Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

A technology for optimizing control and elongation, applied in the direction of elongation control, etc., can solve problems such as elongation fluctuation, and achieve the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

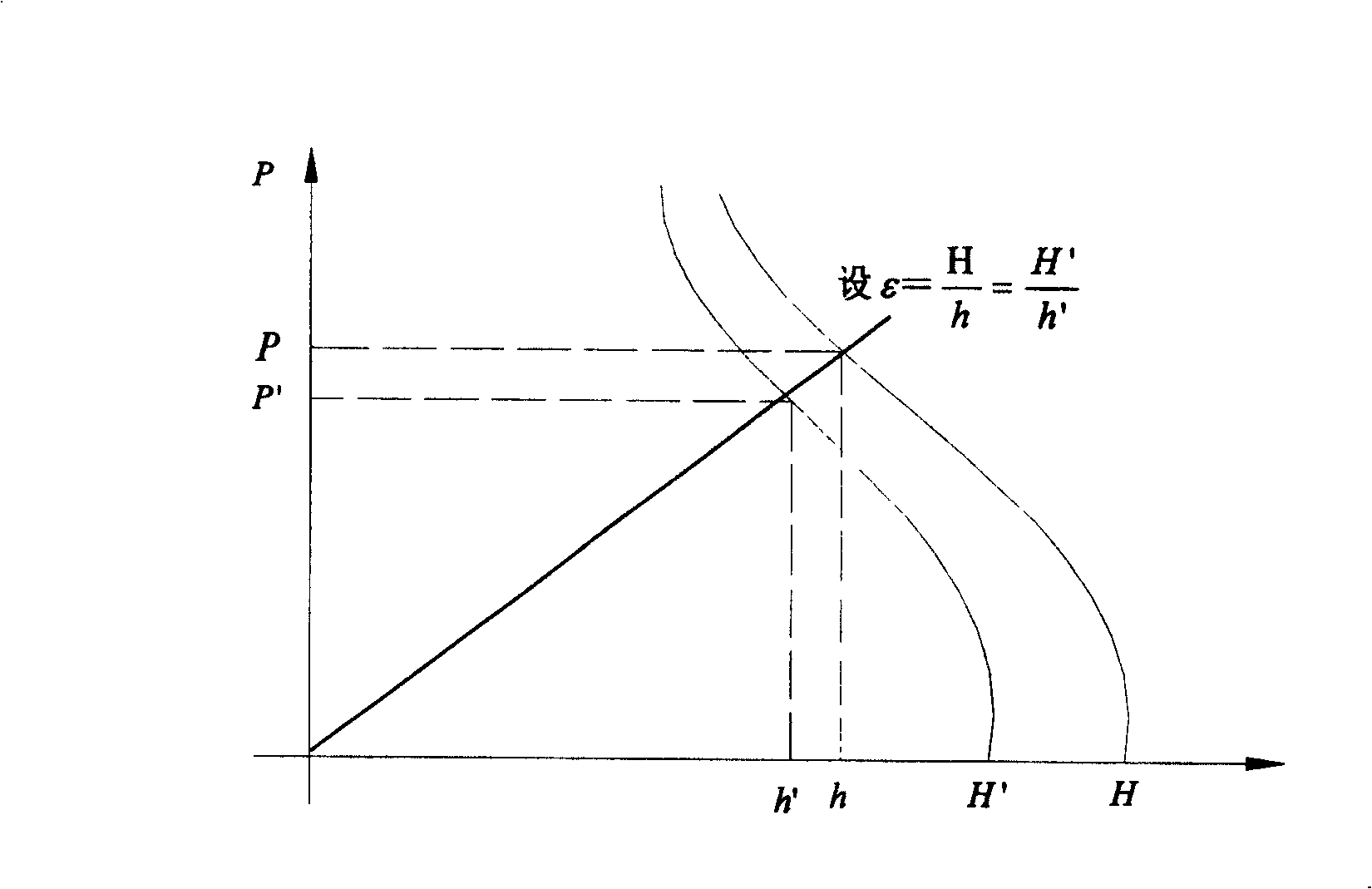

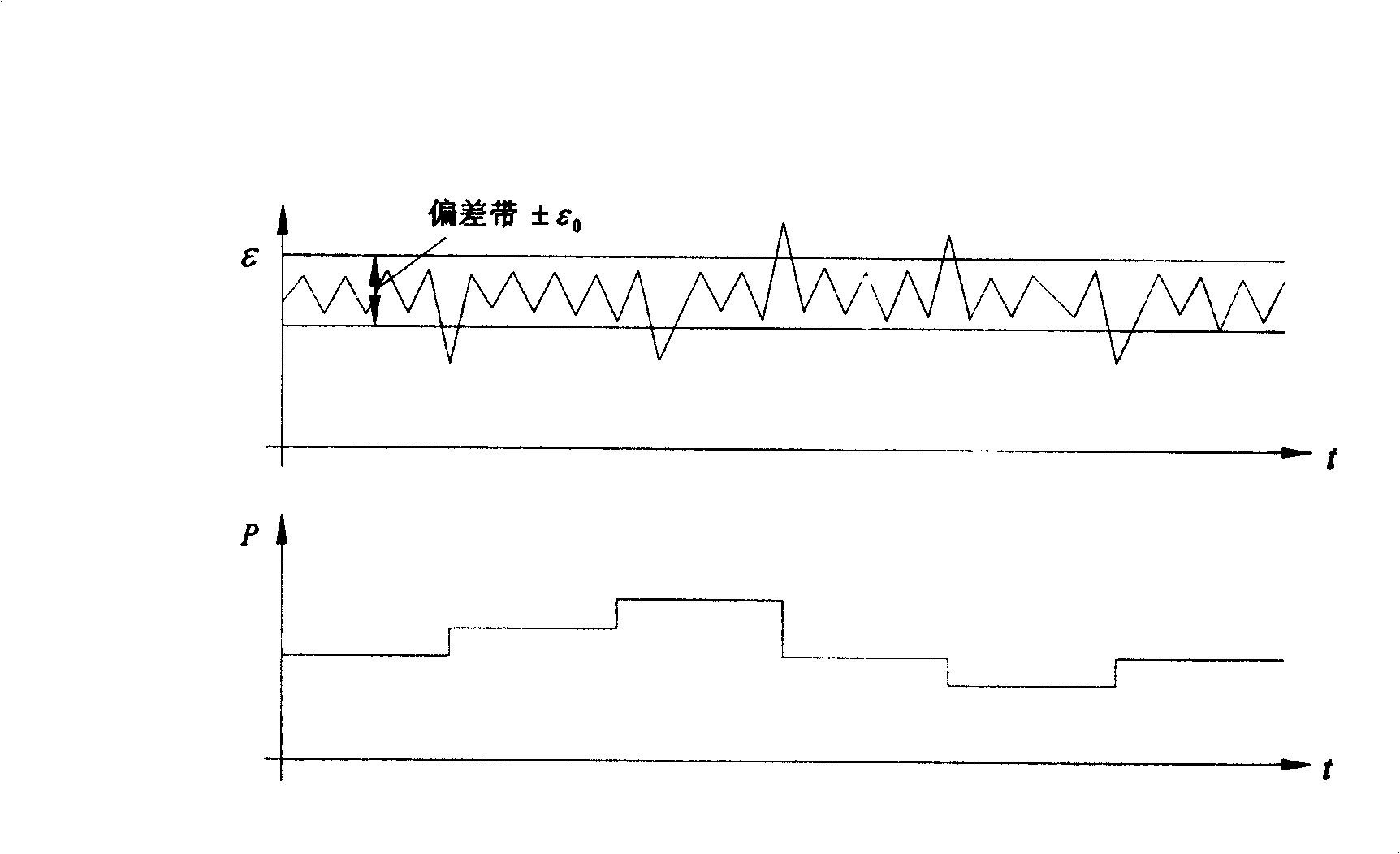

[0096] Steel grade DC51, thickness h=0.2mm, width b=1000mm, given value of elongation ε sv = 0.8%, allowable control deviation of elongation ± 0.2%, the maximum tension T that can be provided by the tension system of the temper mill s =90KN, the maximum rolling pressure P that can be provided by the reduction system of the temper mill s =4000KN, the maximum bending force S that can be provided by the bending system of the skin pass mill s =200KN, take the set value of front and rear tension Rsv=61KN, allowable deviation of elongation Δε 0 = 0.2% ÷ 3 = 0.067%.

[0097] Input the above parameters into the rolling pressure model of the process computer, the optimal roll bending force model and other related models, and obtain the rolling pressure set value Psv=1710KN, the roll bending force set value Ssv=101KN, and the rolling pressure to Elongation transfer coefficient k pε =61502KN, tension to elongation transfer coefficient k σε =12.8KN / mm 2 , the transfer coefficient of...

Embodiment 2

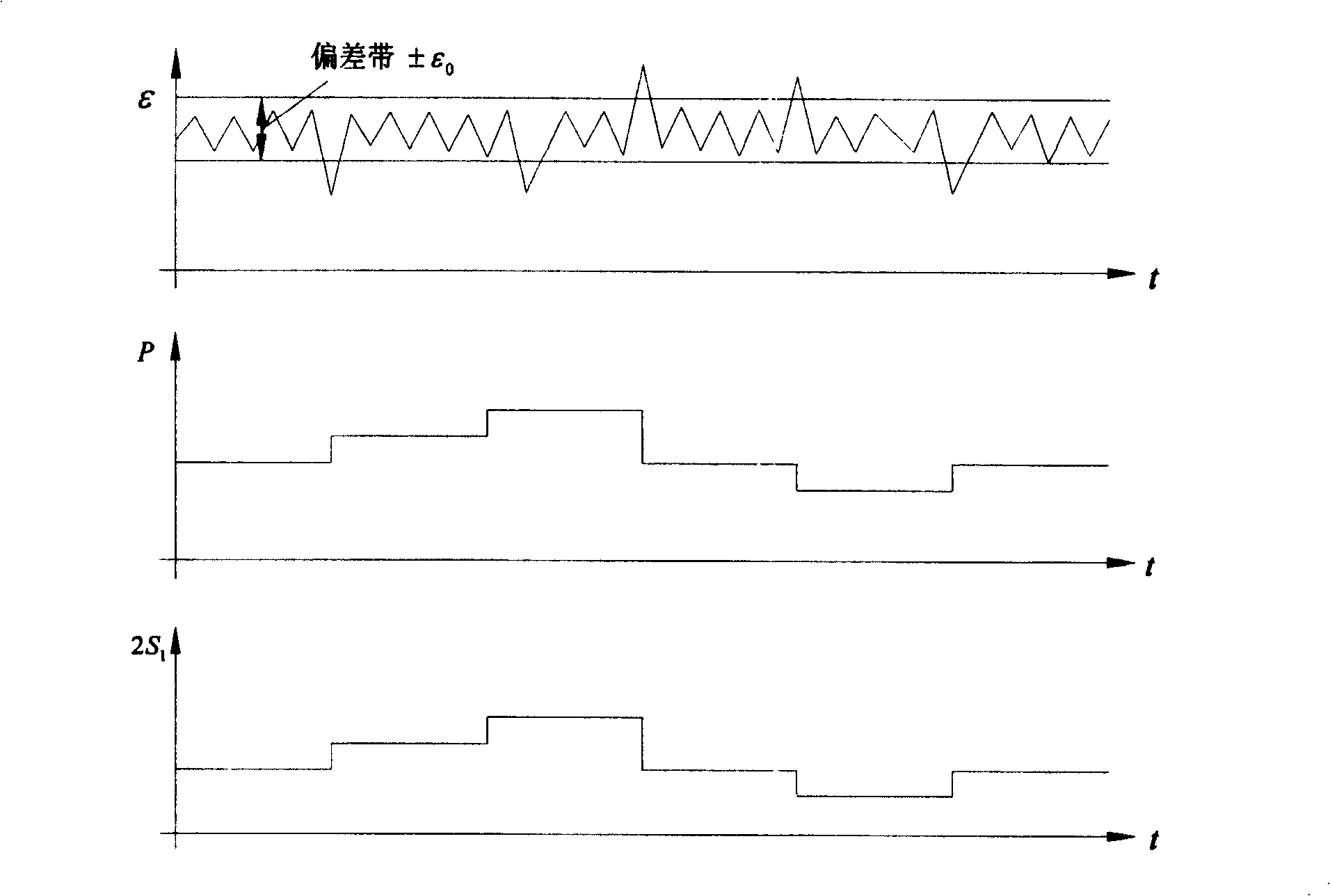

[0103] Steel grade DC51, thickness h=1.2mm, width b=1000mm, given elongation ε sv = 0.8%, allowable control deviation of elongation ± 0.2%, the maximum tension T that can be provided by the tension system of the temper mill s =90KN, the maximum rolling pressure P that can be provided by the reduction system of the temper mill s =4000KN, the maximum bending force S that can be provided by the bending system of the skin pass mill s =200KN, take the set value of front and rear tension Tsv=21KN, allowable deviation of elongation Δε 0 = 0.2% ÷ 3 = 0.067%.

[0104] Input the above parameters into the rolling pressure model of the process computer, the optimal roll bending force model and other relevant models, and through calculation, the rolling pressure set value Psv=2827KN, the roll bending force set value Ssv=156KN, and the rolling pressure to Elongation transfer coefficient k pε =87833KN, tension to elongation transfer coefficient k σε =4.4KN / mm 2 , the transfer coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com