Preparation method of Al-Mg alloy board for autobody

A technology of automobile body and alloy plate, applied in the field of alloy, can solve problems such as deterioration of plate surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of Al-Mg alloy sheet for automobile body, comprising the following steps:

[0032] a) Provide Al-Mg alloy plate after cold rolling, the cold rolling deformation is not less than 70%;

[0033] b) Heating the cold-rolled Al-Mg alloy plate to 480°C-550°C and holding it for 5 minutes for continuous annealing, and the heating rate is not less than 5°C / s;

[0034] c) cooling the continuously annealed Al-Mg alloy plate to below 150°C, and the cooling rate is not less than 10°C / s;

[0035] d) leveling the cooled Al-Mg alloy plate;

[0036] e) heat-treating the leveled Al-Mg alloy sheet to obtain an Al-Mg alloy sheet for an automobile body.

[0037] The method provided by the invention uses cold-rolled sheets with a cold deformation of not less than 70% as raw materials, and performs high-temperature short-time annealing on them, thereby preventing grain coarsening, obtaining fine recrystallized particles, and improving the a...

Embodiment 1

[0066] 4.53wt% of Mg, 0.28wt% of Mn, 0.08wt% of Cu, 0.03wt% of Cr, 0.05wt% of Zn, 0.15wt% of Si, 0.27wt% of Fe, 0.02wt% of Ti and other A large amount of Al and unavoidable impurities are prepared by DC casting to obtain aluminum alloy ingots;

[0067] Homogenizing the obtained ingot at a temperature of 460° C. for 10 hours;

[0068] After the homogenization treatment, the initial cut head and face milling are reheated to 430°C for hot rolling. The final rolling temperature of hot rolling is 320°C, and the final rolling thickness of hot rolling is 5mm;

[0069] The hot-rolled aluminum alloy plate is cold-rolled, and the cold deformation of the cold rolling is 80%, to obtain a 5182 aluminum-magnesium alloy plate with a thickness of 1mm.

Embodiment 2

[0071] The 5182 aluminum alloy plate obtained in Example 1 with a cold deformation of 80% and a thickness of 1mm is heated to 500°C at a heating rate of 5°C / s through a continuous annealing furnace and held for 3min for annealing, and the plate is cooled by strong wind To 140°C, the cooling rate is 20°C / s;

[0072] Then use straightening rollers to level the annealed 5182 aluminum alloy sheet through repeated bending;

[0073] Then the 5182 aluminum alloy plate after leveling was kept warm for 2h at 200°C to obtain an Al-Mg alloy for automobile body panels.

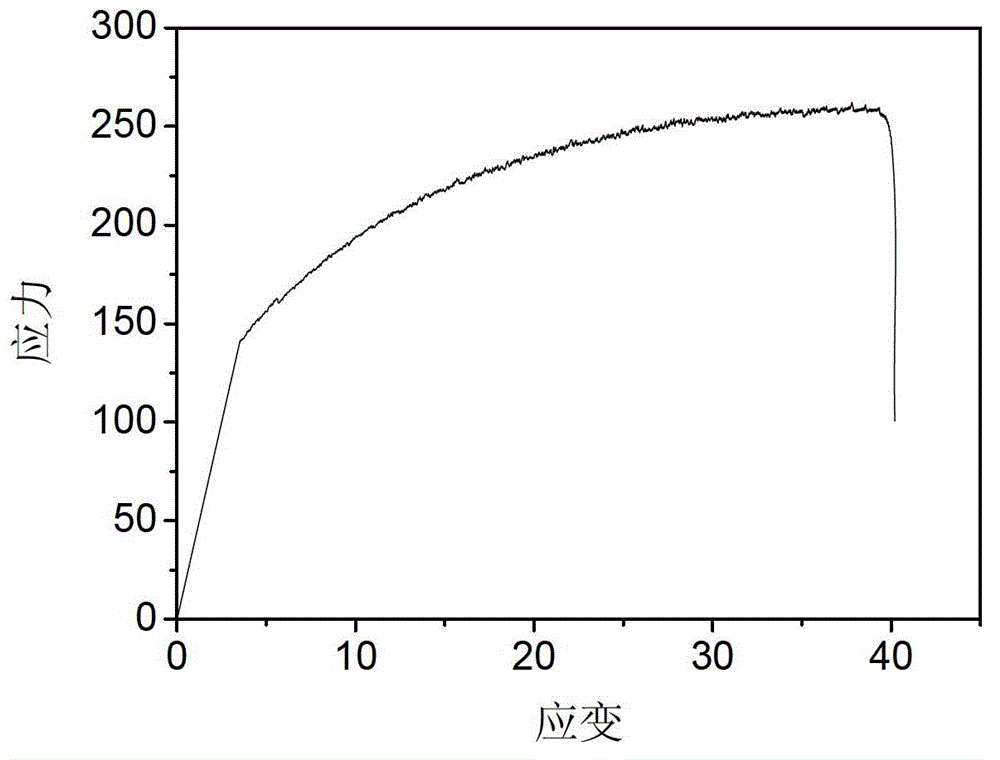

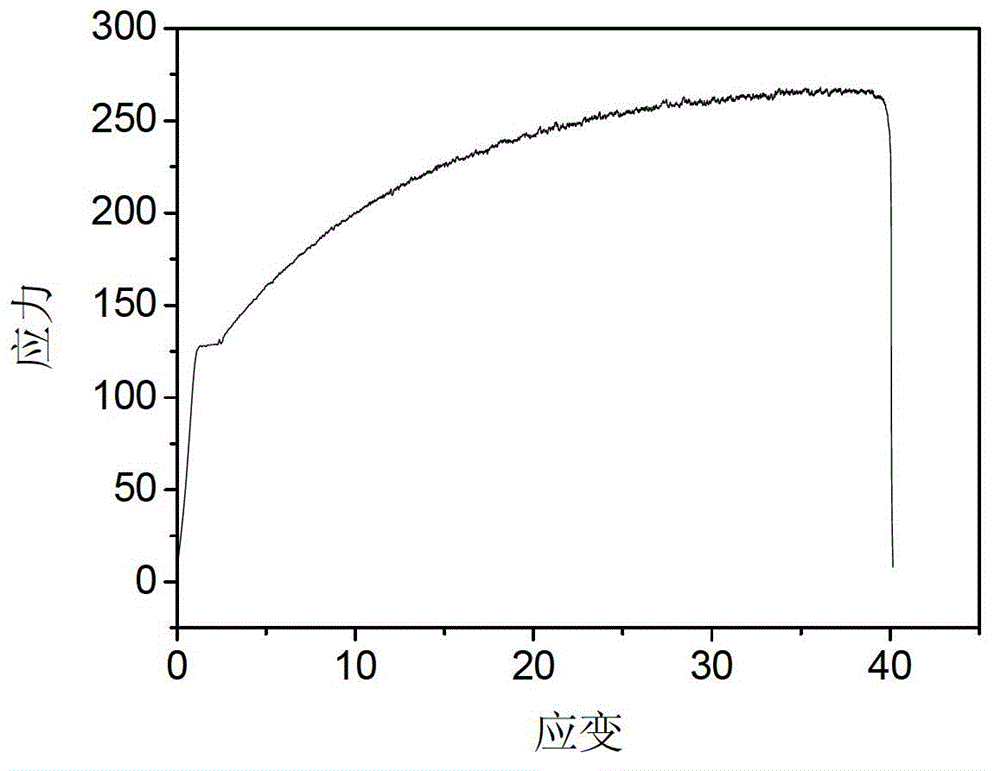

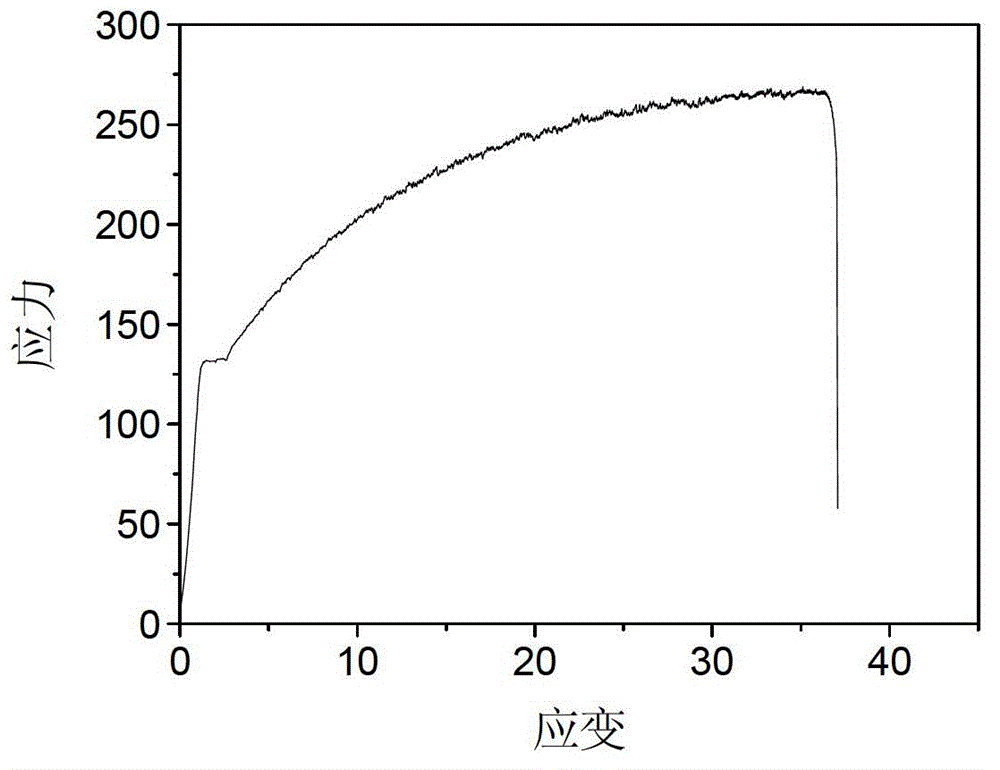

[0074] In the present invention, the Al-Mg alloy plate is subjected to a tensile test at room temperature before leveling, after leveling and after heat treatment, and the results are shown in Table 1. Table 1 shows the Al-Mg obtained at different process stages in Example 2 of the present invention Performance test results of alloy plates.

[0075] The present invention carries out tensile test test to the Al-Mg alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com