CQ-grade hot-dip galvanization steel strip for anti-theft door plate and production process thereof

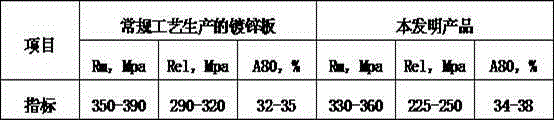

A production process and anti-theft door technology, which is applied in the field of metallurgical plate production, can solve the problems of large performance margin of DQ grade galvanized sheet, insufficient performance of CQ galvanized sheet, and high procurement cost, so as to reduce yield strength and eliminate tensile curve , The effect of improving the molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: The thickness of the finished galvanized sheet for deep-drawing anti-theft door panels is 0.6mm, and the mass percentages of chemical components are: C: 0.05%, Si: 0.011%, Mn: 0.16%, P: 0.015%, S: 0.009%, Als : 0.025%, Fe: balance; gas content in steel T[O]: 25ppm, T[N]: 20ppm.

[0020] Main process and parameters: In the hot rolling process, the coiling temperature is 700°C; the thickness of the hot-rolled sheet is 3.0mm, the thickness of the cold-rolled sheet is 0.58mm, and the cold-rolled reduction rate is 80%; the temperature of the annealing heating section in the galvanizing process is 730 ℃, soaking section temperature 720 ℃, unit speed 90m / min, tension leveling elongation controlled at 1.4%. The yield strength of the finished product is 240Mpa, and the elongation is 36%.

Embodiment 2

[0021] Example 2: The thickness of the finished galvanized sheet for deep-drawing anti-theft door panels is 0.7mm, and the mass percentages of chemical components are: C: 0.05%, Si: 0.010%, Mn: 0.16%, P: 0.017%, S: 0.007%, Als : 0.024%, T[O]: 27ppm, Fe: balance; gas content T[N] in steel: 23ppm.

[0022] Main process and parameters: In the hot rolling process, the coiling temperature is 697°C; the thickness of the hot-rolled sheet is 3.0mm, the thickness of the cold-rolled sheet is 0.68mm, and the cold-rolled reduction rate is 77%; the temperature of the annealing heating section in the galvanizing process is 740 ℃, soaking section temperature 730 ℃, unit speed 85m / min, tension leveling elongation controlled at 1.5%. The yield strength of the finished product is 230Mpa, and the elongation is 35%.

Embodiment 3

[0023] Example 3: The thickness of the finished galvanized sheet for deep-drawing anti-theft door panels is 0.8mm, and the mass percentages of chemical components are: C: 0.06%, Si: 0.011%, Mn: 0.18%, P: 0.015%, S: 0.009%, Als : 0.030%, Fe: balance; gas content in steel T[O]: 20ppm, T[N]: 25ppm.

[0024] Main process and parameters: In the hot rolling process, the coiling temperature is 703°C; the thickness of the hot-rolled sheet is 3.0mm, the thickness of the cold-rolled sheet is 0.78mm, and the cold-rolled reduction rate is 73%; the temperature of the annealing heating section in the galvanizing process is 740 ℃, soaking section temperature 730 ℃, unit speed 80m / min, tension leveling elongation controlled at 1.5%. The yield strength of the finished product is 235Mpa, and the elongation is 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com