Method and device for improving surface cross wrinkles of cold or hot rolled strip steel

A hot-rolled strip, cross-folding and printing technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of quality objection, influence of strip surface quality, easy to produce cross-folding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described below with reference to examples. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

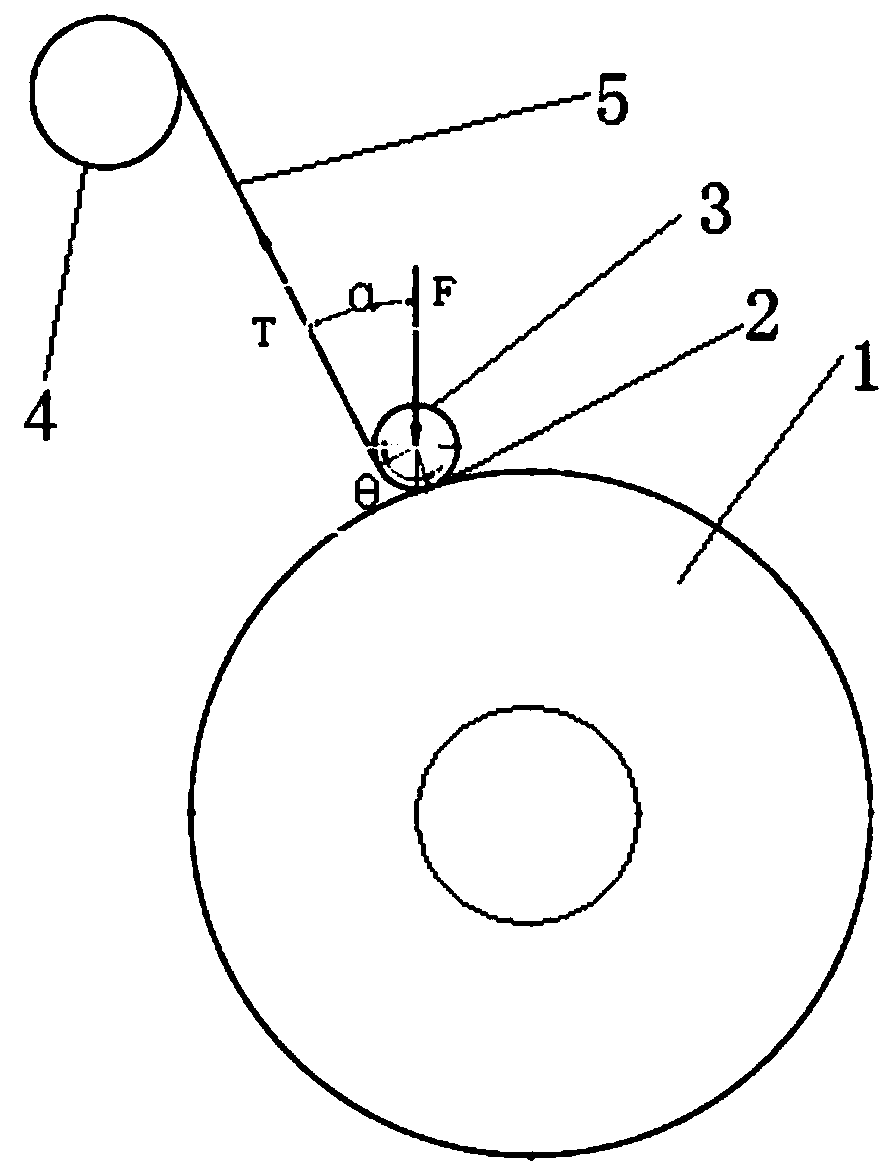

[0028] like figure 1 As shown, as a first aspect of the present invention, a method for improving the cross-folding on the surface of cold and hot-rolled strip steel is provided, comprising the following steps:

[0029] Step 1, set the anti-cross-folding roll 3 with preset roll diameter at the strip uncoiling point 2 of the uncoiler 1 of the unit;

[0030] Step 2, by adjusting the position of the turning roller 4 or the strip unwinding point 2, so that the strip 5 produces a preset wrap angle on the anti-cross-folding and printing roller 3;

[0031] Step 3, apply a vertical downward pressure to the anti-cross-folding and printing roller 3, so that the strip steel 5 is bent in a reverse direction before passing through the turning roller 4;

[0032] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com