DDQ-grade hot-rolled pickling cold-formed steel and manufacturing method thereof

A technology of hot-rolled pickling and manufacturing method, which is applied in the field of hot-rolled pickling and cold-formed steel, can solve the problems of long process and low cost, and achieves improved elongation, elongation improvement, yield strength and tensile strength. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

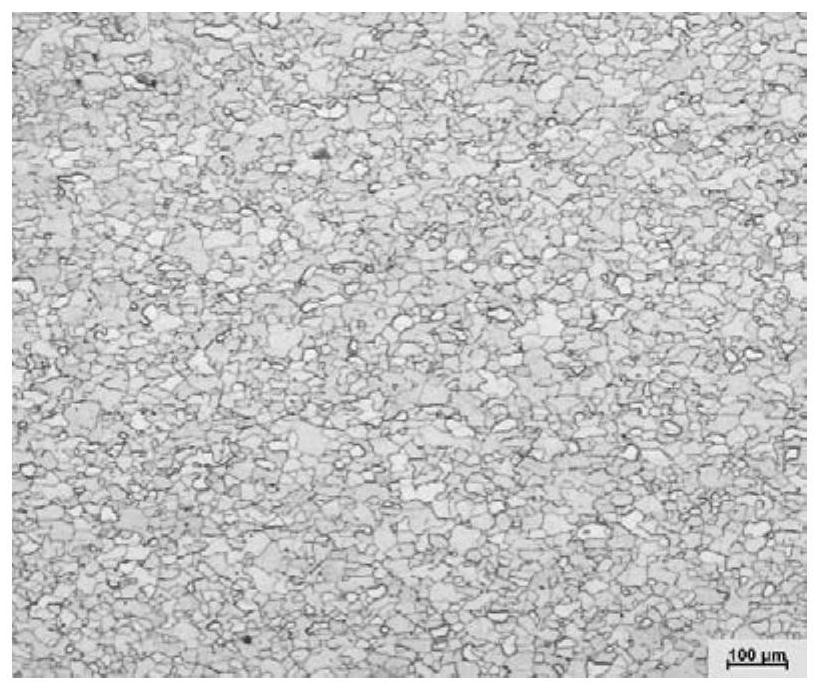

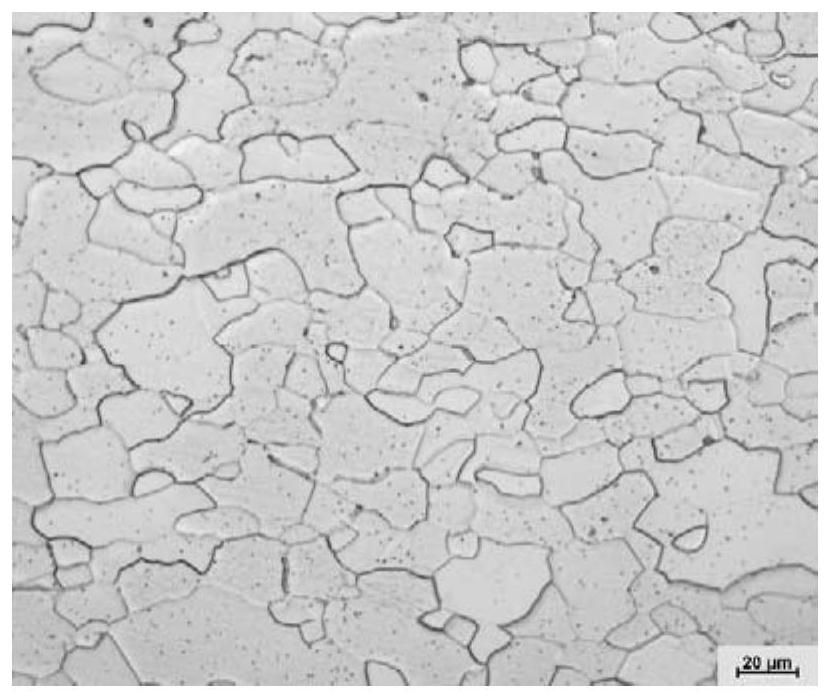

Image

Examples

Embodiment 1

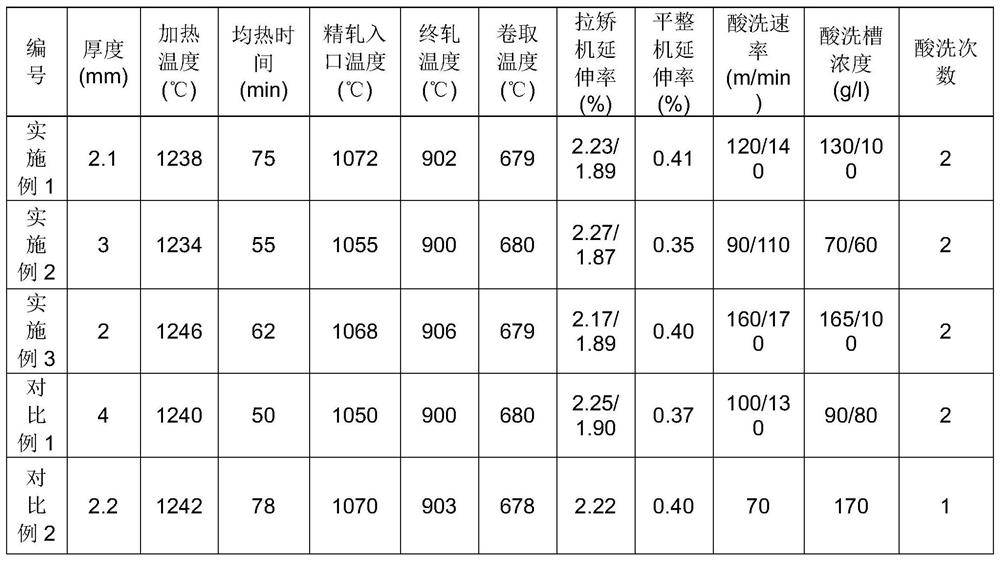

[0058] The chemical composition weight percent of the steel of this embodiment: C: 0.0015%, Si: 0.0022%, Mn: 0.1091%, P: 0.0107%, S: 0.0065%, Als 0.0409%, N: 0.0026%, Ti: 0.0424%, Nb: 0.0227%, the rest is Fe and unavoidable impurities. Specific process parameters refer to image 3 .

Embodiment 2

[0060] The chemical composition weight percent of the steel of this embodiment: C: 0.0019%, Si: 0.0021%, Mn: 0.1096%, P: 0.0102%, S: 0.0061%, Als 0.0394%, N: 0.0026%, Ti: 0.0402%, Nb: 0.0207%, the rest is Fe and unavoidable impurities. Specific process parameters refer to image 3 .

Embodiment 3

[0062] The chemical composition weight percent of the steel of this embodiment: C: 0.0015%, Si: 0.0030%, Mn: 0.1155%, P: 0.0125%, S: 0.0127%, Als 0.0386%, N: 0.0029%, Ti: 0.0388%, Nb: 0.0183%, the rest is Fe and unavoidable impurities. Specific process parameters refer to image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com