Method for eliminating yield point elongation of hot galvanizing low-alloy high-strength steel

A yield platform and low-alloy technology is applied in the field of eliminating the yield platform of hot-dip galvanized low-alloy high-strength steel. The effect of avoiding slip line defects and improving the surface quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

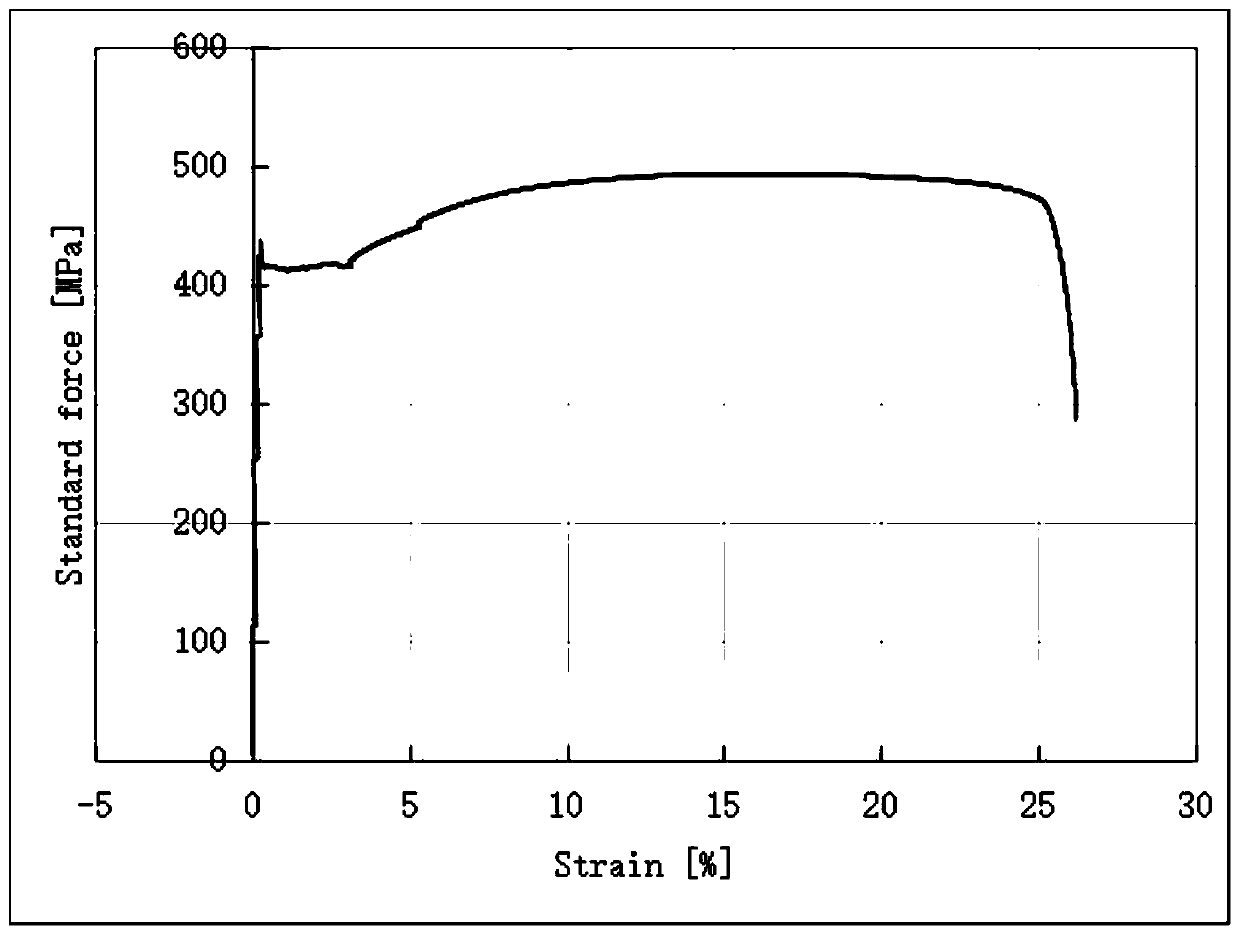

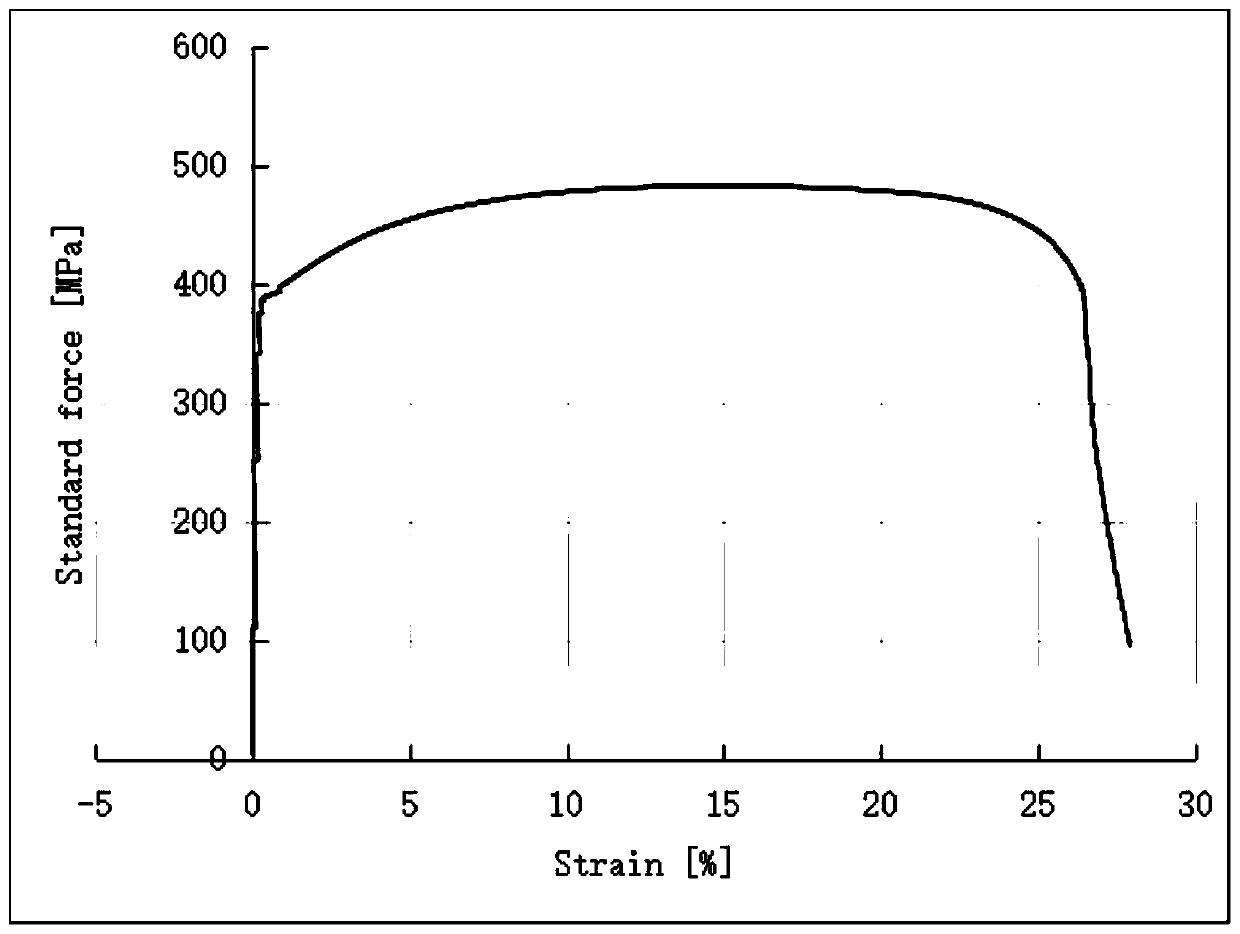

[0017] The present invention is described in further detail now in conjunction with accompanying drawing.

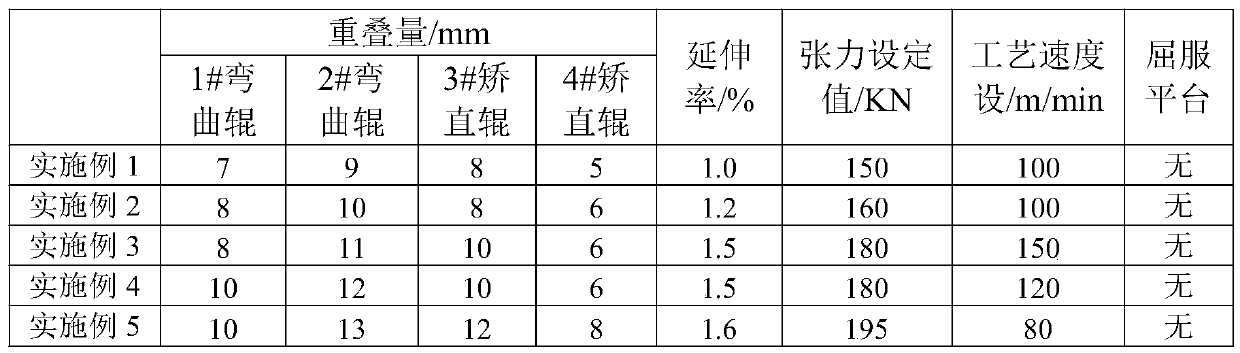

[0018] The method for eliminating the yield platform of hot-dip galvanized low-alloy high-strength steel adopts the mode of two-bending and two-straightening tension leveling machine, and its working roll diameter size: the diameter of the first bending roll is Φ30mm*2; the diameter of the second bending roll is Φ36mm* 2. The diameter of the first straightening roller is Φ50mm / Φ180mm; the diameter of the second straightening roller is Φ70mm / Φ180mm; the setting value of the overlapping amount of the tension leveler: the first bending roller is 7-10mm; the second bending roller is 9-13mm; straightening The first roller is 8-12mm; the second straightening roller is 5-8mm; the tension-leveler adopts constant elongation control mode, and the elongation setting value is 1.0-1.6%; the tension setting value of the tension-leveling unit is 150-200KN; The process speed of the tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com