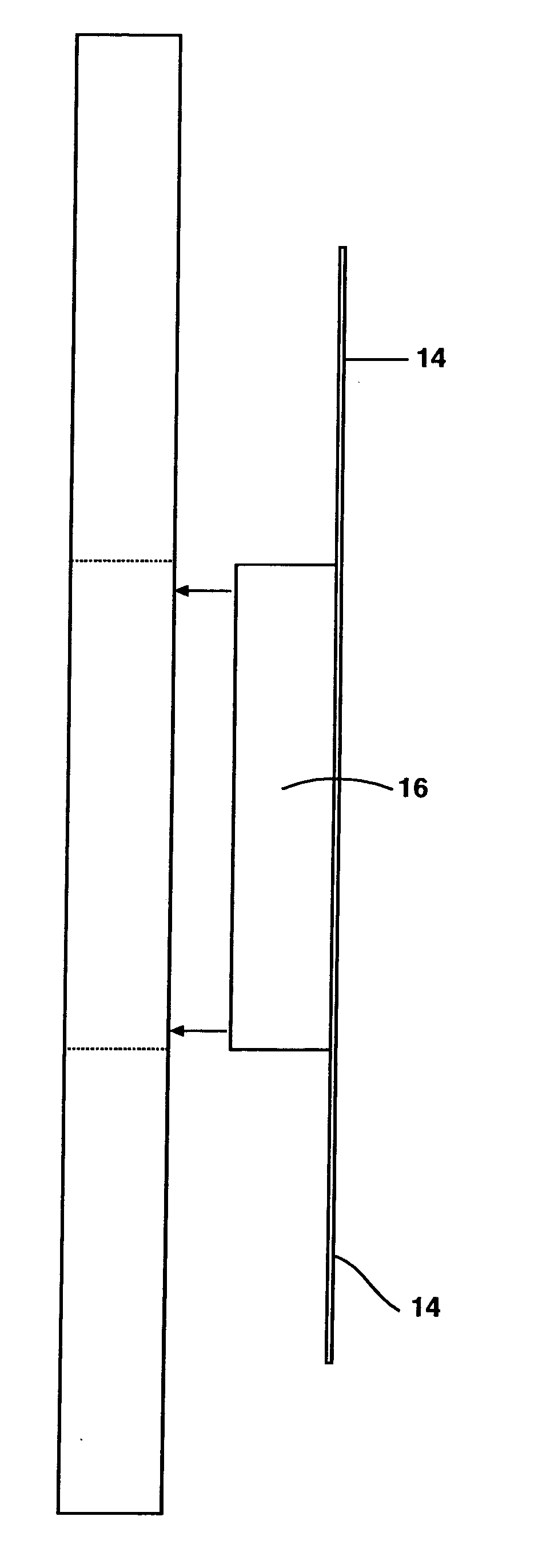

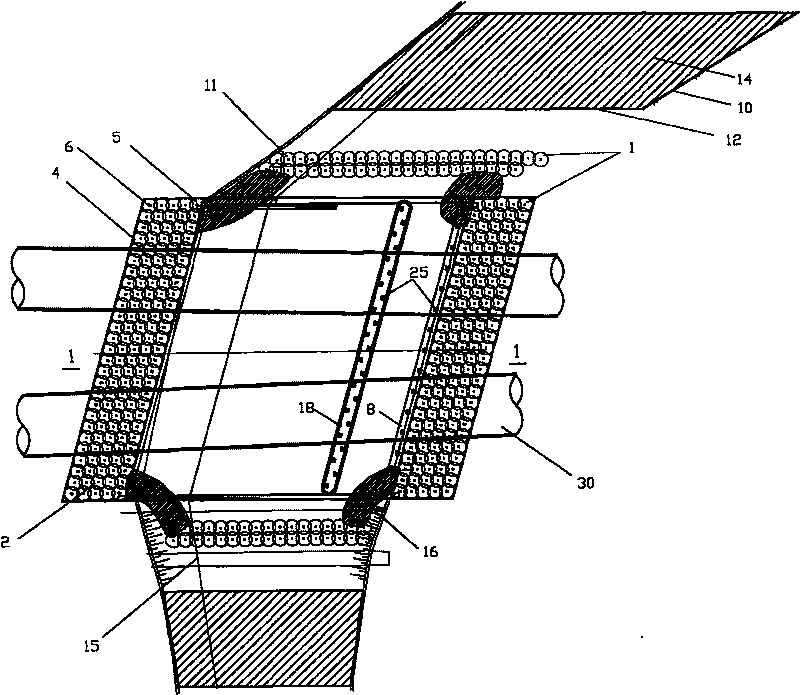

Method for reinforcing underwater structure by fiber-reinforced composite material grid ribs

ActiveCN101503881AMeet emergency repairFast reinforcementArtificial islandsFoundation repairEpoxyUnderwater

The invention relates to a method for reinforcing an underwater structure by using fiber reinforced composite material lattice ribs, which comprises the following steps: treating the concrete surface of the underwater structure to be reinforced; coating at least one layer of the fiber reinforced composite material lattice ribs on the surface of the underwater structure to be reinforced; setting an isolator outside the underwater structure to be reinforced, and making the height of the isolator be more than or equal to the height of the fiber reinforced composite material lattice ribs coated on the surface of the underwater structure to be reinforced; sealing concrete at the bottom of the isolator; and filling underwater epoxy resin or underwater non-dispersed mortar or underwater non-dispersed concrete into the clearance between the isolator and the structure to be reinforced. The process is simple; because the treatment of abandoning and preventing water is not needed during construction, and the periphery of the underwater structure to be reinforced does not need to arrange a cofferdam, the construction process has little influence on a navigation channel; and the reinforcing cost is low, the reinforcing is quick, the construction period is short, and the durability of the structure can be effectively improved.

Owner:BEIJING JIUTONGQU TESTING TECHNOLOGY CO LTD

Drywall patch kit

InactiveUS20060010817A1Same textureImprove usabilityBuilding repairsFoundation repairDrywallBiomedical engineering

A kit for repairing holes in drywall having two principal components, a patch itself and a moistening device for attaching the patch to the surface upon which the patch is intended to be placed. The patch containing an inner portion configured for insertion within an opening and an outer portion configured to attach and connect with the wall upon which the patch is placed. The moistening device, preferably a form of spray on texture provides a means for adhering the patch to the surface upon which it is placed and also provides a means for covering the patch so as to blend with the surrounding surfaces.

Owner:SHULL JACK R

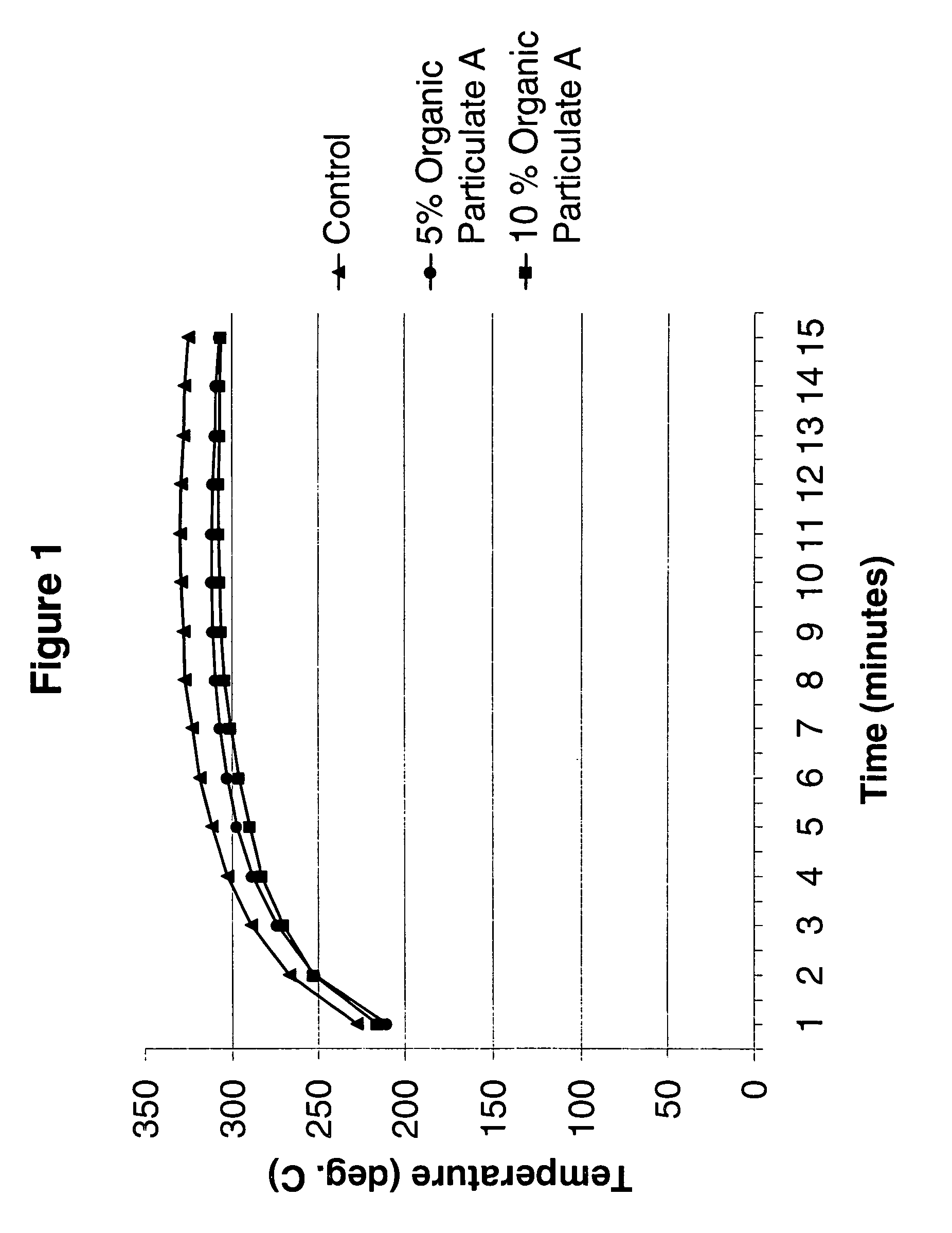

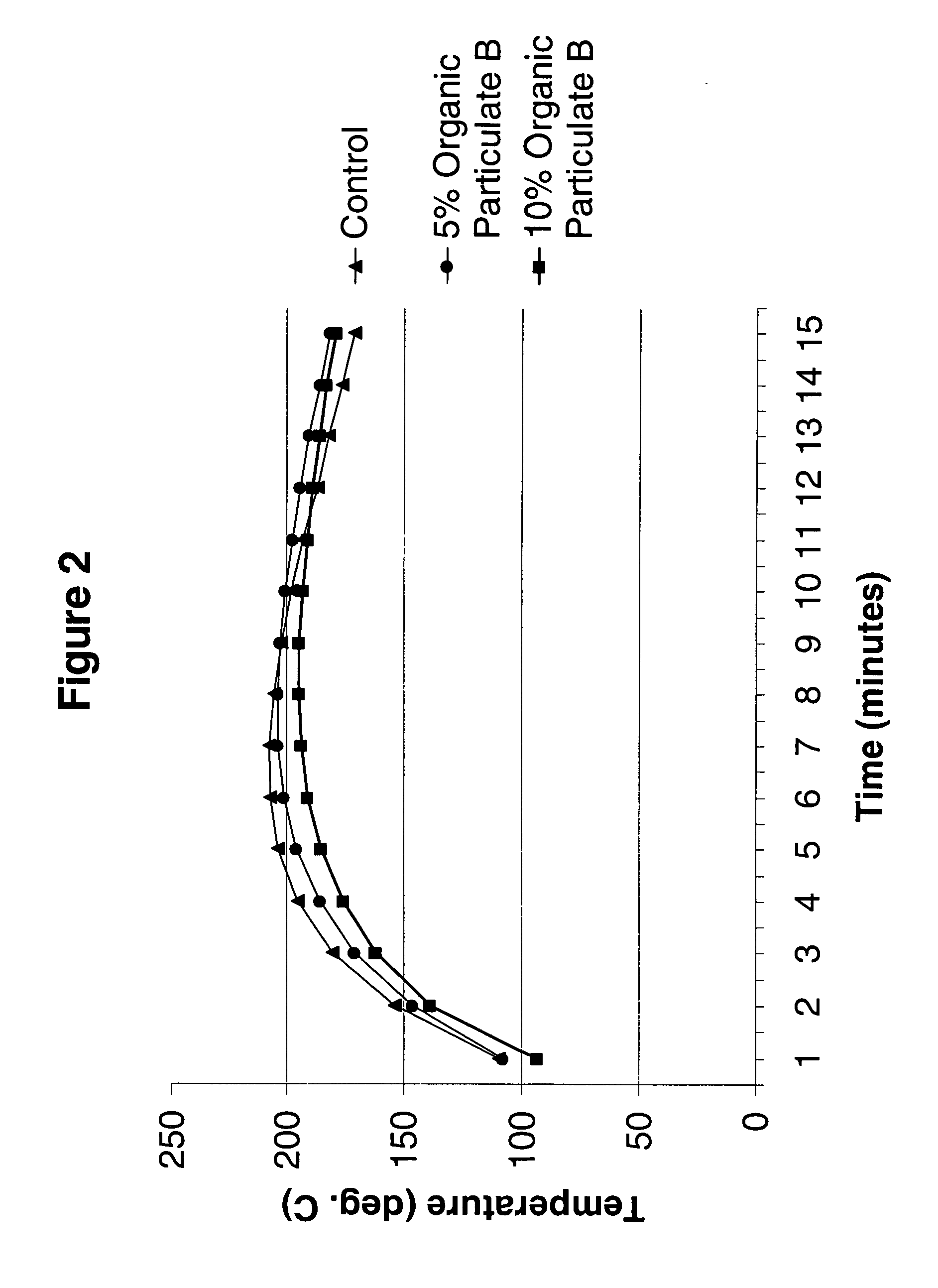

Shingle and mat tensile strength with urea formaldehyde resin modifier

InactiveUS7272915B2Tensile strength of glass fiber matsHigh tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberAsphalt

Owner:BMIC LLC

Box-raft pressure-bearing type foundation underpinning and construction reinforcing method for tunnel across pile foundation of bridge above river

InactiveCN101761068AReduce the impactImprove construction levelFoundation repairBulkheads/pilesCofferdamAbutment

The invention relates to a geotechnical and underground engineering technology field, particularly to a box-raft pressure-bearing type foundation underpinning and construction reinforcing method for tunnels across pile foundations of a bridge above a river. The method of the invention comprises: reinforcing abutment foundation of both sides of the bridge, reinforcing the riverbed outside the cofferdam construction and abutment, strengthening bridge supports, excavating pits under cofferdam bridges, strengthening expanding plate-type foundations inside the pits and ground base under the plates, as well as shield tunneling and removing obstructive file base. The method can smoothly complete construction and guarantee smooth shield tunneling while ensuring normal passage of existing bridge structure, further can effectively reduce construction risk, accelerate construction process, reduce cost and reduce influence to environment to a maximal extent.

Owner:TONGJI UNIV +1

Floor hole repair method

ActiveUS7665272B2Easy to installHigh strengthTyresBuilding repairsFloor coveringBiomedical engineering

A floor hole repair fixture has at least one vertical side wall and a bottom wall which together define an inner volume. The fixture is connected to a hole in a floor with one or more fasteners and is filled with a non-shrink grout. A depending rim or flange extending from the at least one side wall helps seat the fixture within the hole. Intumescent material may be coated onto or applied to external fixture surfaces before the fixture is inserted into the hole. Floor covering material is installed over the grout-filled fixture.

Owner:REEN MICHAEL J

Method and/or apparatus for drywall repair

An apparatus for repairing a hole in a wall. The apparatus comprises an end section, a connection section and a fastener section. The end section may have an area larger than the hole and a cross-section smaller than the hole. The end section may be a continuous piece. The connection section generally has a first end connected to the end section. The fastener section is generally connected to a second end of the connection section.

Owner:SHOCK THOMAS P

Structure for reinforcing concrete member and reinforcing method

InactiveUS6330776B1Improve ductilityImprove proof stressBuilding repairsFoundation repairGlass fiberReinforced concrete

In the structure for reinforcing a concrete member and the reinforcing method of the present invention, a reinforcing sheet is arranged and joined to a various kinds of concrete member, such as column, beam, wall, floor, and the like, by applying the reinforcing sheet to the surface of the concrete member and attaching to the fixing anchors joined to the concrete member or the other concrete member surrounding the concrete member. The fixing anchor comprises a large amount of reinforcing fiber, and is obtained by bundling a part of the reinforcing fiber. The unbundled portion of the fixing anchor is spread along the surface of the concrete member. The reinforcing sheet is over-lapped to the unbundled portion using resin adhesives. In addition, reinforcing fibers, such as carbon fiber, aramid fiber, glass fiber, and the like are preferably used as the material comprising the fixing anchor and reinforcing sheet. Thereby, the reinforcing member can be joined via the fixing anchor to the concrete members. Therefore, it is possible to securely join the edges of the reinforcing member, and reliably exert the reinforcing effects on the concrete member.

Owner:NIPPON STEEL CORP

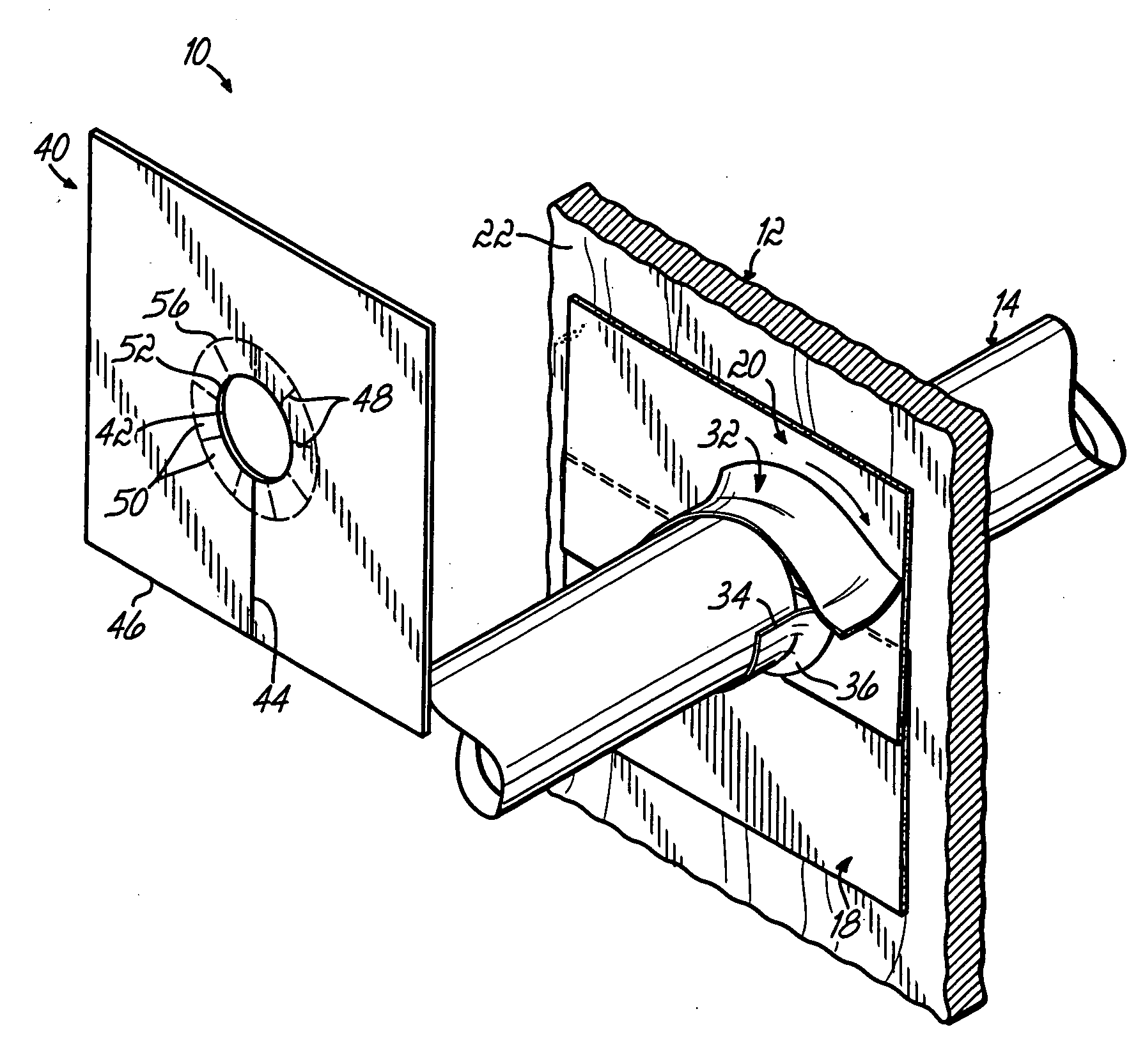

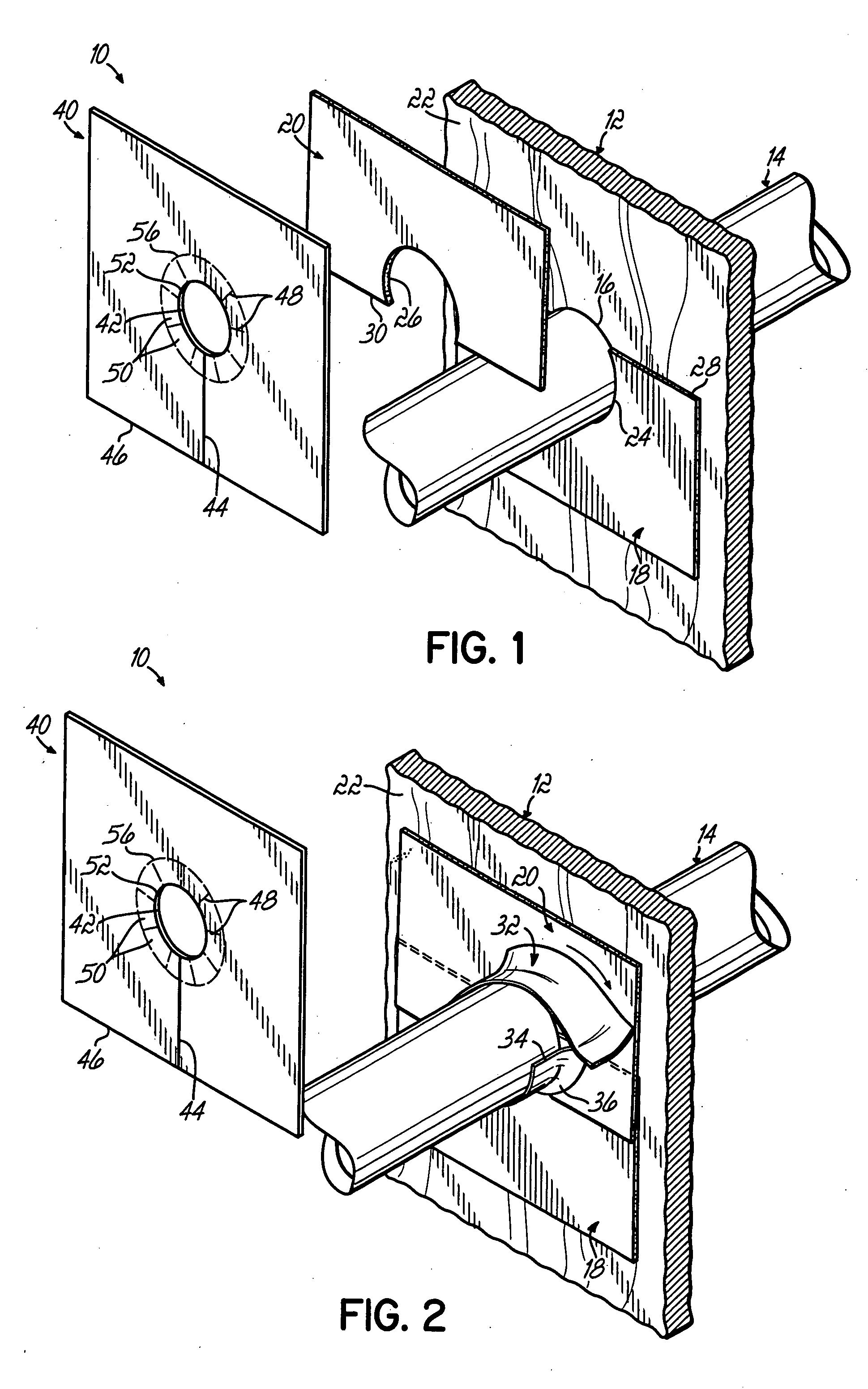

Flashing kit for wall penetrations

InactiveUS20060027388A1Easy and efficient installationPrevent travelRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringWrap around

Owner:TY DAS BUILDING PROD LLC

Process for Treating an Underground Formation

ActiveUS20140303049A1Easy to disassembleAvoid easy removalLiquid/gas jet drillingBuilding repairsSoil scienceCarbonate

The present invention relates to processes for consolidating an underground formation with a consolidating mineral. The consolidating material is a carbonate and is produced from an alkaline treatment fluid containing, in at least some embodiments, environmentally friendly and inexpensive components. In one embodiment, the process can be applied to consolidation of an underground formation during or following drilling. The present invention also provides a treatment fluid suitable for use in such processes.

Owner:CLEANSORP LTD

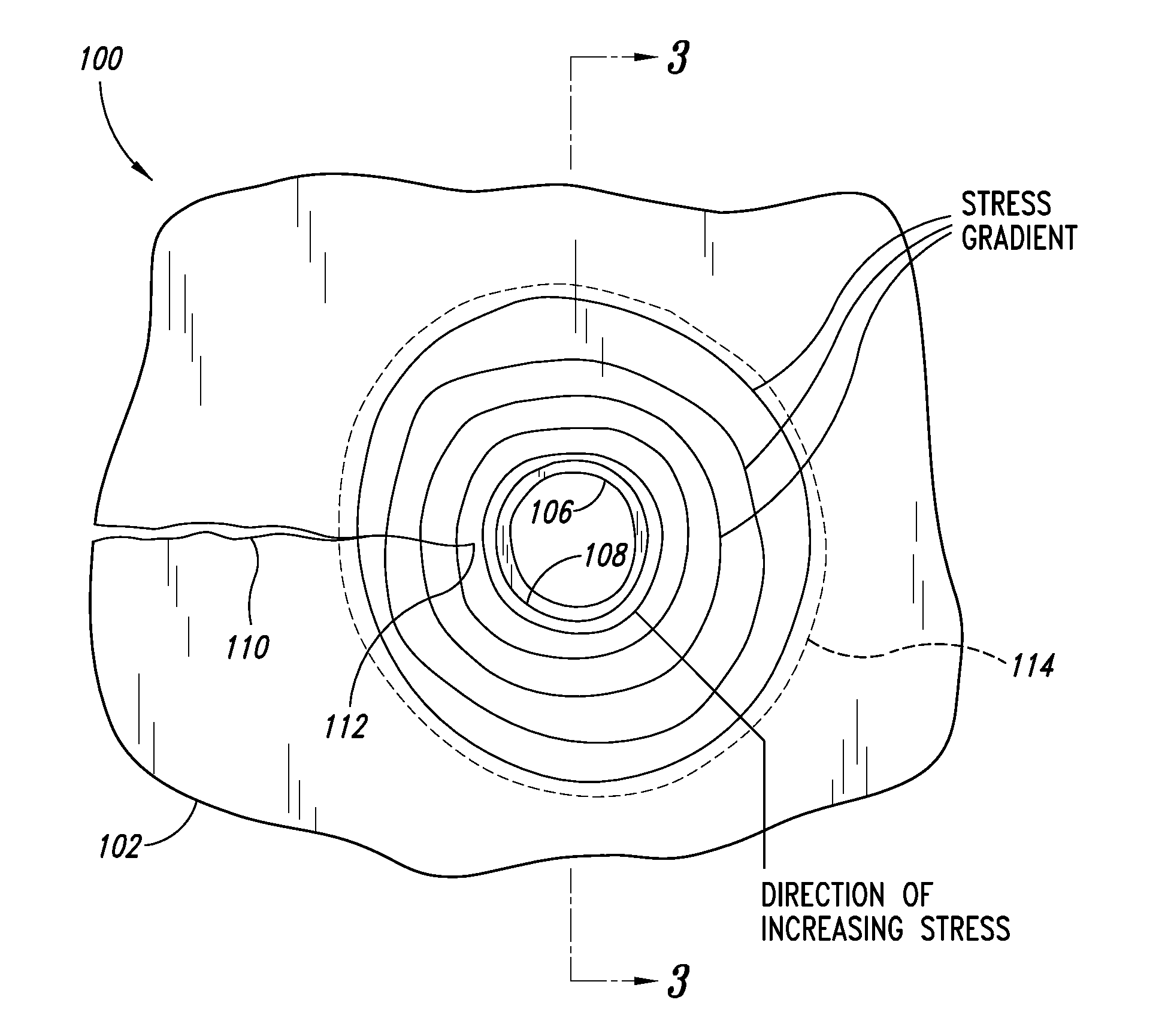

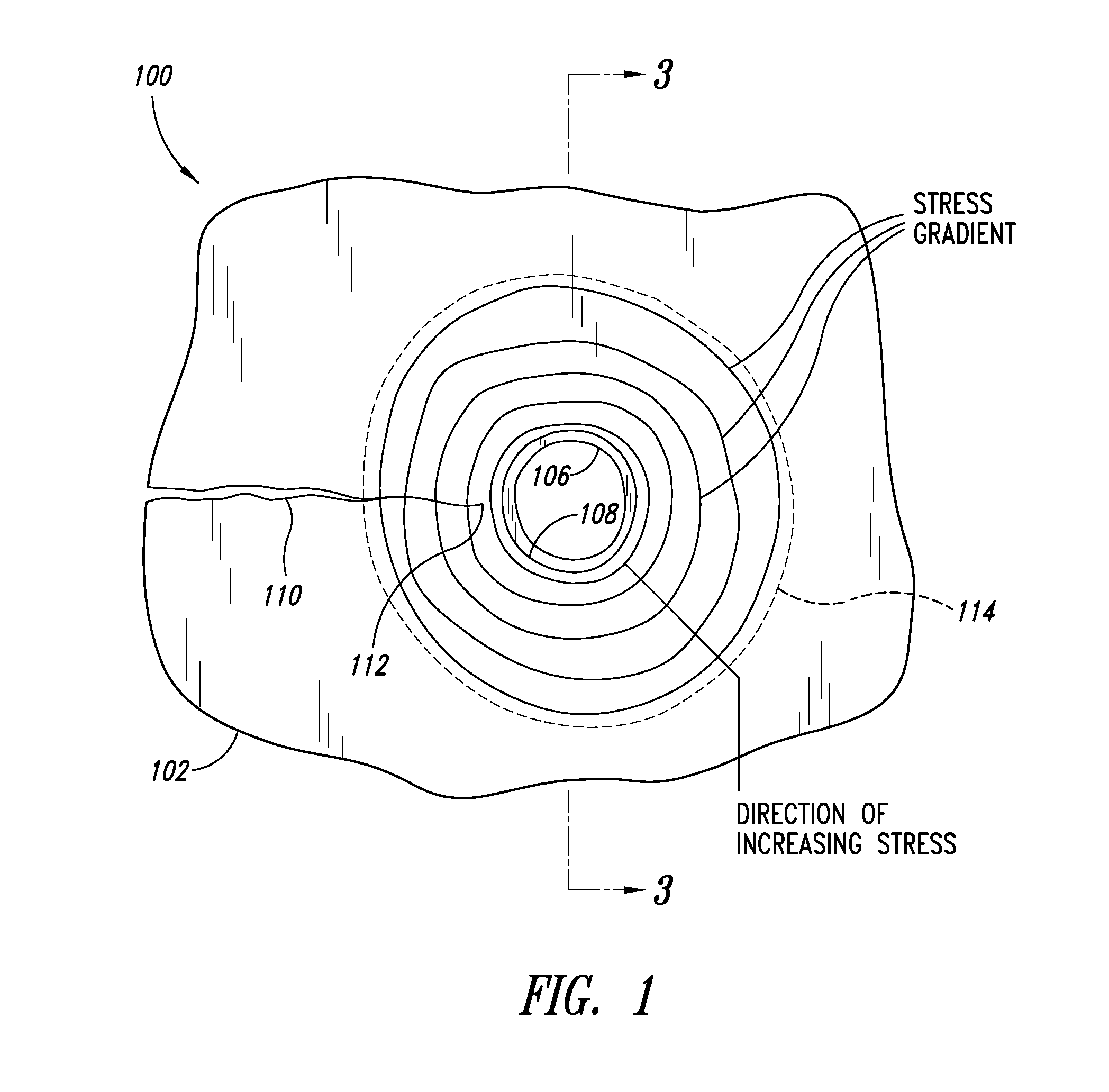

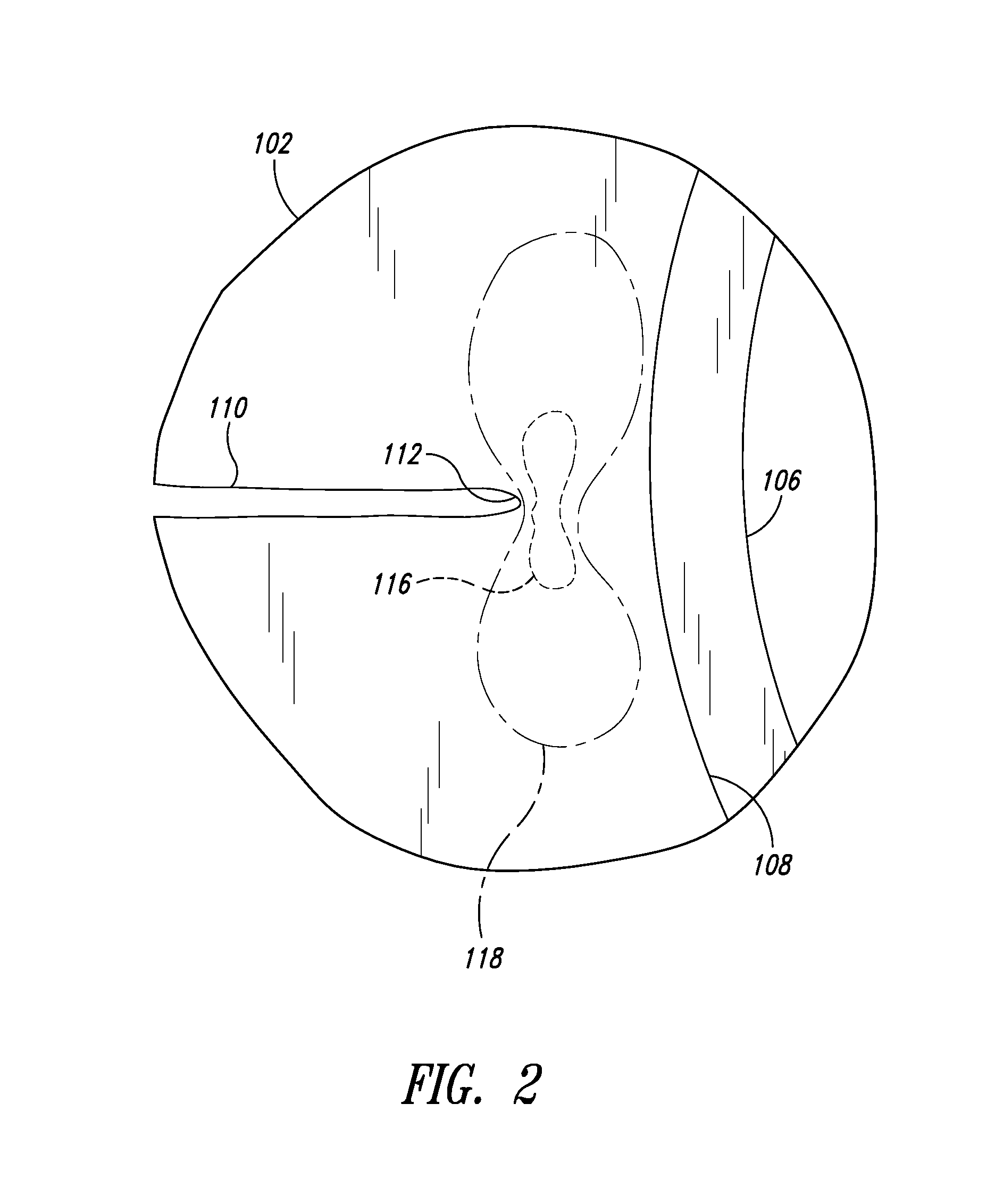

Expandable crack inhibitors and methods of using the same

ActiveUS20120304577A1Extended service lifeImprove fatigue performanceBuilding repairsFoundation repairInterference fitEngineering

One or more crack inhibitors can be installed to improve fatigue performance by producing stress states that prevent or inhibit crack initiation. Crack inhibitors can also prevent or retard crack growth. A mandrel can be used to radially expand the crack inhibitors to both induce compressive residual stresses and to form an interference fit between the crack inhibitor and a workpiece. The mandrel can be removed from the installed crack inhibitor, which is left in the workpiece to ensure proper stress states are maintained.

Owner:FATIGUE TECH

Method and apparatus for repairing concrete

ActiveUS20120110940A1Easy to implementStrongBuilding repairsFoundation repairCivil engineeringArchitectural engineering

Owner:GARLAND INDS

Underground storey-adding process of frame structural building by one-by-one independent foundation underpinning method

ActiveCN101886479AReduce production capacityReduced activityArtificial islandsBuilding repairsBasementSoil properties

The invention relates to an underground storey-adding process of a frame structural building by a one-by-one independent foundation underpinning method. In the process, top beams and top supports of the building with a proposed basement and columns and foundations of the completed basement jointly support an upper structure of the building, and then earth excavation and construction of the columns and the foundations of the residual uncompleted basement are continuously carried out. Earth excavation and top support are simultaneously performed; after the original foundations are removed, the load of the upper frame columns is transferred to the adjacent foundations around the columns through the top beams and transferred to earth through the foundations; and after new foundations and an lower ground level underground frame column are constructed, the load of the upper frame columns can be jointly supported by the new foundations, beam supports and the adjacent foundations. Compared with 'a slab foundation underpinning method' in which the upper structure is simply supported by soil mass under slabs, the method is more reliable and can complete underground storey-adding in areas with worse soil property; compared with the underpinning mode of removing the foundations of the whole building simultaneously, the method is more safe; and even though engineering accidents happen, the building is locally but not integrally unstable.

Owner:SHANDONG JIANGU SPECIAL ENG LIMIT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com