Automotive low-carbon aluminum-killed steel sheet and production method thereof

A production method and low-carbon aluminum technology, which are applied to low-yield strength and high-elongation low-carbon aluminum-killed steel plates for automobiles and their production fields, can solve the problems of unfavorable automobile plate stamping, reduction of r value, and increase of yield strength, etc. Reduce yield strength, increase elongation, eliminate yield plateau effects

Active Publication Date: 2014-04-02

SHOUGANG CORPORATION

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For this type of steel, the content of elements such as C and Mn is usually controlled to meet the requirements of tensile strength, which often leads to an increase in yield strength, an increase in yield ratio (the ratio of yield strength to tensile strength), and a decrease in r value, which is not conducive to Press forming of automotive sheet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

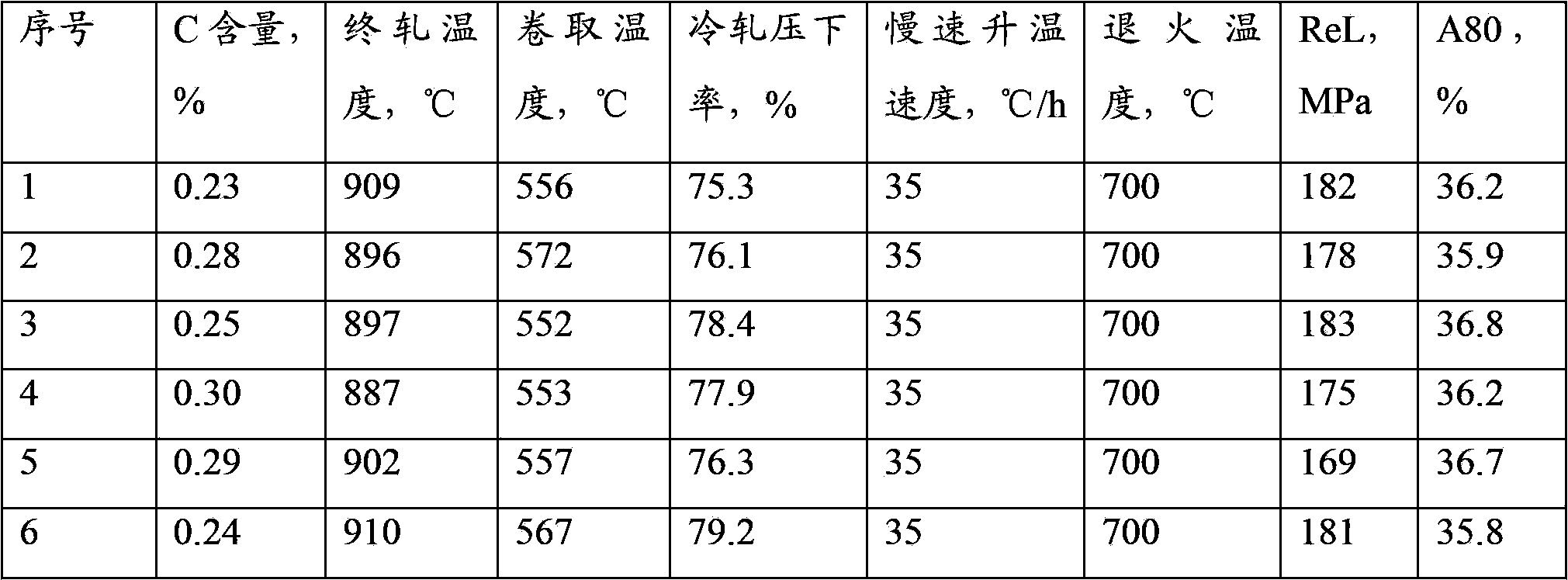

[0020] The following table lists the embodiment of the technical solution provided by the present invention

[0021]

[0022] It can be seen from the above table that the low-carbon aluminum-killed steel sheet for automobiles adopting the composition and method provided by the present invention has low yield strength and high elongation, and its mechanical properties meet the stamping performance requirements of automobile sheets.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an automotive low-carbon aluminum-killed steel sheet and a production method thereof and belongs to the technical field of steel sheets and a processing method thereof. The steel sheet which is low in yield strength and high in percentage of elongation chemically comprises, by mass, 0.02-0.03% of C, 0.1-0.2% of Mn, not more than 0.025% of Si, not more than 0.015% of P, not more than 0.015% of S, 0.03-0.04% of Als, 0.0020-0.0040% of N and the balance Fe. The content of the C in chemical components of the steel sheet is 0.02-0.03% and is relatively low, and the content of Fe3C and pearlites in a substrate can be reduced, so that the yield strength of the steel sheet can be effectively lowered. The production method of the steel sheet is not only beneficial to lowering of the yield strength of the steel sheet but also beneficial to increase of the percentage of elongation, and ageing resistance of the steel plate is improved.

Description

technical field [0001] The invention relates to the technical field of steel plates and processing methods thereof, in particular to a low-carbon aluminum-killed steel plate for automobiles with low yield strength and high elongation and a production method thereof. Background technique [0002] Low-carbon aluminum-killed steel plates are often produced by bell annealing, which are mostly used in the automotive industry, home appliance industry, and construction fields. According to the requirements of GB / T 5213-2001 for similar steel types, its composition is: C, ≤0.08%; Mn, ≤0.4%; Si, ≤0.03%; P, ≤0.020%; S, ≤0.025%; Als, 0.02-0.07%, the balance being Fe. The national standard requires the yield strength to be ≤240MPa, the tensile strength to be 270-350MPa, n90≥1.8, r90≥1.6. In the European standard EN 10130-2006, the composition requirements are C, ≤0.12%; Mn, ≤0.60%; S, ≤0.45%; P, ≤0.045%, and the thickness specification is 0.6~1.0mm. The performance requirement is that ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/04C21D8/04

Inventor 程晓杰乔建军王洋闻达毕安园何砚忠李卫峰陈圣杨

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com