Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Eliminate Yield Platforms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

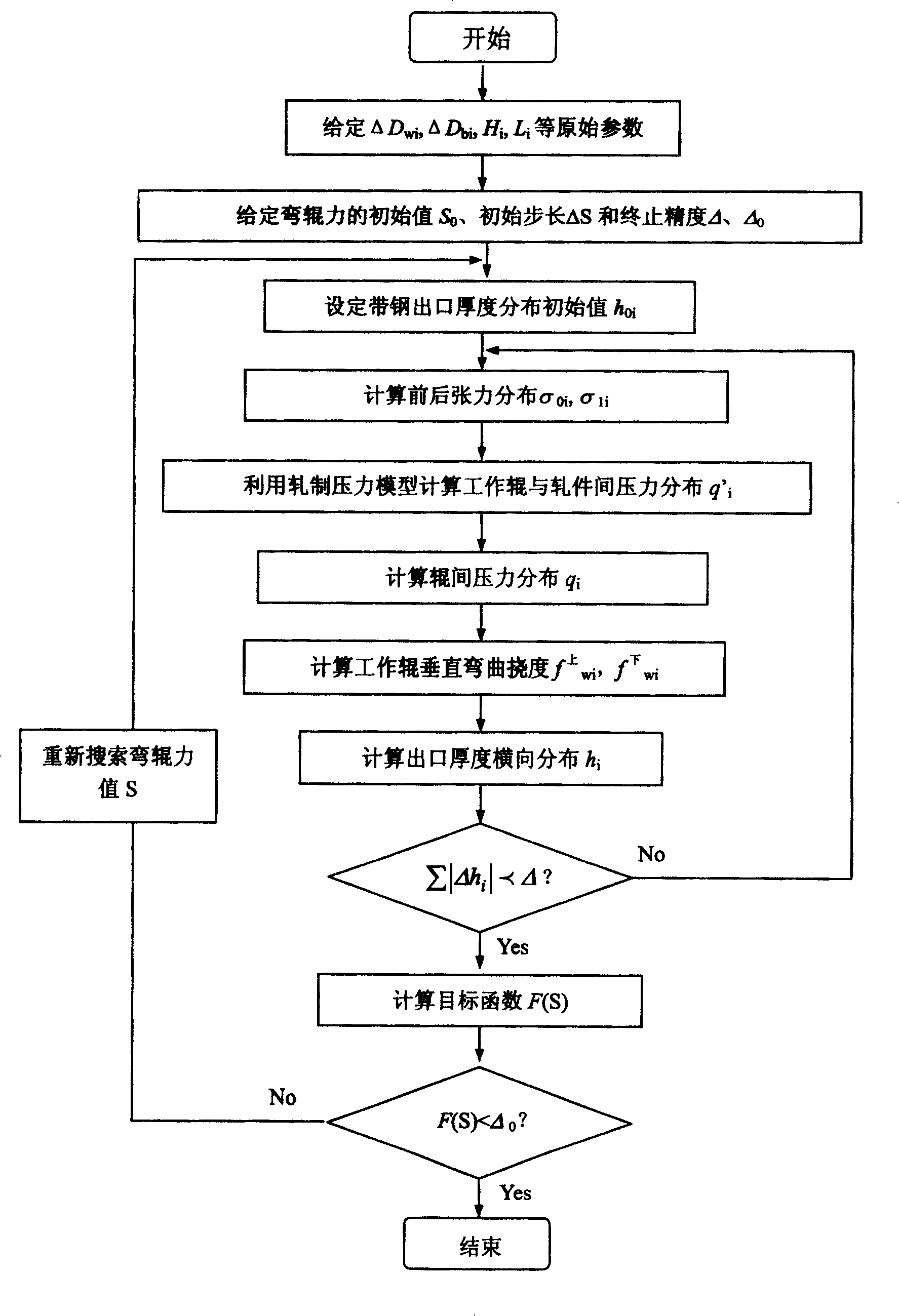

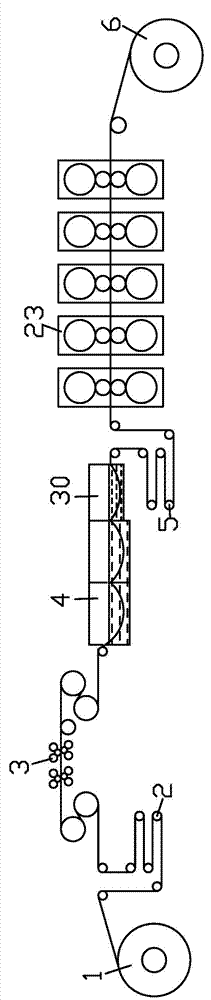

Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

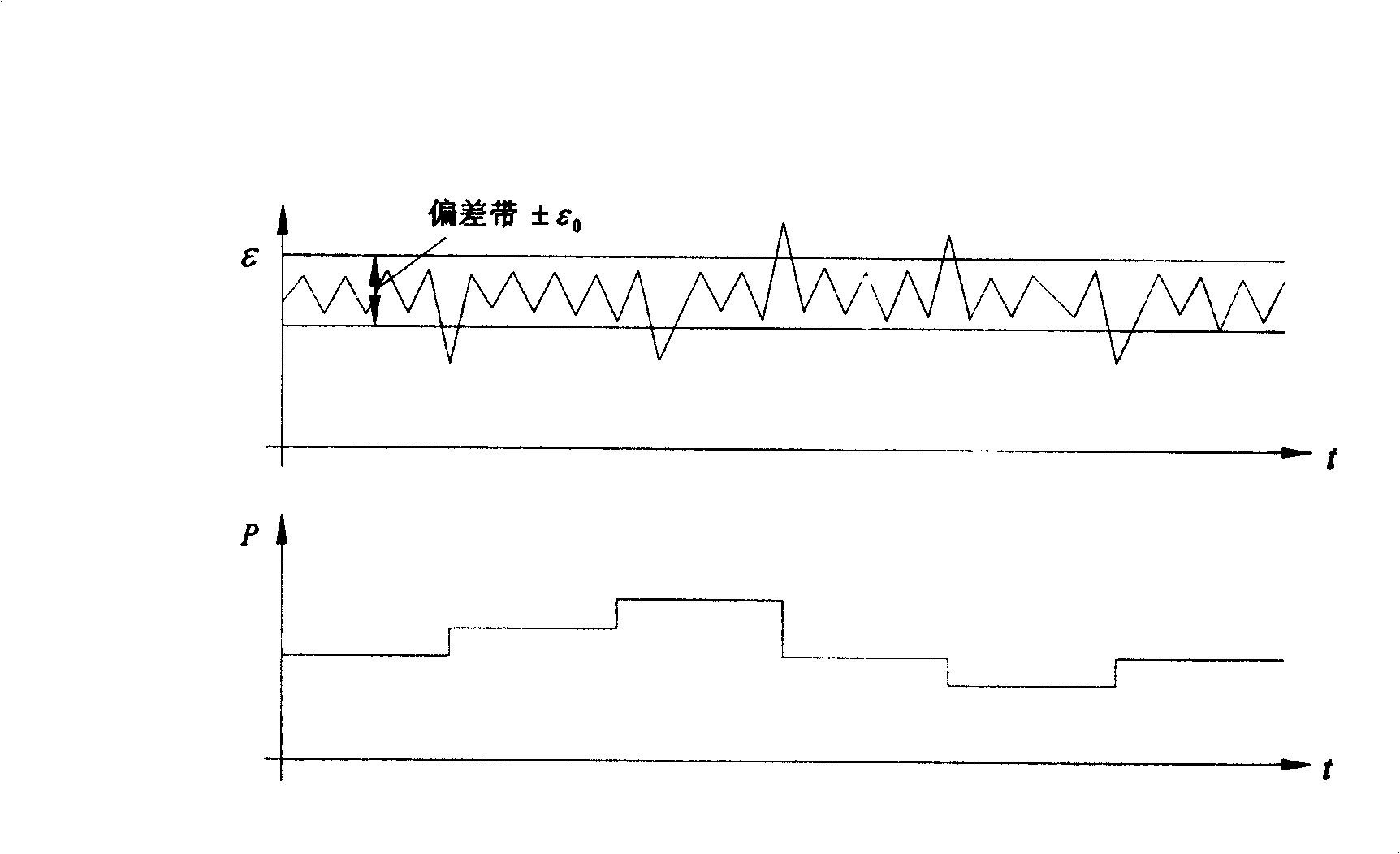

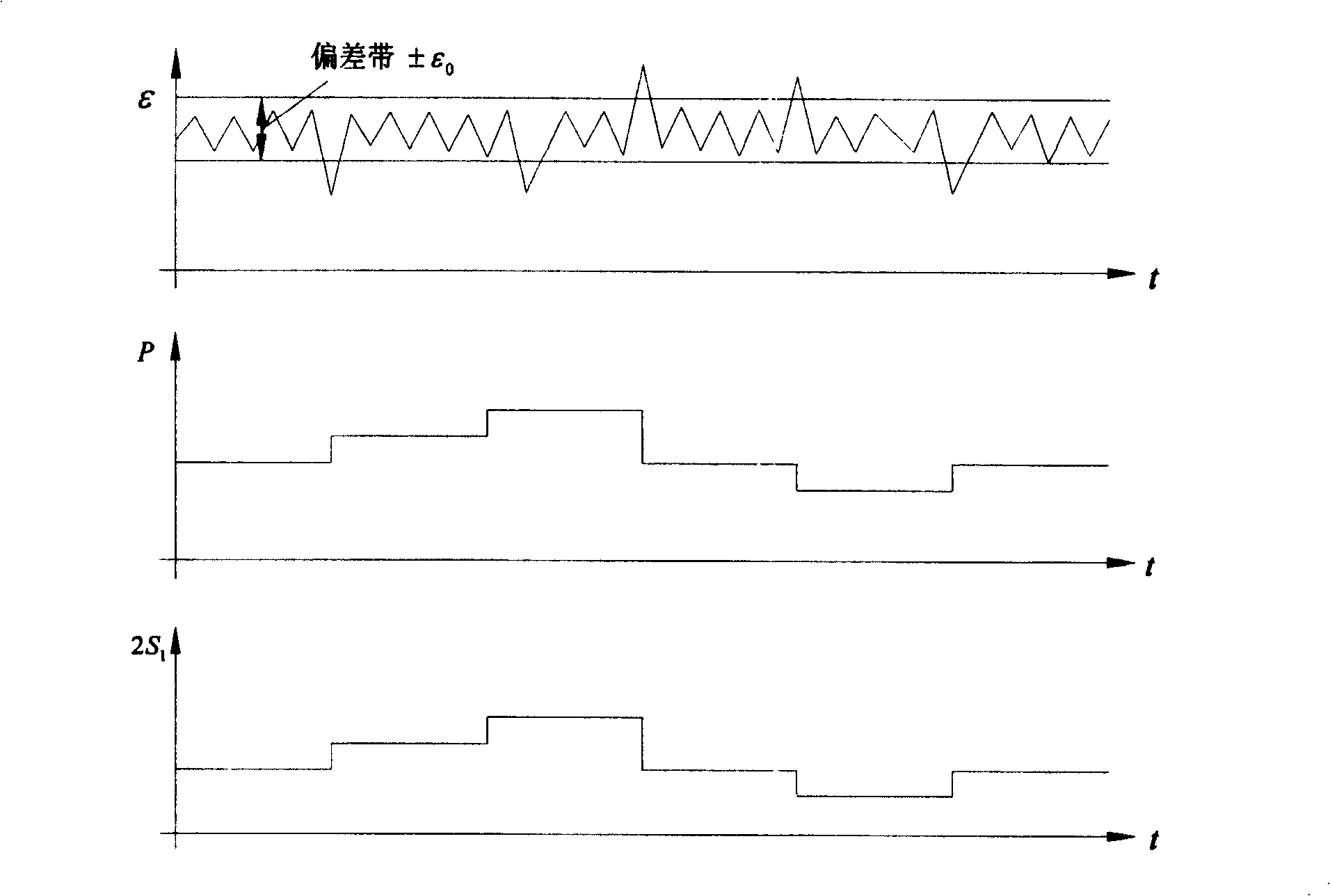

ActiveCN1923391AGuaranteed accuracyGuarantee the shape qualityRoll force/gap control deviceTension/compression control deviceControl systemClosed loop

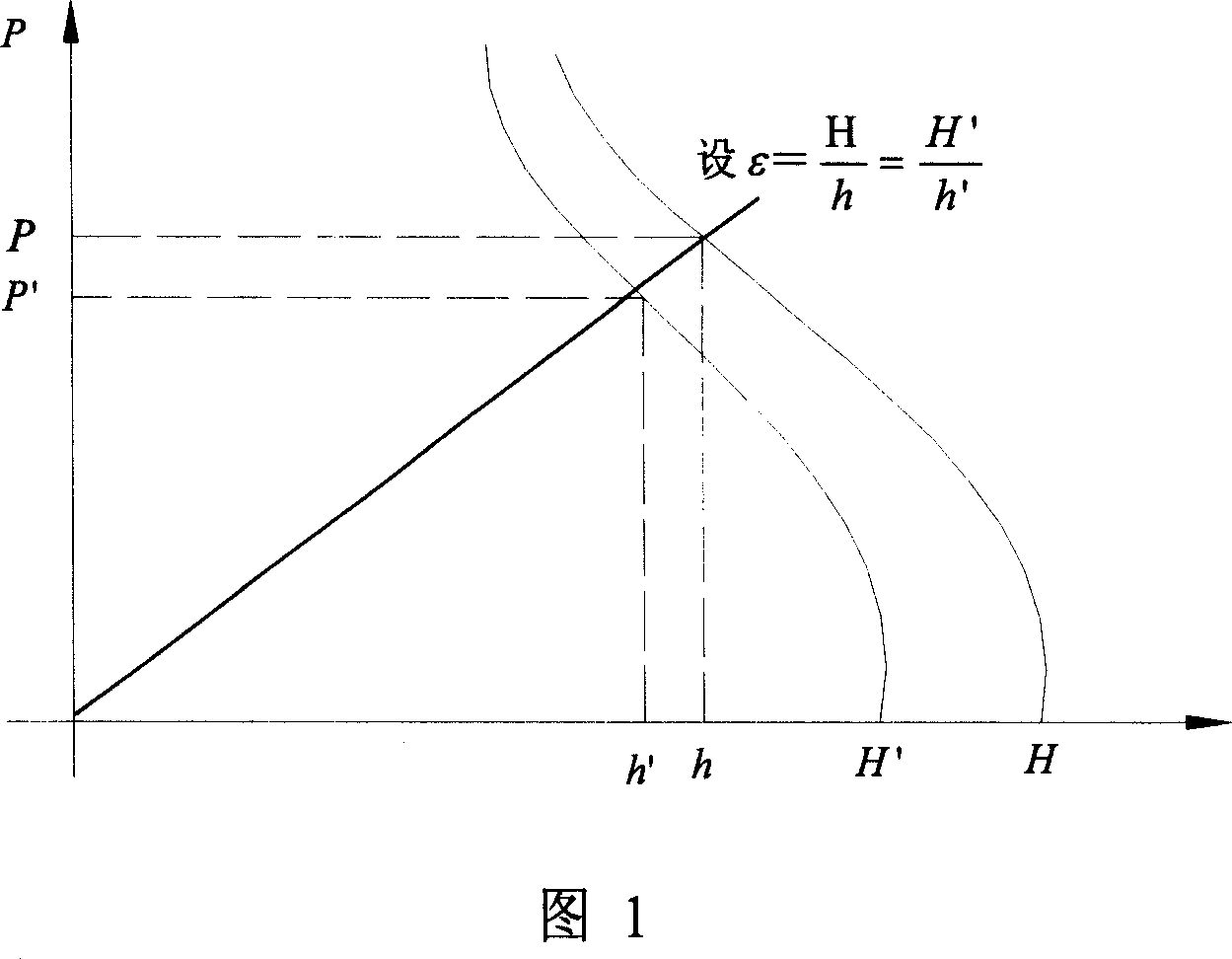

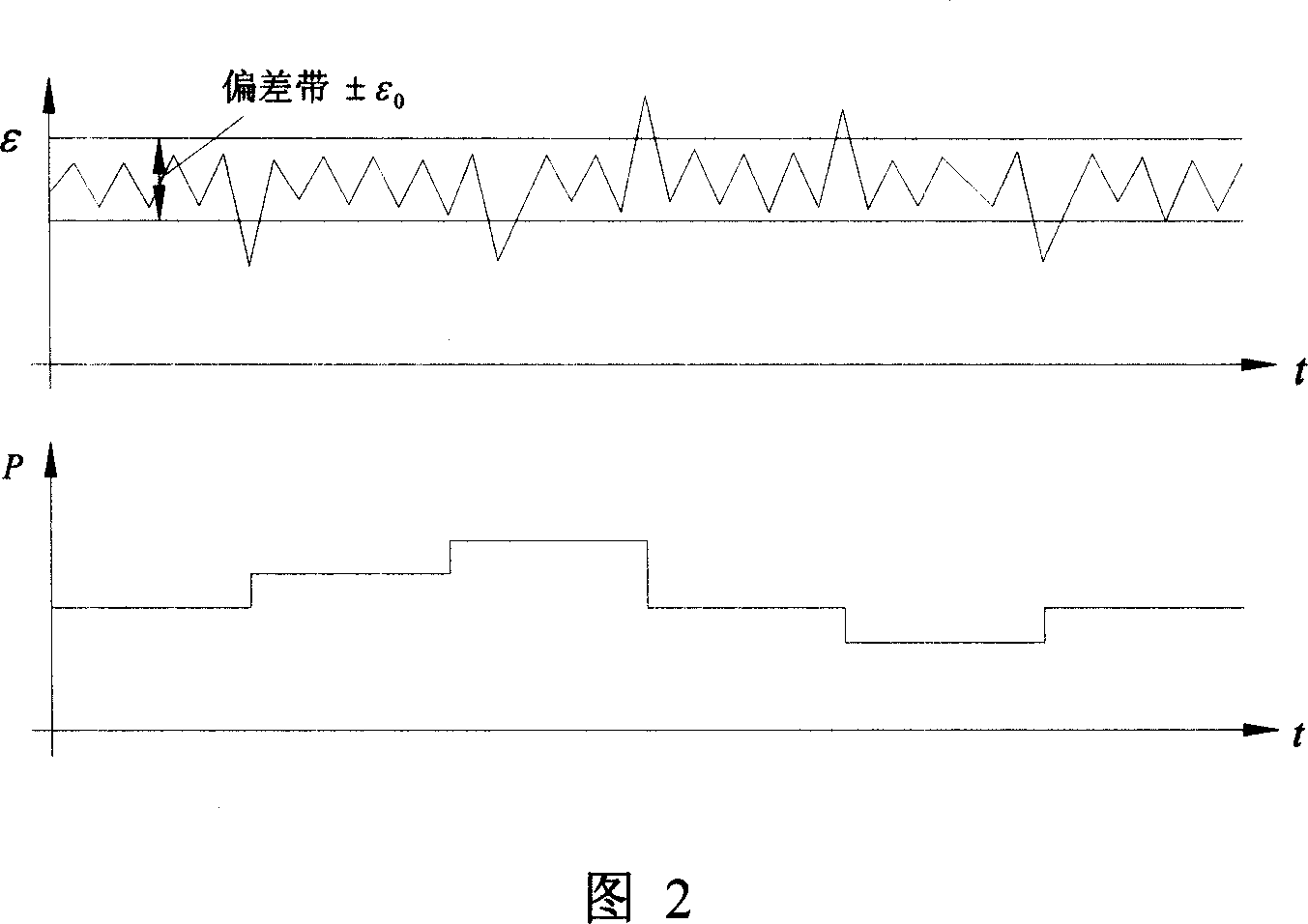

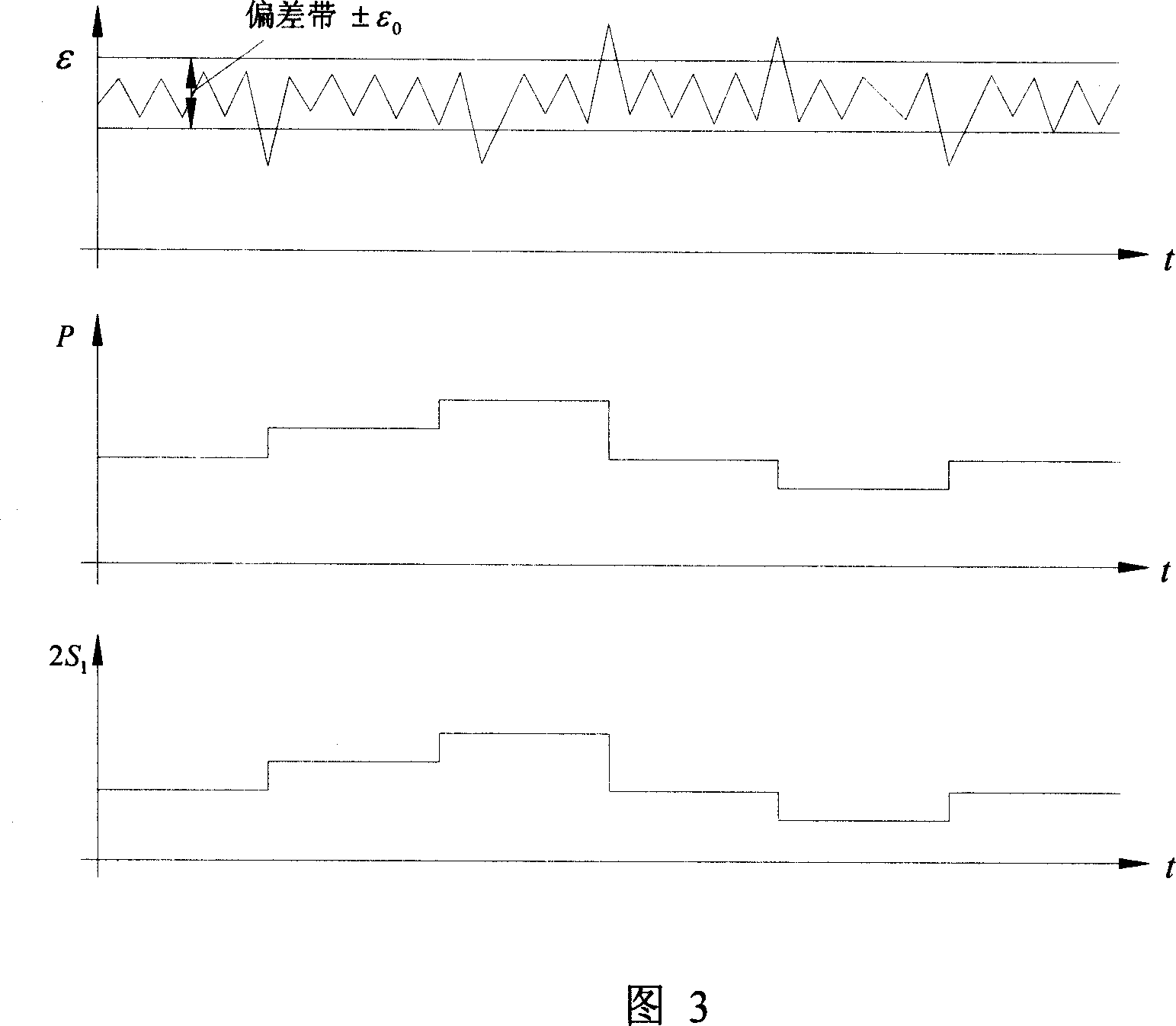

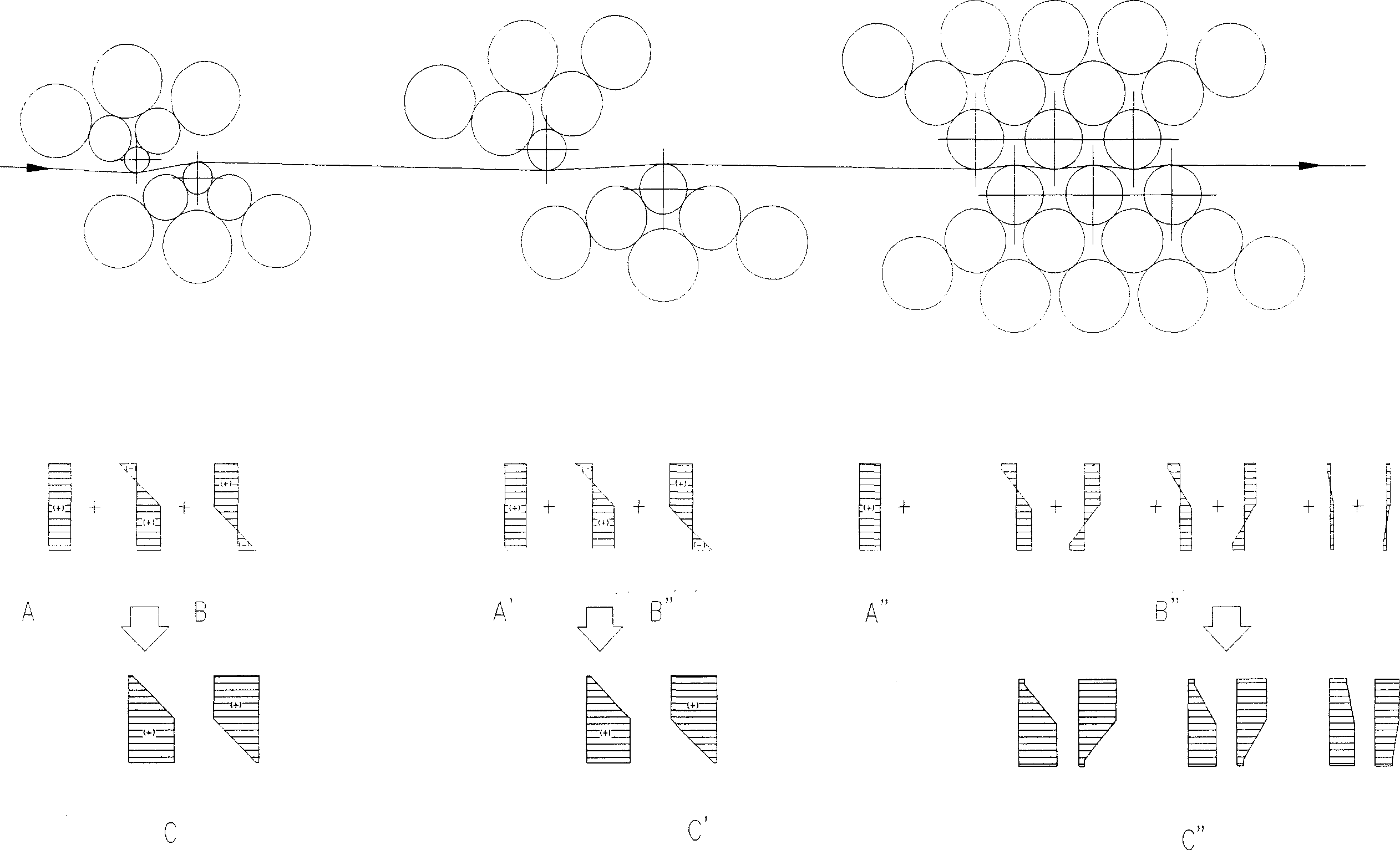

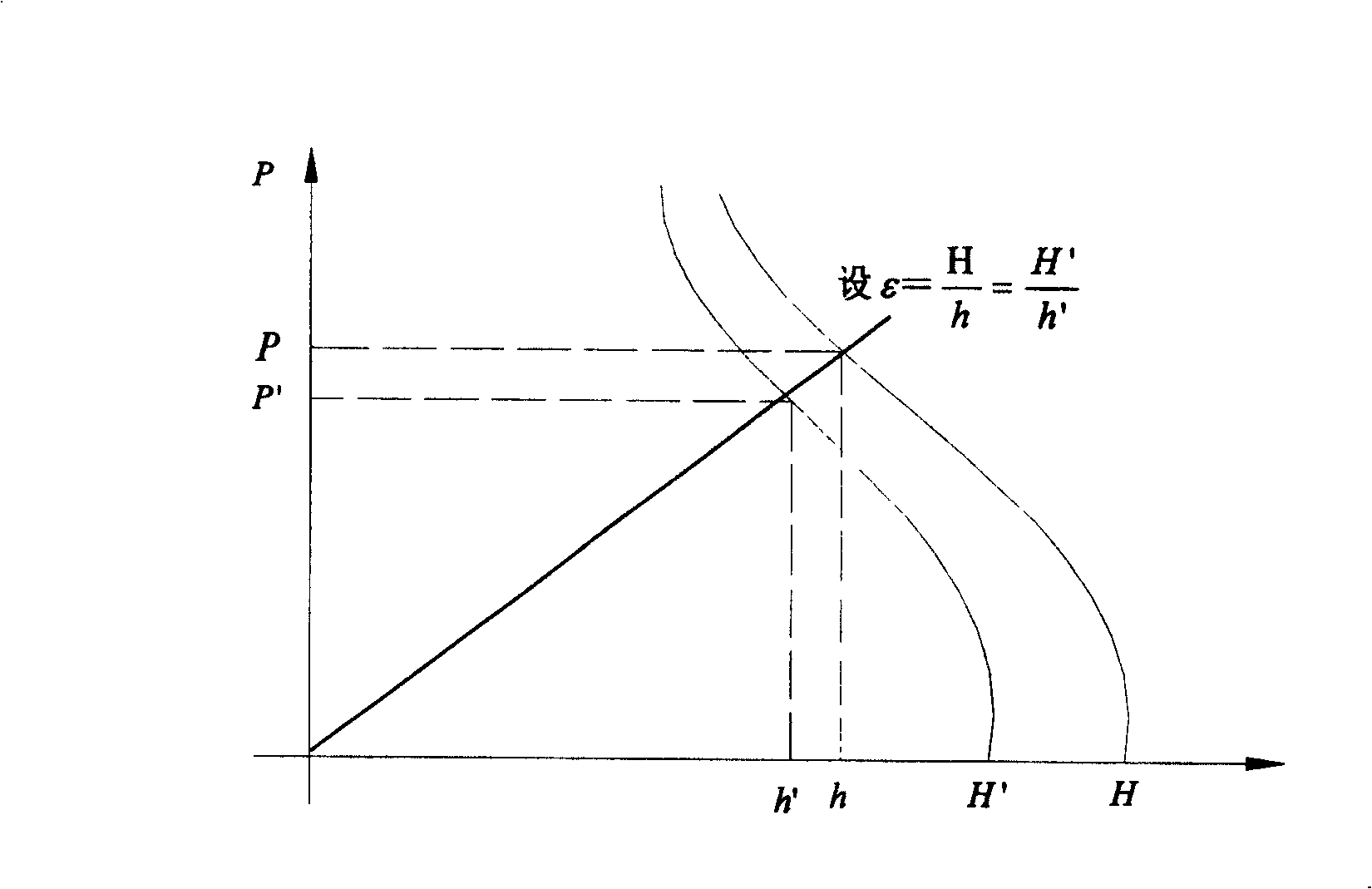

The invention relates to a method for optimizing and controlling the rolling tensioning roller of finisher. Wherein, it is in the extending rate control system; the inner ring of control closed loop is rolling pressure closed loop and tension closed loop; based on the difference of adjustment sequence of tension and rolling pressures, first adjusting tension or first adjusting rolling pressure to control the extending rate, to control extending rate and plate shape; the method that first adjusting tension is that optimizes the tension to control extending rate, when it is over limited range, keeps it constant, and adjusts the rolling force; and the method that first adjusting rolling pressure is that optimizes the rolling pressure to control extending rate, when it is over limited range, keeps it constant and adjusts the tension force. The invention can confirm the accuracy of extending rate and the quality of sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD +1

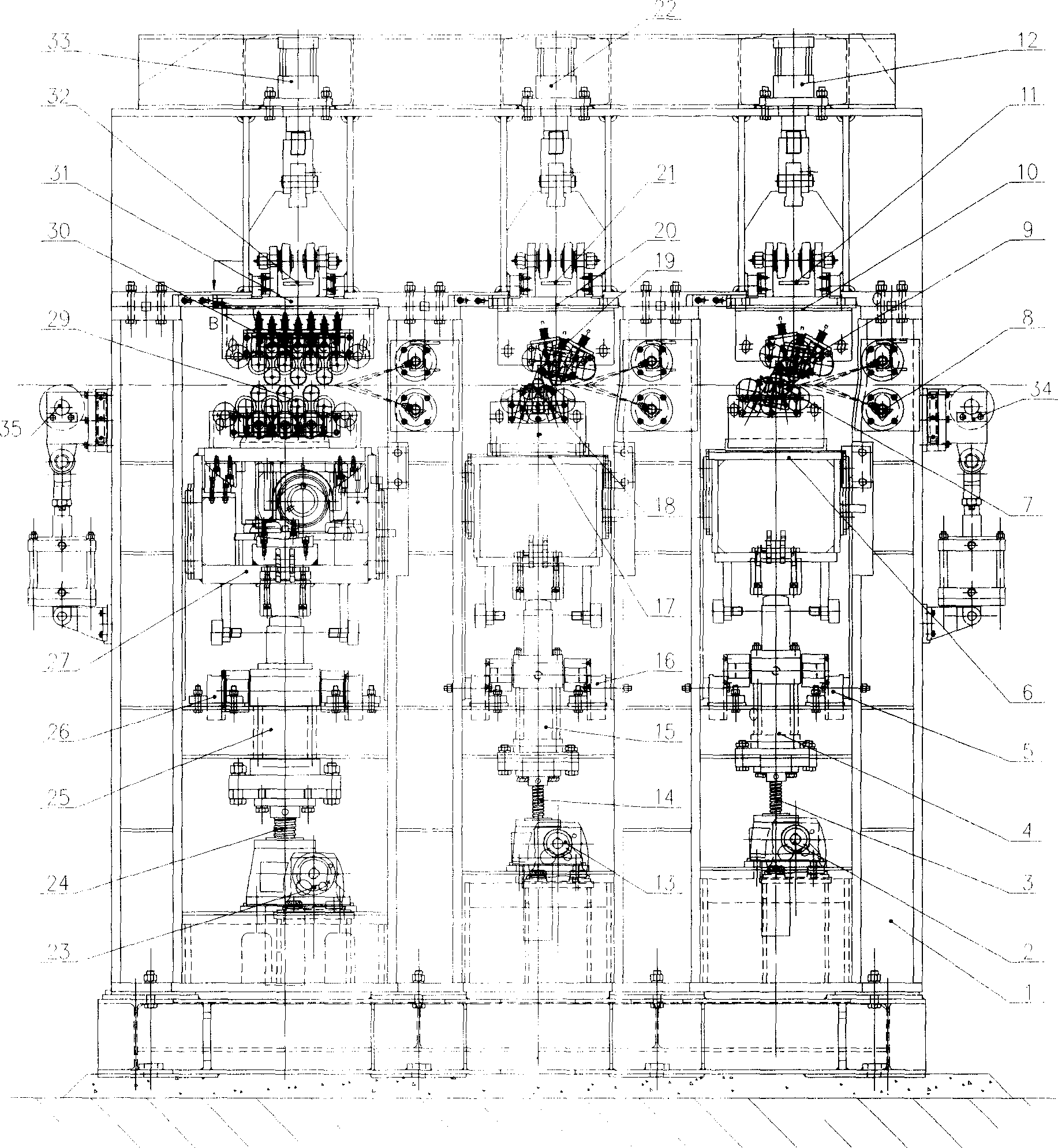

Roller group of bending and straightening machine for band steel and said straightening machine

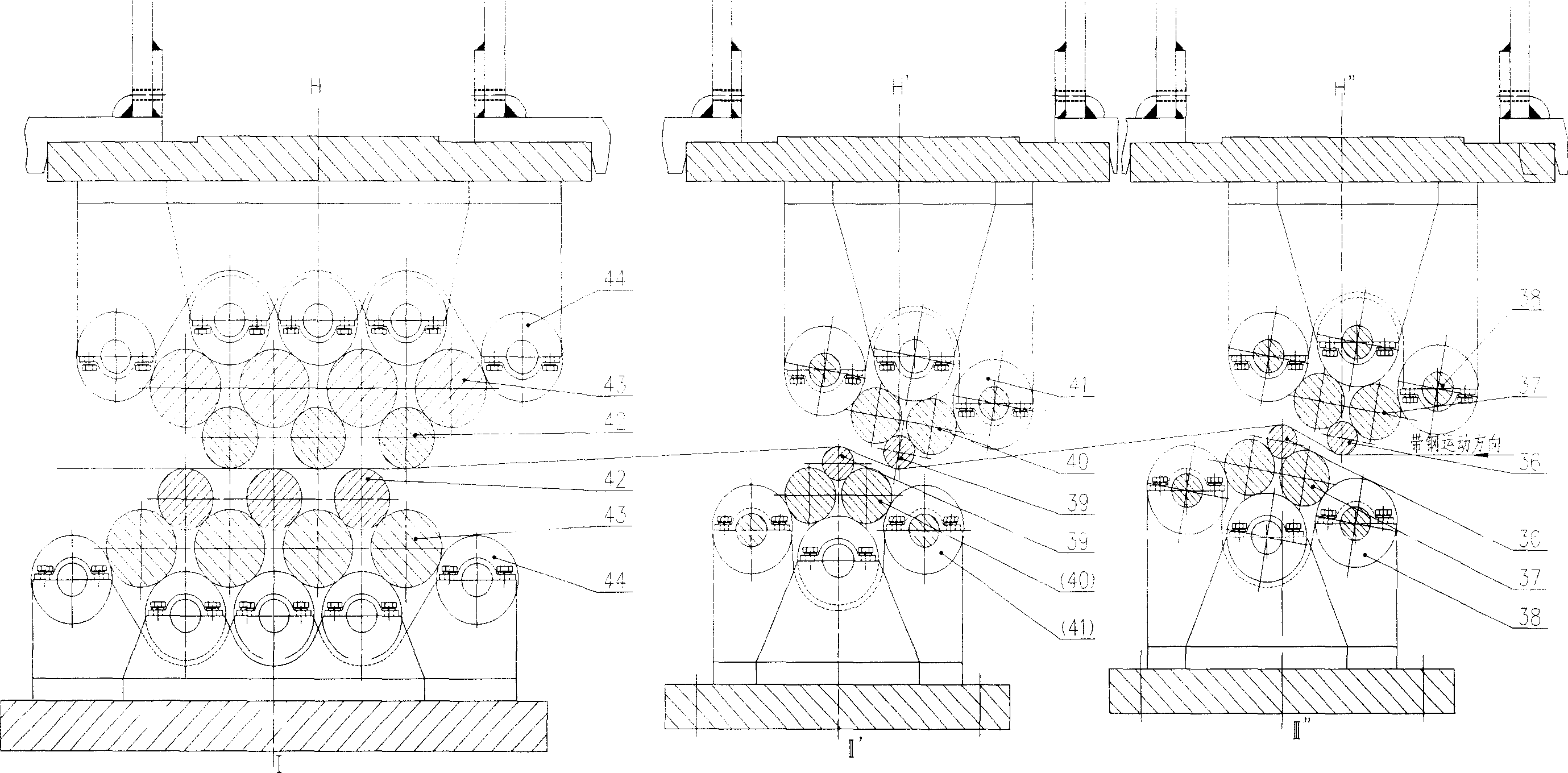

A roller system for the band steel stretching straightener is composed of two groups of bending rollers and a group of straightening rollers. Each group comprises upper and lower roller groups consisting of working roller, intermediate roller and supporting roller. Said straightener features that all the roller groups are installed on its machnie frame and the spray tubes are installed at side of roller groups for wet stretching and wet straightening.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

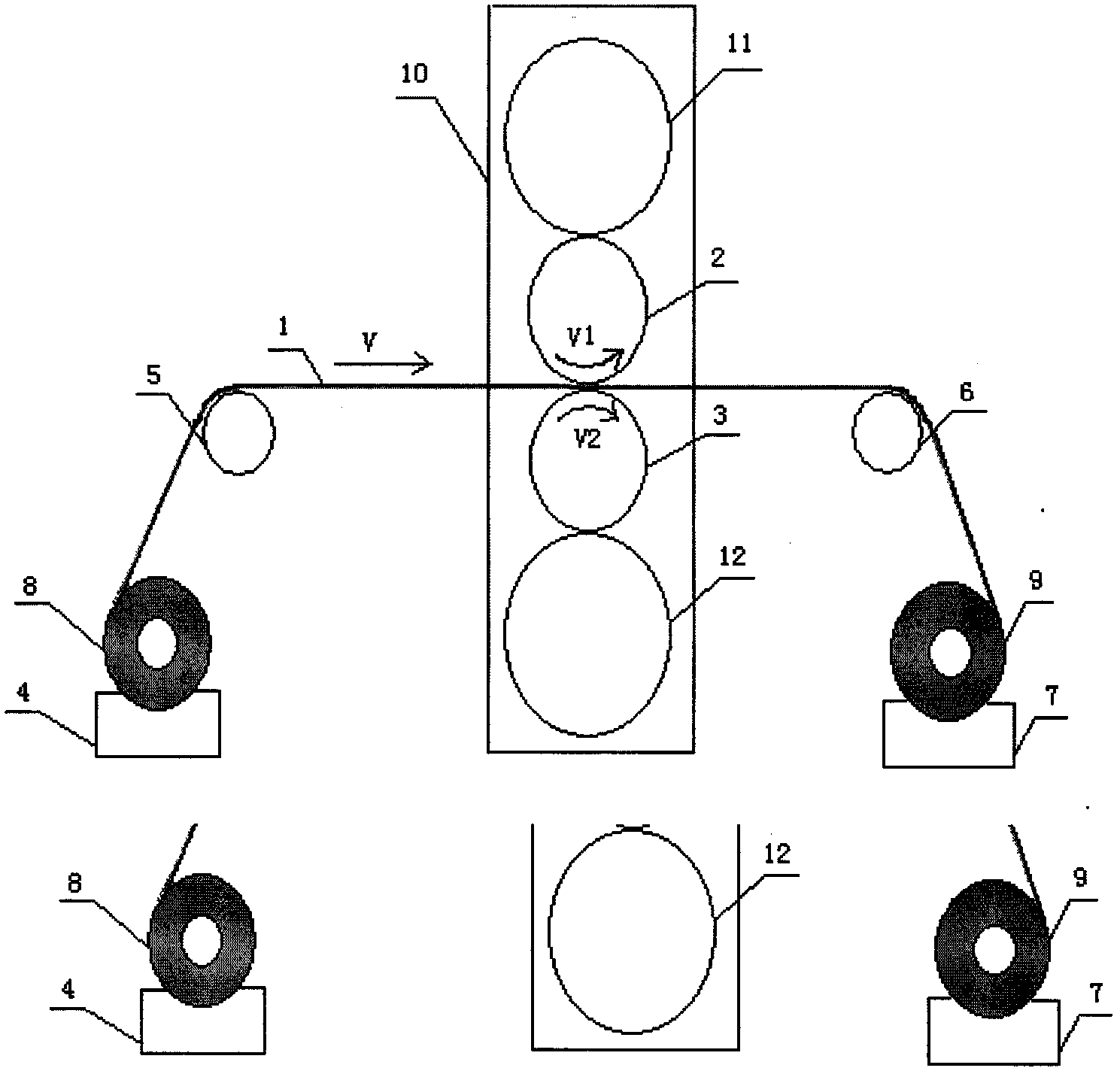

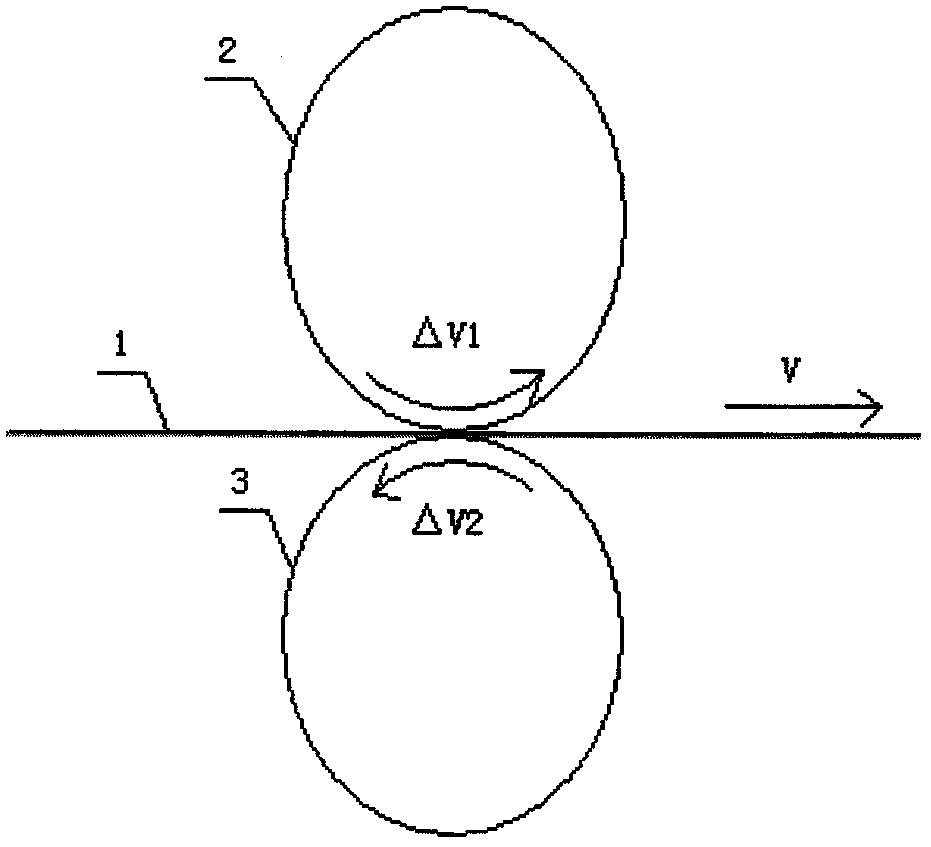

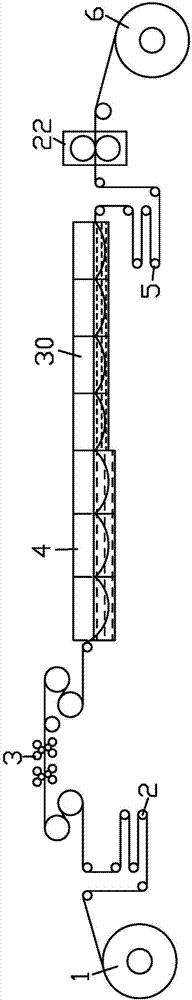

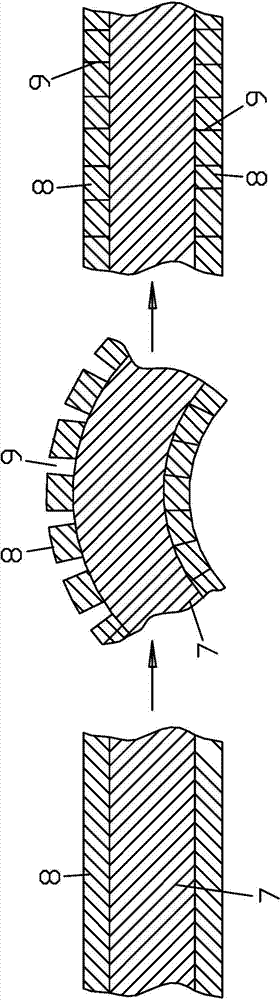

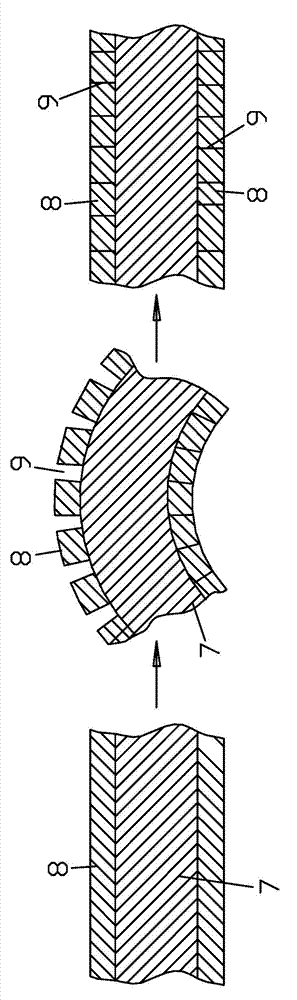

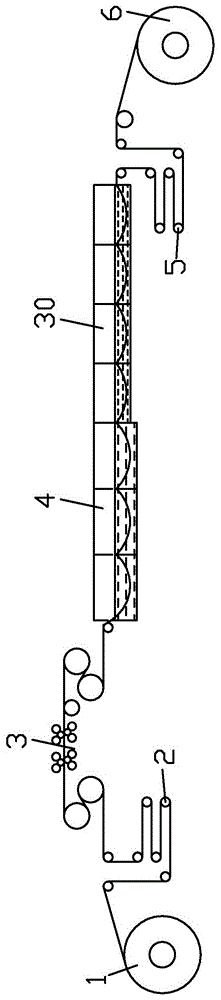

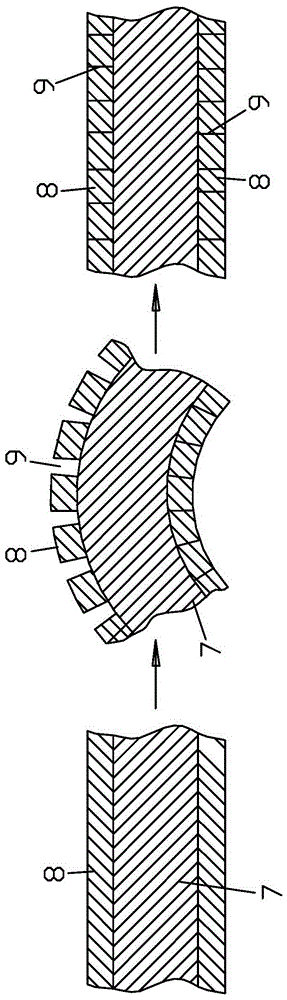

Method and device for differential leveling and rust removing of hot-rolled steel plate

The invention relates to a method and device for differential leveling and rust removing of a hot-rolled steel plate. The device for differential leveling and rust removing of the hot-rolled steel plate comprises a left recoiling machine, a right recoiling machine, a left guide roller, a right guide roller and 1-3 four-roller leveling machines or six-roller leveling machines. The hot-rolled steel plate is level-ground through the leveling machines with upper metal roughened rollers and lower metal roughened rollers, the metal roughened rollers with the uneven surfaces act on the surface of the hot-rolled steel plate under the 60t-1000t pressure and at the differential speed of 5-500 m / minute for differential leveling and rust removing, and oxide scale attached to the surface of the hot-rolled steel plate, surface dirt and various surface defects are destroyed and removed; the speed difference between the upper metal roughened rollers and the hot-rolled steel plate is equal to the speed difference between the lower metal roughened rollers and the hot-rolled steel plate, and the rotating direction of the upper metal roughened rollers and the rotating direction of the lower metal roughened rollers are opposite. According to the device for differential leveling and rust removing of the hot-rolled steel plate, differential leveling of the hot-rolled steel plate is achieved through the meal roughened rollers installed on the leveling machines, the oxide scale on the surface of the hot-rolled steel plate is removed, environment pollution is avoided, the yield platform of the hot-rolled steel plate is eliminated, and the surface quality of the hot-rolled steel plate is improved.

Owner:刘冰利

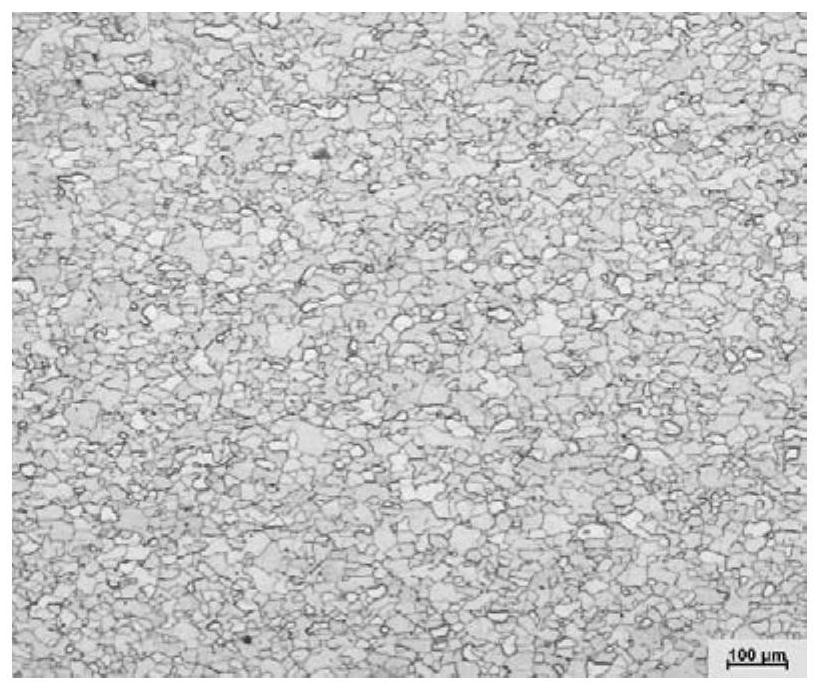

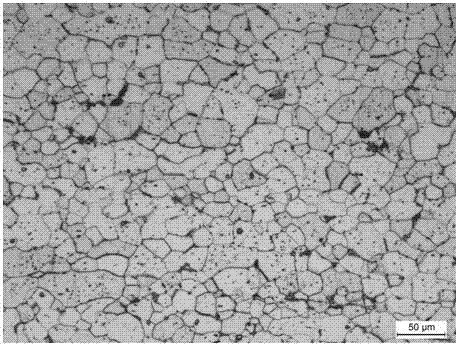

Strip steel production method for improving shape uniformity of steel cup mouth of welded gas cylinder

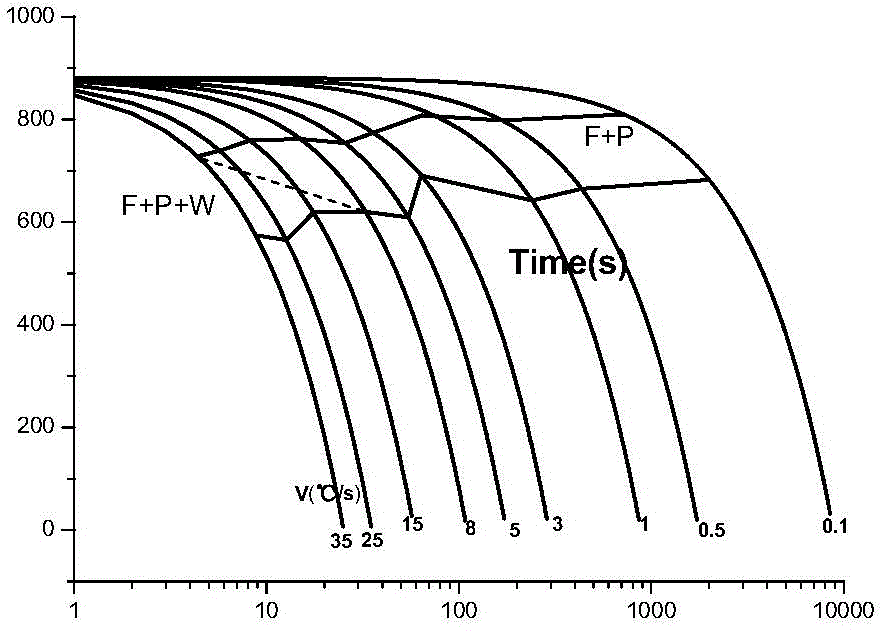

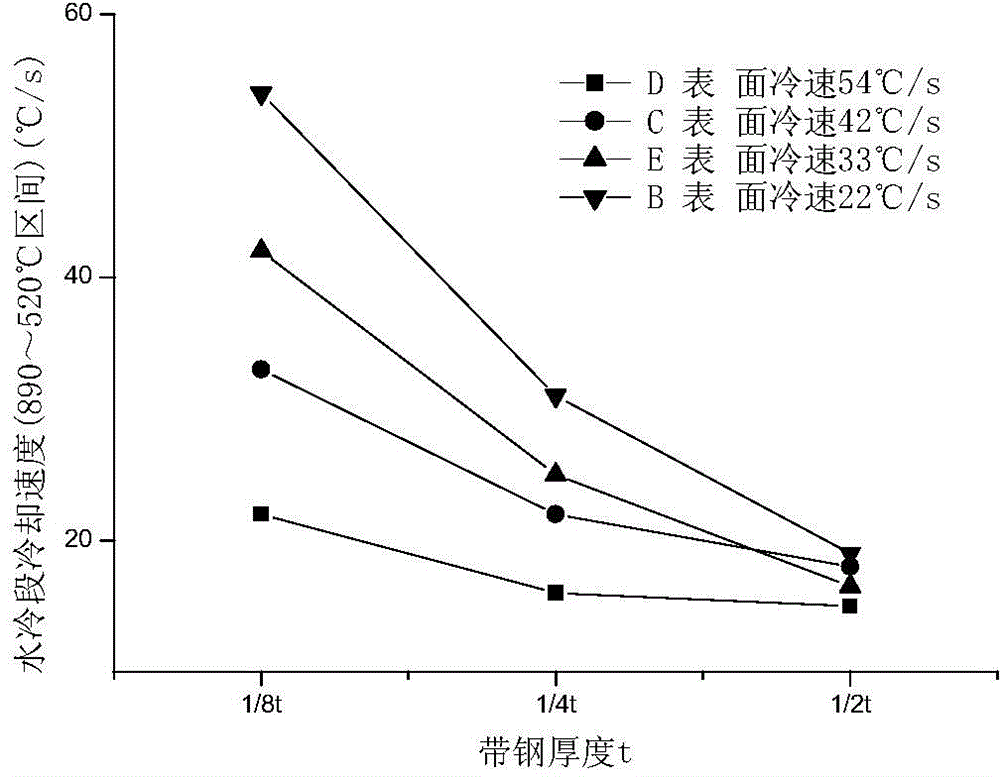

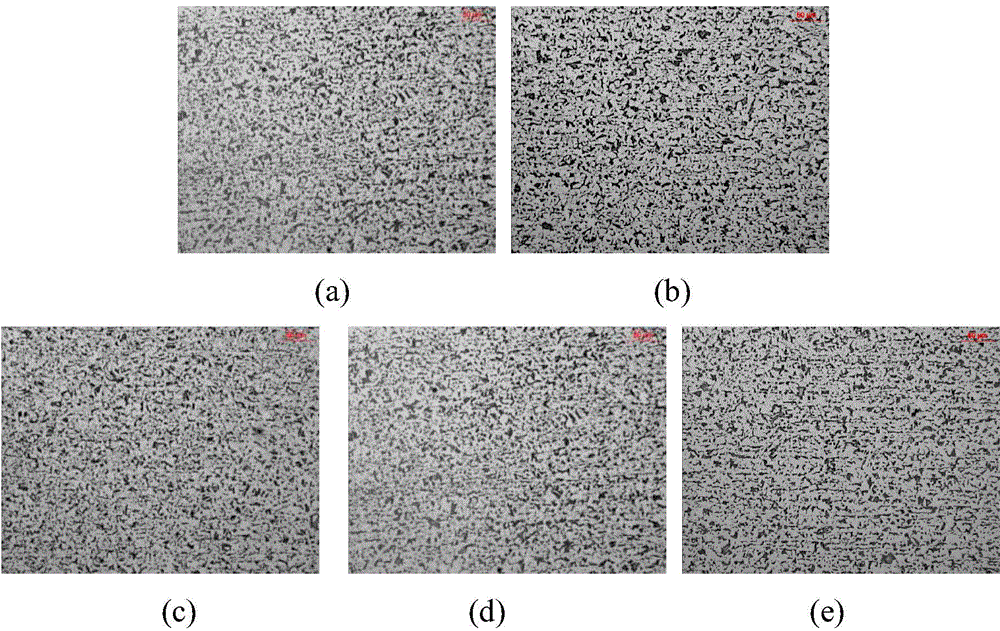

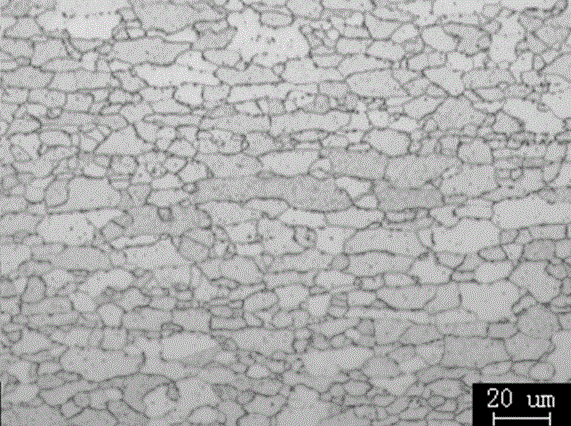

InactiveCN104831166AImprove uniformity of temperature distributionImprove uniformityGas cylinderLaminar cooling

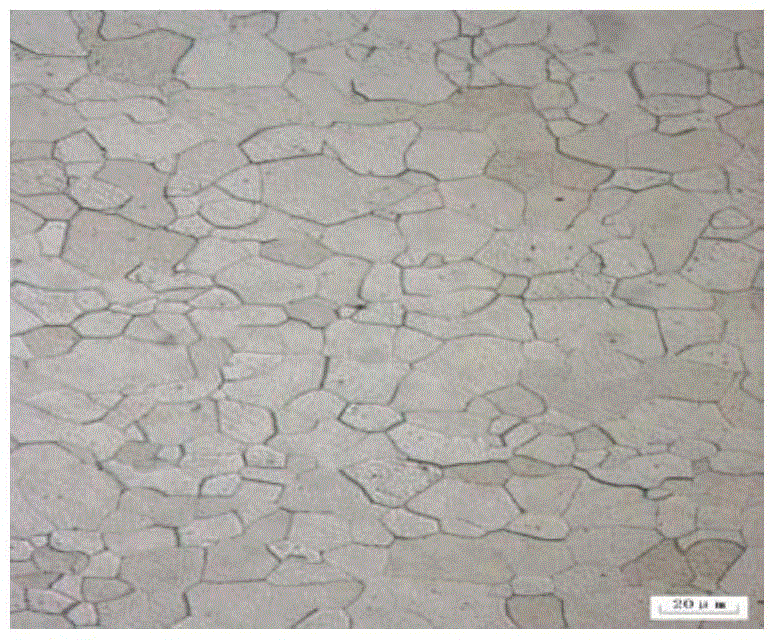

The present invention relates to a strip steel production method for improving the shape uniformity of the steel cup mouth of a welded gas cylinder, which aims to solve the defect of the poor shape of the close-up part of a welded gas cylinder after the steel welding and forming process in the prior art. The heating temperature for the continuous casting blanks of welded gas cylinders is 1160 DEG C to 1240 DEG C. The continuous casting blanks are thermally insulated at the above temperature for 40 minutes to 60 minutes. During the rolling process, the cooling rate for the laminar flow is controlled within 34.1 DEG / S to 92.8 DEG / S. The quantity of the laminar cooling water on the upper surface of the strip steel is 81% to 95% the quantity of the laminar cooling water on the lower surface of the strip steel in weight percentage. The quantity of the 0-120m laminar cooling water at the head part of the strip steel is 70% to 85% the normal quantity of water in weight percentage. The quantity of the 0-120m laminar cooling water at the tail part of the strip steel is 50% to 75% the normal quantity of water in weight percentage. The quantity of the laminar cooling water at the middle part of the strip steel is equal to the normal quantity of water. According to the invention, the entire steel strip coil of a welded gas cylinder is uniform in temperature distribution, larger in crystalline grain and smaller in phase-transformation difference. The uniformity of the mechanical property in every direction and the shape uniformity of the steel cup mouth of the welded gas cylinder after the machining process are improved.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Low carbon cold-rolled steel sheet for LED lead frame and production method thereof

The invention relates to a low carbon cold-rolled steel sheet for a LED lead frame and a production method thereof, and mainly solves the technical problems that the low carbon cold-rolled steel sheet for the LED lead frame in prior art has nonuniform hardness, high surface roughness and bad aging-resistance. The production method comprises the following steps: smelting according to components, molten iron desulphurization, complex top-bottom blowing converter smelting, argon blowing from bottom of a ladle, protective casting with argon blowing in whole course, heating in a slab heating furnace, rough rolling, finish rolling, reeling for obtaining a hot-rolled steel coil, uncoiling, pickling, cold rolling, annealing in a vertical type continuous annealing furnace, flattening, and reeling for obtaining a finished product with a thickness of 0.4-0.5mm; the finishing temperature of the finish rolling is 860-900 DEG C, the reeling temperature of the hot rolling is 620-660 DEG C, the cold rolling reduction is 75-85%, the temperature scope of a soaking zone of the vertical type continuous annealing furnace for a band steel in hard rolled state after cold rolling is 710-730 DEG C, the soaking time for the band steel in the vertical type continuous annealing furnace is 105-120 s, and temper elongation is 1.0-1.4%. The low carbon cold-rolled steel sheet is mainly used for the LED lead frame.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

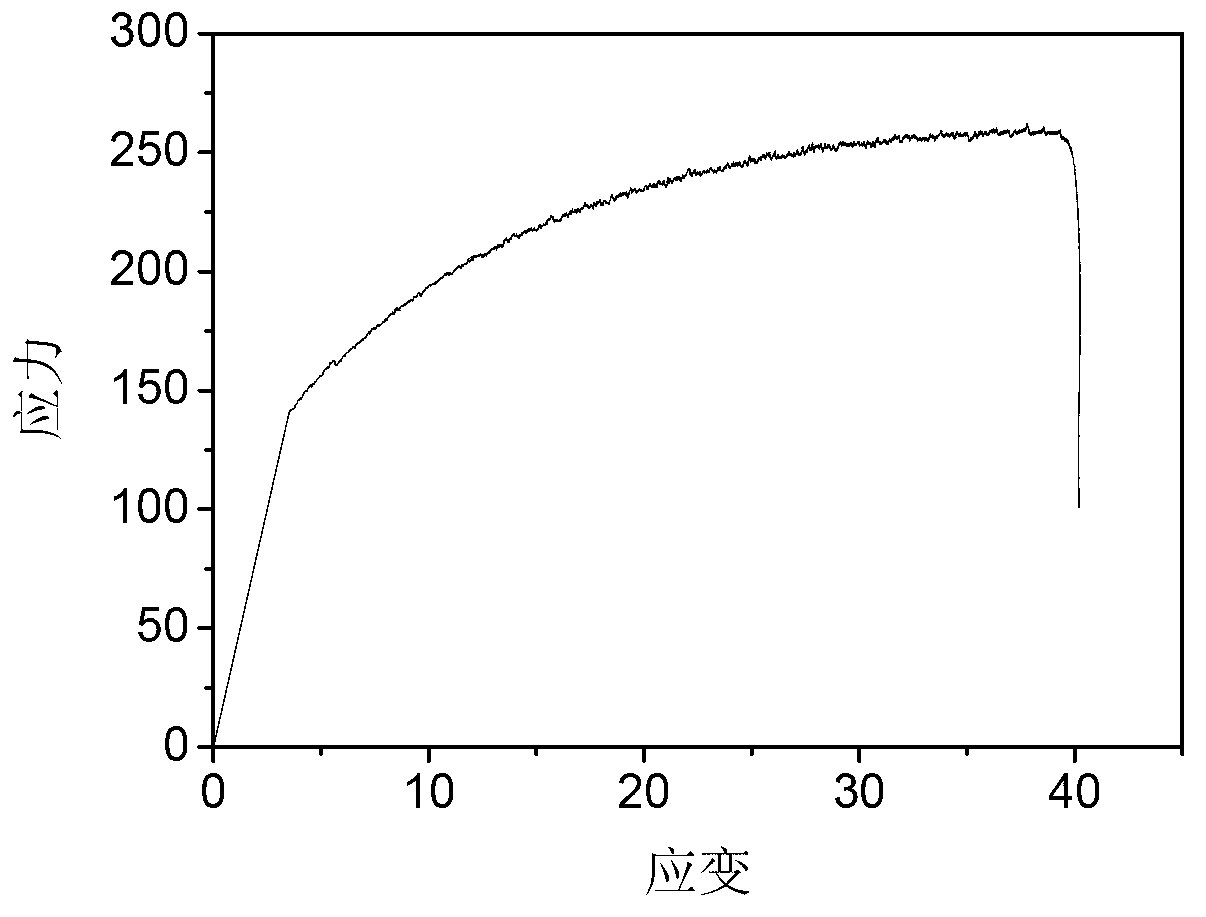

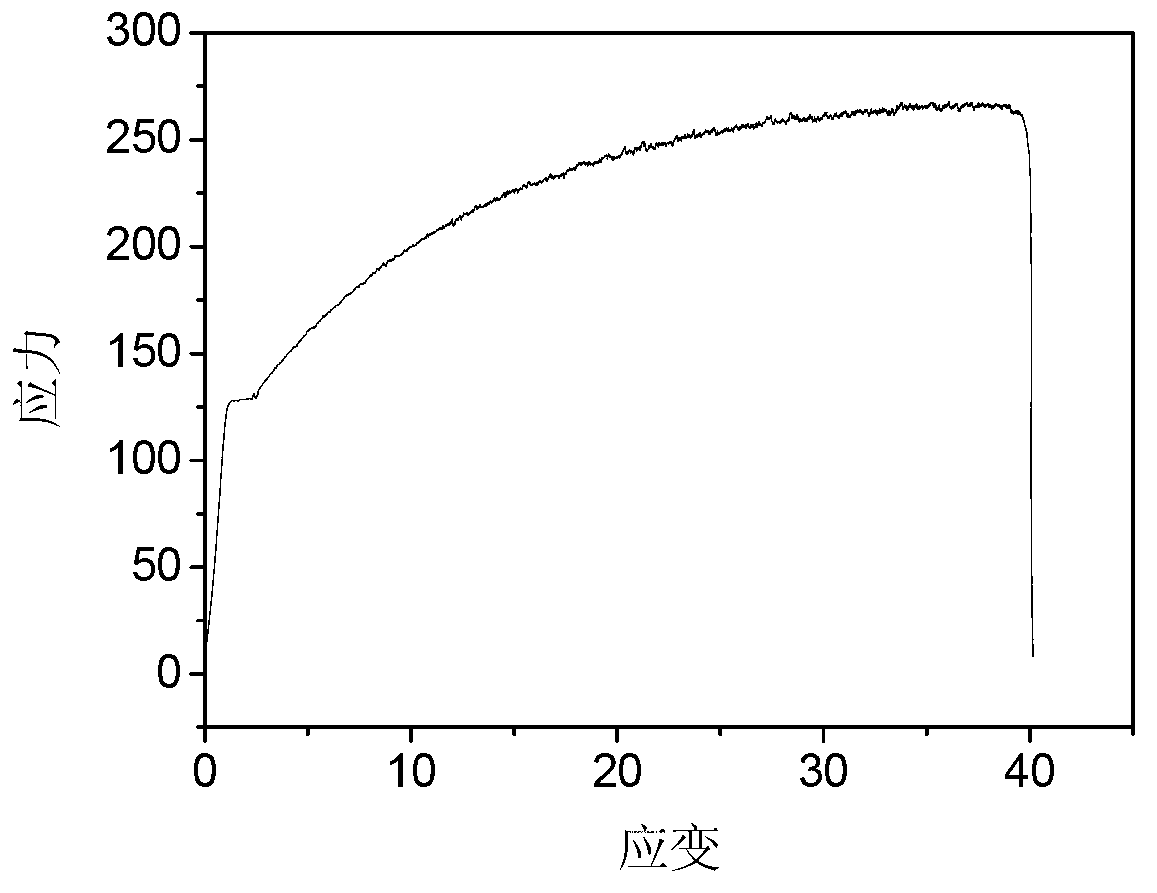

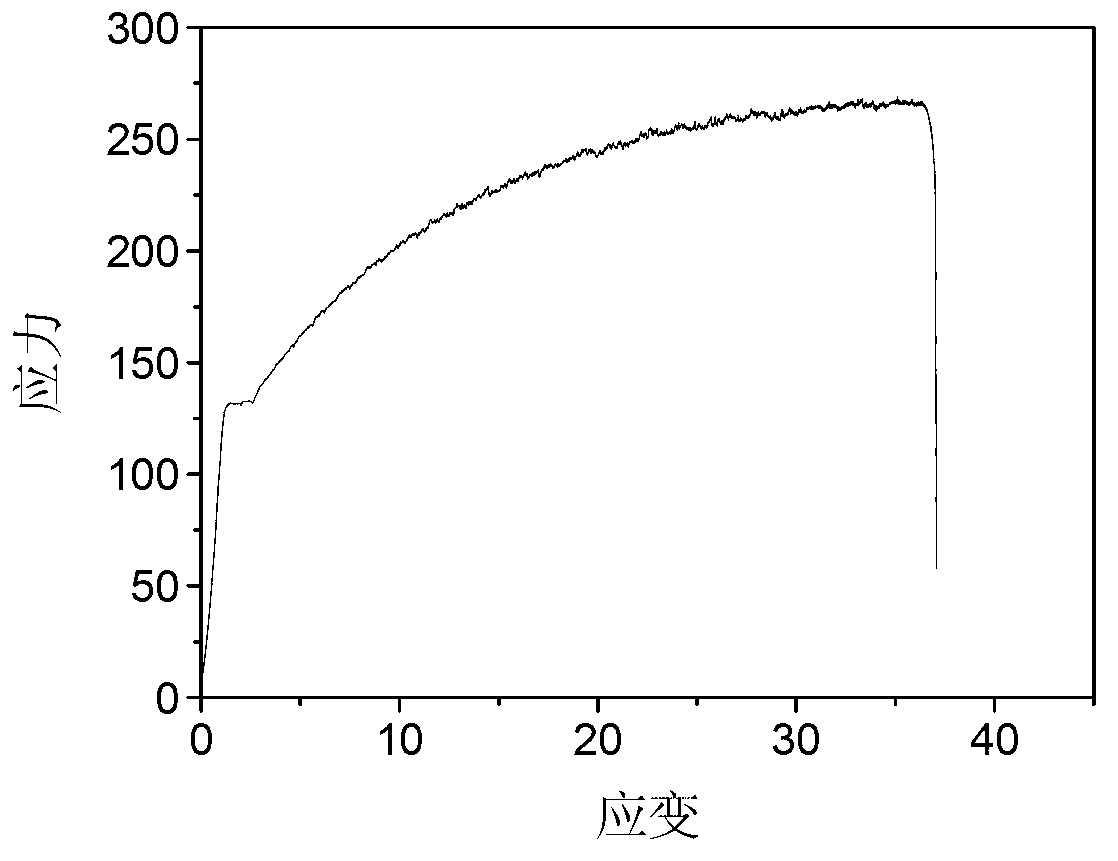

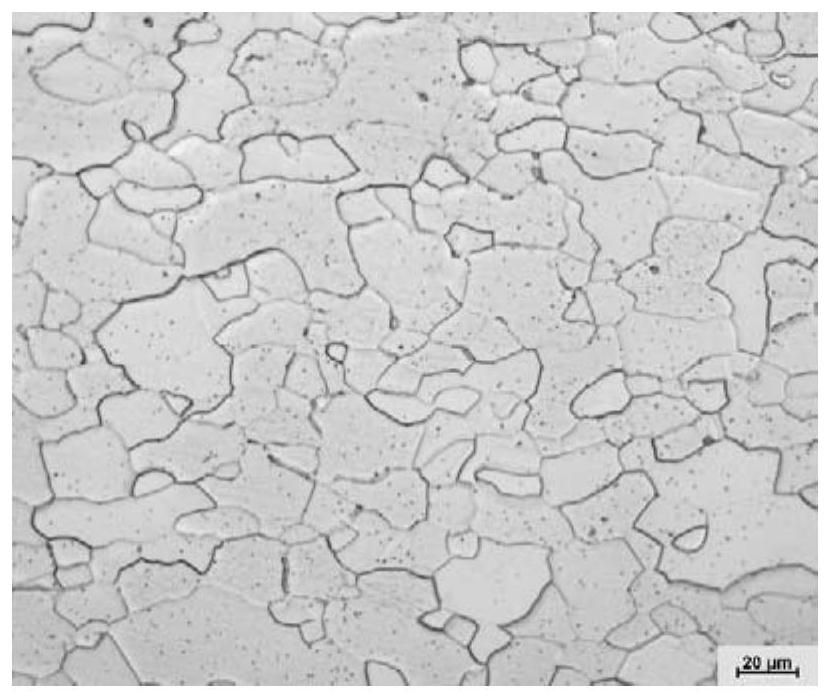

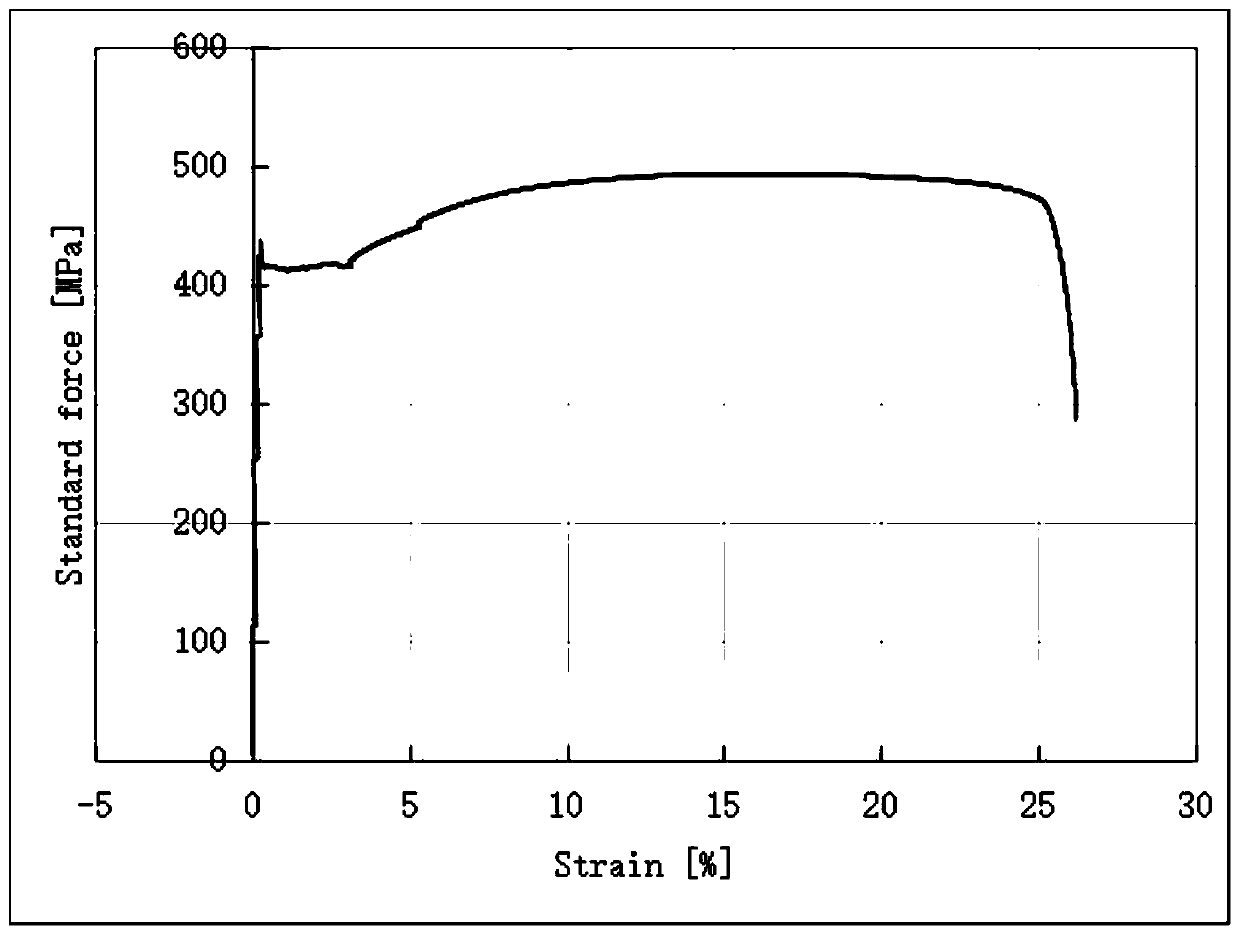

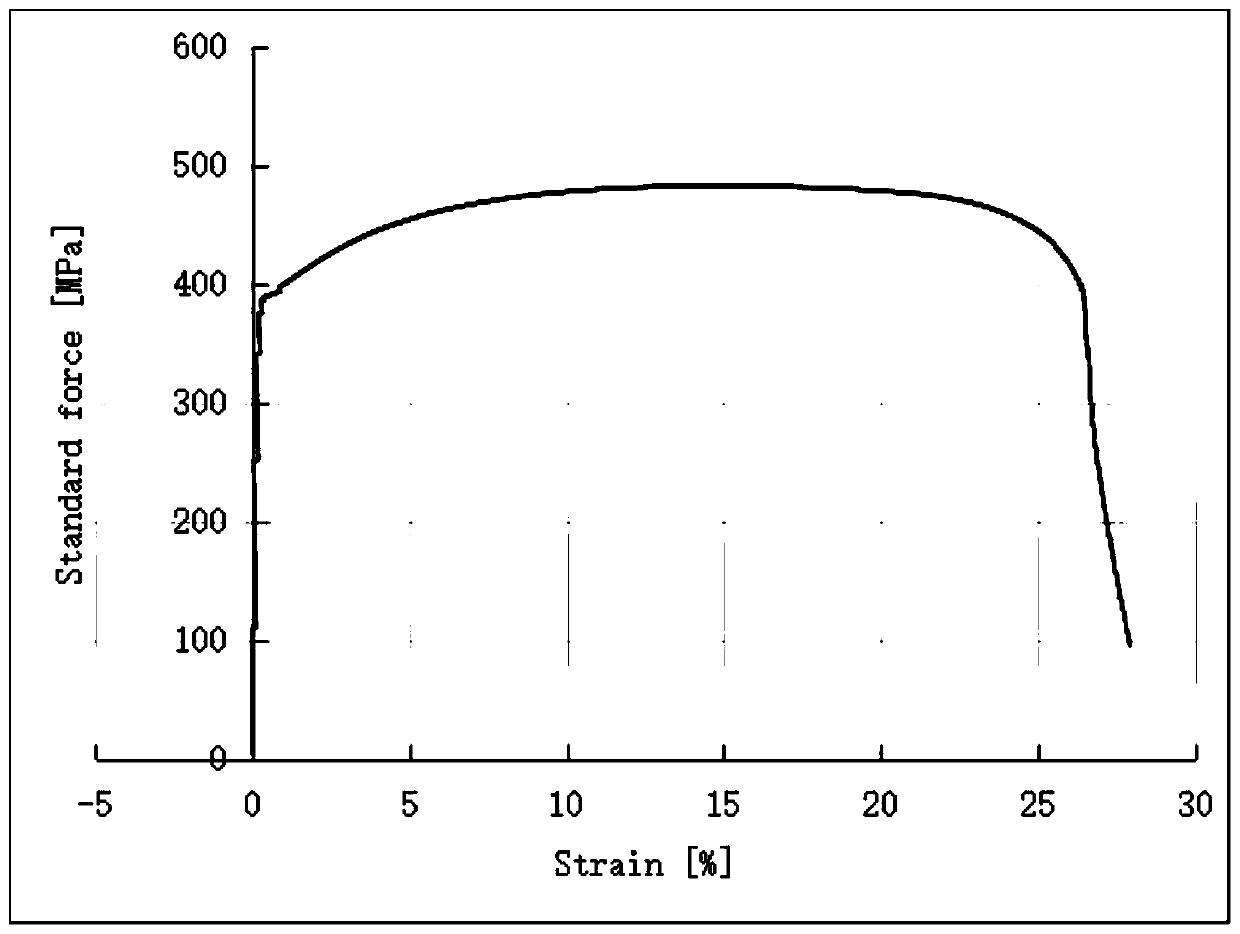

Preparation method of Al-Mg alloy board for autobody

The invention provides a preparation method of an Al-Mg alloy board for an autobody, comprising the following steps: a) providing an Al-Mg alloy board which has undergone cold rolling, wherein cold rolling deformation is less than 70%; b) heating the Al-Mg alloy board which has undergone cold rolling to 480-550 DEG C, carrying out thermal insulation within 5 min, and continuously annealing, wherein the heating speed is not less than 5 DEG C / s; c) cooling the Al-Mg alloy board which has undergone continuous annealing to less than 150 DEG C, wherein the cooling speed is not less than 10 DEG C / s; d) carrying out leveling processing on the cooled Al-Mg alloy board; and e) carrying out heat treatment on the Al-Mg alloy board which has undergone leveling processing. According to the invention, a cold-rolled sheet with the cold rolling deformation being not less than 70% is used as a raw material and undergoes high-temperature short-time annealing, rapid cooling and heat treatment. Thus, forming property of the Al-Mg alloy is raised, and generation of A-type flow lines is avoided during the forming process.

Owner:ZHEJIANG GKO IND CO LTD

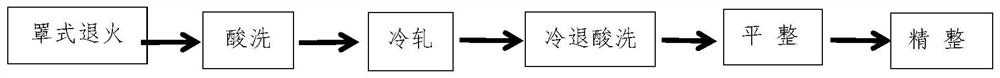

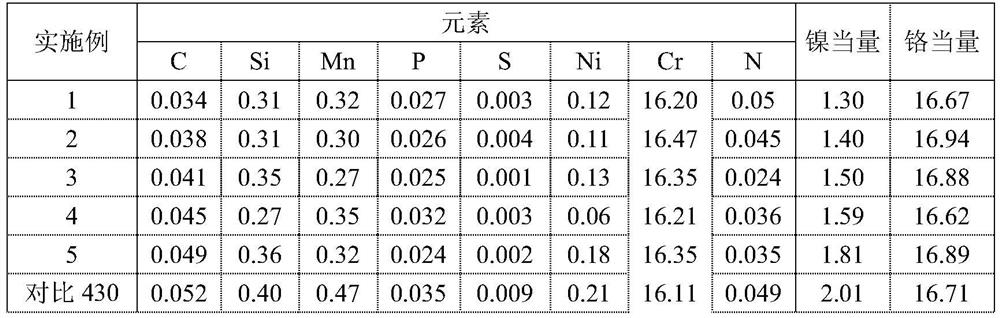

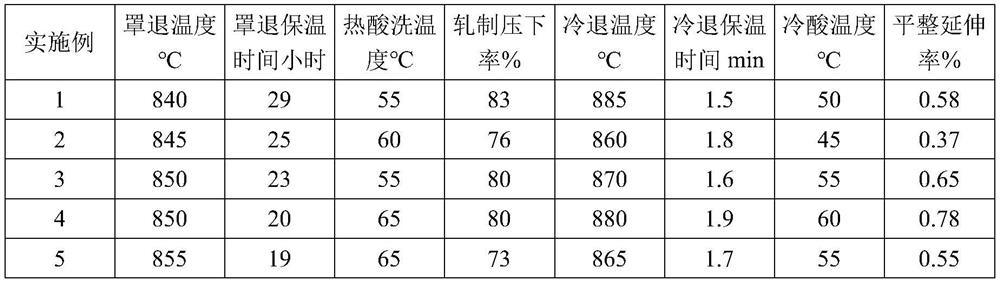

430 ferritic stainless steel for kitchen ware panels and preparation method thereof

InactiveCN113388780AHigh ferrite stabilityReduce work hardeningSS - Stainless steelUltimate tensile strength

The invention discloses 430 ferritic stainless steel for kitchen ware panels and a preparation method thereof. The 430 ferritic stainless steel comprises the following components in percentage by mass: 0.030-0.05% of C, 0.02-0.05% of N, 0.20-0.40% of Si, less than or equal to 0.20% of Ni, less than or equal to 0.35% of Mn, 16.00-16.50% of Cr, less than or equal to 0.035% of P, less than or equal to 0.010% of S, and the balance of Fe and inevitable impurity elements. The equivalent value of nickel is not greater than 2.00, and the equivalent value of chromium is not less than 16.50. During preparation, a hot-rolled black skin roll is subjected to cover annealing, acid pickling, cold rolling, cold annealing and acid pickling, leveling and other procedures to be prepared into a finished product with the required target thickness. The formula and the preparation process of the 430 ferritic stainless steel are scientific and reasonable, and the prepared stainless steel has higher ferritic stability and lower hardness and yield strength, so that the material is more suitable for stamping, can meet the requirement of cost control in the kitchen ware industry, and is suitable for production and processing of high-end kitchen ware.

Owner:NINGBO BAOXIN STAINLESS STEEL

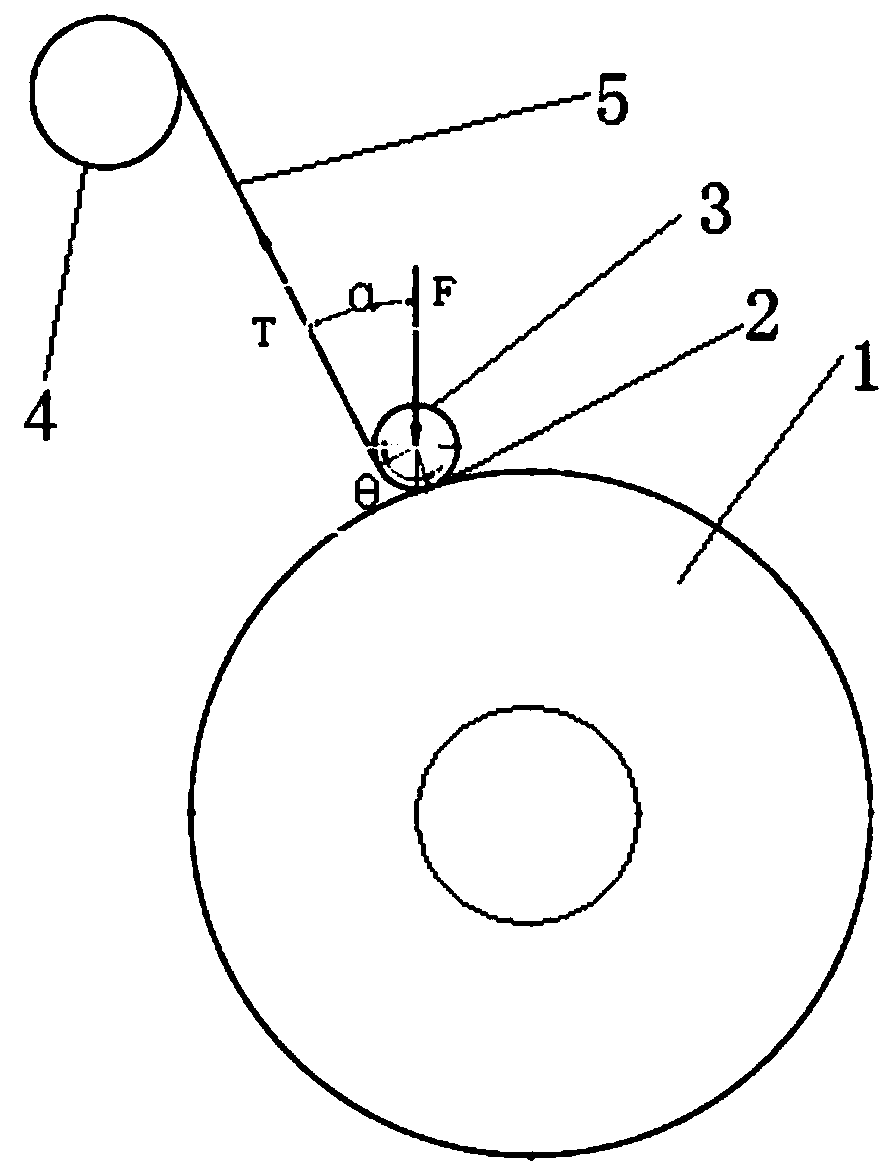

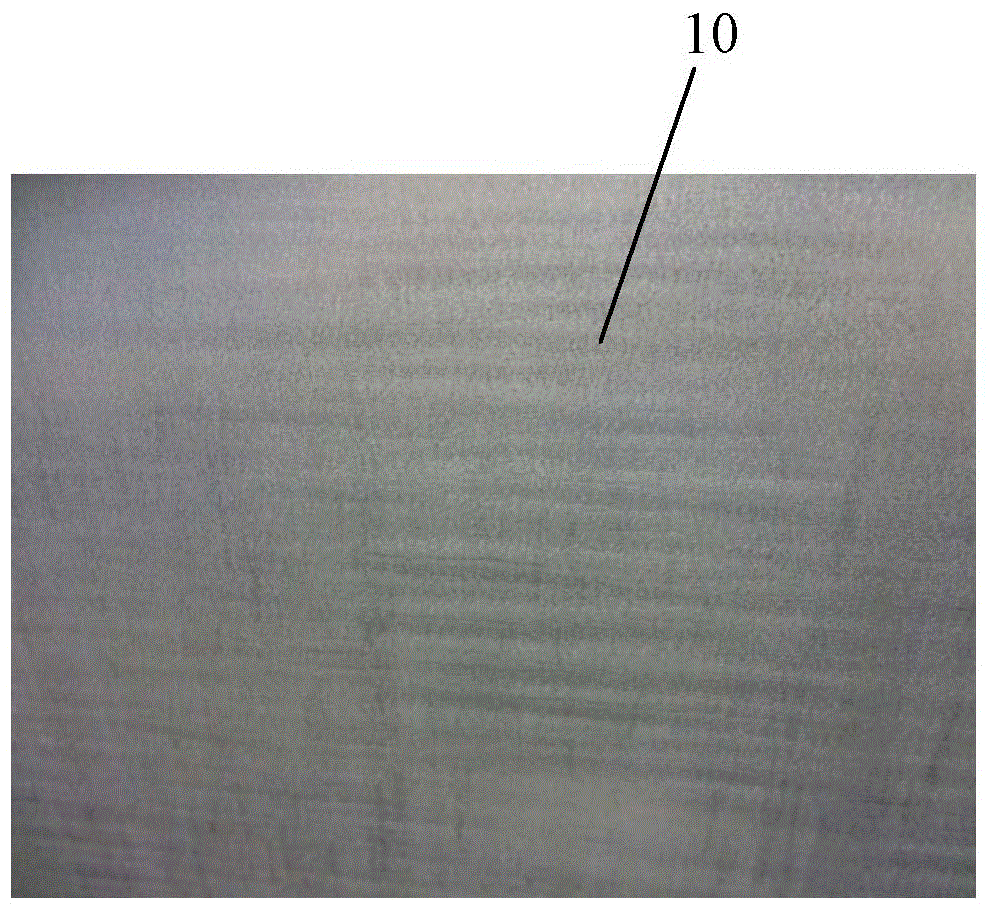

Method and device for improving surface cross wrinkles of cold or hot rolled strip steel

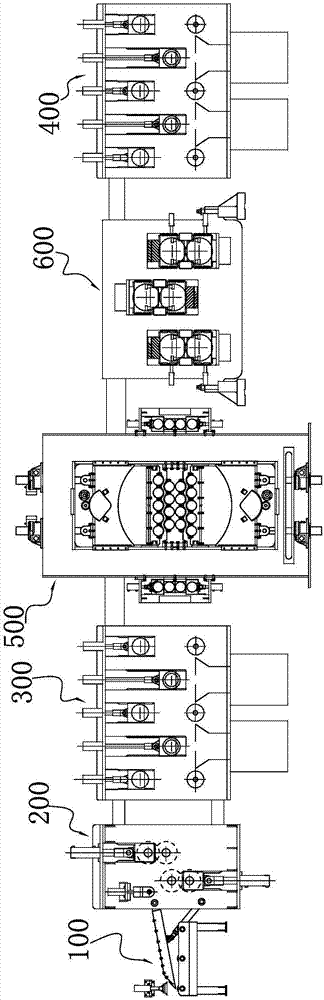

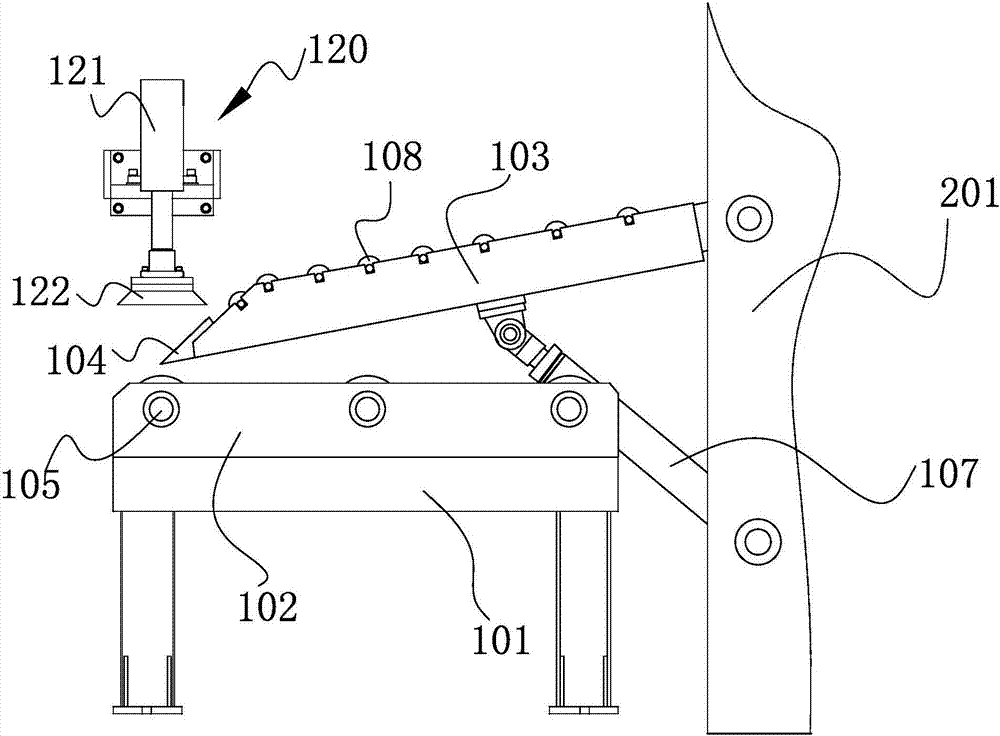

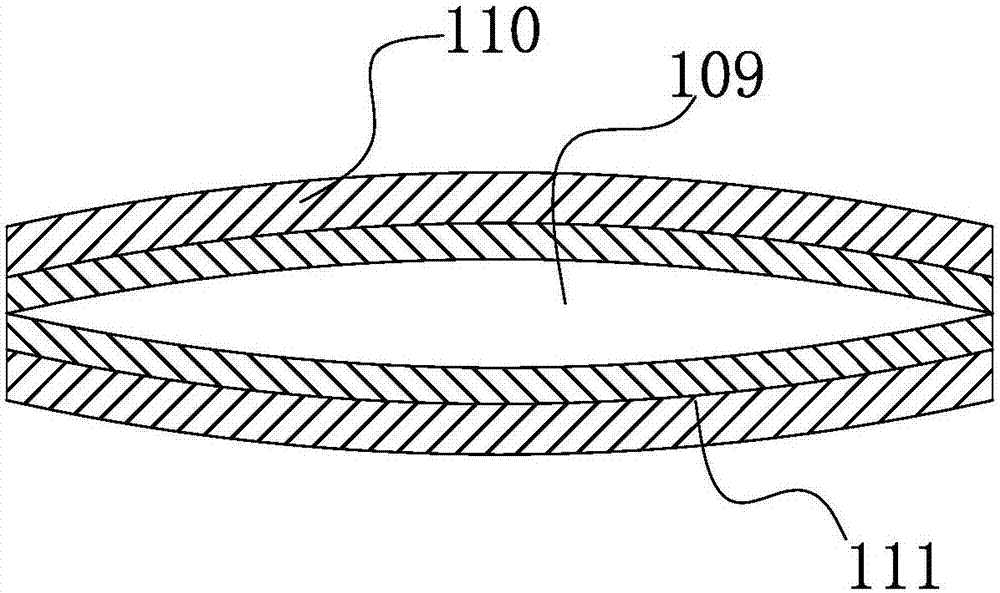

ActiveCN109351805AEliminate Yield PlatformsThere will be no cross-folding defectsMetal rolling arrangementsWrinkle skinStrip steel

The invention relates to a method and device for improving the surface cross wrinkles of cold or hot rolled strip steel. The method comprises the following steps that an anti-cross-wrinkle roller is arranged on a strip steel uncoiling point of an unit uncoiler; and the position of a direction turning roller or the position of the strip steel uncoiling point is adjusted, so that the strip steel isenabled to generate a preset wrap angle on the anti-cross-wrinkle roller; a vertical downward pressure is applied to the anti-cross-wrinkle roller, so that the strip steel is subjected to primary reverse bending before passing through the direction turning roller; and uncoiling production is carried out on cold or hot rolled strip steel coils. According to the method and device, the anti-cross-wrinkle roller is arranged on the unit uncoiler, the anti-cross-wrinkle roller is always pressed on the uncoiling point of the strip steel in the strip steel uncoiling process, under the action of reverse bending force, a stable and uniform plastic deformation area is formed by the strip steel in a wrap angle area of the anti-cross-wrinkle roller, a yield platform of the strip steel can be eliminated, so that obvious cross wrinkle defects will not occur; and the roller diameter of the roller through which the strip steel passes in rear working procedures is larger than the roller diameter of theanti-cross-wrinkle roller, and a new cross wrinkle defect cannot be generated in the subsequent procedures as well.

Owner:WISDRI ENG & RES INC LTD

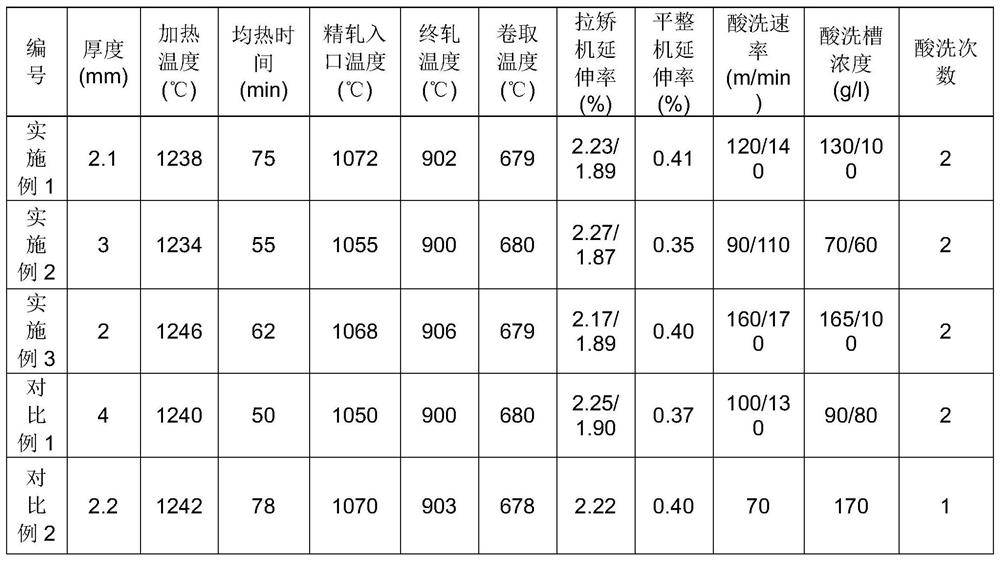

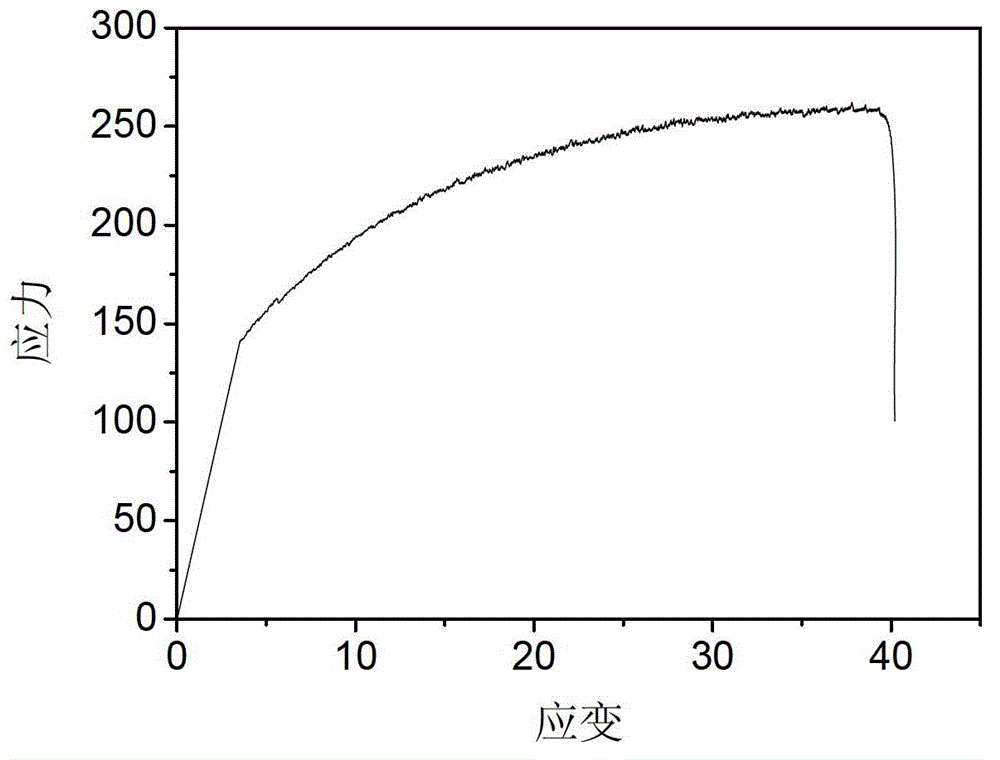

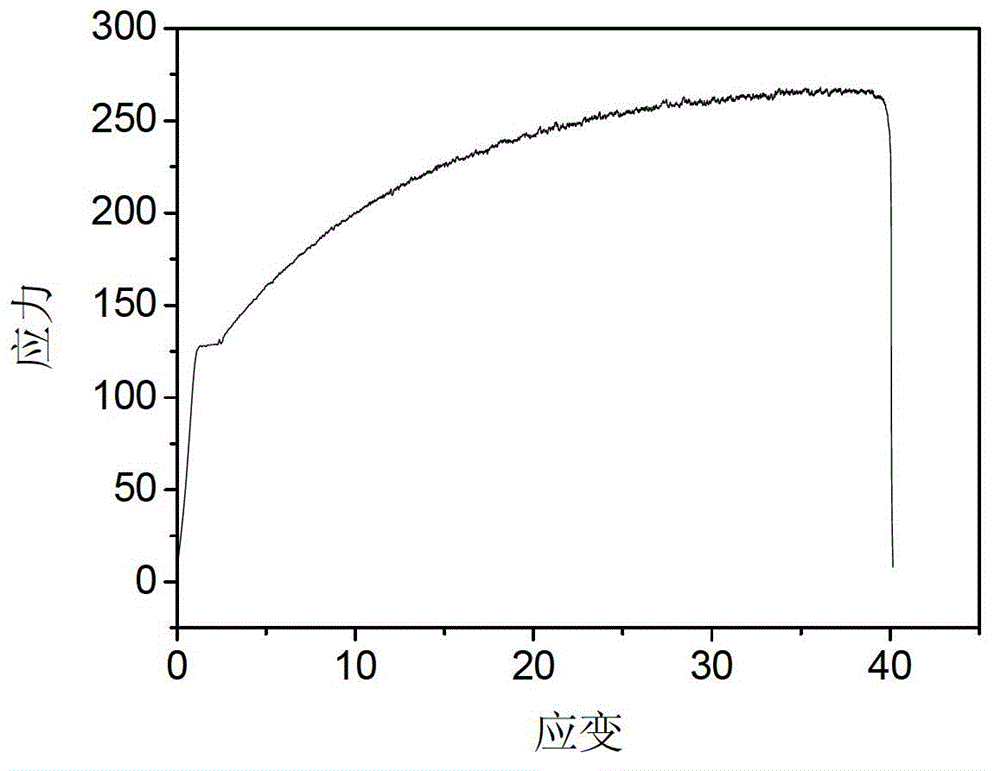

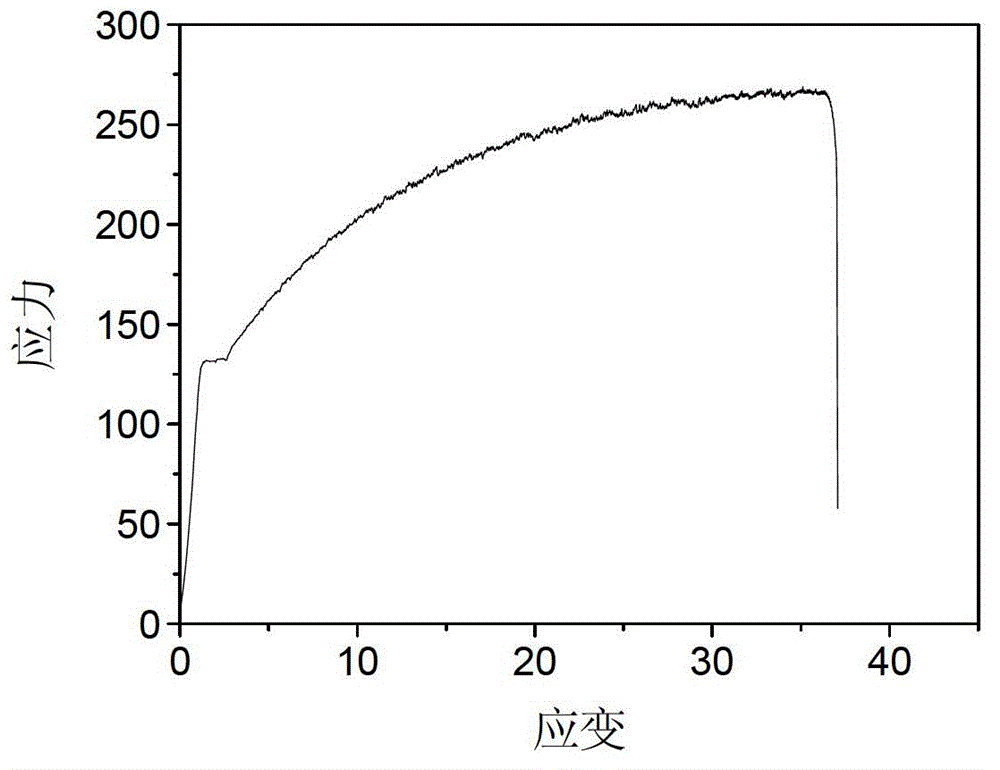

Titanium chromium acid pickling plate and preparing method thereof

The invention belongs to the field of steel smelting, and particularly relates to a titanium chromium acid pickling plate and a preparing method thereof. The titanium chromium acid pickling plate comprises, by weight percentage, 0.01%-0.03% of C, 0.01%-0.03% of Si, 0.14%-0.30% of Mn, 0.012%-0.015% of P, 0.003%-0.005% of S, 0.1%-0.6% of Cr, 0.012%-0.023% of Ti and the balance Fe and unavoidable impurities. The titanium chromium acid pickling plate which is excellent in performance and the production method of the titanium chromium acid pickling plate are provided; the titanium chromium acid pickling plate rolling and cooling processes and the acid pickling tension leveling process are mainly controlled, on one hand, the yield point elongation of the acid pickling plate is effectively eliminated, on the other hand, the original mobile dislocation density is increased, and therefore the defect of cross breaking of the acid pickling plate with lower yield strength is restrained; more importantly, the micro-carbon and chromium titanium alloy technological manner is adopted, and the produced acid pickling plate is lower in yield ratio and high in elongation; and the titanium chromium acid pickling plate and the preparing method have the beneficial effects that the method is simple, the production cost is low, and the molding performance and the welding performance of the product are excellent.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Titanium-containing acid pickling plate and preparation method thereof

ActiveCN105441802AEliminate Yield PlatformsSuppression of cross-fold defectsChemical compositionTitanium

The invention belongs to the field of steel and iron smelting and particularly relates to a titanium-containing acid pickling plate and a preparation method thereof. The titanium-containing acid pickling plate is prepared from, by weight, not larger than 0.05% of C, not larger than 0.05% of Si, not larger than 0.40% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, not larger than 0.03% of Ti and the balance Fe and inevitable impurities. The invention provides the titanium-containing acid pickling plate excellent in performance and the preparation method of the titanium-containing acid pickling plate. Mainly, by controlling the rolling, cooling and acid pickling tension leveling technology of the titanium-containing acid pickling plate, on one hand, an acid pickling plate yield platform is effectively eliminated, on the other hand, original mobile dislocation density is increased, and therefore the cross break defect of the acid pickling plate lower in yield strength is inhibited. The beneficial effects of being simple in method, low in production cost and excellent in product performance and welding performance are achieved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

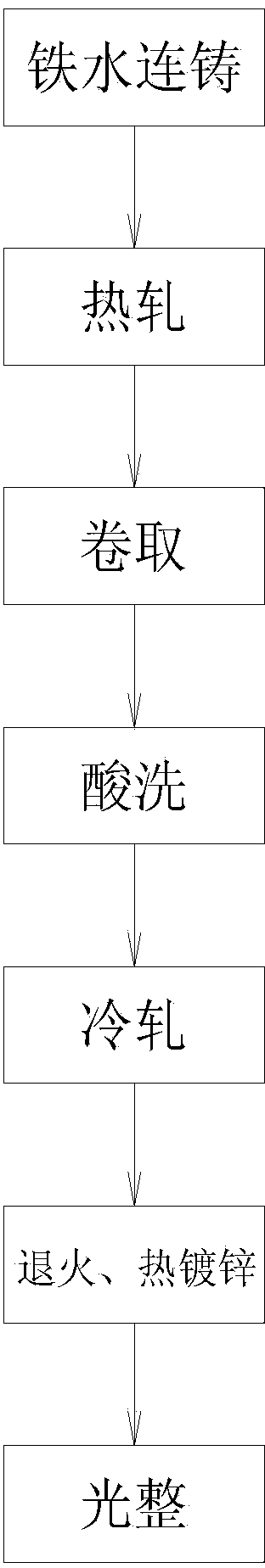

High-yield-ratio hot-galvanized micro-carbo/aluminum killed steel plate and production method thereof

InactiveCN104046890AEffective pinningHigh yield strengthHot-dipping/immersion processesSheet steelContinuous annealing

The invention relates to a high-yield-ratio hot-galvanized micro-carbo / aluminum killed steel plate and a production method thereof. The method comprises the following steps: carrying out desulphurization, bessemerizing, RH vacuum refining and continuous casting on molten iron so as to obtain a continuous casting sheet billet; carrying out hot rolling on the continuous casting sheet billet so as to obtain a hot rolled sheet billet; rolling the hot rolled sheet billet so as to obtain hot-rolled steel coil; carrying out uncoiling and acid pickling on the hot-rolled steel coil; carrying out cold rolling on the hot-rolled steel coil subjected to acid pickling so as to obtain a cold-rolled steel plate; carrying out annealing and hot galvanizing on the cold-rolled steel plate in a continuous annealing furnace; and carrying out finishing processing on the annealed cold-rolled steel plate. The high-yield-ratio hot-galvanized micro-carbo / aluminum killed steel plate produced according to the method has good forming properties and mechanical properties, and can satisfy the requirements of cargo trucks on the stamping formability of steel plates.

Owner:SHOUGANG CORPORATION

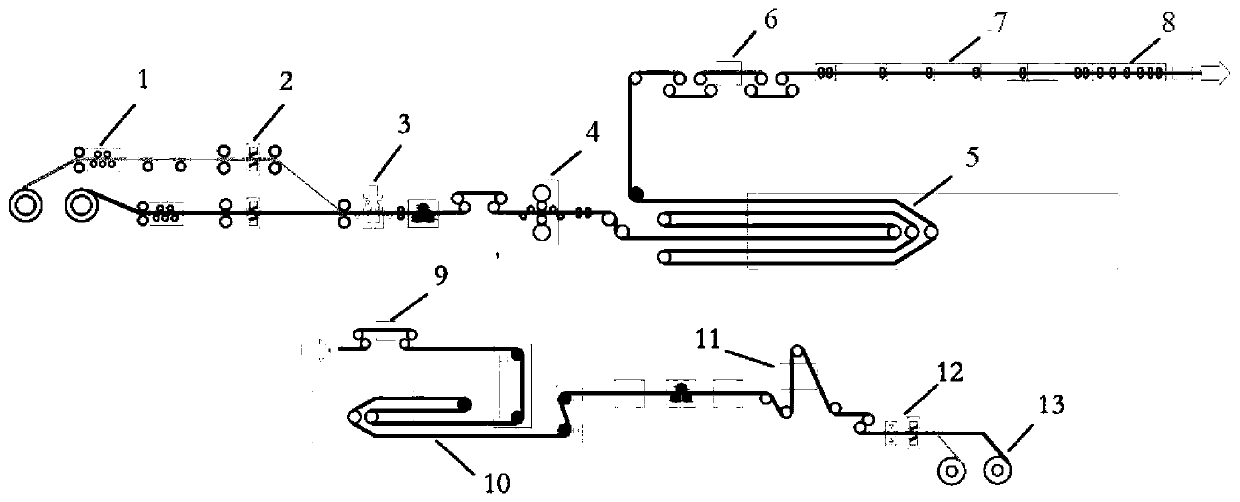

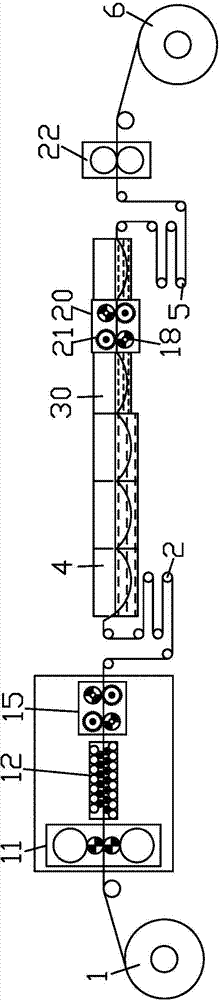

Leveling and acid pickling production line capable of controlling transverse crease defects

PendingCN111590335AReduce cross-fold defectsEliminate Yield PlatformsOther manufacturing equipments/toolsMetal rolling arrangementsManufacturing lineManufacturing engineering

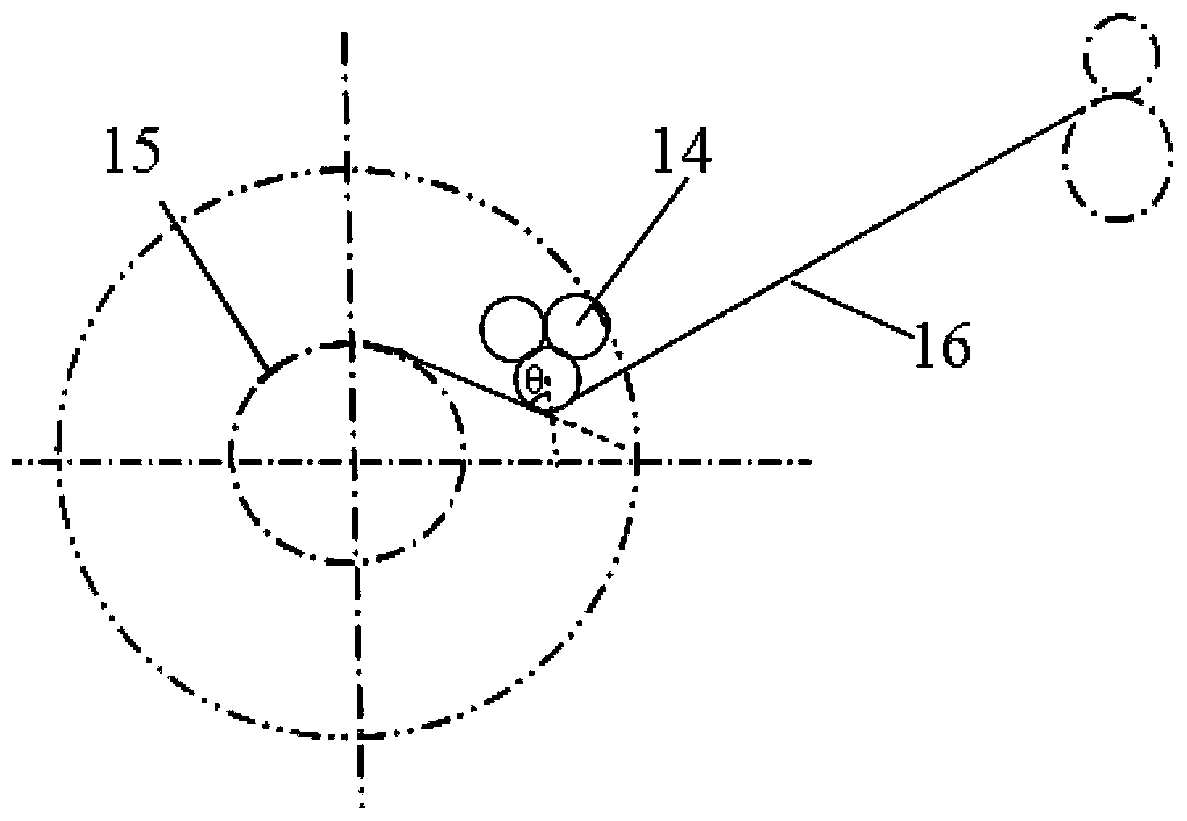

The invention discloses a leveling and acid pickling production line capable of controlling transverse crease defects, and relates to a metallurgical production line. The leveling and acid pickling production line comprises an uncoiling machine, a pair of inlet shears, a welding machine, a leveling machine, an inlet looper, a descaling machine, an acid pickling section, a rinsing section, a withdrawal and straightening machine, an outlet looper, a pair of outlet shears and a coiling machine which are connected in sequence; and reverse bending rollers are arranged at the back of the uncoiling machine and arranged on the upper rear part of an uncoiling machine drum, and the wrap angle theta of the reverse bending rollers is 35-55 degrees. Compared with the prior art, the leveling and acid pickling production line can reduce the production cost and improve the production efficiency.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

CQ-grade hot-dip galvanization steel strip for anti-theft door plate and production process thereof

The invention relates to deep-drawing steel plates and production processes thereof and in particular relates to a low-yield strength high-ductility CQ-grade hot-dip galvanization steel strip for an anti-theft door plate and a production process of the steel strip. The steel strip comprises the following chemical components in percentage by mass: 0.030-0.060 percent of C, less than or equal to 0.03 percent of Si, 0.15-0.25 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.020-0.055 percent of Als and the balance of iron and inevitable impurities. According to the optimized composition design, the process parameters of hot rolling, cold rolling and hot galvanizing procedures are adjusted and optimized, the yield strength of the product is reduced, and the product ductility is improved. According to inspection, the yield strength of the product disclosed by the invention is 230-260MPa, the elongation is 35-38 percent, and the maximum stamping depth is 20mm.

Owner:TANGSHAN GUOFENG IRON & STEEL

Enameled steel plate and production method thereof

The invention discloses an enameled steel plate. The enameled steel plate comprises components including, by weight percent, smaller than or equal to 0.05 of C, smaller than or equal to 0.03 of Si, smaller than or equal to 0.40 of Mn, smaller than or equal to 0.020 of P, smaller than or equal to 0.015 of S, and larger than or equal to 0.020 of Alt. The invention further discloses a production method of the enameled steel plate. According to the enameled steel plate and the production method thereof, by optimizing and controlling the component content and the parameter of the rolling technology, the production cost of the obtained enameled steel plate is low, and no precious metal element needs to be added. The defects in the quality aspects such as swelling upheaval, cold crackle, fish scale crackle, scale crackle, pitted bubbles and holes do not exist, the market prospect is wide, and the requirement of social development is met beneficially. The production method of the enameled steel plate is suitable for industrialized production, and the preparation method is simple.

Owner:BAOTOU IRON & STEEL GRP

Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

ActiveCN100421825CGuaranteed accuracyGuarantee the shape qualityElongation control deviceControl systemClosed loop

The invention relates to a method for optimizing and controlling the rolling tensioning roller of finisher. Wherein, it is in the extending rate control system; the inner ring of control closed loop is rolling pressure closed loop and tension closed loop; based on the difference of adjustment sequence of tension and rolling pressures, first adjusting tension or first adjusting rolling pressure to control the extending rate, to control extending rate and plate shape; the method that first adjusting tension is that optimizes the tension to control extending rate, when it is over limited range, keeps it constant, and adjusts the rolling force; and the method that first adjusting rolling pressure is that optimizes the rolling pressure to control extending rate, when it is over limited range, keeps it constant and adjusts the tension force. The invention can confirm the accuracy of extending rate and the quality of sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Hot-dip galvanized low-alloy high-strength steel with yield strength of 700Mpa and preparation method thereof

ActiveCN114525452AGuaranteed Yield StrengthGuaranteed tensile strengthHot-dipping/immersion processesProcess efficiency improvementAlloyContinuous annealing

The invention discloses hot-dip galvanized low-alloy high-strength steel with yield strength of 700Mpa and a preparation method of the hot-dip galvanized low-alloy high-strength steel. The hot-dip galvanized low-alloy high-strength steel comprises the following chemical components in percentage by weight: 0.07-0.12% of C; 0.2 to 0.5 percent of Si; mn: 1.1 to 1.5%; 0.02% to 0.06% of Nb; 0.06% to 0.12% of Ti; less than or equal to 0.020% of P; s is less than or equal to 0.012%; the content of Als is 0.02 to 0.06 percent; n is less than or equal to 0.006%, and the balance is Fe and inevitable impurities. The preparation method comprises the procedures of smelting, hot rolling, cold rolling and hot galvanizing. Through reasonable design of low-carbon, Nb and Ti microalloying components, hot rolling, cold rolling reduction rate and a hot dipping continuous annealing process are matched, a certain amount of temper mill extension is used, the precipitation strengthening effect of a steel plate is strengthened, and the hot-dip galvanized low-alloy high-strength steel which is uniform in structure, stable in mechanical performance, good in cold bending performance and high in corrosion resistance is obtained.

Owner:HANDAN IRON & STEEL GROUP +1

Low acid consumption anti-corrosion hot-replacing-cold product production method

ActiveCN103924254AResidue reductionHigh mechanical phosphorus removal efficiencyWork treatment devicesMetal rolling arrangementsSurface roughnessBrush device

The invention relates to a low acid consumption anti-corrosion hot-replacing-cold product production method. The low acid consumption anti-corrosion hot-replacing-cold product production method comprises the following steps: uncoiling by adopting an uncoiler; breaking and stripping oxide on the surface of strip steel by adopting a temper mill; further breaking and stripping the oxide on the surface of the strip steel by adopting a multi-roll straighter; eliminating the oxide which falls off and is loose on the surface of the strip steel by adopting a brushing device; carrying out acid pickling and rinsing on the treated strip steel; then eliminating residue on the surface of the strip steel by adopting a mechanical way; carrying out surface roughness homogenization finishing on the strip steel; recoiling by adopting a recoiler. By virtue of the technical scheme, the low acid consumption anti-corrosion hot-replacing-cold product production method has the advantages that firstly more cracks and large gaps are formed in the oxide on the surface of the strip steel, so that acid pickling efficiency is high; secondly, eliminating part of oxide while breaking scale, so that acid picking reacting dose is reduced, and acid consumption is reduced; thirdly, added value of yield strength of the strip steel after processing is low; fourthly, a Luders strip is avoided from being formed on the surface of a common hot rolling product; fifthly, chlorine ion residue on the surface of a product is reduced, and corrosion resistance of the product is improved.

Owner:WISDRI ENG & RES INC LTD

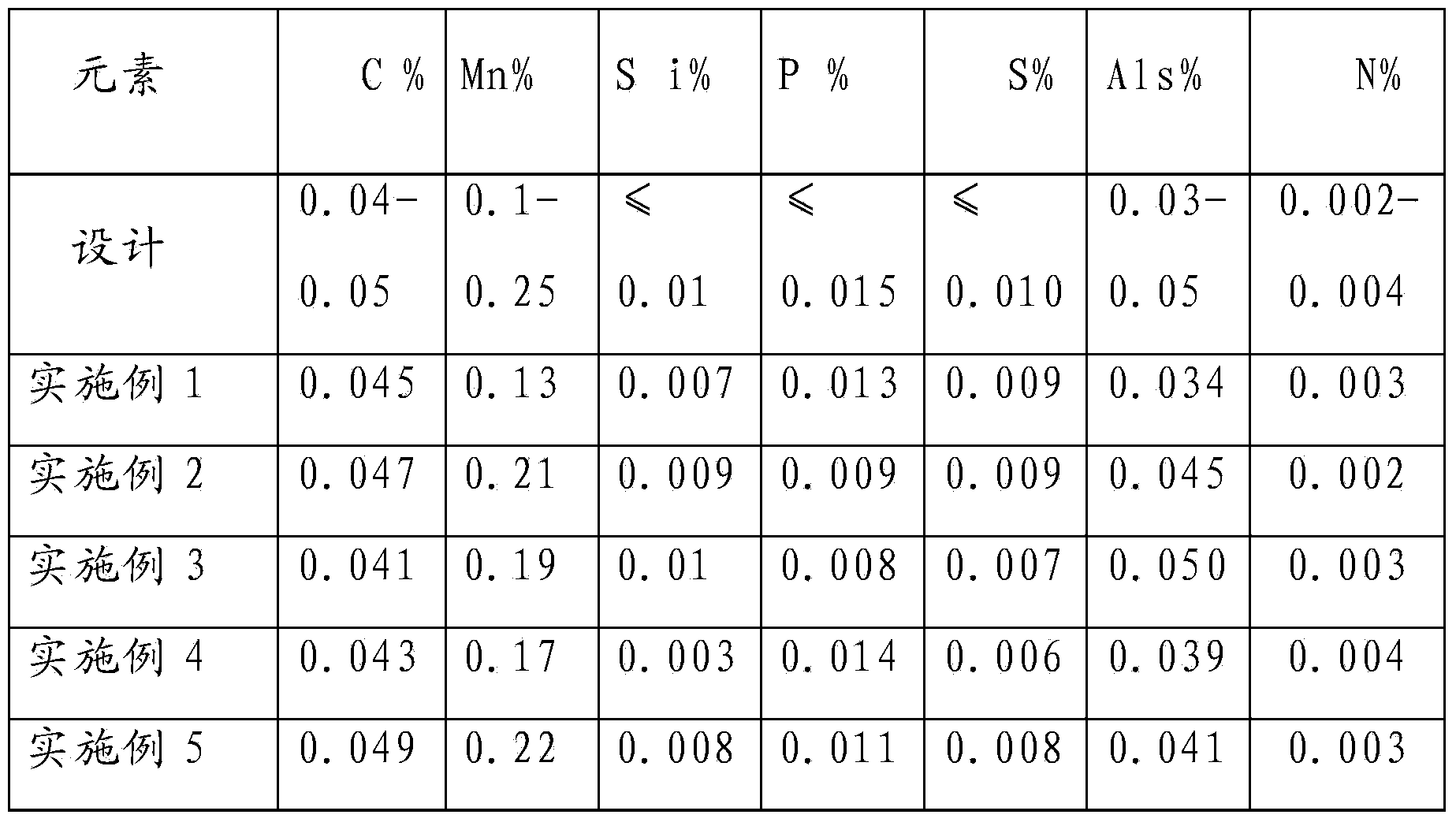

Steel for motor turbine of roller washing machine and production method thereof

ActiveCN103614617AInhibition of precipitation growthLower outlet temperatureSheet steelChemical composition

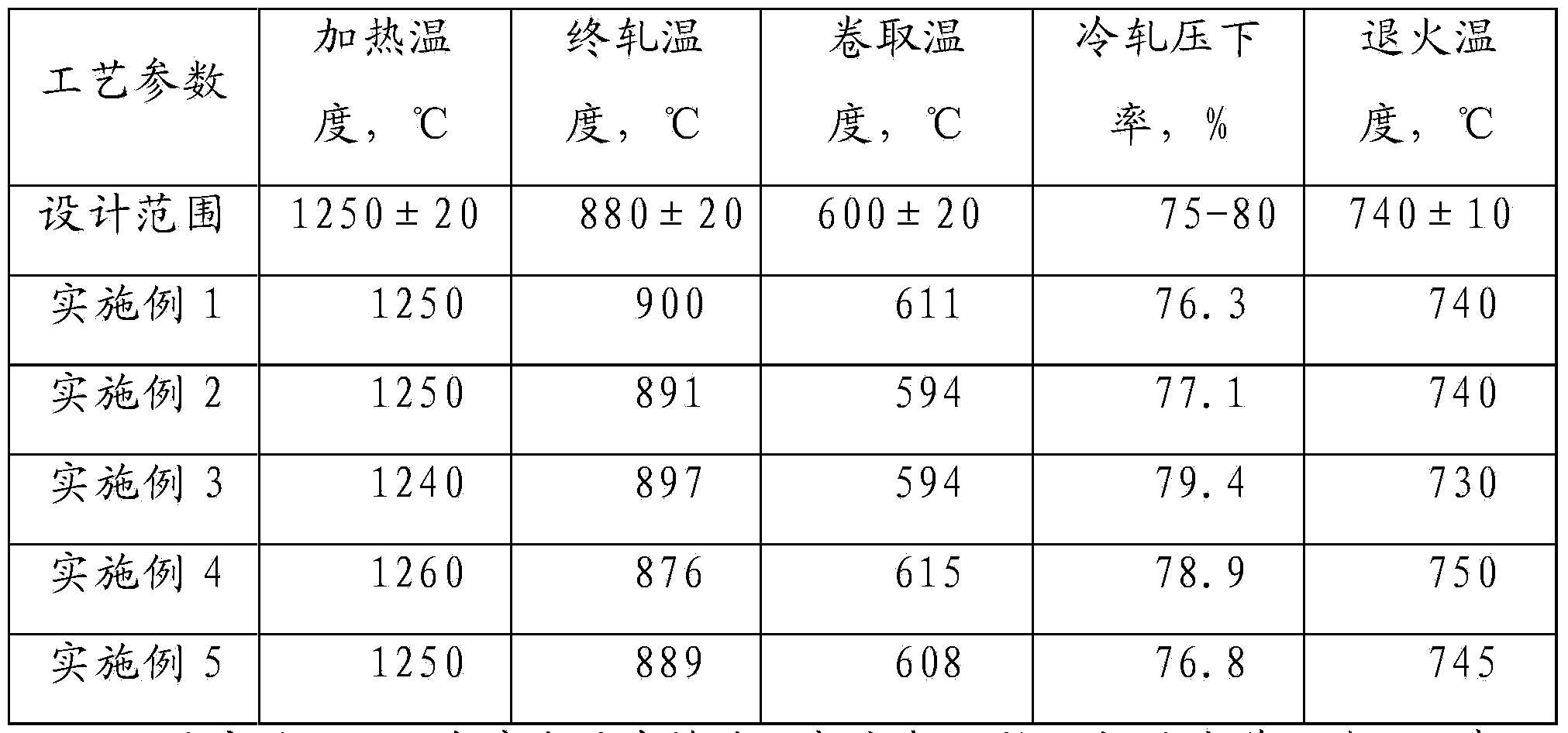

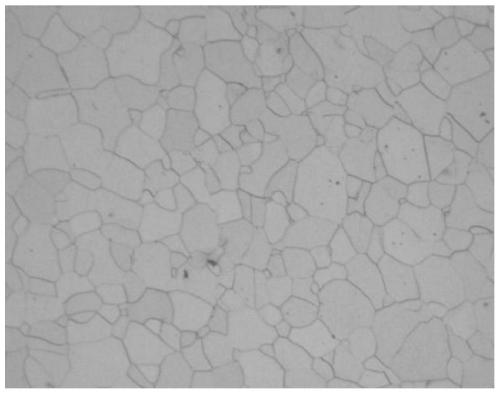

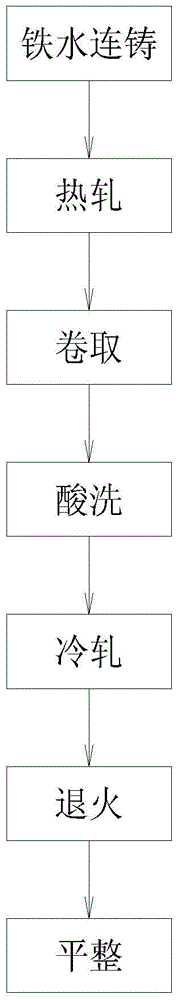

The invention provides steel for a motor turbine of a roller washing machine. The steel comprises the following chemical ingredients in percentage by mass: 0.04-0.05% of C, 0.10-0.25% of Mn, not higher than 0.01% of Si, not higher than 0.015% of P, not higher than 0.01% of S, 0.03-0.05% of Als, 0.0020-0.0040% of N and the balance of Fe and unavoidable impurities. According to a production method, process parameters are as follows: the hot-rolling heating temperature is 1,250+ / -20 DEG C, the final rolling temperature is 880+ / -20 DEG C, the coiling temperature is 600+ / -20 DEG C, the cold-rolling reduction ratio is controlled to be 75-80%, the annealing temperature is controlled to be 740+ / -10 DEG C, and the flat elongation percentage is 1.0%. The steel produced by the production method has certain yield strength, high elongation percentage and good forming property and can replace silicon steel through circuit transformation, so that considerable economic benefits are brought for household electrical appliance enterprises.

Owner:SHOUGANG CORPORATION

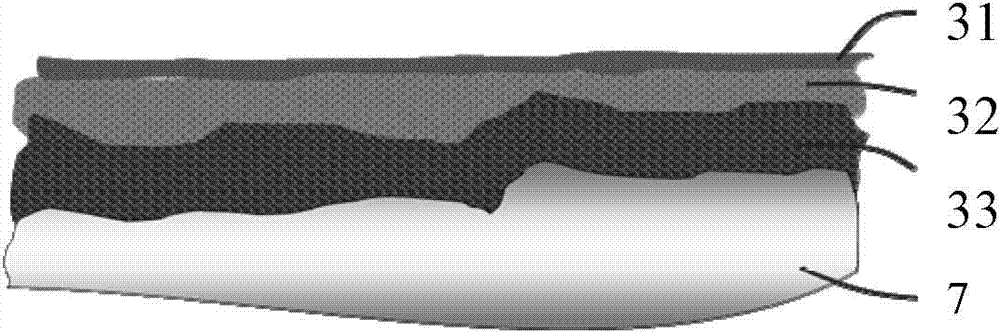

B-containing high-formability extremely thin hot-rolled pickling plate and preparation method thereof

ActiveCN111155033AGood mechanical propertiesImprove stamping formabilityUltimate tensile strengthSteel belt

The invention belongs to the technical field of pickling steel strip production, and particularly relates to a B-containing high-formability extremely thin hot-rolled pickling plate and a preparationmethod thereof. The B-containing high-formability extremely thin hot-rolled pickling plate with high surface quality and the preparation method thereof are provided. The hot-rolled pickling plate comprises 0-0.005% of C, 0.10-0.20% of Si, 0.60-1.00% of Mn, 0.002-0.005% of B, 0.03-0.06% of Ti, 0.010-0.060% of Als, 0-0.010% of P, 0-0.002% of S, 0-0.0050% of N, 0-0.0040% of O and the balance and inevitable impurities. The hot-rolled pickling plate obtained by controlling steel chemical components and the preparation process has the advantages of being high in tensile strength, high in elongation,low in yield strength and low in yield ratio.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of steel with high r value and thick specification IF automobile and its production method

The invention relates to a high-r-value thick IF automotive steel and a production method thereof. The method comprises: desulfurizing molten iron, converter blowing, RH vacuum refining, and continuous casting to obtain continuous casting slabs; heating the continuous casting slabs rolling to obtain hot-rolled slabs; coiling hot-rolled slabs to obtain hot-rolled steel coils; uncoiling pickling of hot-rolled steel coils; cold-rolling hot-rolled steel coils after pickling to obtain cold-rolled steel sheets ; Anneal the cold-rolled steel plate in the continuous annealing furnace; smooth the cold-rolled steel plate after annealing; the high r-value thick specification IF automotive steel produced by this method has good formability and mechanical properties, and can meet the requirements of medium and high grades. Stamping performance requirements for automotive sheets.

Owner:SHOUGANG CORPORATION

Double-layer composite plate finishing unit

The invention discloses a double-layer composite plate finishing unit and relates to finishing unit equipment. The double-layer composite plate finishing unit comprises a double-layer composite plate shoveling-separating device, a double-layer composite plate bidirectional tortoise back straightening machine, a double-layer composite plate slag removal machine, a double-layer composite plate leveler, a double-layer composite plate finishing machine and a double-layer composite plate sand mill which are connected sequentially. Therefore, the double-layer composite plate finishing unit adopts a layering, tortoise back treatment, slag removal, leveling, finishing and sand milling combined process for achieving finishing of a double-layer composite plate and removing oxide on the composite surface. Through the double-layer composite plate finishing unit, finishing treatment can be conducted on upper double metal composite plates and lower double metal composite plates simultaneously, production efficiency is high, and production cost is reduced.

Owner:山东易川新材料科技股份有限公司

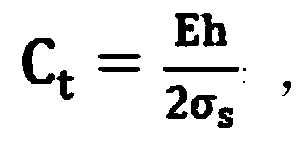

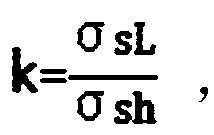

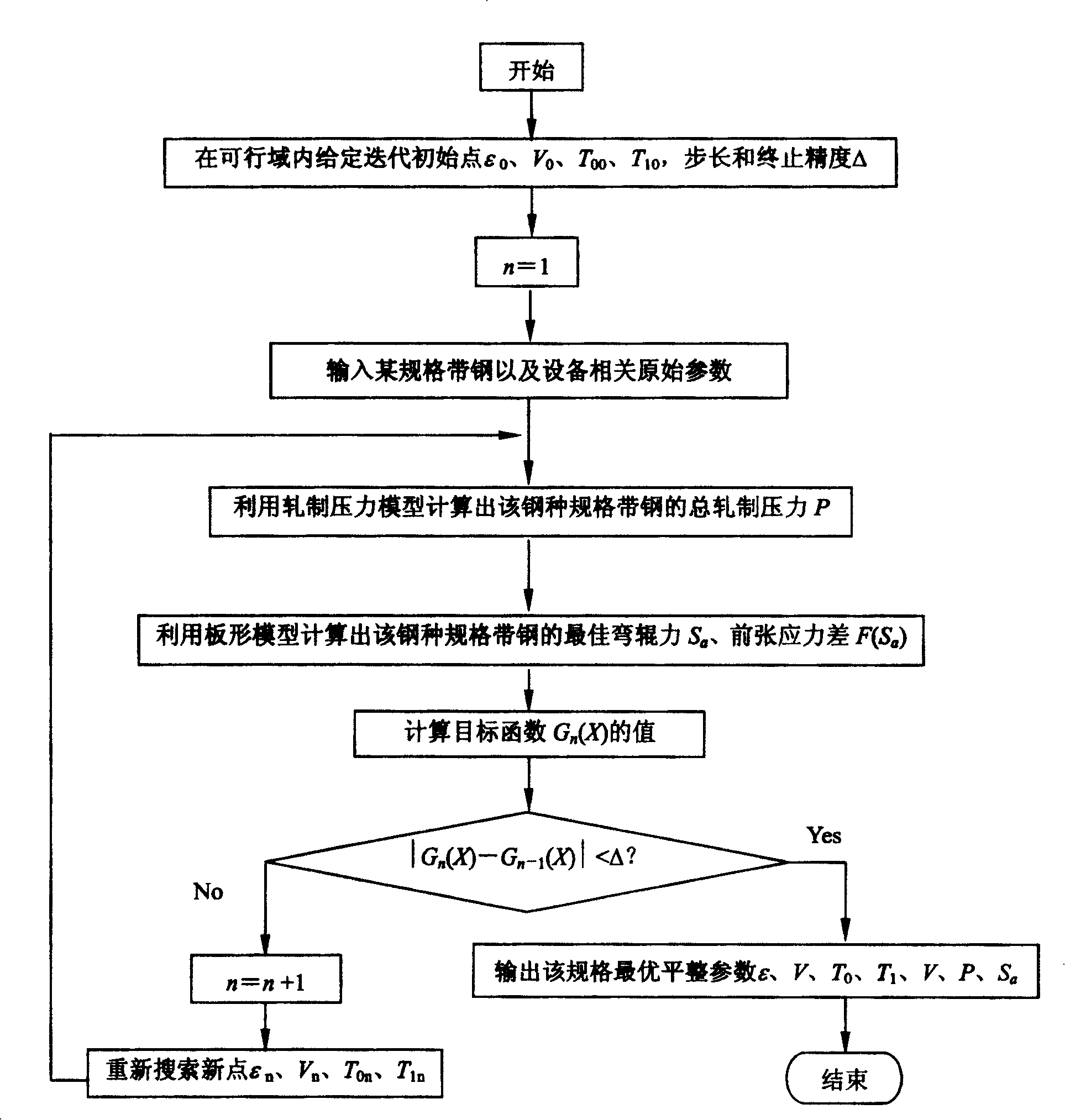

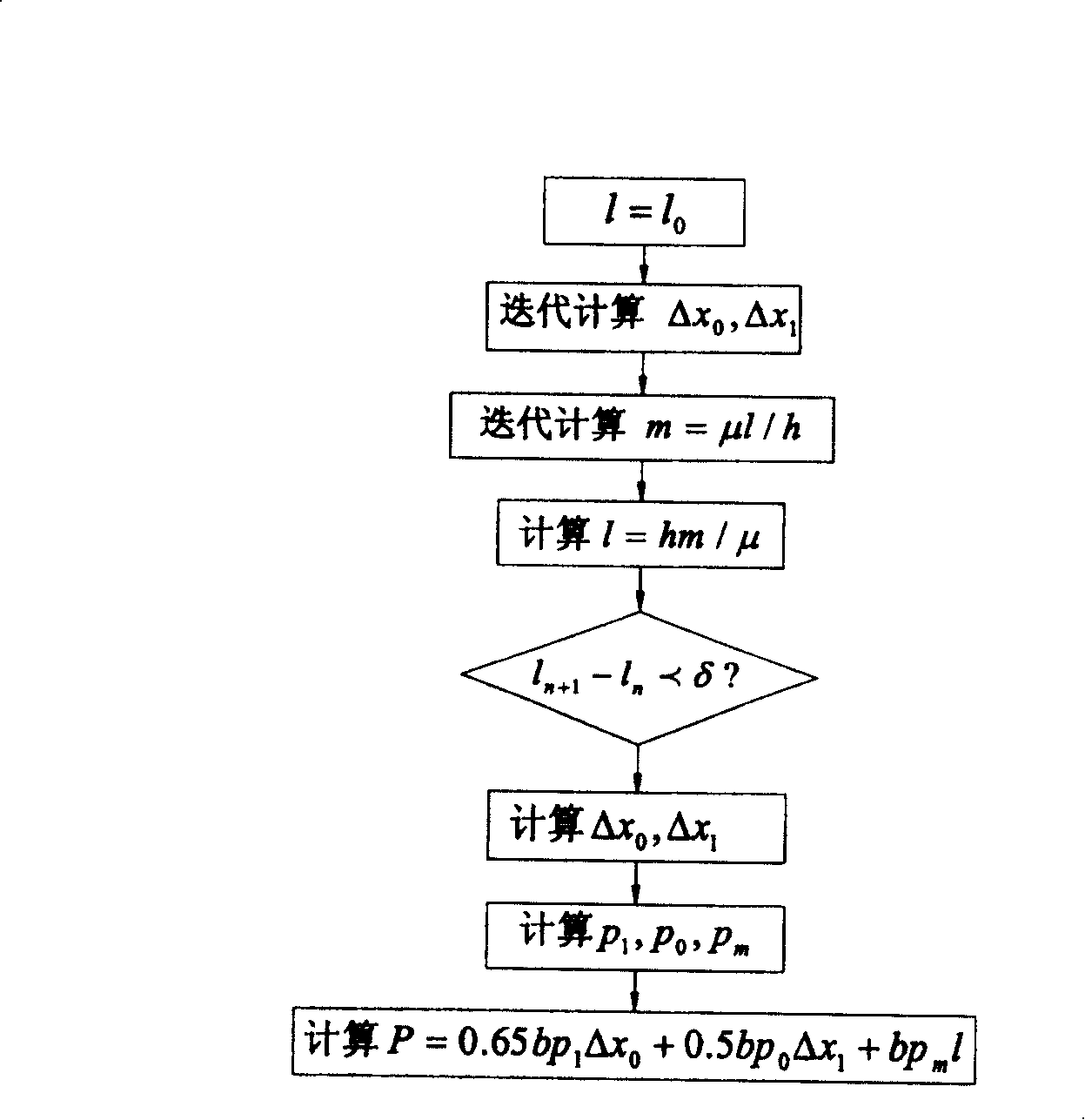

Optimized presetting method for steel strip-flattening technological parameter

ActiveCN100406146CEasy to shapeImprove mechanical propertiesProfile control deviceStrip steelMechanical property

The invention discloses an optimization presetting method with belt steel flattening processing parameter, which consists of optimization presetting object function of flattening processing parameter, constraint condition (range of value) of flattening processing parameter optimization, wherein rolling belt steel with the processing parameter which sets by the invention can improve belt steel mechanical property, which also improves the property of cold rolling flattening strip and slab-shaped quality.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of low-consumption corrosion-resistant high-surface-quality cold-rolled product

ActiveCN103920708AImprove efficiencyShort pickling timeWork treatment devicesMetal rolling arrangementsCorrosion resistantOxide

The invention relates to a production method of a low-consumption corrosion-resistant high-surface-quality cold-rolled product. The method specifically includes the following steps: uncoiling via an uncoiler; breaking oxides on the surface of strip steel via a leveler; further breaking and stripping the oxides via a multi-roll straightener; removing the oxides via scrubbing rolls in a scrubbing device; subjecting the leveled, straightened and scrubbed strip steel to acid pickling; feeding the strip steel into a mechanical lapping device for repairing surface defects; feeding the strip steel into a mechanical plate surface residue removing device for mechanical surface residue clearing; performing cold rolling; recoiling via a recoiler. Through the method, convenience is brought to rapid permeation of acid liquor, and efficiency of acid pickling is improved; part of the oxides is removed, reacting dose of acid pickling is decreased, and acid consumption is lowered; the added value of yield strength of the strip steel after scale breaking is lowered, and performance of the strip steel is basically unaffected; through mechanical surface lapping, surface quality of the product is improved; by virtue of mechanical surface residue clearing, corrosion resistance of the strip steel is enhanced.

Owner:WISDRI ENG & RES INC LTD

DDQ-grade hot-rolled pickling cold-formed steel and manufacturing method thereof

The invention discloses DDQ-grade hot-rolled pickling cold-formed steel and a manufacturing method thereof, and belongs to the technical field of hot-rolled pickling cold-formed steel. The steel comprises the following chemical components including, by weight percent, smaller than or equal to 0.0020% of C, smaller than or equal to 0.03% of Si, 0.08%-0.25% of Mn, 0.005%-0.015% of P, 0.05%-0.015% ofS, 0.025%-0.045% of Als, smaller than or equal to 0.0040% of N, 0.030%-0.050% of Ti, 0.015%-0.030% of Nb, and the balance Fe and inevitable impurities. According to the steel, multiple elements are added on the basis of traditional hot-rolled cold-formed steel, the content of each element is reasonably adjusted, so that the yield strength and the tensile strength of the steel are improved to a certain extent, the ductility of the steel is well improved, meanwhile, the thickness of a steel plate meets the use requirement, and a cold-rolled steel plate is effectively replaced. According to themanufacturing method of the steel, the components, the component content and the specific production process of the steel plate are optimally designed, the yield strength and the elongation of the obtained steel plate are guaranteed, and meanwhile, the surface characteristics of the steel plate are improved through secondary pickling, so that the steel plate has high-grade roughness and surface gloss comparable with surface gloss of a cold-rolled plate.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation method of Al-Mg alloy board for autobody

The invention provides a preparation method of an Al-Mg alloy board for an autobody, comprising the following steps: a) providing an Al-Mg alloy board which has undergone cold rolling, wherein cold rolling deformation is less than 70%; b) heating the Al-Mg alloy board which has undergone cold rolling to 480-550 DEG C, carrying out thermal insulation within 5 min, and continuously annealing, wherein the heating speed is not less than 5 DEG C / s; c) cooling the Al-Mg alloy board which has undergone continuous annealing to less than 150 DEG C, wherein the cooling speed is not less than 10 DEG C / s; d) carrying out leveling processing on the cooled Al-Mg alloy board; and e) carrying out heat treatment on the Al-Mg alloy board which has undergone leveling processing. According to the invention, a cold-rolled sheet with the cold rolling deformation being not less than 70% is used as a raw material and undergoes high-temperature short-time annealing, rapid cooling and heat treatment. Thus, forming property of the Al-Mg alloy is raised, and generation of A-type flow lines is avoided during the forming process.

Owner:ZHEJIANG GKO IND CO LTD

A production method of low-acid-consumption corrosion-resistant hot-rolled pickling products

The invention relates to a production method of low-acid-consumption corrosion-resistant hot-rolled pickling products, which specifically comprises the following steps: uncoiling by an uncoiler; crushing and stripping oxides on the surface of strip steel by a tempering machine; The oxides on the surface are further broken and peeled off; the brushing device removes the peeled and loose oxides on the surface of the strip; pickling and rinsing the treated strip; then mechanically removes the residue on the surface of the strip; the coiler coils Pick. Through this technical scheme, 1. There are many oxide cracks and large gaps on the surface of the strip, which facilitates the rapid penetration of acid solution and high pickling efficiency; 2. While breaking phosphorus, part of the oxides are removed, reducing the amount of pickling reaction and acid consumption. 3. The increased value of the yield strength of the strip steel after processing is low, and the performance of the strip steel is basically not affected; 4. The flattening process eliminates the yield platform of the strip steel and avoids the formation of Lüders bands on the surface of ordinary hot-rolled products; 5. Reduces The chloride ion residue on the surface of the product is eliminated, and the product has good corrosion resistance.

Owner:WISDRI ENG & RES INC LTD

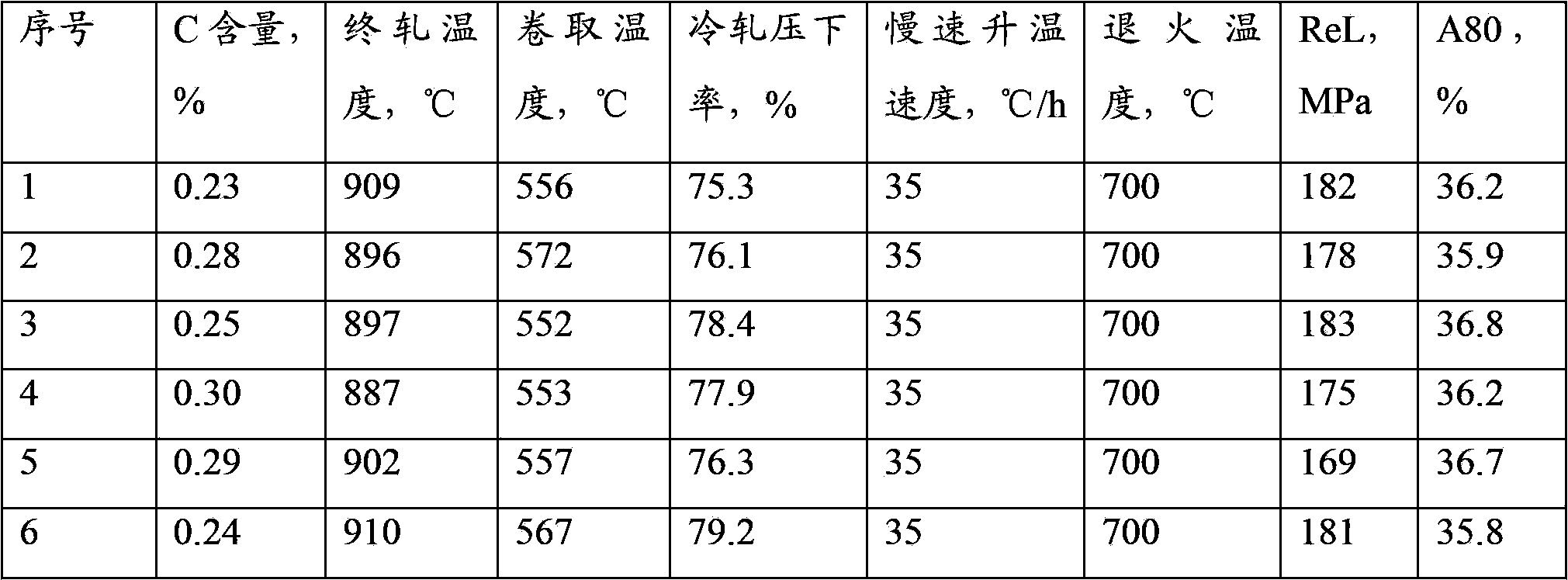

Boron-containing cold-rolled enamel steel suitable for continuous annealing production and its manufacturing method

The invention relates to a boron-containing cold-rolled enamel steel suitable for continuous annealing production and a manufacturing method thereof. The chemical composition mass percentage of the steel is: C 0.03-0.05%; Si≤0.02%; Mn 0.20-0.40%; P≤0.020% ; S 0.020‑0.035%; Als 0.020‑0.07%; B 0.0010‑0.0020%; N 0.0020‑0.0060%; the balance is Fe and inevitable impurities. It can be used for thin-gauge water heater liner and decorative panels for subways and tunnels, yield strength 200-240MPa, tensile strength 290-340MPa, elongation 38-44%, hardening exponent n value greater than 0.20, average plastic strain ratio rm value greater than 1.6 , The hydrogen lag time of 1mm thick steel plate is more than 50min, no scale explosion occurs after enamel, and the enamel adhesion performance reaches the national standard.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

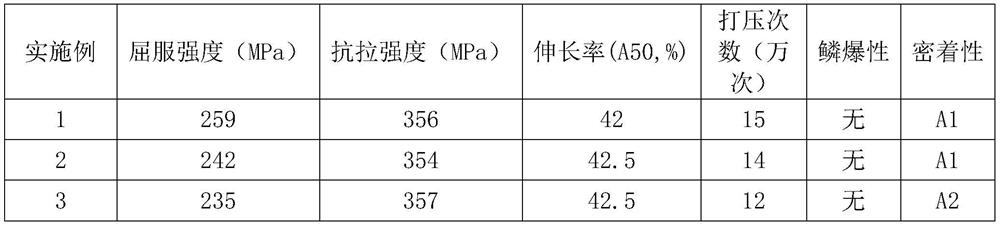

Fatigue-resistant enamel steel for water heater inner container and preparation process thereof

The invention discloses fatigue-resistant enamel steel for a water heater inner container. The fatigue-resistant enamel steel comprises the following chemical components in percentage by weight: lessthan or equal to 0.08 percent of C, less than or equal to 0.05 percent of Si, less than or equal to 0.40 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent ofS, more than or equal to 0.020 percent of Alt, less than or equal to 0.01 percent of Nb and the balance Fe and inevitable impurity elements. The invention also discloses a preparation process of thefatigue-resistant enamel steel. The fatigue-resistant enamel steel for the water heater inner container is produced by using a CSP (continuous casting and rolling) production line; and the water heater inner container made of the fatigue-resistant enamel steel can bear more than 150,000 fatigue-resistant tests through a bulge test of a water heater manufacturer; and the bulge times of the inner container made of common low-carbon steel is only 60,000-80,000. The enamel steel plate manufactured by using the preparation process has excellent fatigue resistance, fish scaling resistance, enamel performance and formability.

Owner:BAOTOU IRON & STEEL GRP

Automotive low-carbon aluminum-killed steel sheet and production method thereof

Owner:SHOUGANG CORPORATION

Method for eliminating yield point elongation of hot galvanizing low-alloy high-strength steel

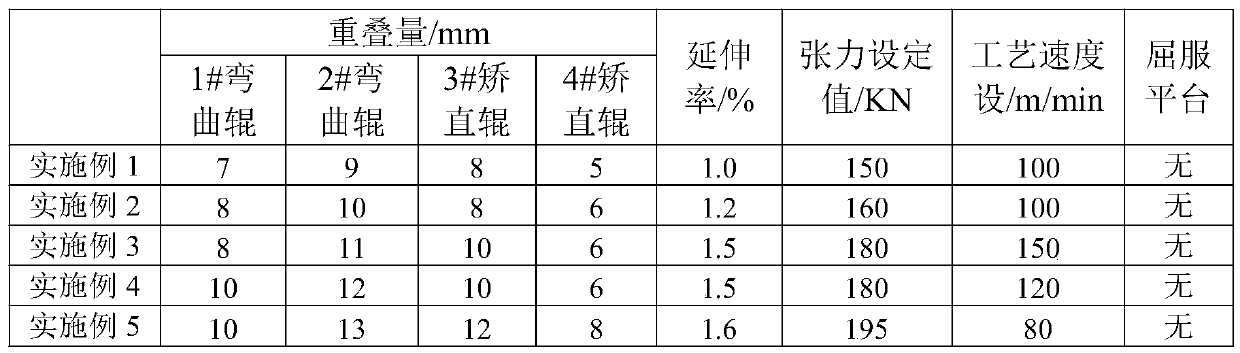

The invention relates to a method for eliminating yield point elongation of hot galvanizing low-alloy high-strength steel. The method comprises the steps of 1, setting of working rolls of a withdrawaland straightening machine, 2, setting of the overlapping amount, 3, setting of the elongation rate, 4, setting of the tension value and 5, setting of the process speed. In the step 1, the diameter ofa first bending roll is set as phi 30mm*2, the diameter of a second bending roll is set as phi 36mm*2, the diameter of a first straightening roll is set as phi 50mm / phi 180mm, and the diameter of a second straightening roll is set as phi 70mm / phi 180mm; in the step 2, the overlapping amount of the first bending roll of is set as 7-10mm, the overlapping amount of the second bending roll is 9-13mm,the overlapping amount of the first straightening roll is 8-12mm, and the overlapping amount of the second straightening bending roll is 5-8mm; in the step 3, the elongation rate is set as 1.0-1.6%;in the step 4, the tension value is set to 150-200 KN; and in the step 5, the process speed is set to 80-150 m / min. By the withdrawal and straightening machine, a certain elongation rate and tension are given, so that a certain amount of strain is generated by the steel strip, and the purpose of eliminating the yield point elongation of a steel strip is achieved.

Owner:SD STEEL RIZHAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com