Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Bulge test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulge Test. The hydraulic bulge test is used to evaluate formability and determine the flow stress data of the material. The stress state in the hydraulic bulge test is biaxial; therefore, this test can provide the flow stress data for higher strain values without localized necking compared to a uniaxial tensile test.

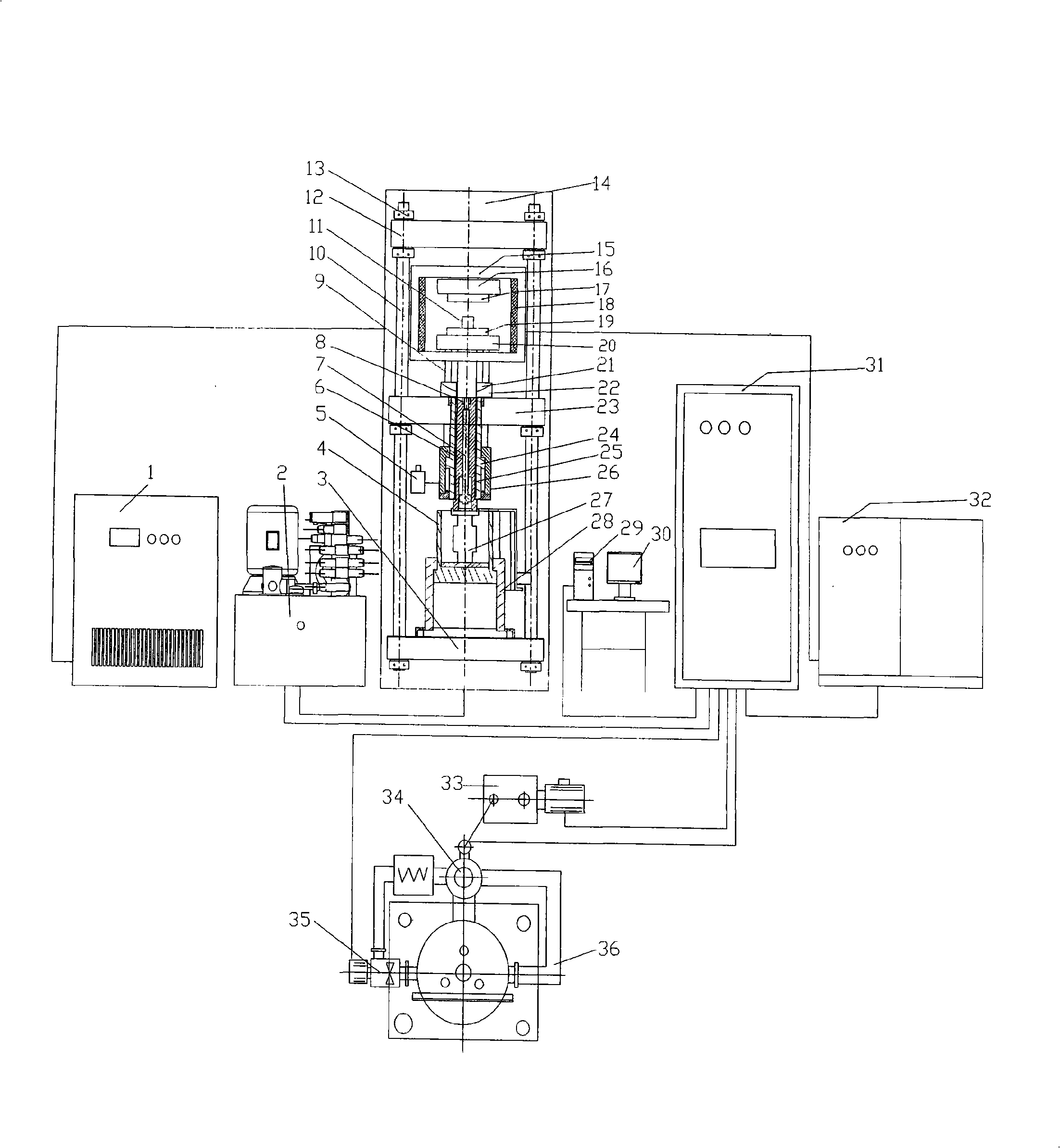

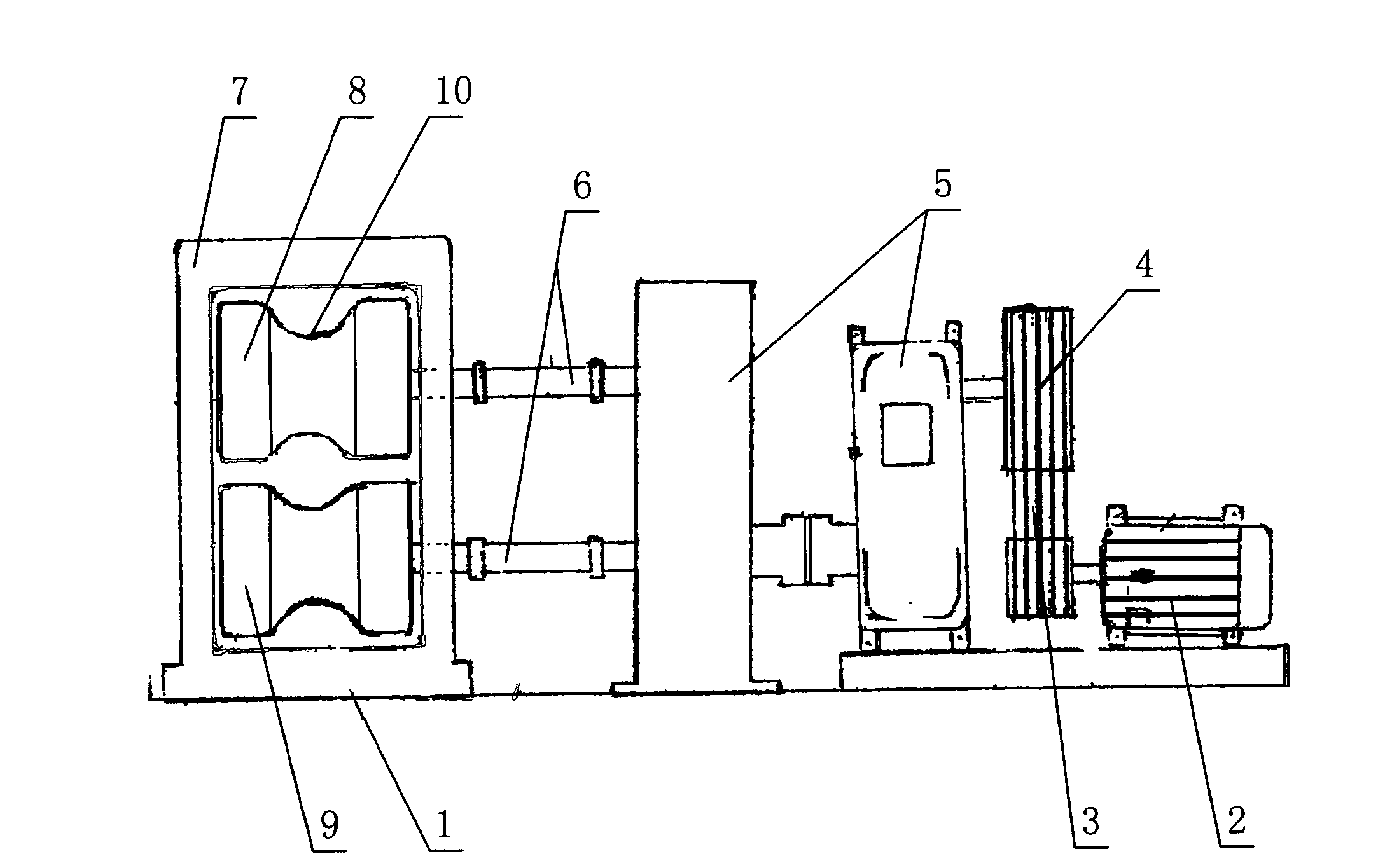

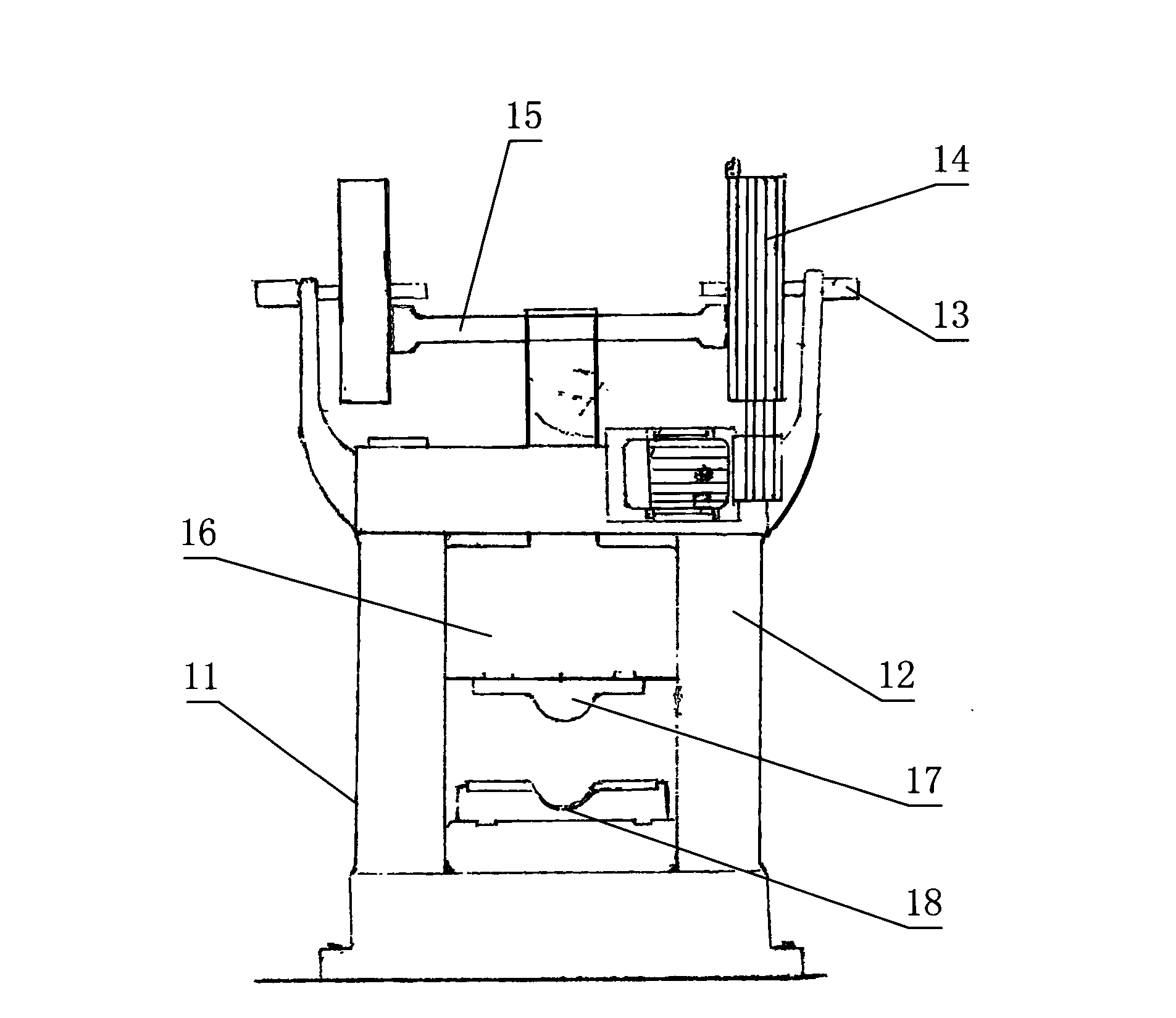

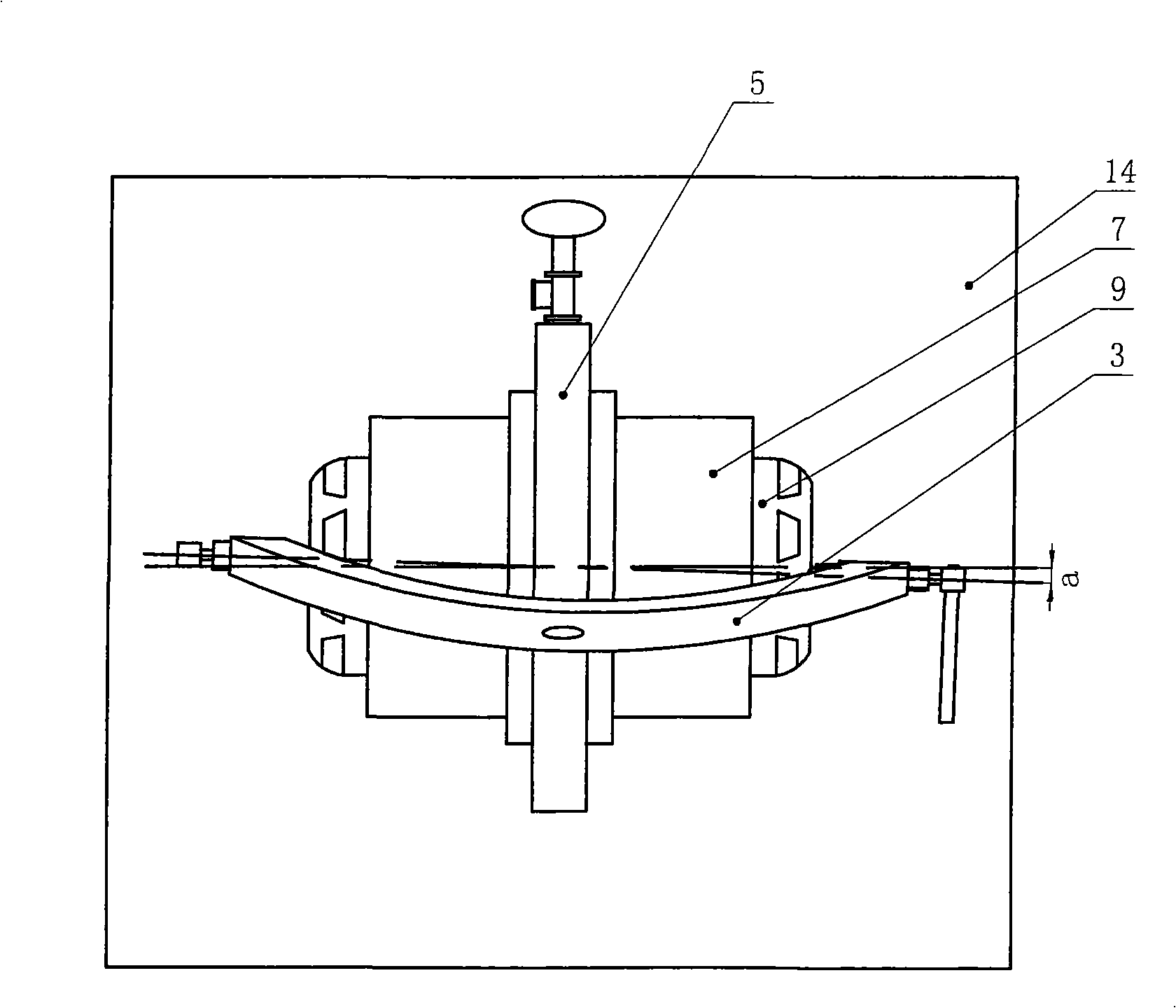

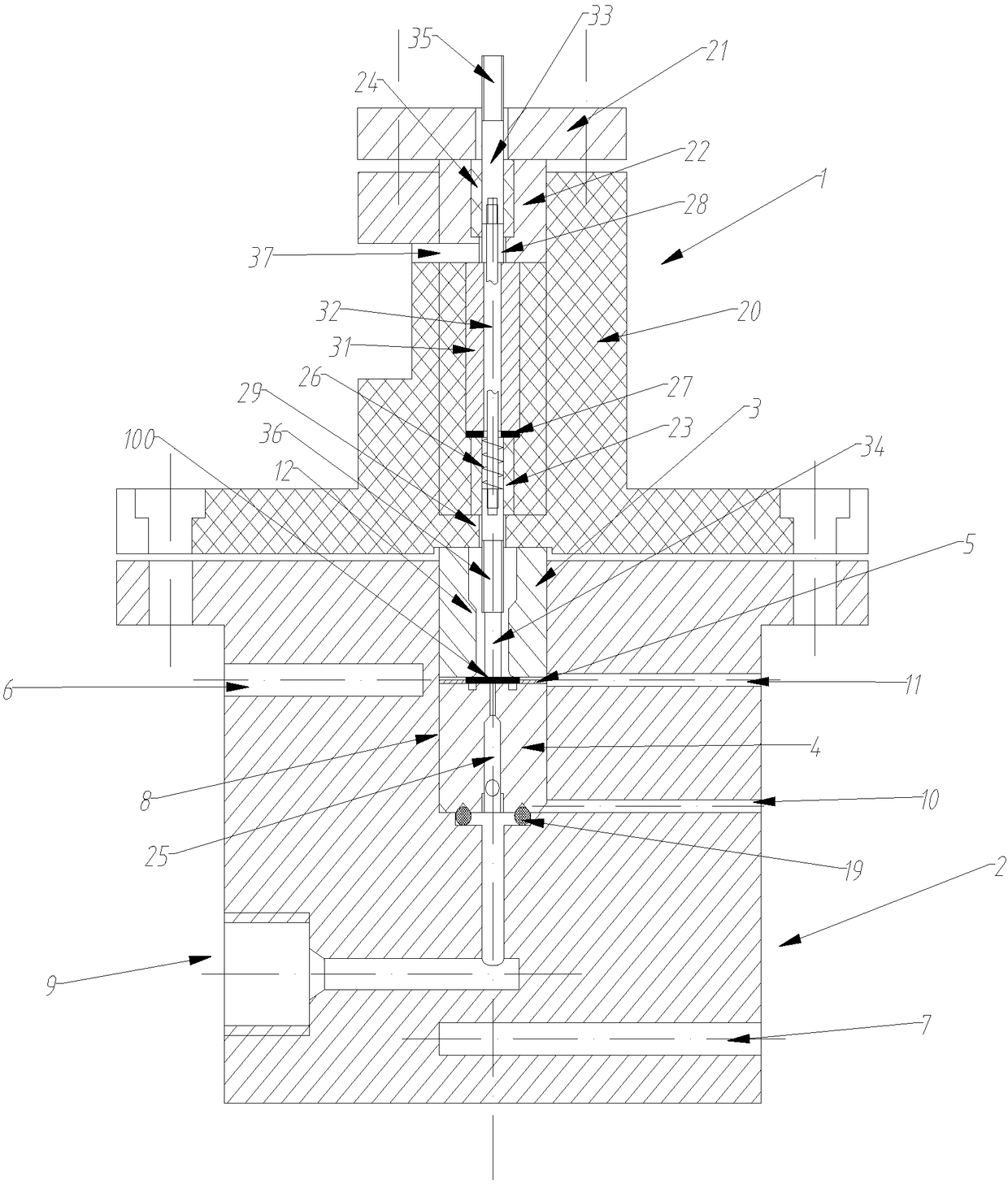

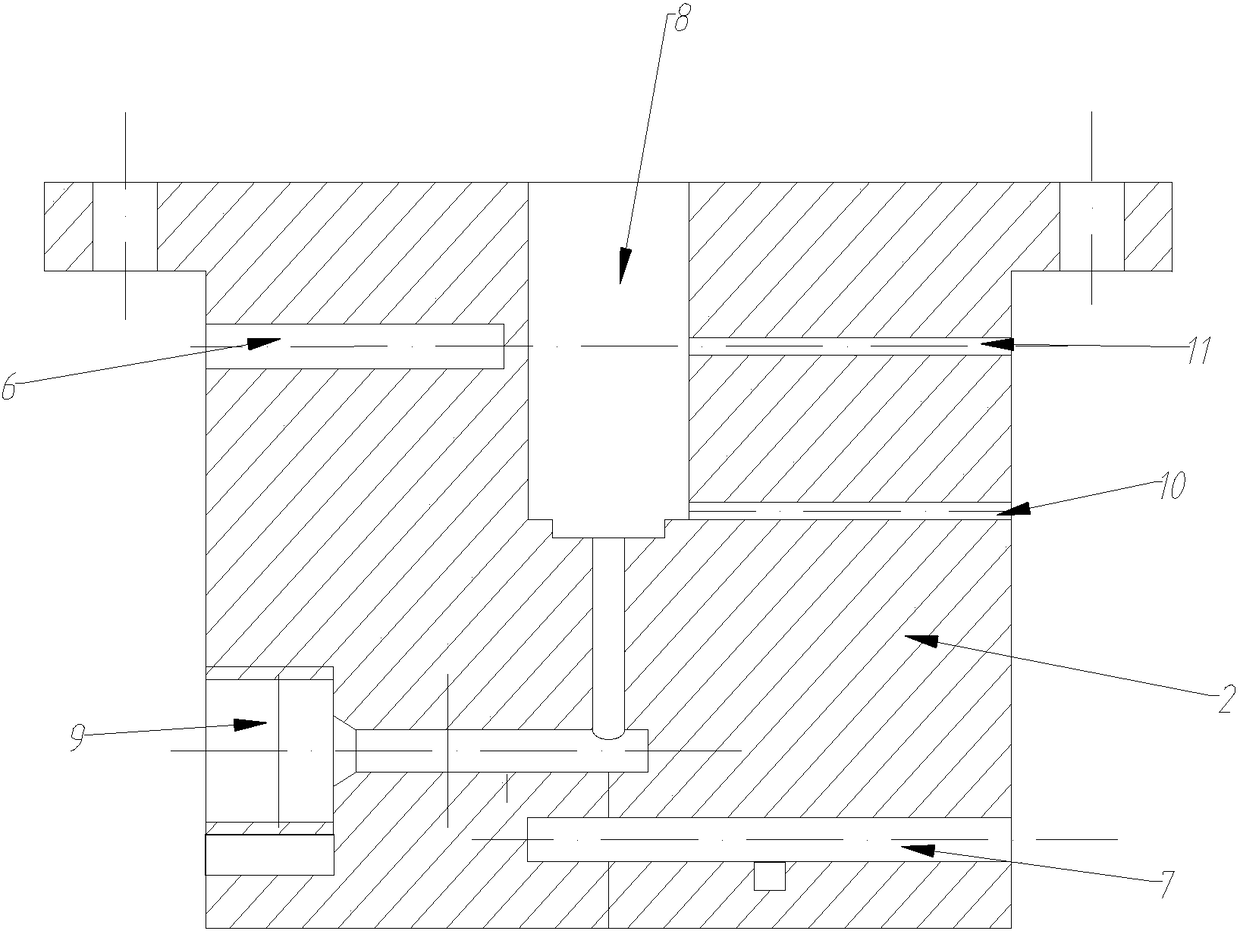

Tepid environment universal sheet shaping test machine

InactiveCN101290280AEasy to realize formability testUsing mechanical meansStrength propertiesWorking pressureControl system

The invention provides a device of performing various simulative forming performance tests to a panel under warm and vacuum state, consisting of a mechanical system, a hydraulic station, a heating furnace, a cooling system, a vacuumizing system and a detection control system. A host system adopts a three-beam four-column structure, the heating furnace not only guarantees vacuum inside the furnace during testing, but also heats a mould and a check bar; a force plug and a beading rod adopt moving seal with the bottom of the heating furnace to guarantee that the vacuity inside the furnace chamber is not reduced during actuating; the cooling system can guarantee that temperature of a furnace mantle, the force plug, the beading rod, an electrode and other positions do not rise along with the rising temperature inside the heating furnace; the detection control system is responsible for acquiring every parameter in a test and controlling the test to automatically perform at the same time. The device can complete a cupping test, a drawing test, a drifting test, a conical cup test, an earing test, a rigid die bulge test and so on under the room temperature of 1311 DEG C below zero and the working pressure with the vacuity reaching 10 <-3> Pa.

Owner:BEIHANG UNIV

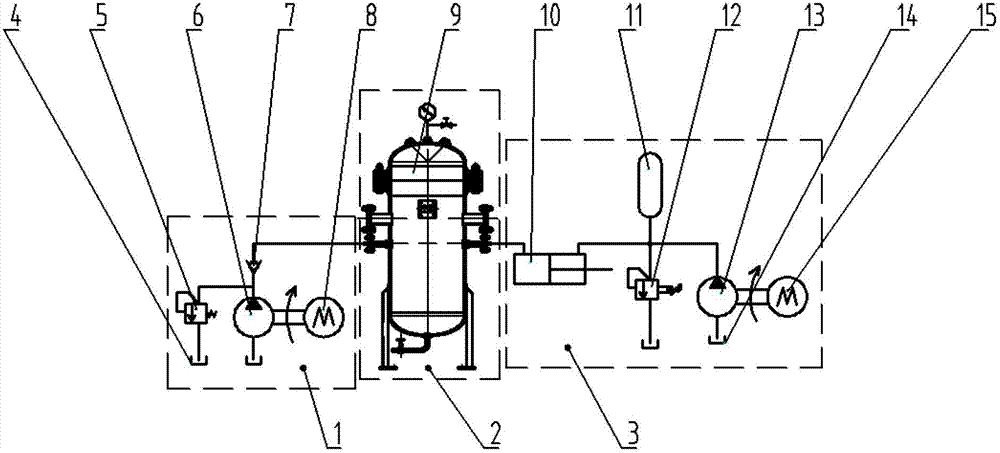

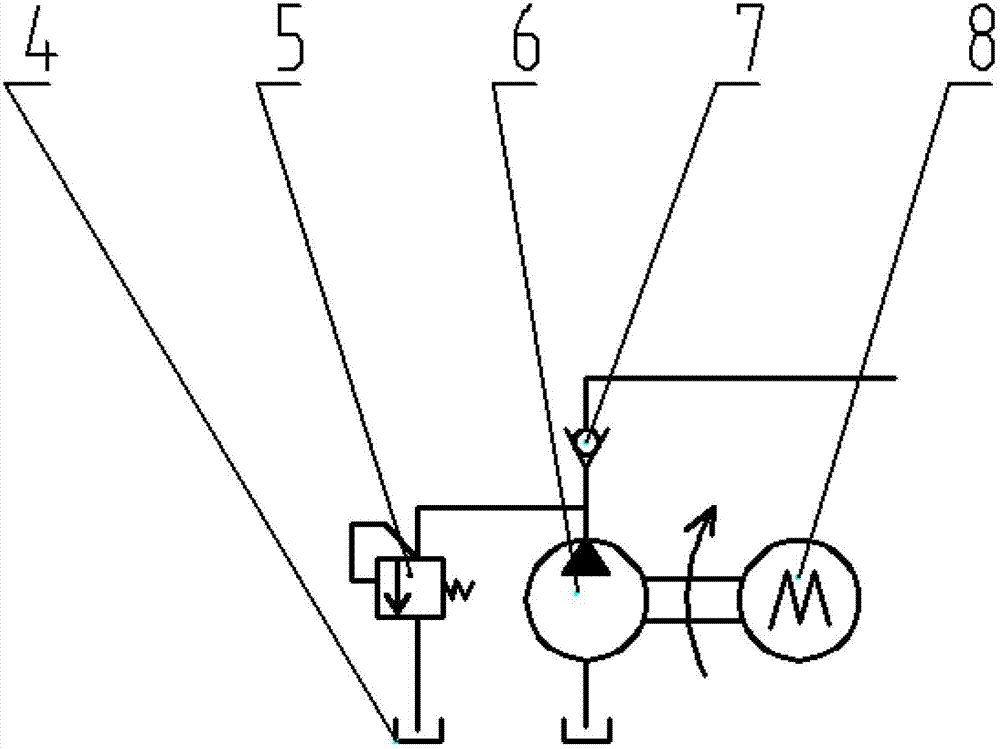

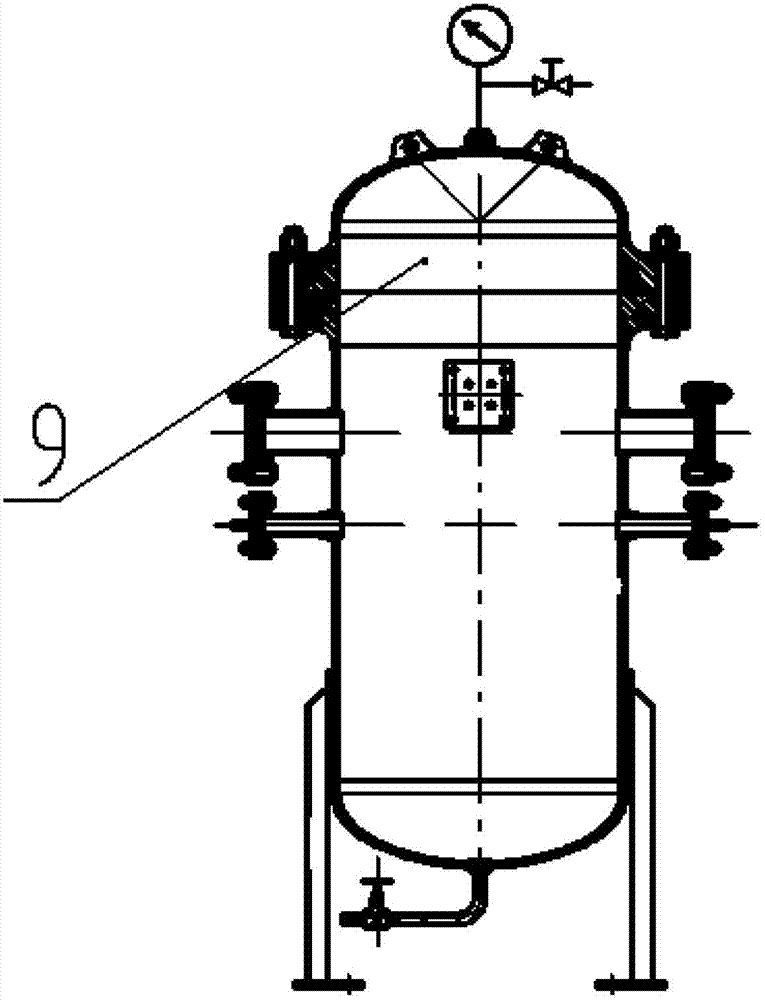

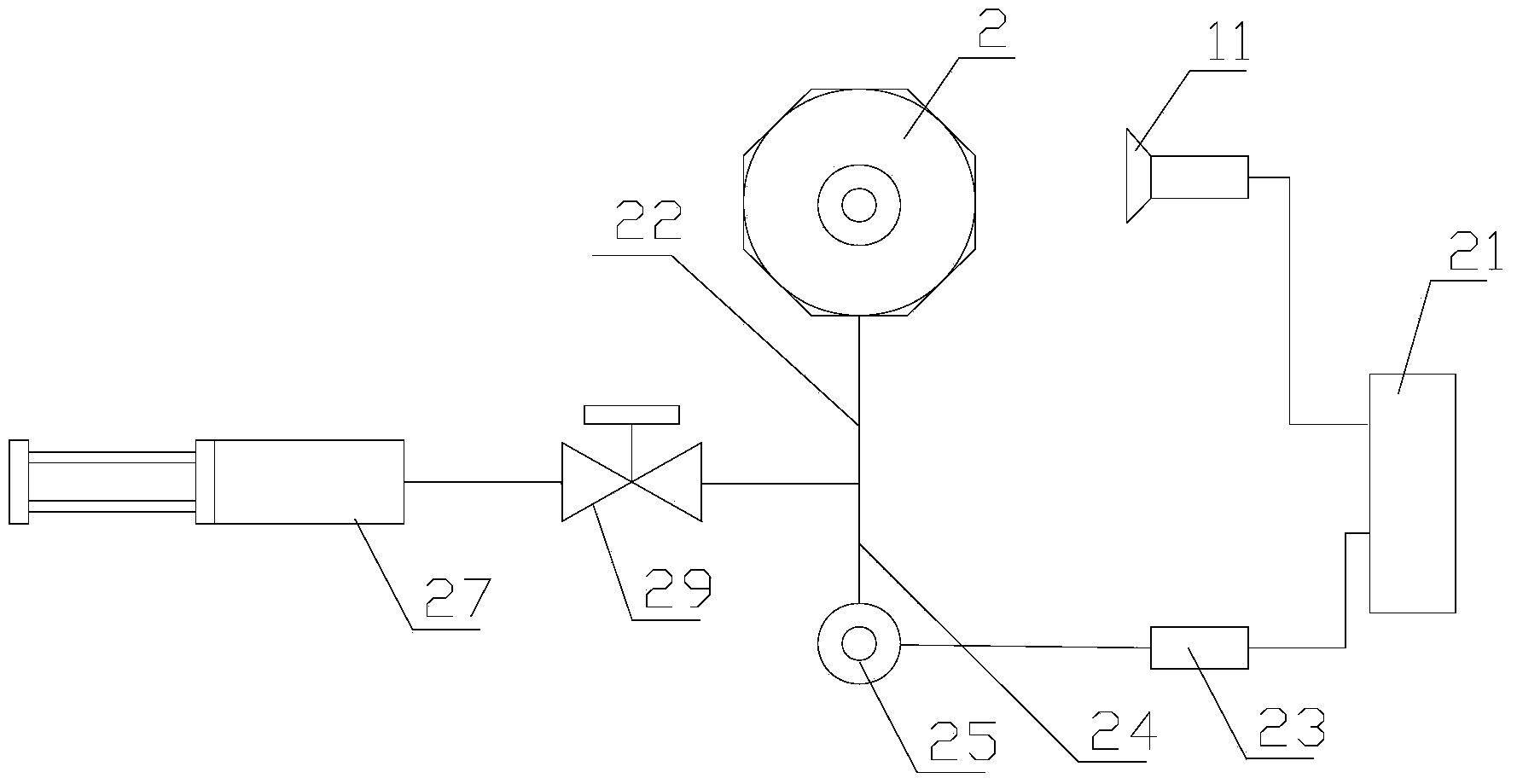

Volumetric capacity-variable constant-pressure maintenance device of pressure vessel

InactiveCN102927269AEasy to adjustEasy to operateFluid pressure control using electric meansPressure vesselsLoop controlEngineering

The invention aims at providing a volumetric capacity-variable constant-pressure maintenance device of a pressure vessel. The volumetric capacity-variable constant-pressure maintenance device comprises a pressurization system, a pressure vessel system and a volumetric capacity-variable constant-pressure maintenance system which are sequentially connected, wherein the pressurization system comprises a water tank and a pressure test pump; the pressure vessel system comprises a pressure vessel, and the pressure test pump is respectively communicated with the water tank and the pressure vessel; and a one-way valve is mounted between the pressure test pump and the pressure vessel, a pipeline communicated with the water tank is arranged between the pressure test pump and the one-way valve, an overflow valve is mounted on the pipeline, and the pressure vessel is communicated with the volumetric capacity-variable constant-pressure maintenance system. The volumetric capacity-variable constant-pressure maintenance device has the advantages that the occupied space is small, the bulge test of tested equipment by the pressure vessel is realized; the magnitude of pressure in the pressure vessel cannot change along with the volumetric change of the tested equipment; the change of volumetric capacity is realized through the movement of a piston, and accurate regulation can be performed; a close-loop control circuit is constituted, the pressure regulation speed is quick; and accurate constant pressure can be realized through the volumetric capacity-variable constant-pressure maintenance system; and the volumetric capacity-variable constant-pressure maintenance device is simple to operate and convenient to use.

Owner:HARBIN ENG UNIV

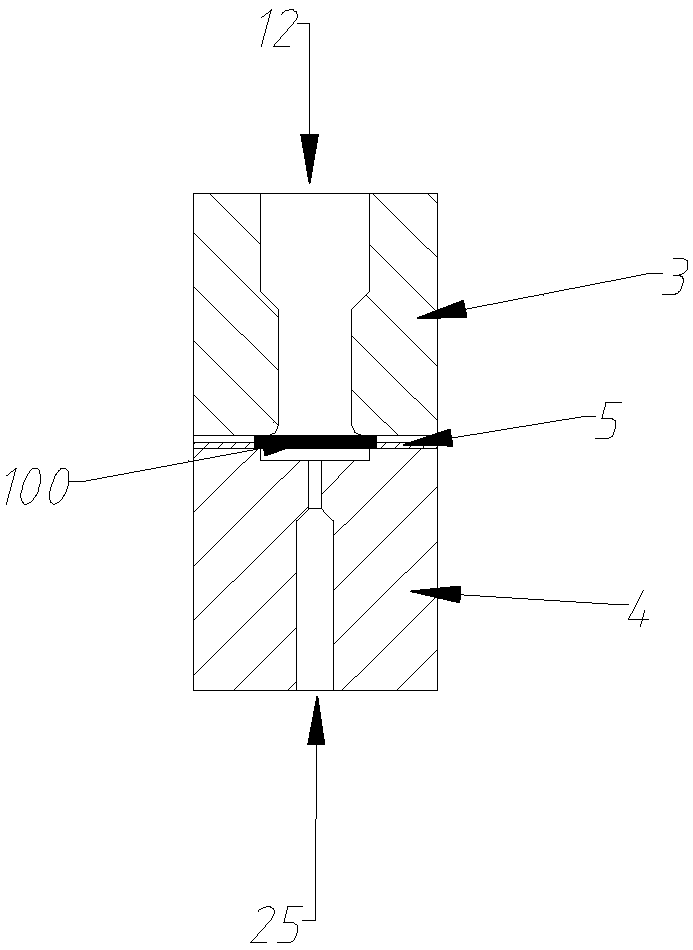

Test specimen hydraulic bulging test method and device

InactiveCN104344998AThe overall stress situation is simplifiedAccurately reflect the real forceMaterial strength using tensile/compressive forcesEngineeringScrew thread

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

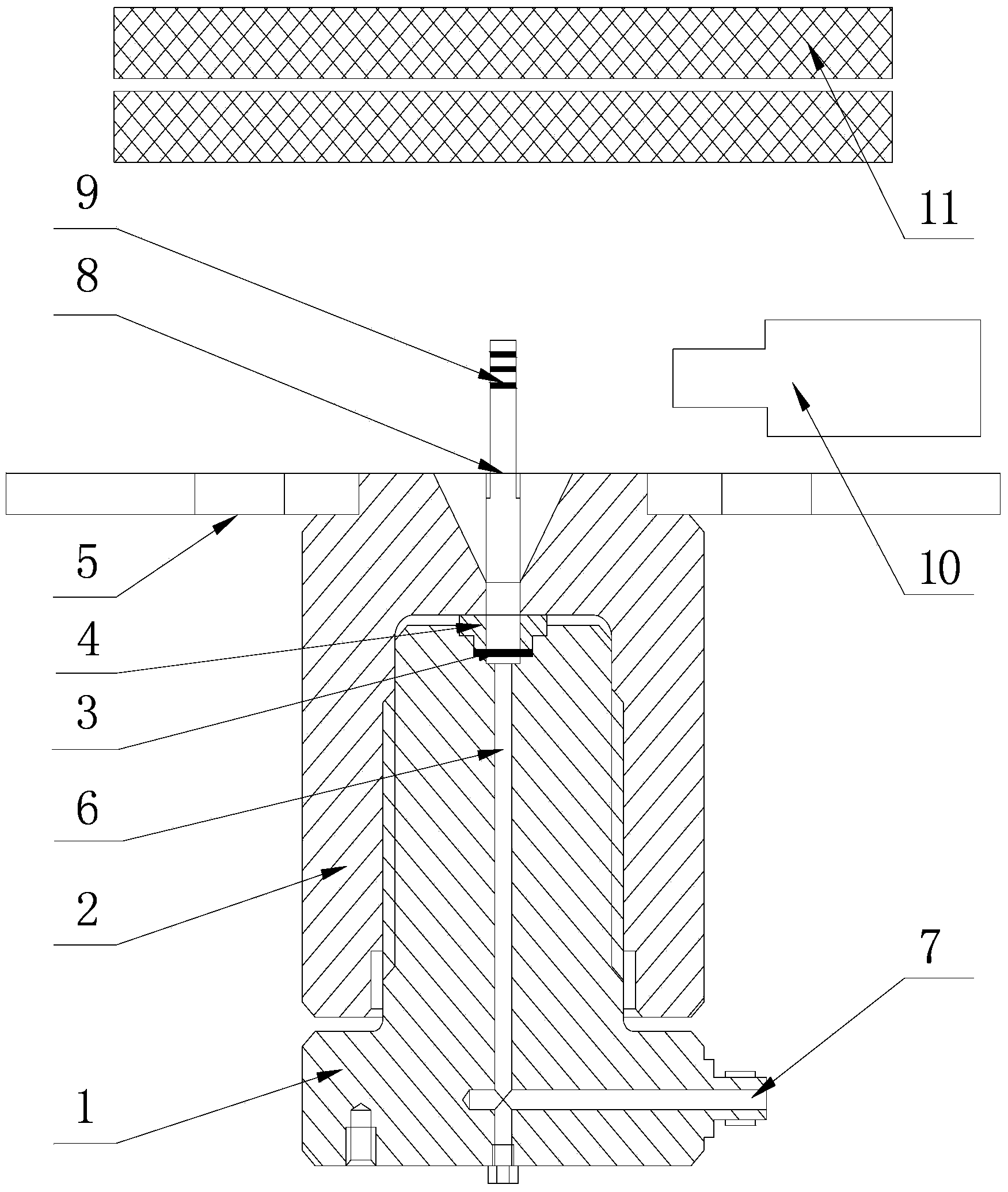

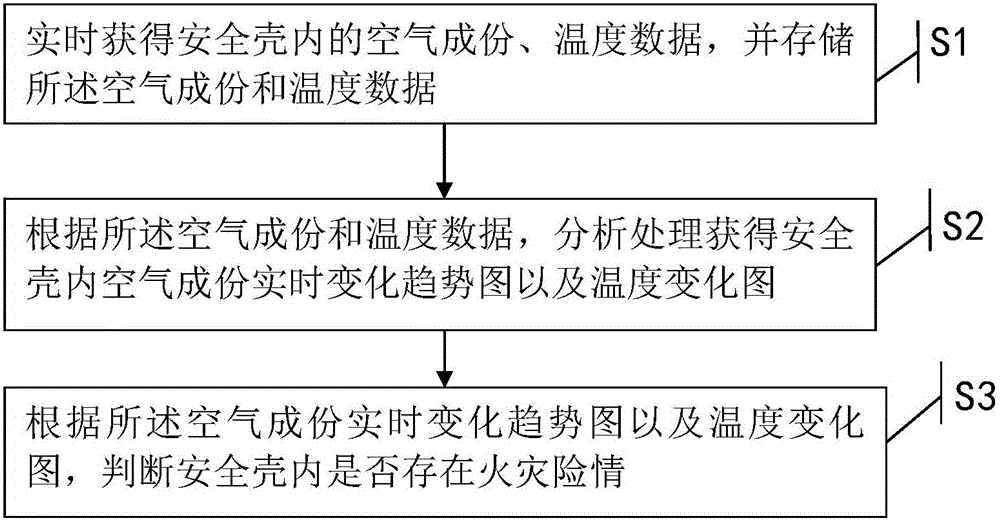

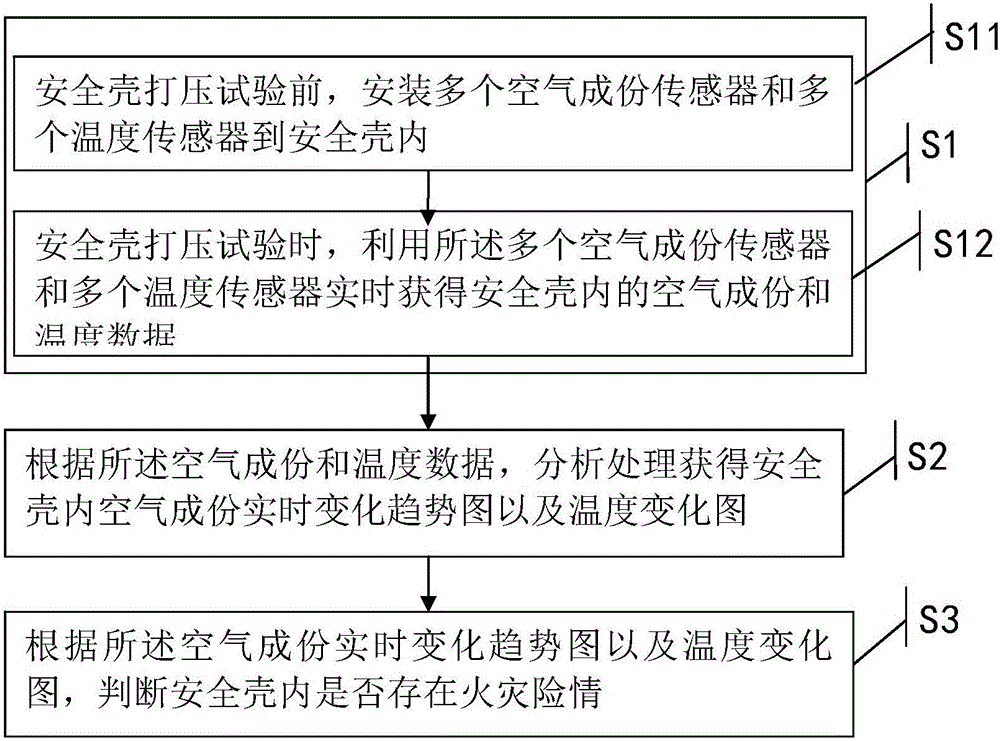

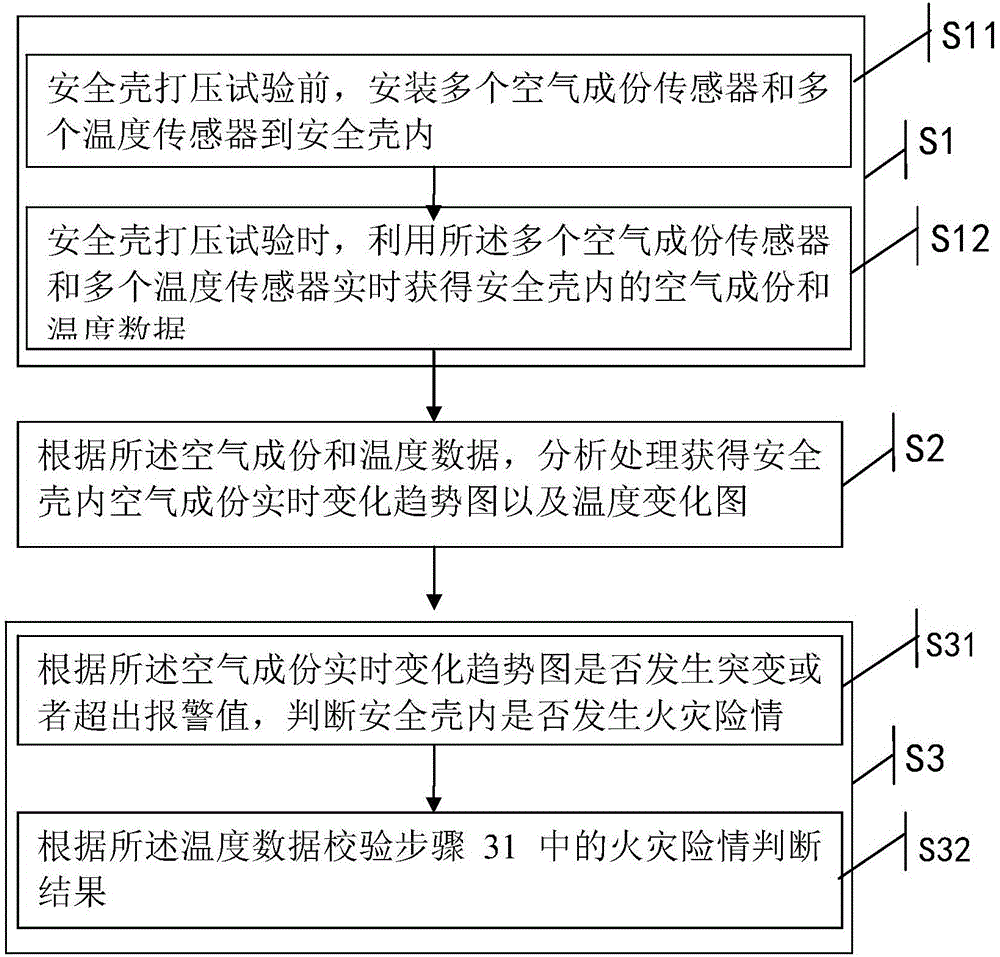

Fire monitoring method and system for containment vessel of nuclear power station during bulge test

ActiveCN105957293AImprove timelinessImprove accuracyNuclear energy generationNuclear monitoringNuclear powerDisplay device

The invention discloses a fire monitoring method and system for a containment vessel of a nuclear power station during a bulge test, and the system comprises an air component detection sensor which is used for obtaining the data of the air components in the containment vessel in real time; a data collection and processing module which is used for storing and processing the data of the air components, obtaining a real-time change tendency chart of the air components, and judging whether there is a fire danger happening in the containment vessel or not; and a monitoring display device which is used for displaying the real-time change tendency chart of the air components and the judgment result of the fire danger in real time. Through an air-sensitive resistor and a smoke sensor, the system can achieve the real-time monitoring of the interior of a nuclear island plant during the bulge test of the containment vessel, visually displays the temperature change at the nuclear island plant and the content variation tendency of each type of gas generated after burning, and timely judges the fire condition in the containment vessel. According to the technical scheme of the invention, the system is suitable for the bulge test of the containment vessel at a construction phase, and also can be used for fire monitoring a service phase during the bulge test of the containment vessel.

Owner:中广核工程有限公司 +1

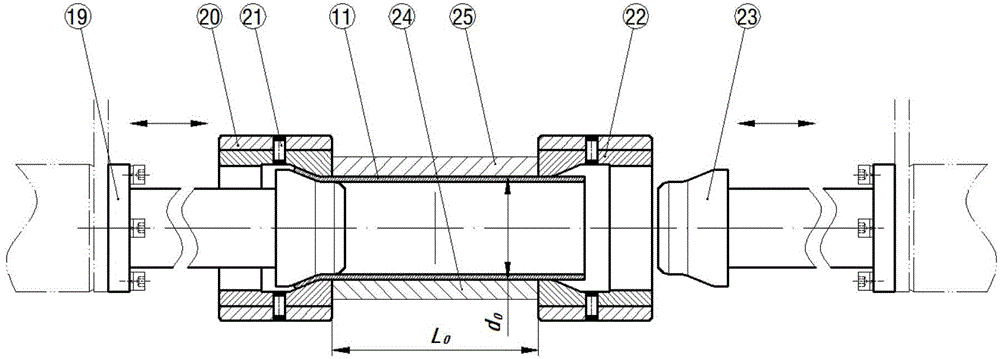

Pipe liquid filling bulging test method and device

InactiveCN104634665AMaterial strength using tensile/compressive forcesInternal pressureForming limit diagram

The invention discloses a pipe liquid filling bulging test method and device. The pipe liquid filling bulging test method comprises the following steps: restraining two ends of a test pipe, only releasing the freedom degree of axial movement of the test pipe, applying uniformly-increased hydraulic pressure p inside the test pipe, and synchronously applying equal force on the two ends of the pipe respectively until the pipe is broken; acquiring a real-time wall thickness t and a bulging height h of a highest point of the pipe in a bulging process; when the axial force can be used for rightly counteracting the acting force of internal pressure to the end surface of an inner cavity of the pipe, deducing an axial free bulging stress-strain curve and material parameters of the pipe by virtue of acquired bulging process data p, t and h according to a plastic theory. Pipe forming tests under different loading routes can be completed by applying different pulling force or pushing force at the two ends of the pipe so as to provide test data for the drawing of a pipe forming limit diagram. Embodiments show that a pipe bulging stress-strain curve and pipe stress-strain data with a relatively large strain range can be accurately acquired by using the method disclosed by the invention; and the test device and the pipe are convenient to disassemble and assemble repeatedly in expansion and bulging processes, and are good in implementation effect.

Owner:BEIHANG UNIV

Hydraulic pressure test method for PCCP pipeline

InactiveCN107436261AShorten the test cycleReduce temporary facilitiesMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesExhaust valveEconomic benefits

The invention belongs to the technical field of PCCP pipelines, and relates to a hydraulic pressure test method for a PCCP pipeline. The method includes the following steps: three-time joint bulge test; automatic exhausting of a high-point exhaust valve and manual exhaust of a valve welded in the three-way valve of a steel converter in the hydrostatic stage; hydrostatic test and recording of a test pipeline through a water injection technology. The novel hydraulic pressure test method for the PCCP pipeline shortens the test period, reduces temporary facilities and abandoned water and obtains great economic benefits in the application process.

Owner:SINOHYDRO BUREAU 11 CO LTD

Method for rapidly detecting surface formation defect of thin sheet

ActiveCN102095683AEasy to measureHigh speedUsing mechanical meansMaterial analysisSlip lineCommon cold

The invention relates to a method for rapidly detecting the surface formation defect of a thin sheet, belonging to the technical field of steel plate surface detection. The detection steps comprises the following steps: processing the thin sheet to be measured to sheet-like samples with a thickness identical to the shin sheet and a size meeting the requirement for a bulging test; cleaning the surface of the samples and drying; carrying out a rigid convex die bulging test to detect the surface formation defect, wherein different surface formation defects can be detected according to the different bulging depths because different bulging depths result in different deformation amount and different strain state of the thin sheet. The method has the advantages that the method not only can detect the surface formation defects of common cold plate, such as slip line, surface roughening and impurities, but also can detect the formation defects of Zn-plated plate, such as scaling and powderingof the surface Zn layer. In addition, the method is simple, and has high speed and high accuracy.

Owner:SHOUGANG CORPORATION

Processing method for rubber pipe

The invention discloses a processing method for a rubber pipe. The processing method comprises the steps that inner layer rubber, middle layer rubber and outer layer rubber are prepared through mixing of a mixing mill according to the formula; an inner layer rubber pipe is squeezed out through an extrusion machine, and the inner layer rubber pipe coats a soft core or hard core coated with a release agent; the middle layer rubber is pressed into a middle layer rubber sheet through a calendar, a separant is added, the middle layer rubber sheet is rolled, and the rolled middle layer rubber sheet is cut to prescribed width according to the technological requirement; a coppered steel wire or coppered steel wire rope is wound on the inner layer rubber pipe containing the pipe core on a winding machine or knitting machine, the middle layer rubber sheet is synchronously wound between every two layers of coppered steel wires or coppered steel wire ropes on the winding machine or knitting machine, and heads and ends of the winding steel wires are bound; the extrusion machine is coated with the outer layer rubber again, and then is coated with a lead or cloth vulcanization protection layer again; vulcanization is carried out through a vulcanizing tank or salt bath; and finally, the vulcanization protection layer is removed, the pipe core is pulled out, pipe connectors are buckles, and sampling is carried out for bulge test. Compared with the prior art, the method can provide the high-pressure rubber pipe which meets the user requirement.

Owner:TIANJIN TIANYU HOSE

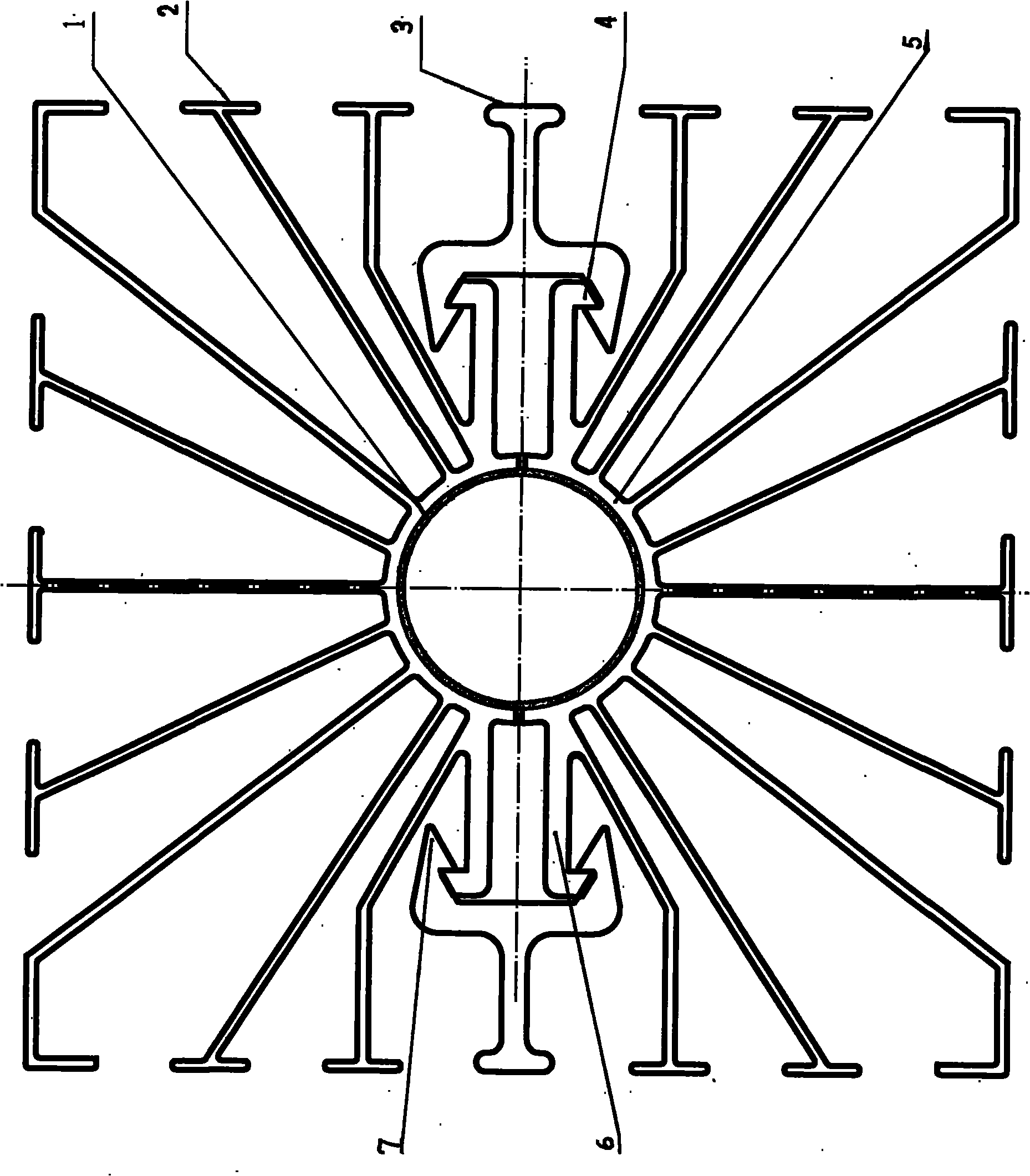

Modular stainless steel aluminum alloy radiator and manufacturing method thereof

InactiveCN101769690ANice appearanceLow costStationary conduit assembliesTubular elementsSteel frameMachine tool

The invention discloses a modular stainless steel aluminum alloy radiator and a manufacturing method thereof, aiming at achieving the purposes of low cost, high radiating efficiency and simple manufacturing process. The radiator comprises a header pipe, a vertical water pipe, radiating fins, locking bars, a radiating cover, a support frame, a decorative plate, a flow guide plate and a plug, wherein the two radiating fins are symmetrical in structure; each radiating fin respectively comprises a central semicircular pipe and radial fins with the semicircular pipe as the center; and the two radiating fins are combined to form the complete central circular pipe and the complete radial fins. In the manufacturing method of the radiator, the header pipe is punched and flanged, and the welding temperature is adjusted to 320-350 DEG C; a welding ring is sheathed on the vertical water pipe, a machine tool switch is turned on, and a tuner automatically enters a welding station; a clamping workpiece is inverted to be welded at the other end; wire rings are pressed into both ends of the header pipe on a press-mounting machine; a bulge test is carried out on a welded stainless steel frame; the radiating fins are oppositely buckled on the vertical water pipe; one locking bar is first arranged, and then the other locking bar is pressed in after the position of the first one is well adjusted.

Owner:山西正和机械制造有限公司

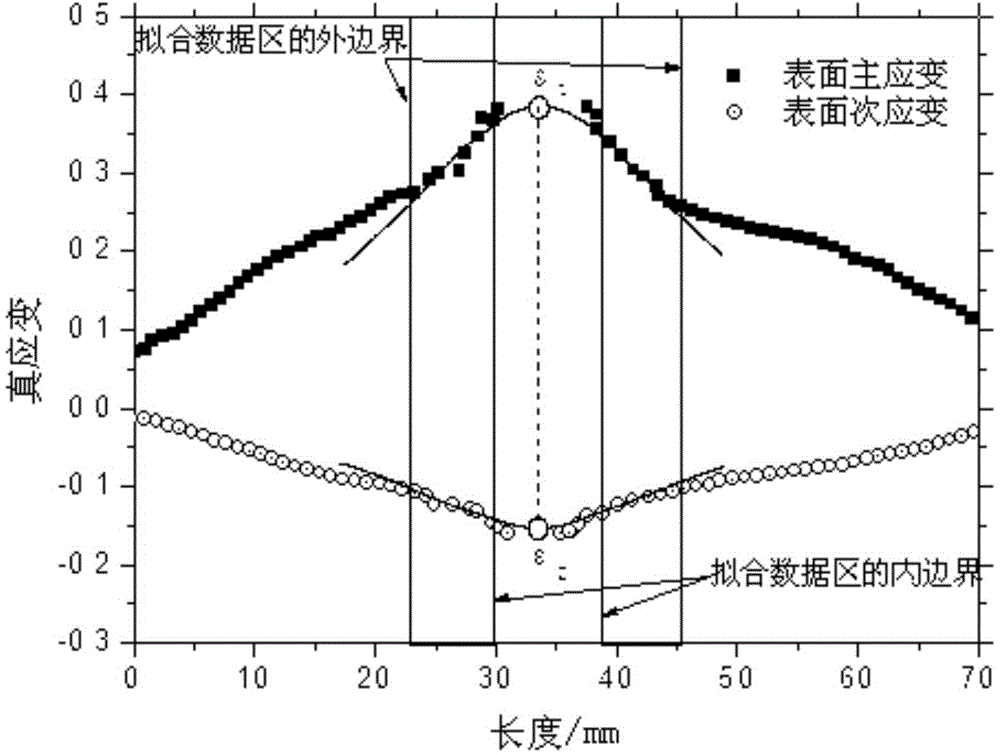

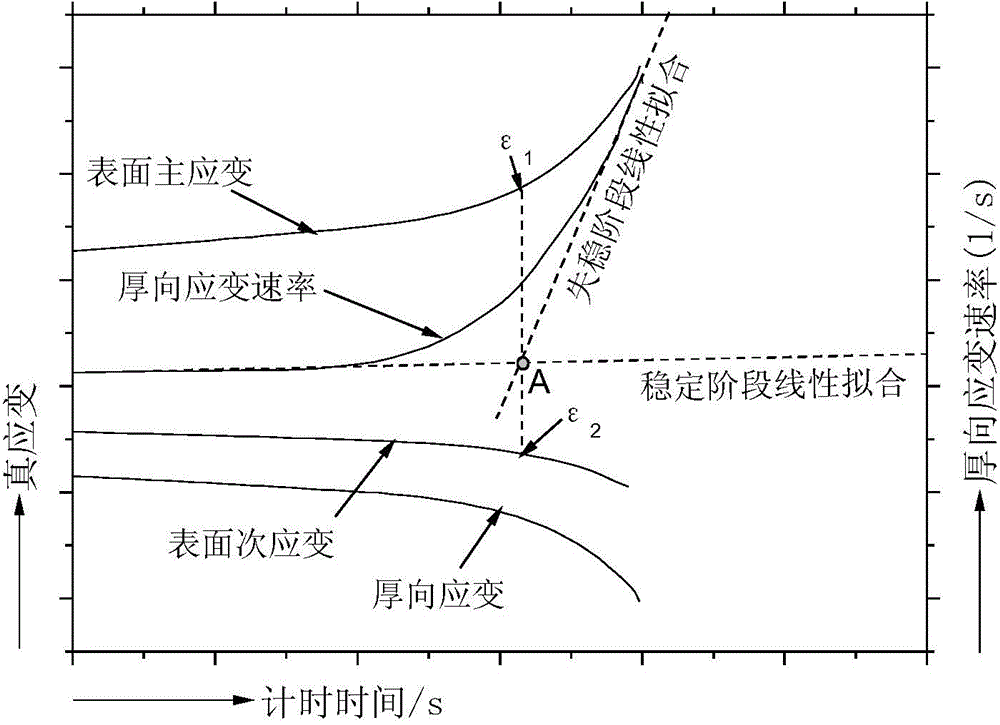

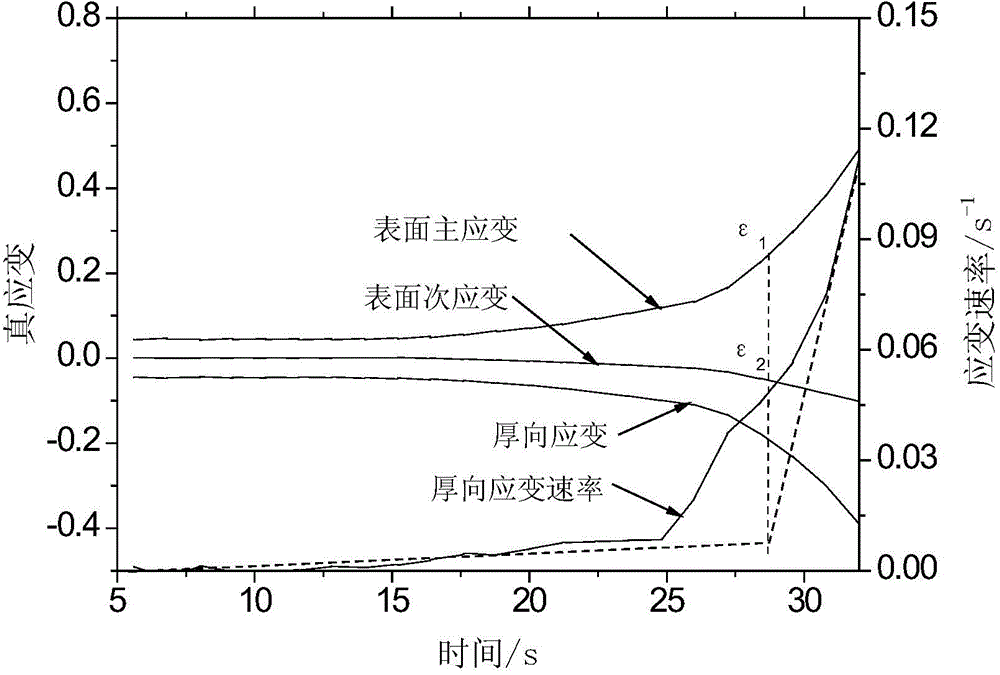

Time-based sheet forming limit determination method

The invention discloses a time-based sheet forming limit determination method and belongs to the technical field of stamping processes. The time-based sheet forming limit determination method comprises the following steps: establishing a steel ball die bulging test; performing the steel ball die bulging test on a sheet material, and shooting a bulging sample until the sheet material is broken; obtaining a previous frame of image of the sample which is just broken according to a shot photo, taking a breaking point as a center, and selecting a region near the part close to the breaking point as an inspection region; obtaining primary and secondary surface strain mean values of the inspection region; performing calculation to obtain primary thickness direction strain and thickness direction strain rate; and obtaining data at stable and instable stages according to the thickness direction strain rate, and comparing the data at stable and instable stages to obtain a forming limit point. The time-based sheet forming limit determination method is capable of really determining limit strain of just happened tightening or cracking to fully reflect in-situ deformation situation of an inspection point.

Owner:SHOUGANG CORPORATION

Method for measuring sheet metal deformation based on images

InactiveCN101520318APerfect data processingStrain Measurement ScienceUsing optical meansForming limit diagramData file

The invention discloses a method for measuring sheet metal deformation based on images, which adopts a multi-axis rotation and lifting structure, a CCD camera, an optical lens, and an image and data processing computer. The images of a sheet metal before and after deformation are shot and stored in the image and data processing computer to form data files; and a forming limit diagram and parameter information are acquired through a bulging test and a tension test respective to form standard data files. The method can store and analyze material performance in various aspects so as to screen spare sheet metals from various aspects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

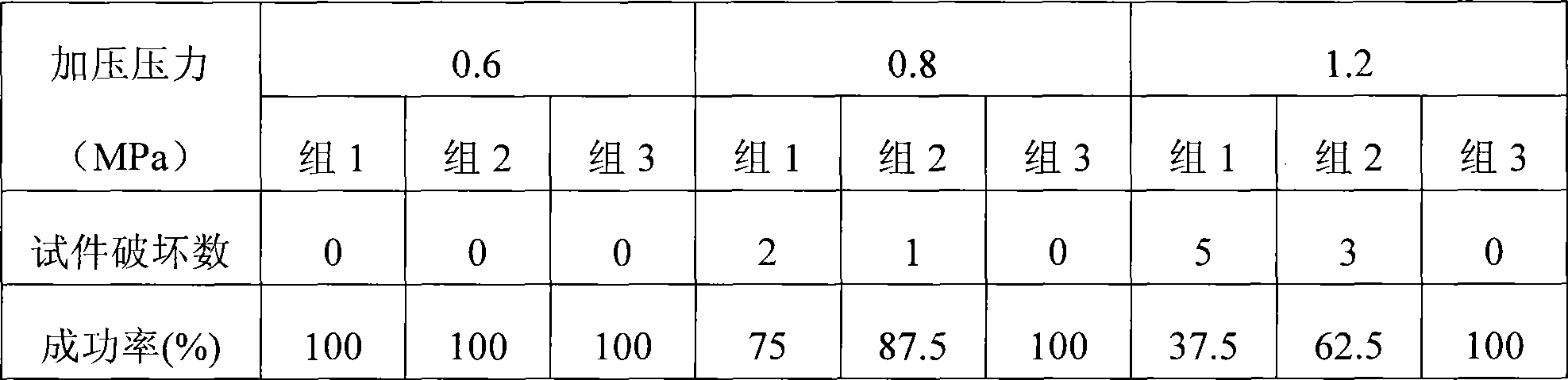

Concrete impervious test piece sealant

The invention relates to a sealant for a concrete impermeability test piece, which belongs to the technical field of building materials. The sealant for the concrete impermeability test piece consists of calcium base grease, talcum powder, bentonite, and kaolin according to the weight proportion of 1 to 0.25-0.8 to 0.15-0.4 to 0.15-0.4. Raw materials are fully stirred evenly according to the proportion and prepared into a paste form, then is evenly coated on side elevations of the concrete impermeability test piece, and the concrete impermeability test piece is loaded into an impermeability test mold and is subject to a bulge test by a cement impermeability tester. The sealant has the advantages that the sealant adopts a cold coating method to coat, has safe and convenient use and simple operation, ensures the sealing quality of the concrete impermeability test piece, and improves the success ratio and work efficiency of impermeability tests.

Owner:济南四建(集团)有限责任公司

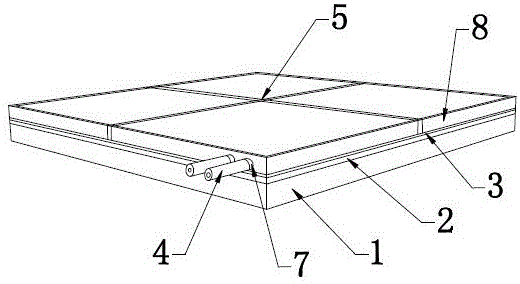

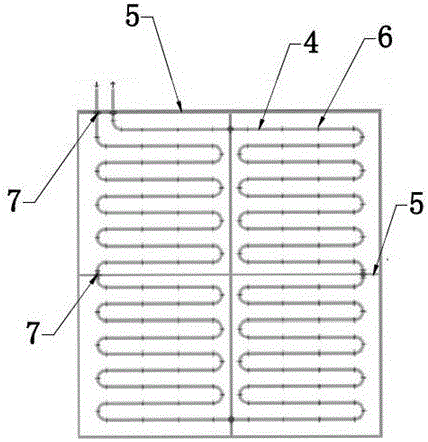

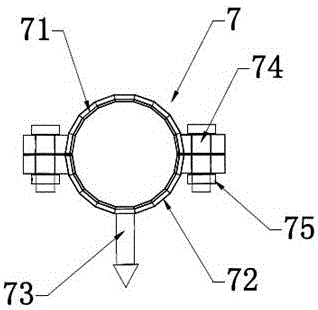

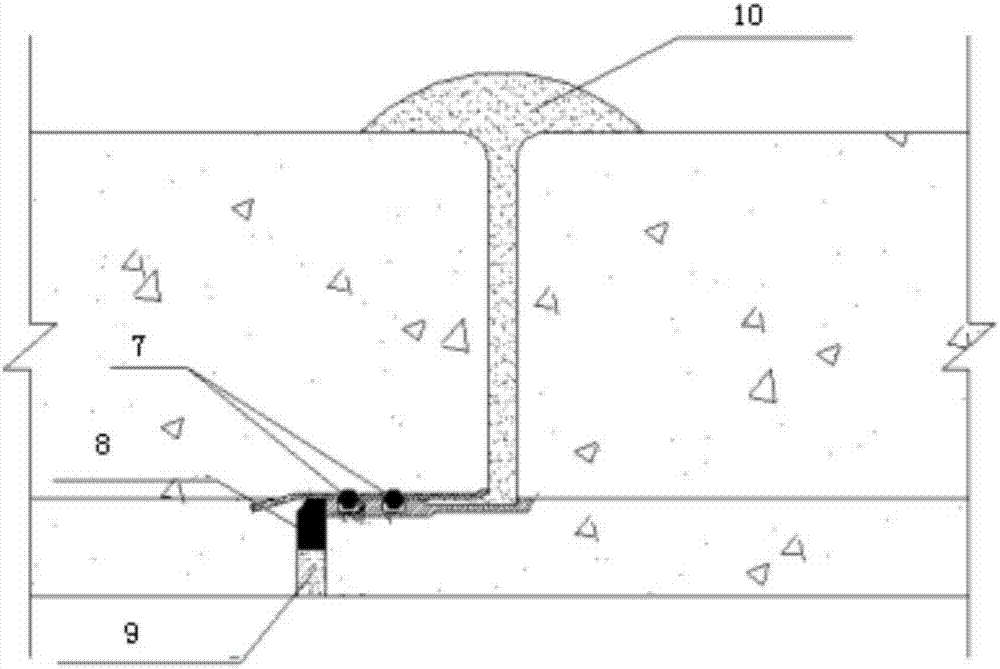

Pipe-embedding type underfloor heating construction method capable of preventing ground cracks

InactiveCN106760377AUniform temperatureAvoid cracking problemsCovering/liningsLighting and heating apparatusStructure of the EarthUnderfloor heating

The invention discloses a pipe-embedding type underfloor heating construction method capable of preventing ground cracks. The method comprises the following steps that firstly, construction preparation is conducted, specifically, a water heating pipeline arrangement diaphragm is drawn according to process requirements, a plan of the set position and number of expansion joints is made, and materials are prepared according to the arrangement diaphragm and the planned number of the expansion joints; secondly, surface clearing and leveling are conducted on a structural layer; thirdly, a heat insulating layer and a reflecting layer are laid on the structural layer sequentially; fourthly, a water heating pipeline is laid, then foamed polyethylene foam strips are mounted so as to form the underfloor heating expansion joints, and finally fixing clamps are adopted for fixing the water heating pipeline; fifthly, tap water is led into the water heating pipeline, and a water heating system is subjected to primary bulge test; a packing layer is poured on the reflecting layer; ground maintenance is conducted on the poured packing layer, and the water heating pipelines is subjected to secondary bulge test; and a water collector and a water knockout trap are mounted. The obtained pipe-embedding type underfloor heating construction method capable of preventing the ground cracks has the effects that the construction steps are simple, and the ground cracks can be effectively prevented.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

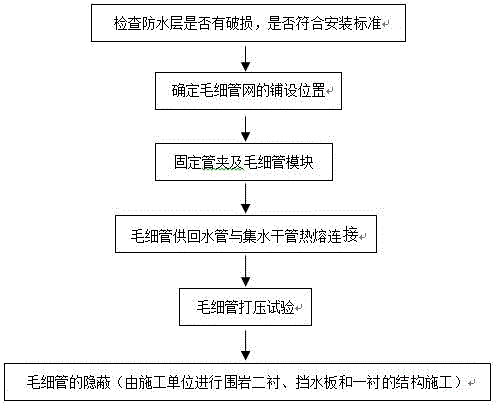

Capillary construction technology

InactiveCN101825331AQuick installationSolve the empty drum problemLighting and heating apparatusSpace heating and ventilation detailsEngineeringPre embedding

The invention discloses a capillary construction technology, comprising the following steps: (1) processing a top surface structure layer; (2) pre-embedding a head card; (3) fixing a capillary clamp and a net boom; (4) connecting a capillary main pipe and a system pipeline; (5) performing a bulge test; and (6) concealing the capillary. The capillary construction technology in the invention has simple operation, the concealment and fixation of the capillary net are easy, the firmness is good, the installation of the capillary can be finished rapidly, and the wall surface is beautiful after concealment of the capillary.

Owner:SHANGHAI LANDSEA PLANNING & ARCHITECTURAL DESIGN CO LTD

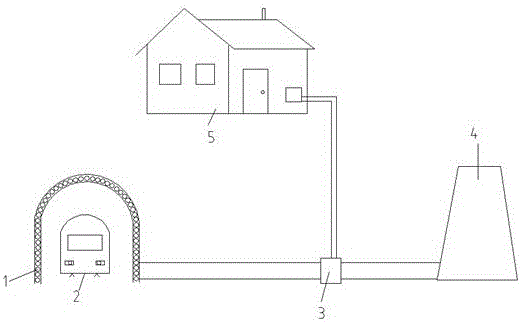

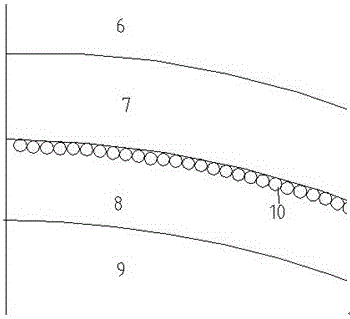

Construction method for mounting front-end capillary tube heat exchanger of subway tunnel heat pump

The invention aims to a construction method for mounting a front-end capillary tube heat exchanger of a subway tunnel heat pump. The construction method comprises the following steps: (1) checking whether a waterproof layer is damaged and whether the waterproof layer meets the mounting standard; (2) determining a laying position of a capillary tube network; (3) fixing a tube clamp and a capillary tube module; (4) enabling a water supplying and returning tube of the capillary tube to be in hot-melt connection with a water collection main pipe; (5) carrying out bulge test of the capillary tube; and (6) hiding the capillary tube and carrying out structure construction of a surrounding rock secondary lining, a water retaining plate and a primary lining by construction units. Compared with the prior art, through the process steps, the situation that the capillary tube is used as a front-end heat exchanger and is constructed in subways is solved; the method is simple, and is convenient to implement, rapid in construction progress, high in possibility of guaranteeing construction quality and excellent in construction effect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Manufacturing process of integrally forged and pressed axle housing without welding seam

InactiveCN103658502AOvercome oil leakageHigh densityRailway componentsVehicle componentsManufacturing technologyWeld seam

The invention provides a manufacturing process of an integrally forged and pressed axle housing without a welding seam, and belongs to the technical field of machinery manufacturing technology. The manufacturing process of the integrally forged and pressed axle housing without the welding seam comprises the steps that roll forging refining is carried out on a primary blank through a forge rolling machine, then a friction press is used for stamping a central pot, the central pot is loaded into a combined module, extrusion forming is carried out through a multi-head extruding machine, overall shaping is carried out through a comprehensive molding press, flanges and burrs are removed through an edge grinding machine, the combined module is taken out to finish the precision forging of the blank, the blank is placed into a normalizing furnace for aging normalization, flaw detection observation is carried out on the blank after the blank is cooled, cold pressing and correction are carried out on the blank, coarse cooling processing is carried out on the overall blank, quenched-tempered heat treatment is carried out, finish machining is carried out on the blank in all directions after cooling, a bulge test is carried out the blank, paint is sprayed on the blank, and the blank is packaged and put in storage. The manufacturing process of the integrally forged and pressed axle housing without the welding seam improves the quality of products, improves the rigid strength, compression resistance, fracture resistance and tenacity of the products, overcomes the defect of oil impregnation and leakage of welded axle housings and cast steel axle housings, and lightens the weight of products. By means of the process, production efficiency is largely improved, and production cost is largely lowered.

Owner:潘富荣

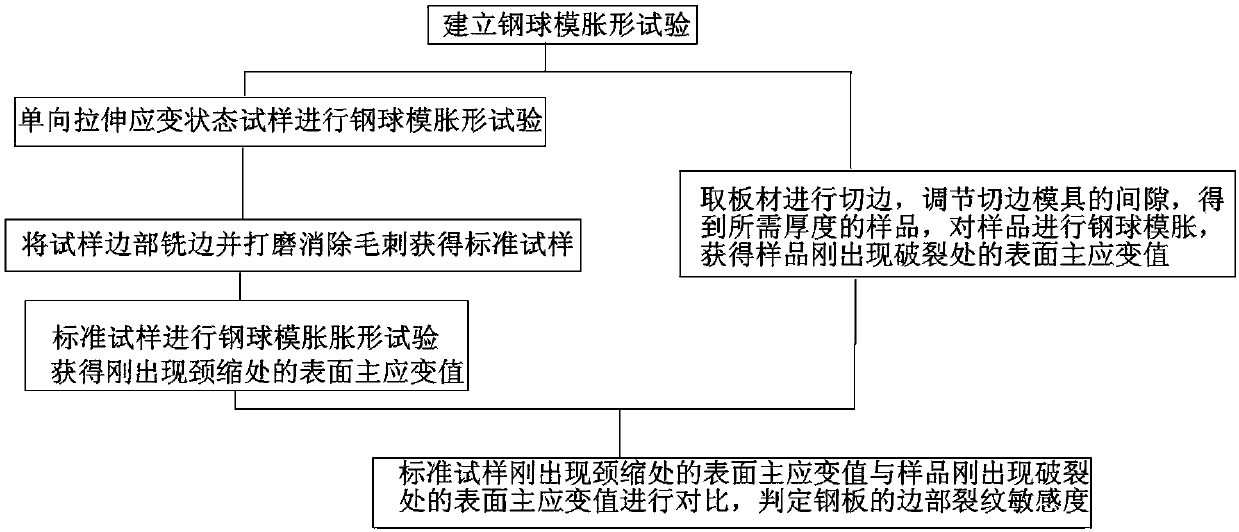

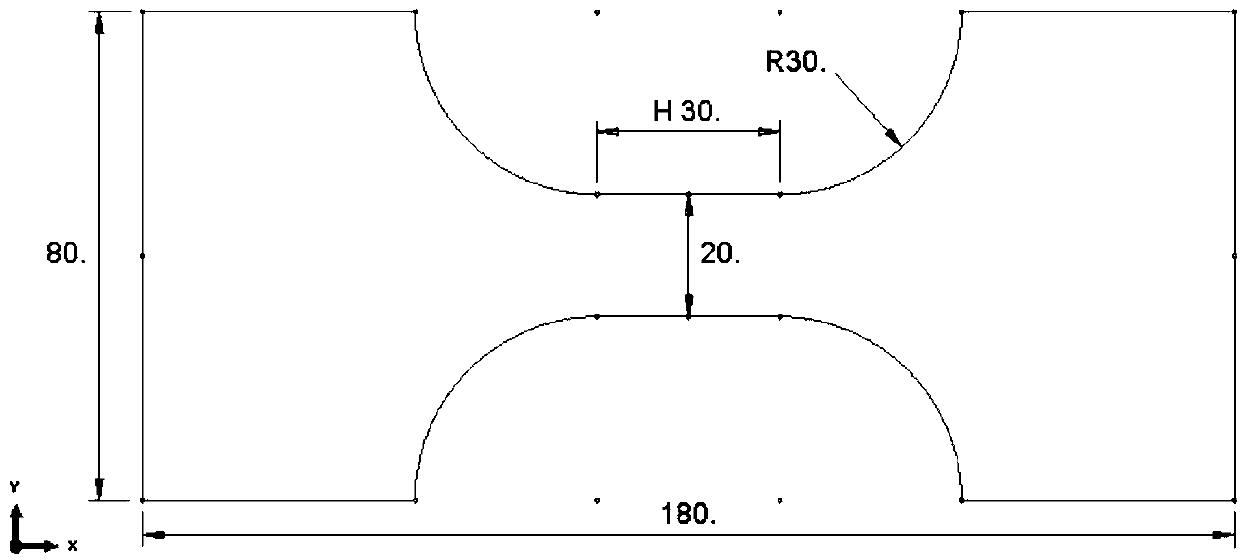

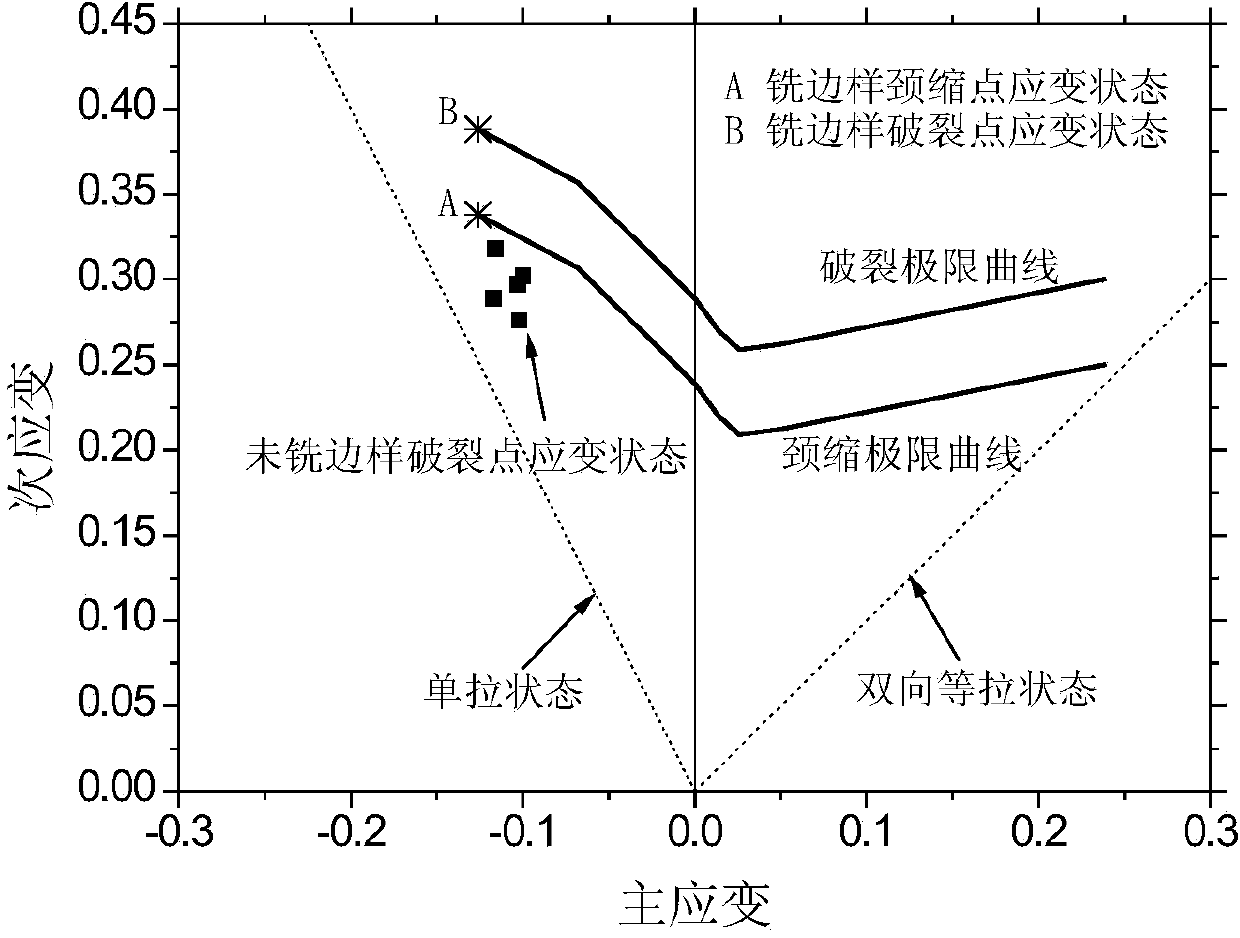

Method for evaluating sensitivity of edge crack of high-strength thin steel plate

The invention discloses a method for evaluating the sensitivity of an edge crack of a high-strength thin steel plate, belonging to the technical field of thin steel plate formability indexes. The method comprises the following steps: firstly, establishing a steel ball die bulging test; then performing the steel ball die bulging test on a test sample in a one-way tensile strain state; then, carrying out edge milling on the edges of the test sample and polishing to remove burrs to obtain a standard test sample; afterwards, performing the steel ball die bulging test on the standard test sample to obtain a surface main strain value of a part in which necking just appears; trimming a plate, and carrying out steel ball die bulging on the sample, thereby obtaining a surface main strain value of a part, in which cracking just appears, of the sample; and finally, comparing the surface main strain value of the part, in which necking just appears, of the standard test sample with that of the part, in which cracking just appears, of the sample, thereby judging the sensitivity of the edge crack of the steel plate. The sensitivity of the edge crack of a material can be accurately evaluated by the method provided by the invention.

Owner:SHOUGANG CORPORATION

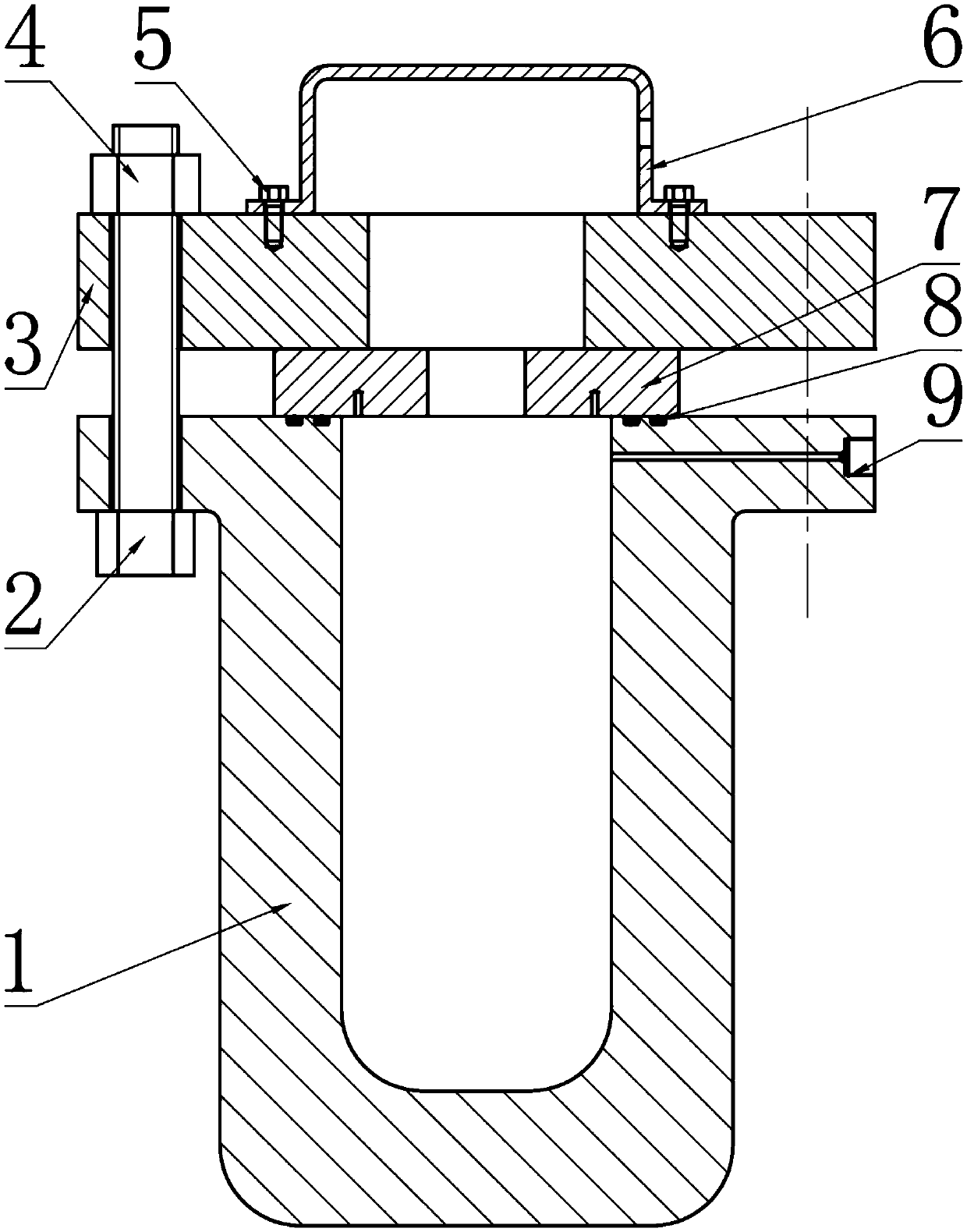

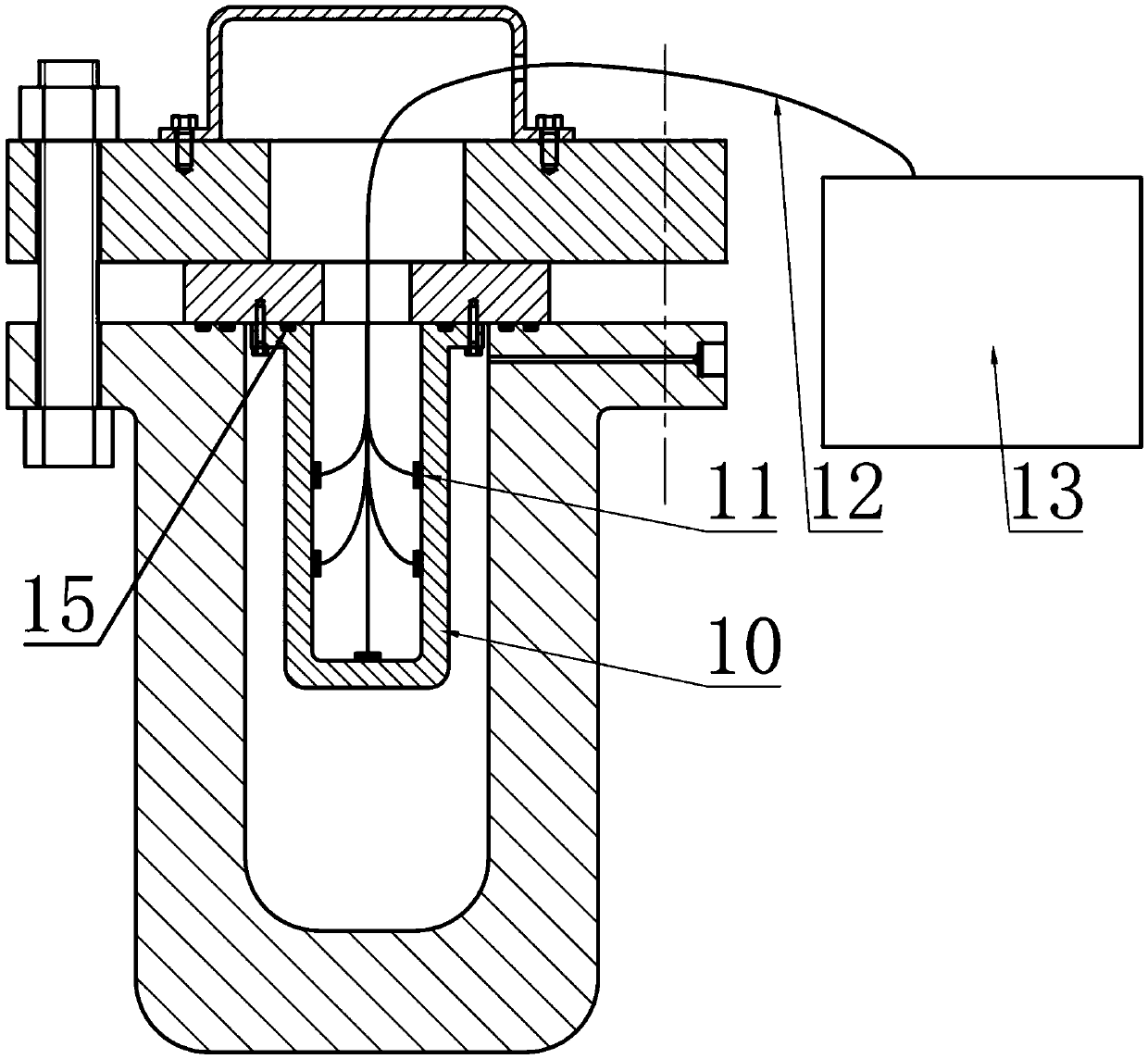

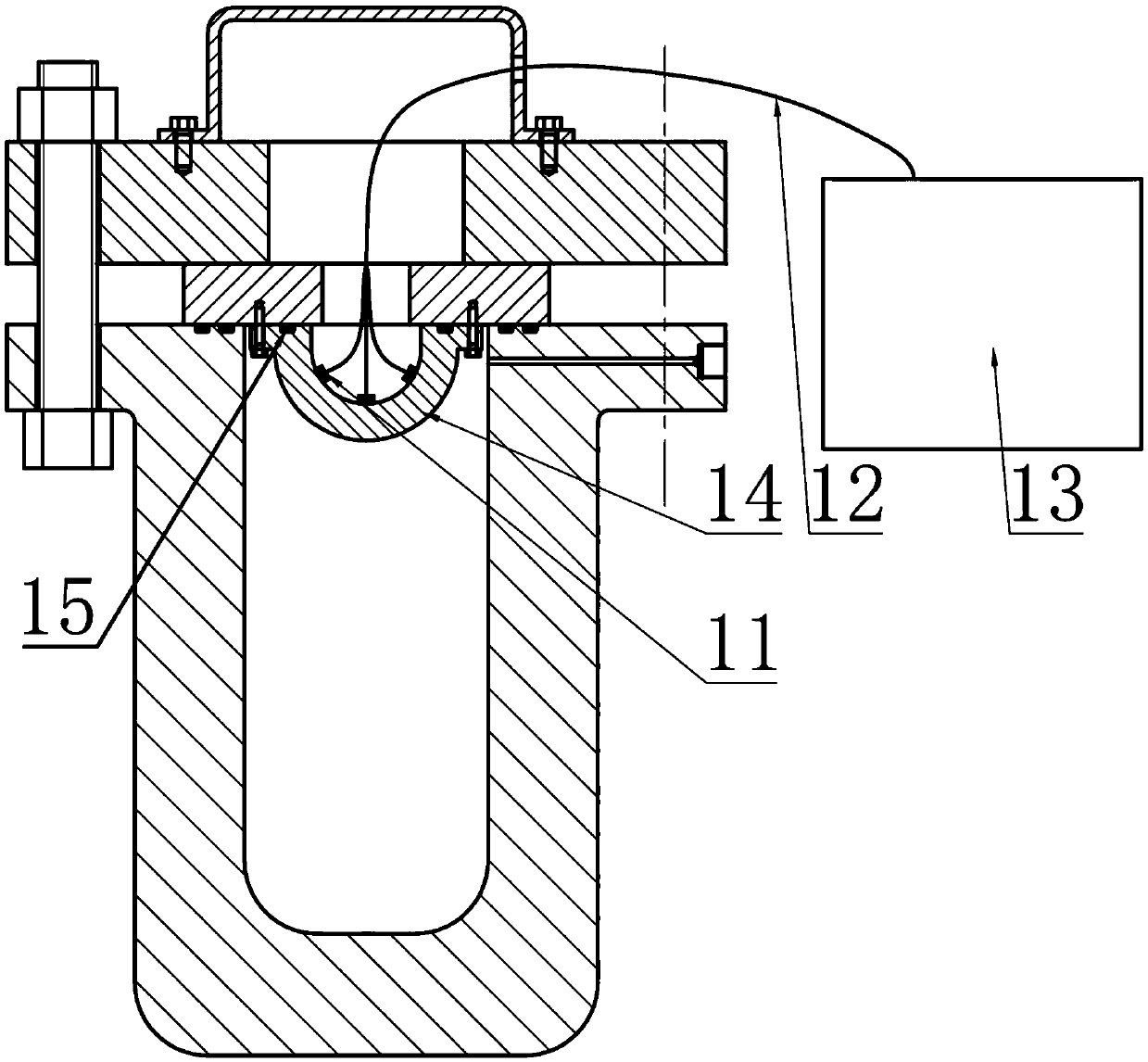

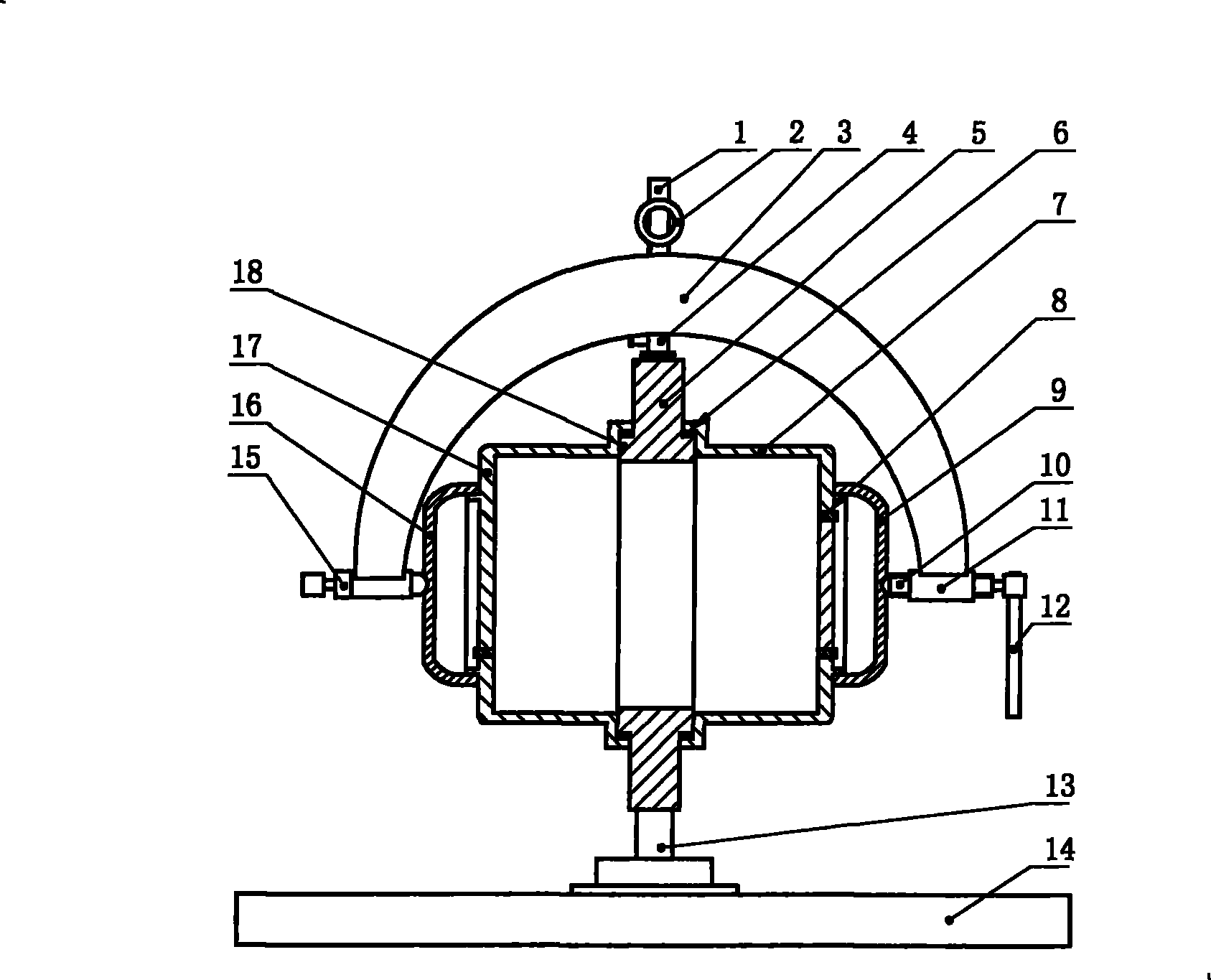

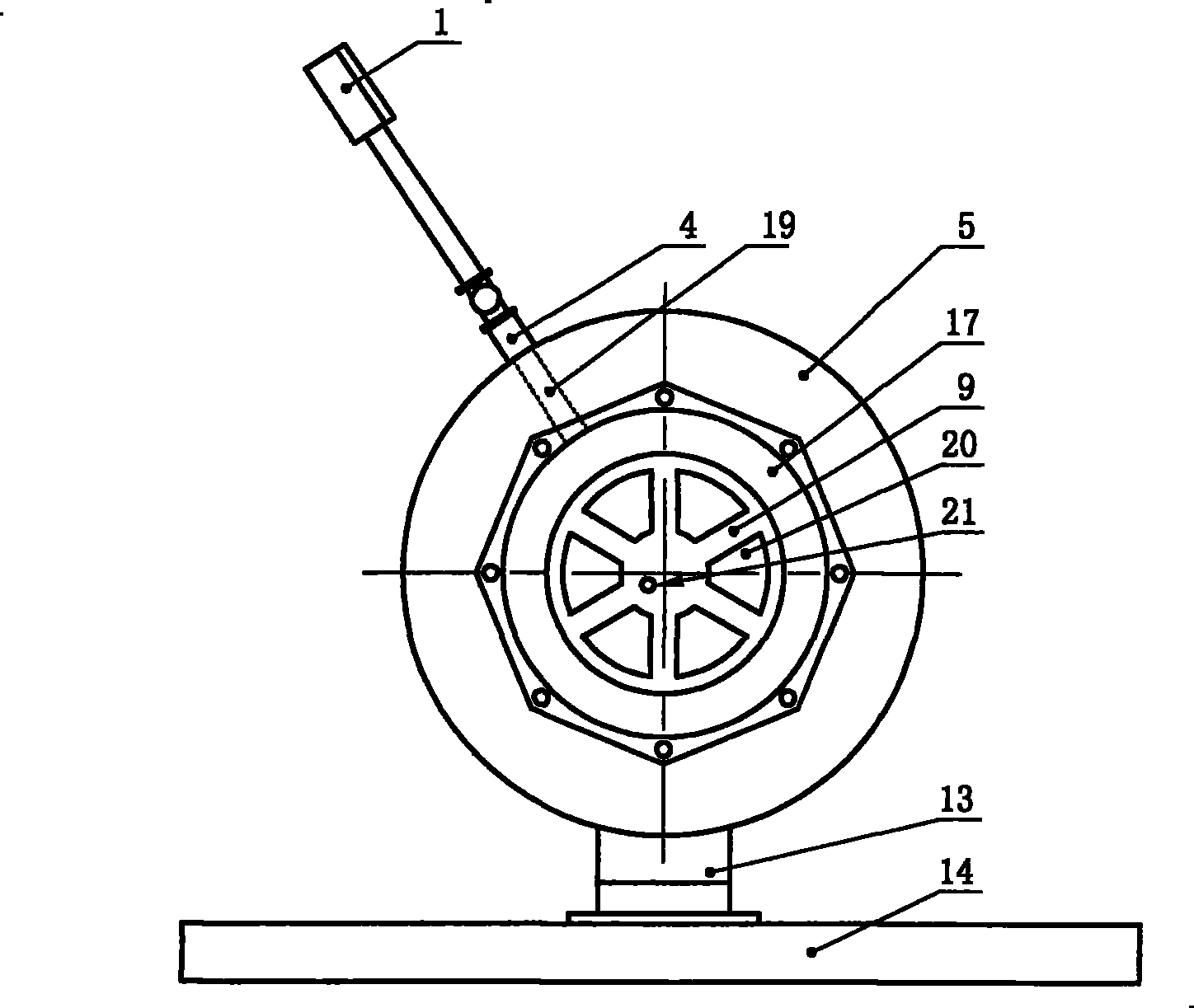

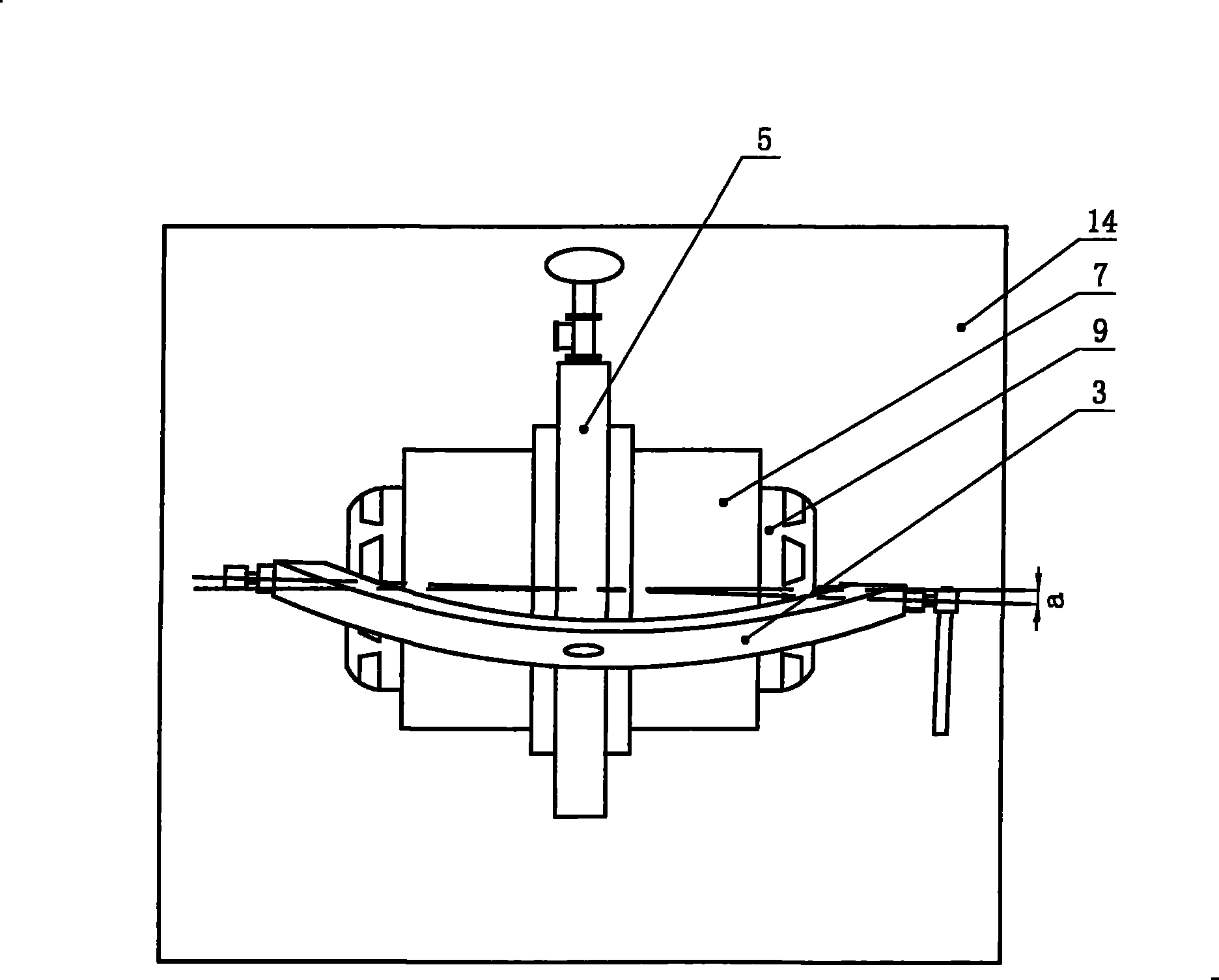

Hyperbaric cabin device for external pressure test of pressure container model

InactiveCN105571952AEasy to measureRealize the protection functionMaterial strength using tensile/compressive forcesEngineeringPressure vessel

The invention discloses a hyperbaric cabin device for an external pressure test of a pressure container model. The hyperbaric cabin device mainly comprises a hyperbaric cabin barrel, an annular pressure container fixing disc, an annular hyperbaric cabin cover and a protective cover which are coaxially arranged from bottom to top. The device can carry out an external bulge test on the pressure container model. The device can conveniently measure the strain of the inner wall of the pressure container model, the leakage problem caused when watertight sensing parts, sealing rings and the like are adopted for strain measuring in the prior art is avoided, in this way, the inner wall of the pressure container model directly makes contact with the exterior, further expansion can be achieved on the basis, and multiple kinds of data, such as pressure, temperature and displacement, needed for tests are measured; the protective cover can protect testers during conquassation of the pressure container model, and the hyperbaric cabin device with multiple pressure grades can be obtained by designing the structural sizes of the cabin barrel, the cabin cover, bolts and nuts.

Owner:ZHEJIANG UNIV

Caulking construction method for PCCP connector

The invention discloses a caulking construction method for a PCCP connector. The caulking construction method includes the physical recovery and repair process and a double-component polysulfide sealant repair process. Large water delivery projects adopting PCCPs are increased day by day, and PCCP prestress concrete pipes of the large water delivery projects have beneficial effects not capable of being replaced by other concrete, wherein the beneficial effects mainly include the large pipe diameter, the long laying distance and the like. While for the prestress concrete pipes, in the construction process, pipe seam connection becomes the key link of the project quality. It is found in the third-time bulge test conducted on the connector after pipeline backfilling that the phenomenon that the pressure value is decreased happens to part of prestress concrete pipeline connectors, and the design requirement is not met. If pipe replacement is conducted and backfilling is conducted again, cost is high and the process is complex. The caulking construction method for the PCCP connector is put forward, and the situation that the third-time bulging is not qualified is eliminated. Cost is saved, operation is easy, and the pipe opening quality is reliable after caulking.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

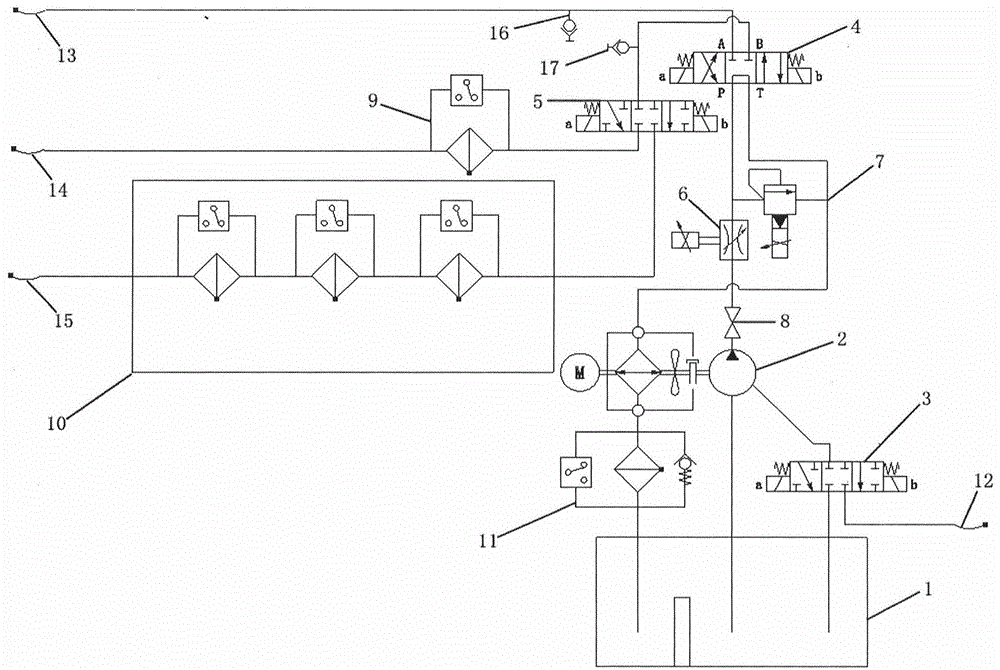

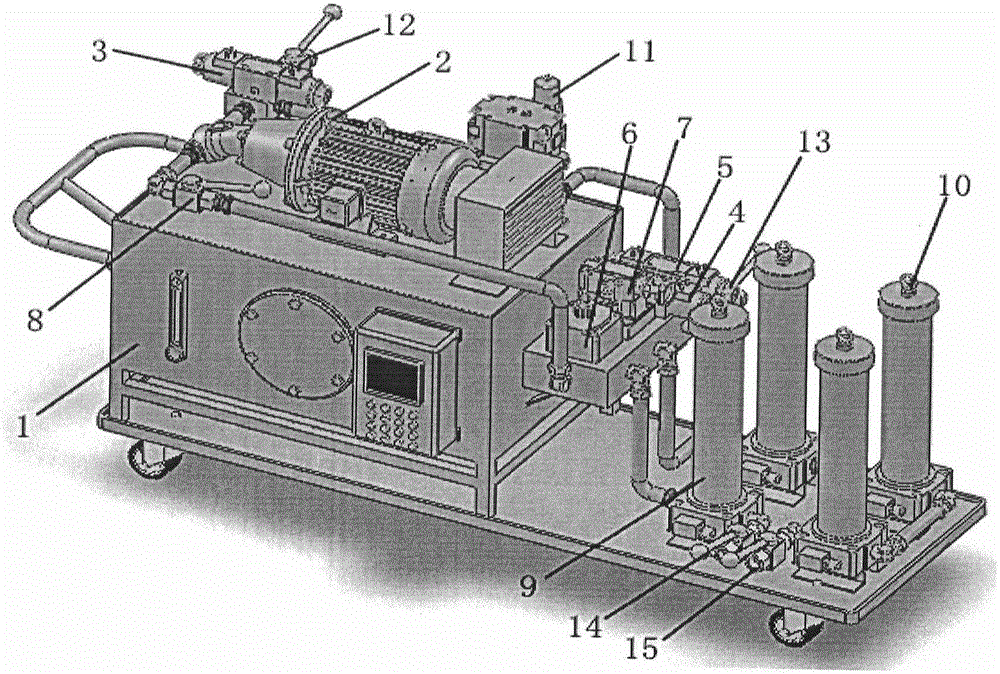

Full-automatic control hydraulic multifunctional trolley

InactiveCN104989938AFluid-pressure actuator testingLubrication check valvesHydraulic cylinderAutomatic control

Disclosed is a full-automatic control hydraulic multifunctional trolley. Various traditional hydraulic trolley functions are integrated. The full-automatic control hydraulic multifunctional trolley can be used in hydraulic lubricating systems of various working conditions. According to the scheme, the requirements for online circulating filtration, system oiling, hydraulic cylinder bulge tests, system valve station and local pipeline bulging and fresh oil filtration of the hydraulic lubricating systems of various kinds can be met, the working efficiency can be improved, and the high-integration structural style and high practicability are achieved. According to the body structure, the full-automatic control hydraulic multifunctional trolley comprises an oil tank, a system pump set, a control valve set, a system filter set, a system functional interface and a control panel. The full-automatic control hydraulic multifunctional trolley is controlled in a full-automatic manner, and a user can freely switch the full-automatic control hydraulic multifunctional trolley to corresponding functional modes. After the corresponding functional modes are selected through the control panel, a PLC sends out an instruction to a corresponding control valve, the system can be automatically switched to the corresponding oil way, the pressure and flow of the corresponding loop are automatically set, the requirements for various working conditions are met, and the corresponding functions are achieved.

Owner:ZHENJIANG SILIAN MECHATRONIC TECH

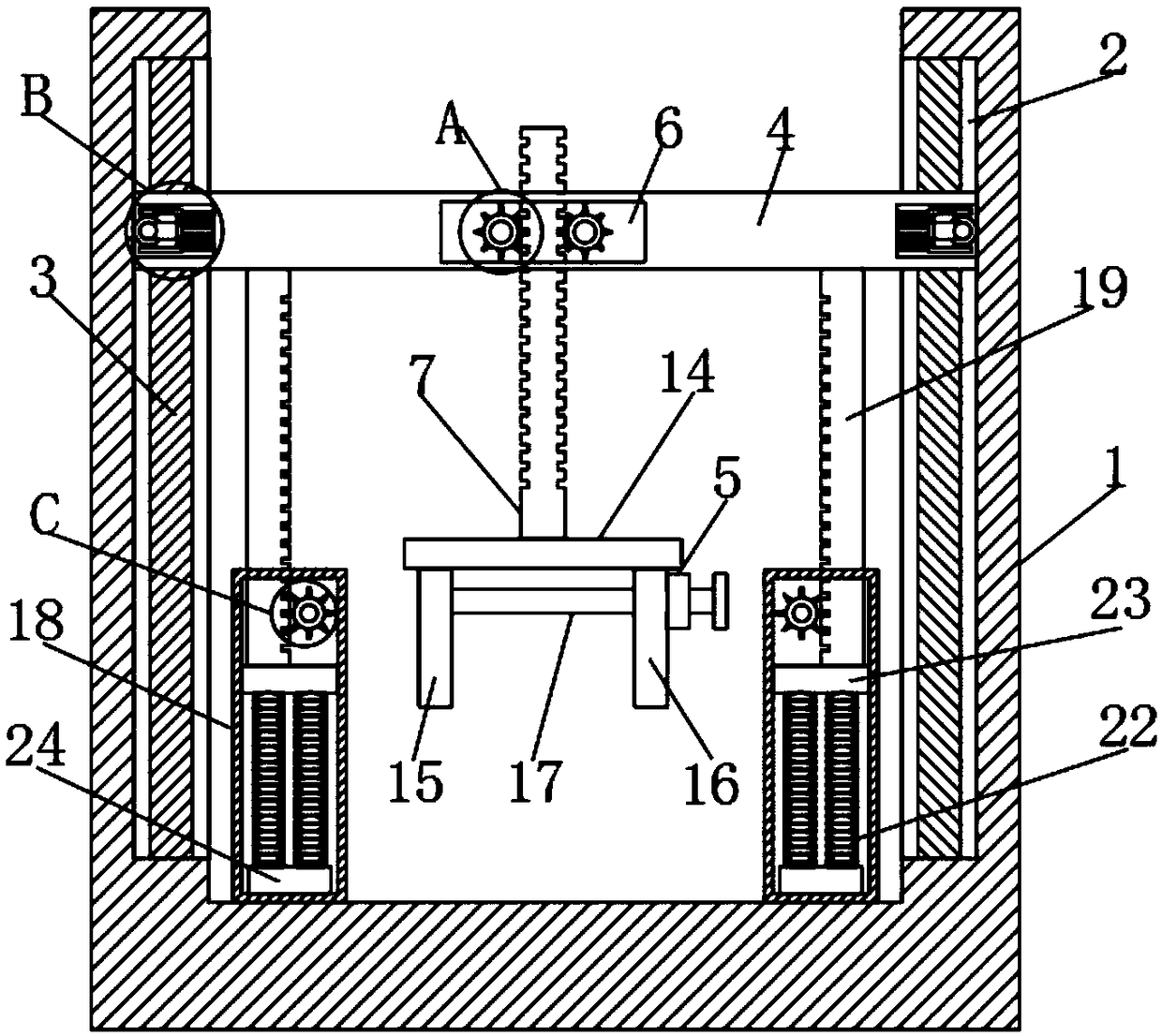

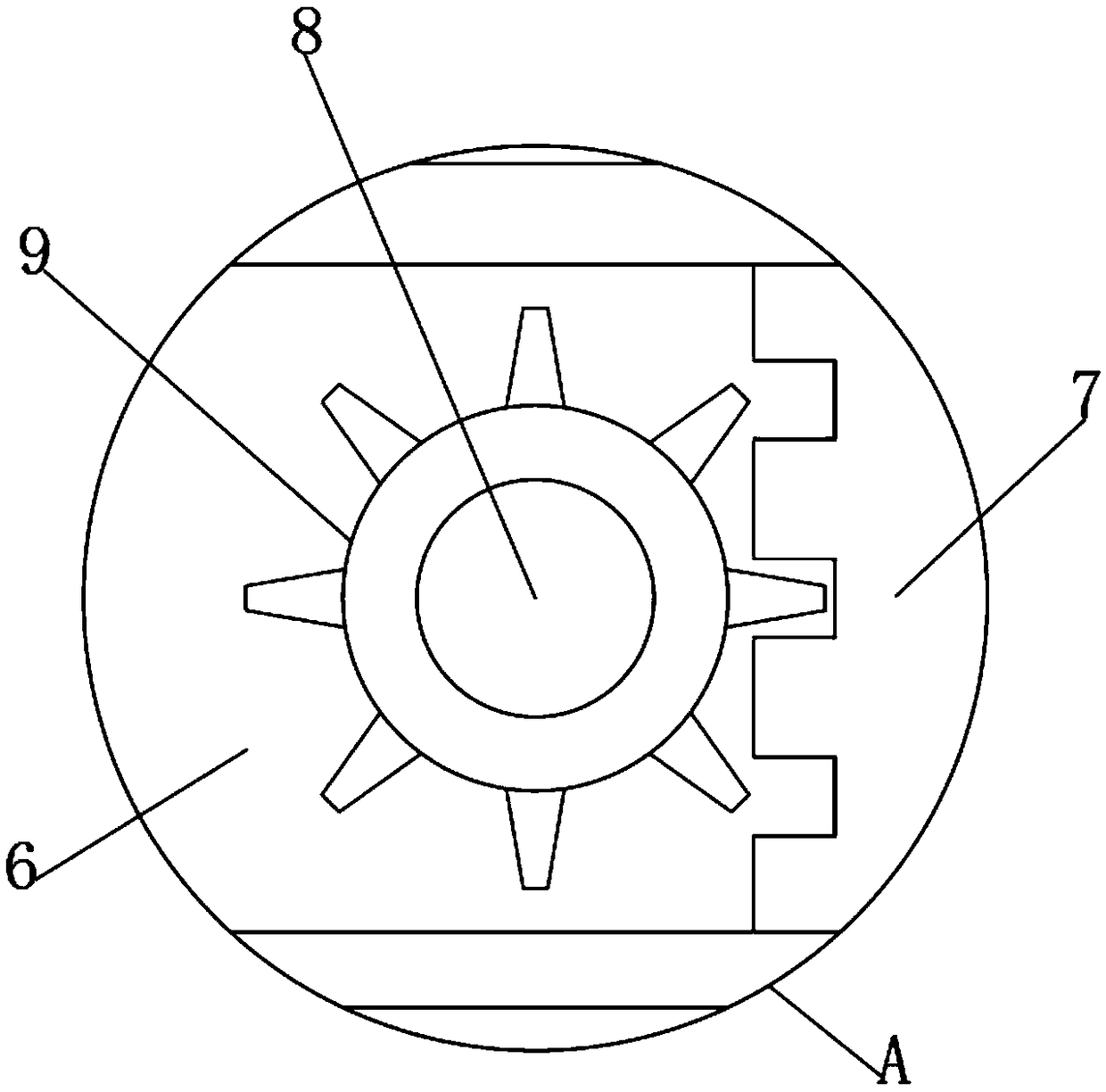

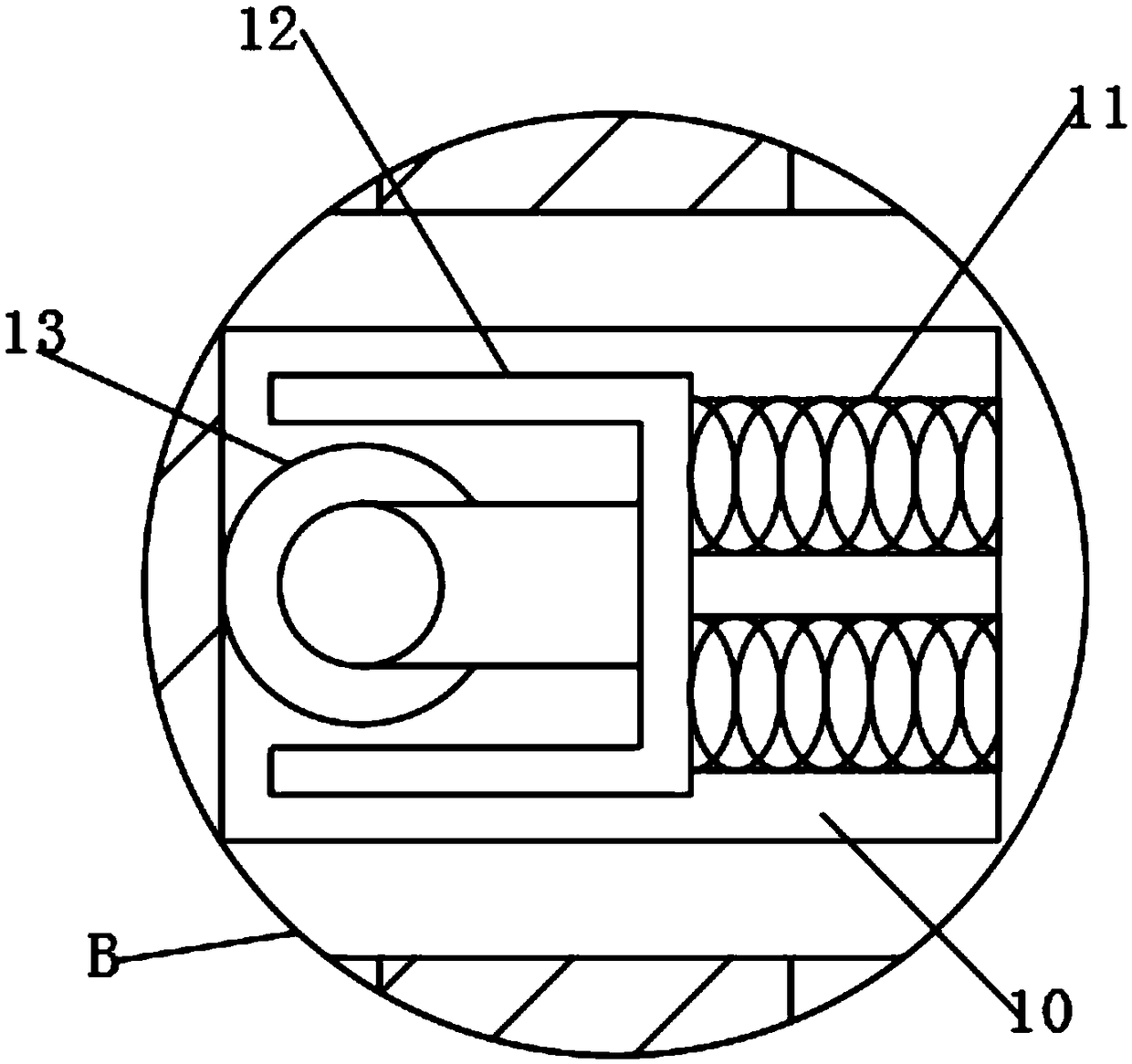

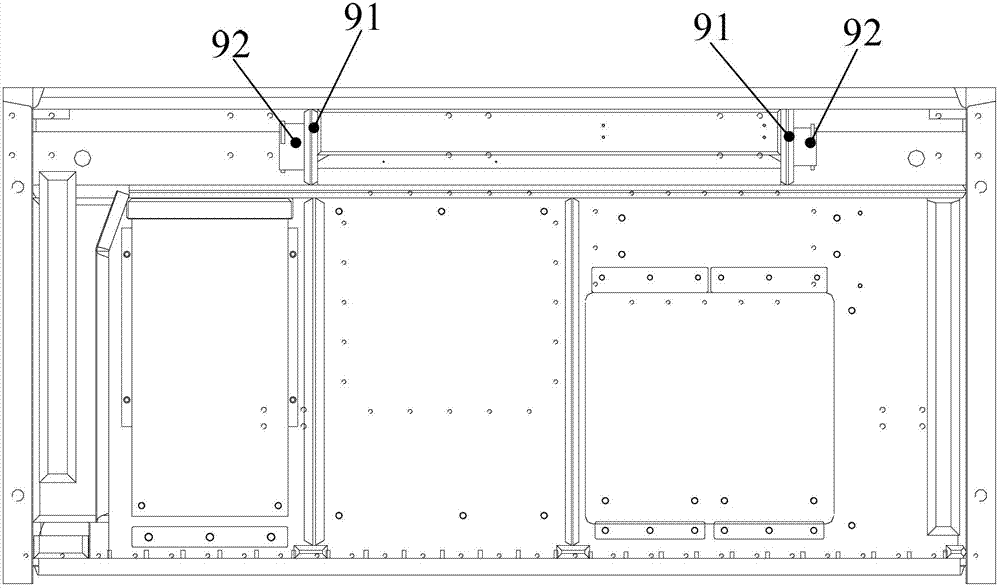

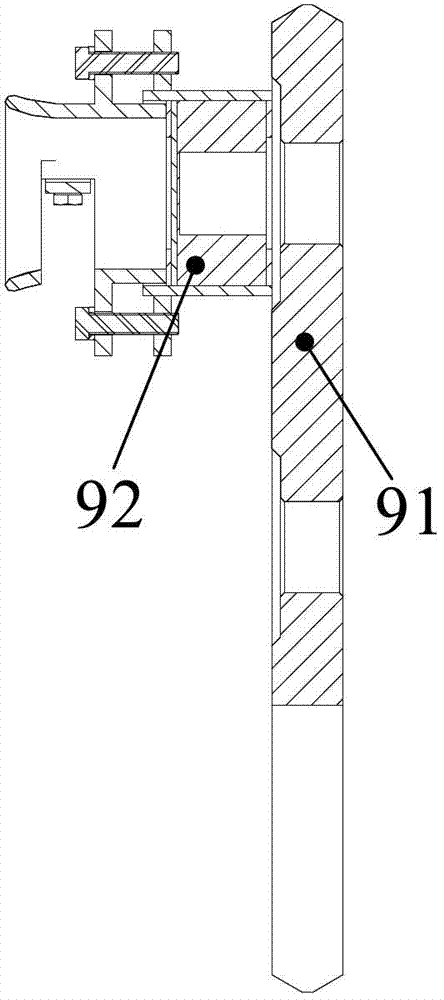

Device for bulge test and leakage test of casing

InactiveCN108956035AStable clampingThe location of the leak is easy to judgeDetection of fluid at leakage pointLeakage testBulge test

The invention discloses a device for bulge test and leakage test of a casing. The device comprises a detection slot. Chutes with opposite openings are formed in the two side walls of the detection slot, wherein the two chutes are arranged vertically; and fixation rods are arranged in the two chutes respectively. A first support plate arranged horizontally is arranged in the detection slot; the twoends of the first support plate sleeve the two fixation rods in a sliding manner respectively; and the first support plate is connected with the bottom wall of the detections slot by two symmetric telescopic sleeve rods. A mounting cavity is formed in the first support plate; a vertical rod is arranged at the first support plate vertically; one end of the vertical rod penetrates the side wall ofone side of the first support plate and the other end of the vertical rod is connected with a clamping device; and two symmetric first rotating rods are arranged in the mounting cavity, wherein the two first rotating rods are arranged at the two sides of the vertical rod respectively. Therefore, a casing can be clamped stably and can be immersed into a detection solution step by step, so that thelocation of leakage on the housing is determined conveniently.

Owner:赵笑妍

Cable connection device and explosion-proof electric control box

InactiveCN102780187AEven by forceEasy to fixHermetically-sealed casingsElectric controlElectric cables

The invention provides a cable connection device which is used for an explosion-proof electric control box. The cable connection device comprises a connection part, a sealing ring and a fixation part, wherein a first through hole is formed on the connection part; a second through hole is formed on the fixation part; and in the explosion-proof electric control box, a cable penetrates through the first through hole, the second through hole and a protection plate in the explosion-proof electric control box respectively; the first through hole is a step hole; the sealing ring is arranged on the part with a large inner diameter in the first through hole; the fixation part is detachably connected to one end of the connection part and used for tightly pressing the sealing ring on steps in the step hole, and the other end of the connection part stretches in the through hole of the protection plate and is detachably connected with the protection plate. The cable connection device provided by the invention cannot damage the electric control box during installation because welding is not needed, installation for devices such as an elbow and dragging for the cable are more convenient, and the cable connection device has no need to be installed on the electric control box during a bulge test, so that the damage of the bulge test on the cable connection device is avoided. The invention further provides the explosion-proof electric control box.

Owner:SANY HEAVY EQUIP

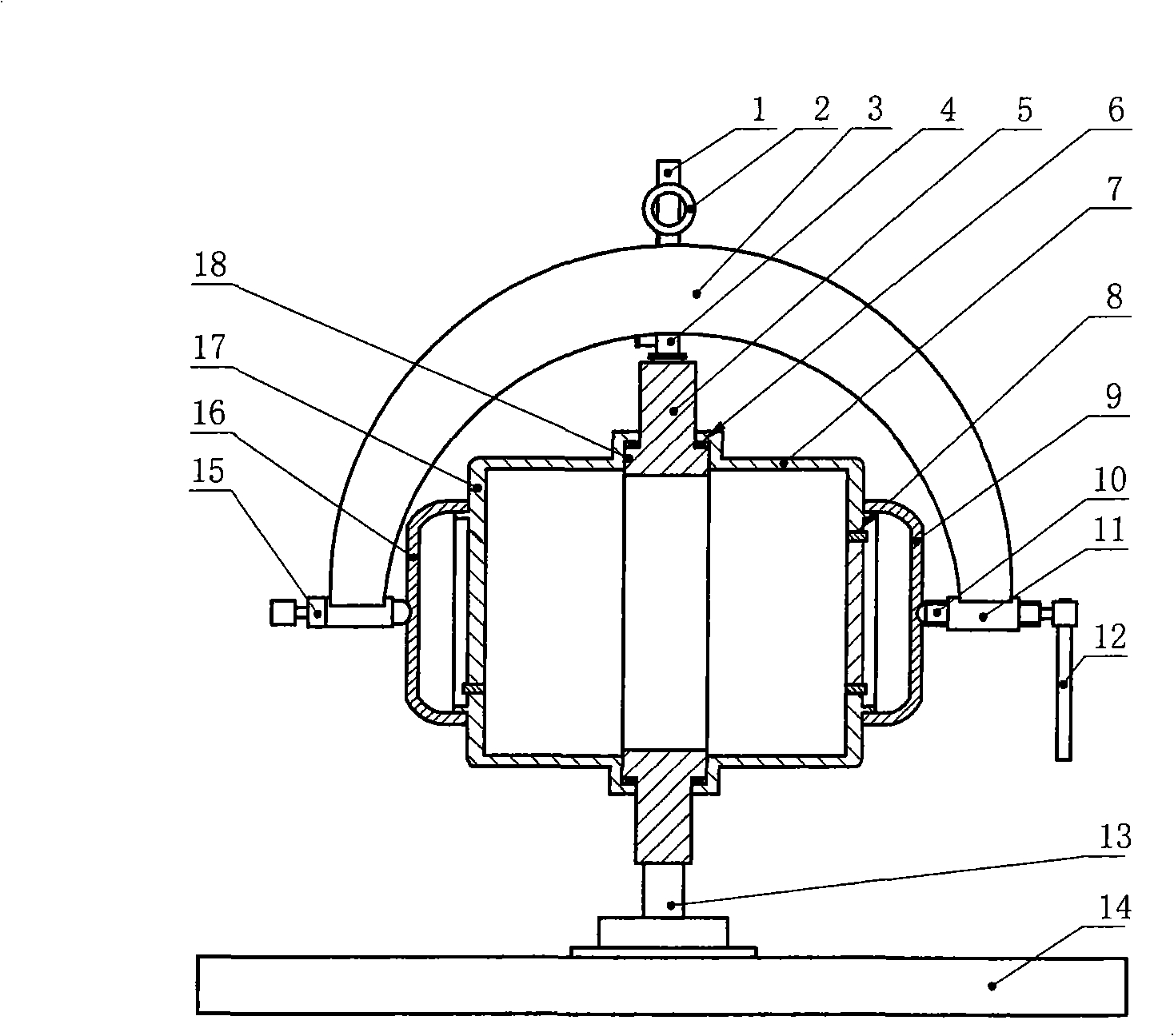

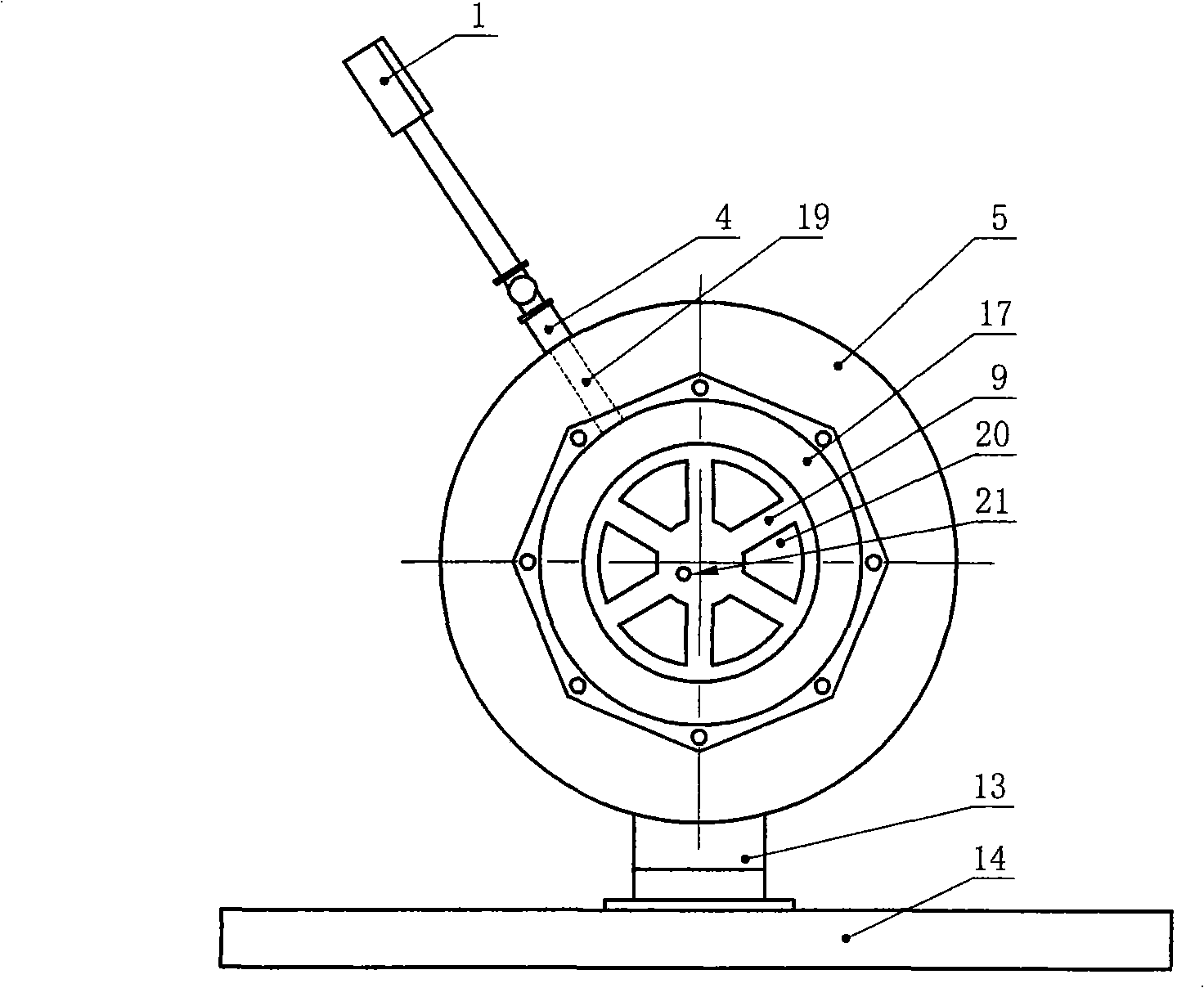

Seal and bulge test device of shell of gas flow meter

InactiveCN101526414AGuaranteed accuracyEasy to installDetection of fluid at leakage pointEngineeringUltimate tensile strength

The invention relates to a seal and bulge test device of a shell of a gas flow meter, which consists of a pedestal, a ring support, a clamp and two compaction bowls, wherein the ring support is vertically and fixedly arranged on the upper surface of the pedestal, the ring support is provided with radial air inlets, and two lateral surfaces of the ring support are provided with mounting ring tables axially clamped inside an open end of a work piece; two end parts of a clamp are oppositely provided with top cores respectively, wherein at least one top core is an axially adjustable; the lateral surfaces of the two compaction bowls are provided with positioning centers; and the clamp can clamp and arrange the work pieces at two sides of the ring support through the two compaction bowls. The test device has the advantages of scientific and reasonable structure design, simple operation, convenient use and low cost, and can effectively reduce the labor intensity of sealability test of the shell of the gas flow meter, improve seal and bulge test efficiency and simultaneously ensure the test accuracy; and the seal and bulge test device has higher innovation and is suitable for popularization and application.

Owner:TIANJIN BOHAI VOCATIONAL TECHN COLLEGE

Method for machining inner container of water heater by using resin

The invention discloses a method for machining an inner container of a water heater by using resin. The resin inner container is provided with a water inlet, a water outlet and a sensor port, and a flange connecting port is formed in the end of a shell. The method comprises the following steps that a flange component, a water inlet composite pipe, a water outlet composite pipe and a temperature sensor port pipe are formed through injection molding; the water inlet composite pipe, the water outlet composite pipe and the temperature sensor port pipe are placed in a forming mold of the resin inner container to be positioned and fixed; the resin inner container is formed in a blow molding mode; the flange component is connected with the resin inner container; the water inlet and the water outlet of the resin inner container, the flange connecting port and an outer connecting port of a temperature sensor are sealed tightly, and the preset pressure is adopted for the sealing bulge test; theouter surface of the resin inner container is activated to form a relatively rough anti-skid surface; a reinforcing material for increasing the stress strength of the resin inner container is wound around the outer surface of the resin inner container; the reinforcing material is solidified; and the sealing performance is detected through the bulge test. According to the inner container prepared through the method, the overall strength is high, the structural stability is good, and the use is safe and reliable.

Owner:袁园

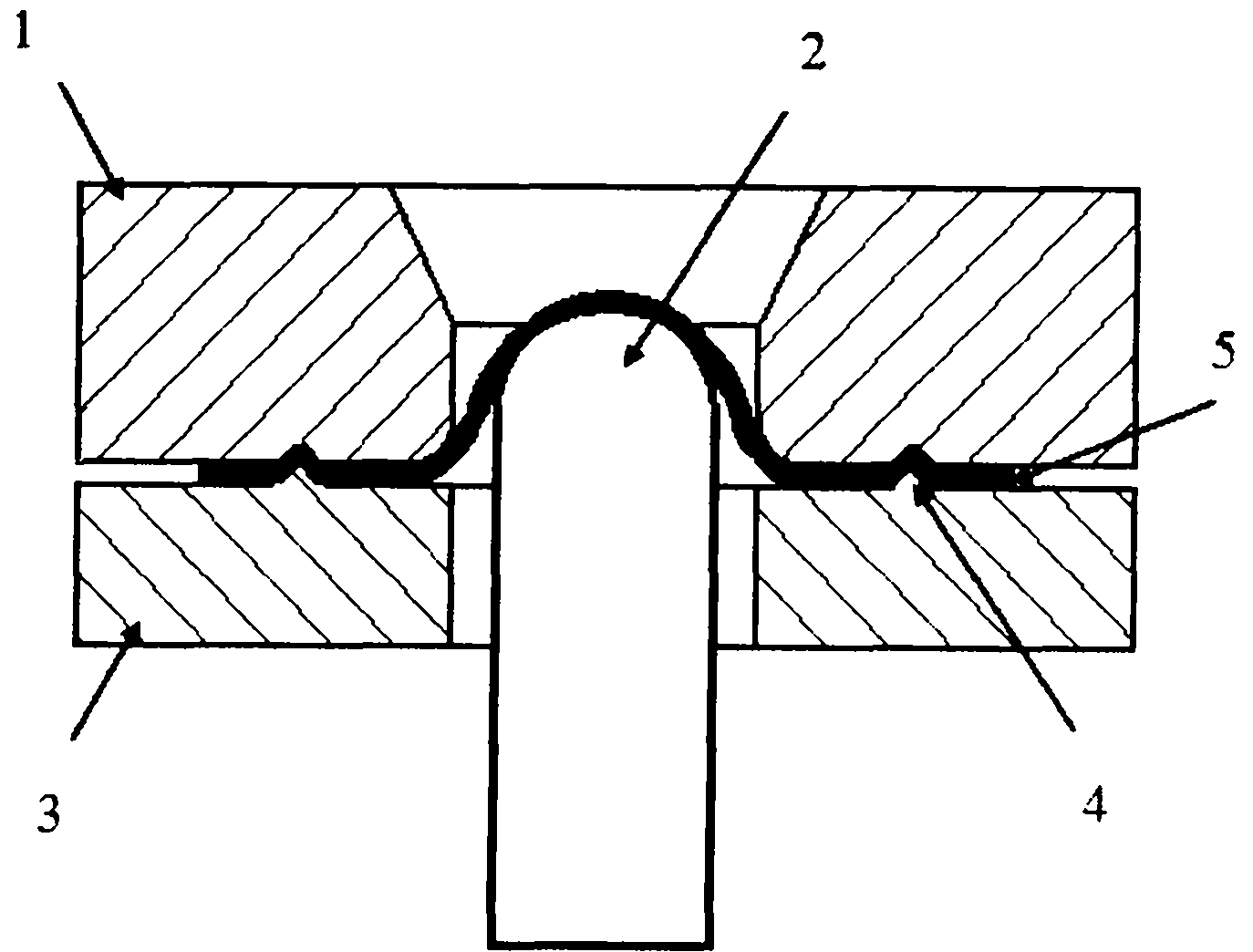

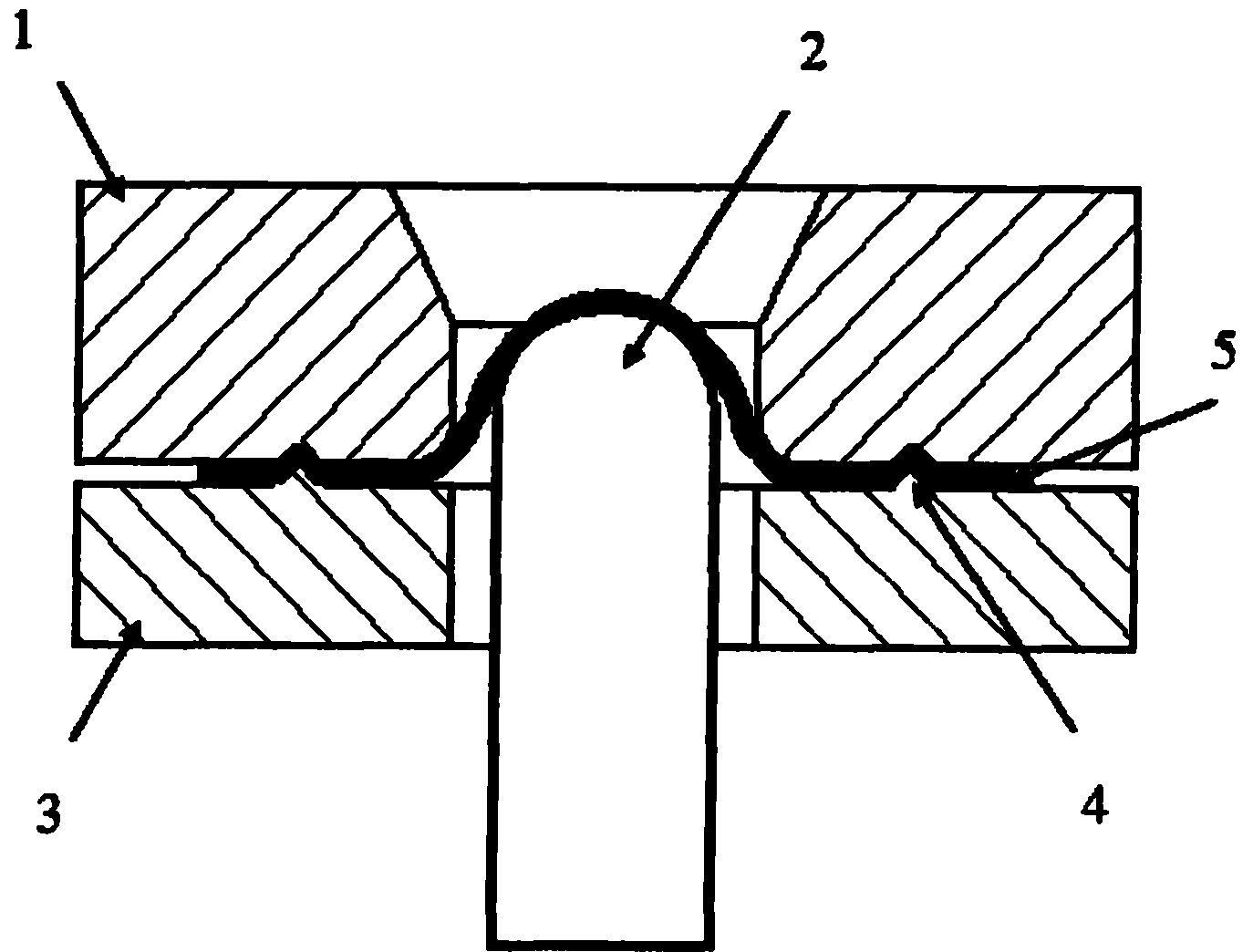

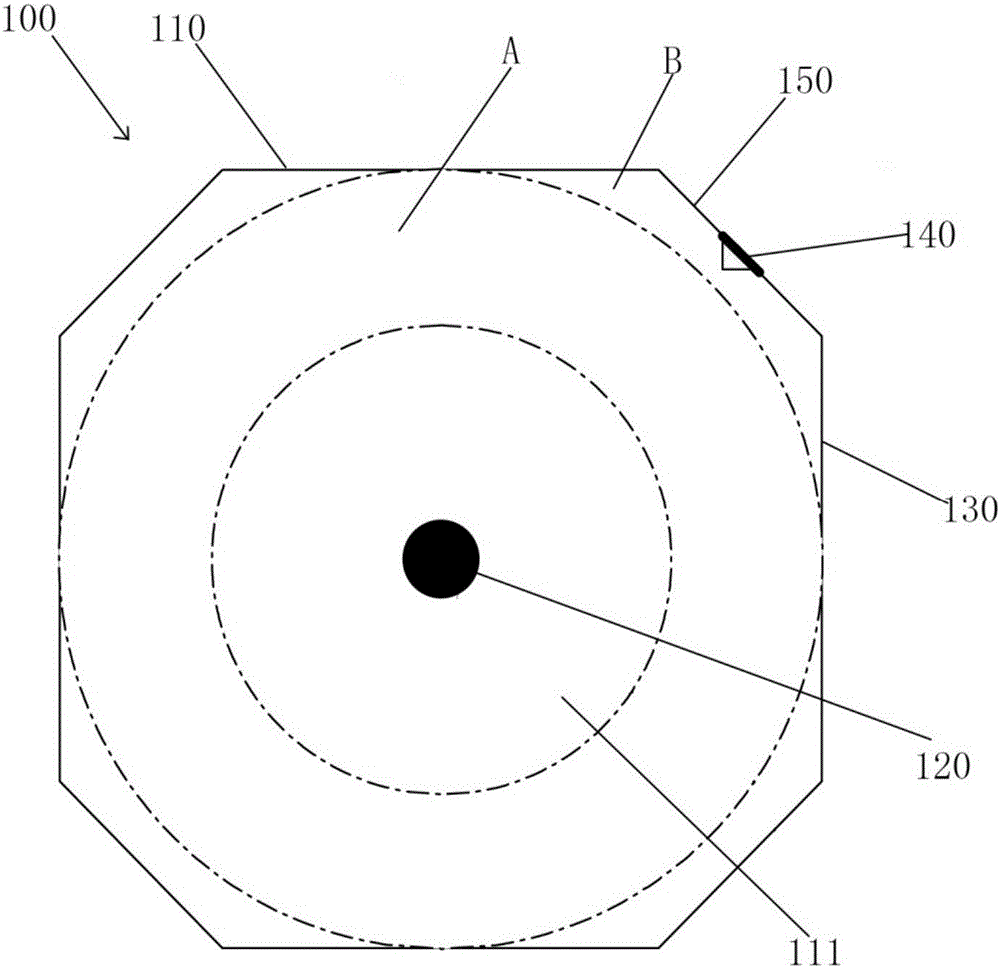

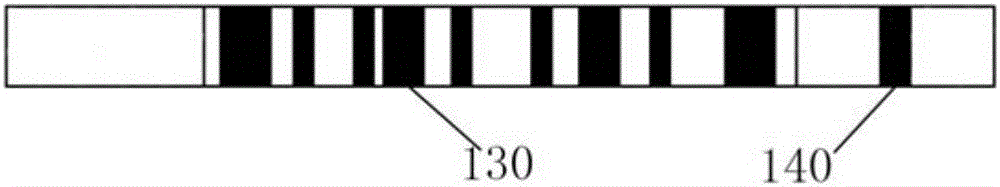

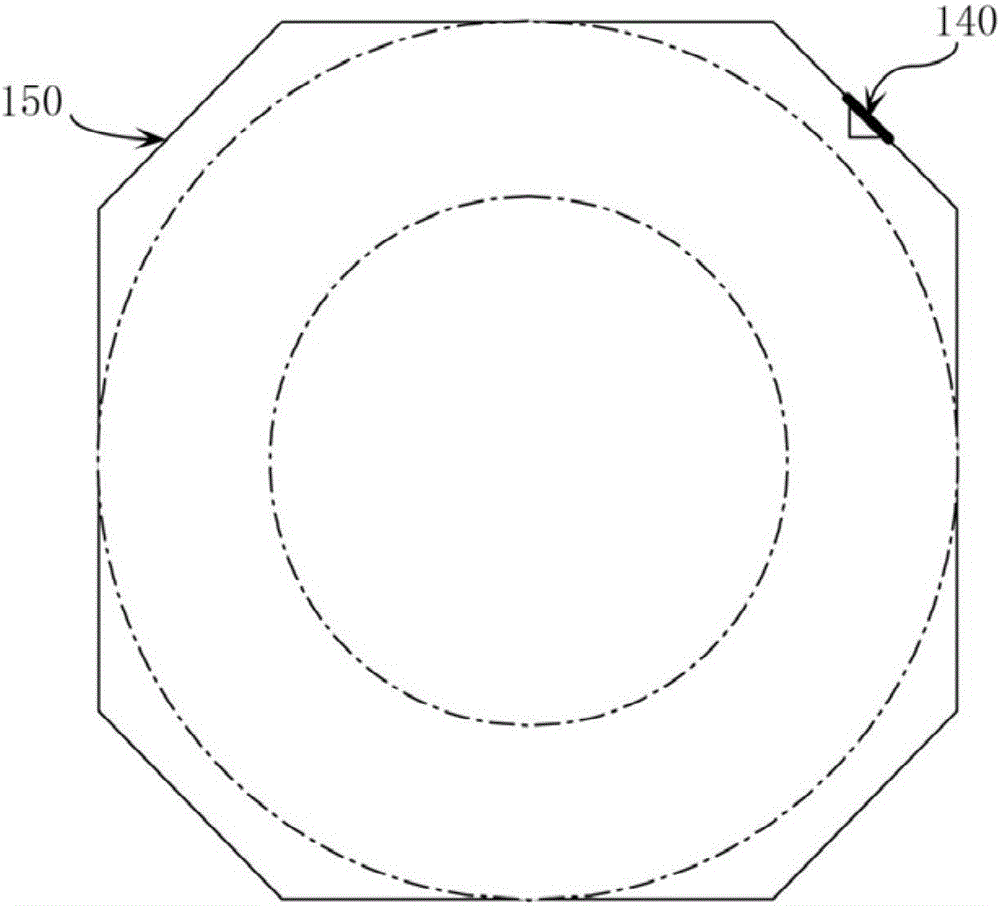

Micro specimen and hydraulic bulge testing method

ActiveCN105699204AReduce measurement errorReduce the value gapMaterial strength using tensile/compressive forcesStrength of materialsMechanical property

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Seal and bulge test device of shell of gas flow meter

InactiveCN101526414BGuaranteed accuracyEasy to installDetection of fluid at leakage pointEngineeringUltimate tensile strength

The invention relates to a seal and bulge test device of a shell of a gas flow meter, which consists of a pedestal, a ring support, a clamp and two compaction bowls, wherein the ring support is vertically and fixedly arranged on the upper surface of the pedestal, the ring support is provided with radial air inlets, and two lateral surfaces of the ring support are provided with mounting ring tables axially clamped inside an open end of a work piece; two end parts of a clamp are oppositely provided with top cores respectively, wherein at least one top core is an axially adjustable; the lateral surfaces of the two compaction bowls are provided with positioning centers; and the clamp can clamp and arrange the work pieces at two sides of the ring support through the two compaction bowls. The test device has the advantages of scientific and reasonable structure design, simple operation, convenient use and low cost, and can effectively reduce the labor intensity of sealability test of the shell of the gas flow meter, improve seal and bulge test efficiency and simultaneously ensure the test accuracy; and the seal and bulge test device has higher innovation and is suitable for popularization and application.

Owner:TIANJIN BOHAI VOCATIONAL TECHN COLLEGE

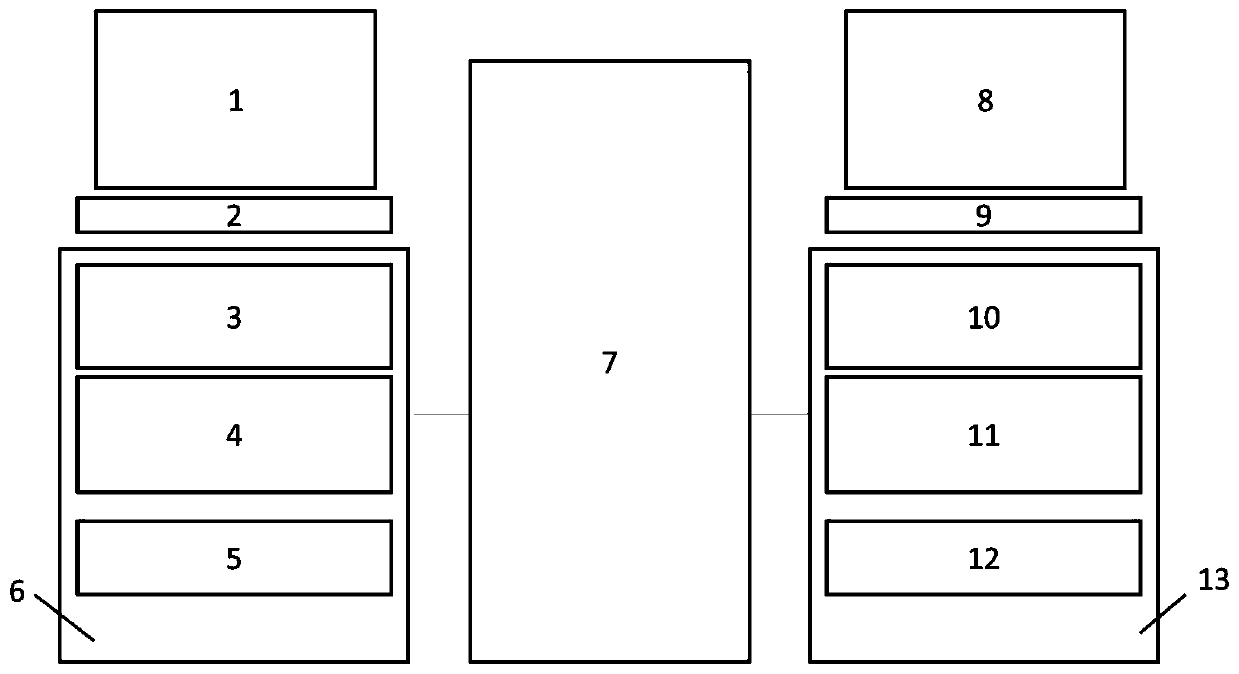

Containment bulge test parameter collection device and collection method thereof

PendingCN109855804AImprove accuracyImprove reliabilityFluid-tightness measurement using fluid/vacuumNuclear powerData acquisition

The invention belongs to the field of nuclear power plant operation technology and particularly relates to a containment bulge test parameter collection device and a collection method thereof. The device comprises a displayer A, a keyboard A, a collection cabinet A, a middle wiring cabinet, a displayer B, a keyboard B and a collection cabinet B. The collection method of the containment bulge testparameter collection device comprises the steps that first, connection with the containment bulge test parameter collection device is established; second, data in the collection cabinet A (6) is collected; and third, data in the collection cabinet B (13) is collected. The designed containment bulge test parameter collection device is successfully applied to a containment overall sealing test of four nuclear power units in a certain nuclear power plant, and through actual operation, the device fully shows the advantages of high system accuracy and reliable design.

Owner:JIANGSU NUCLEAR POWER CORP

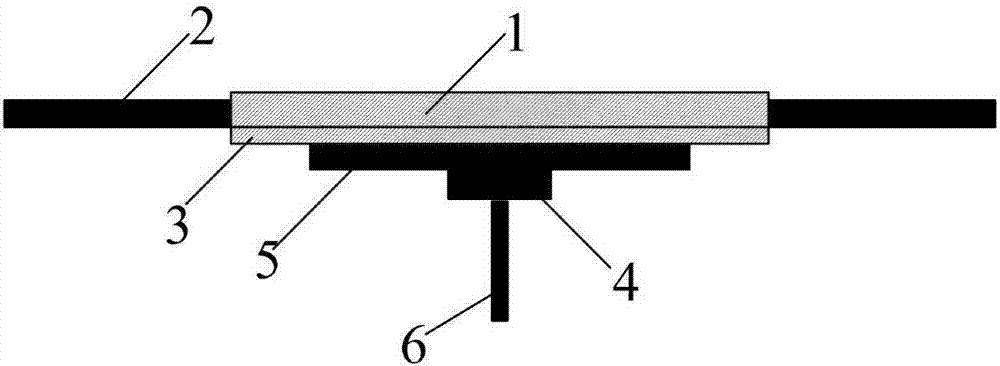

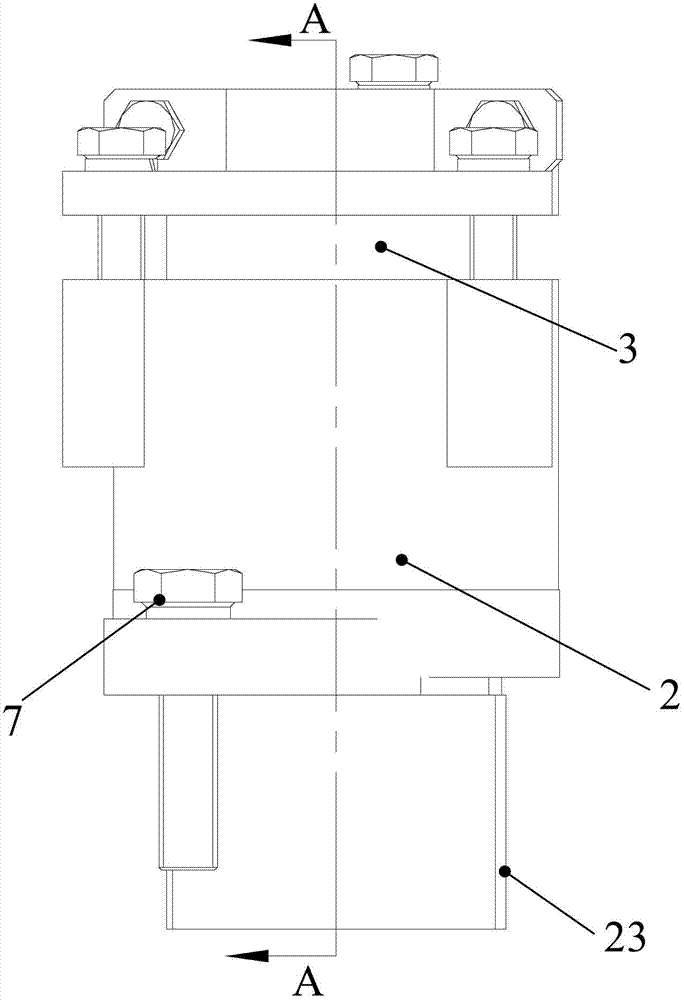

Novel hydraulic bulging test clamp

The invention relates to a novel hydraulic bulging test clamp. The novel hydraulic bulging test clamp comprises an upper clamp, a lower clamp, an upper sleeve and a lower sleeve, the lower sleeve is provided with a first through hole, the upper sleeve is provided with a second through hole, and an inwardly-extending mounting chamber is arranged at the upper part of the lower clamp; an oil fillingchannel, a first oil leakage channel and a second oil leakage channel which extend inwardly and communicate with the mounting chamber are arranged in the side surface of the lower clamp; and the lowersleeve is mounted at the bottom of the mounting chamber, the upper sleeve is mounted at the upper part of the mounting chamber, the central axis of the second through hole and the central axes of thefirst through hole are on the same straight line, and the upper clamp is fixedly mounted above the lower clamp. The novel hydraulic bulging test clamp has the advantages of low loss of hydraulic oil,short clamp cleaning time, convenience in installation, high measurement precision and high safety.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

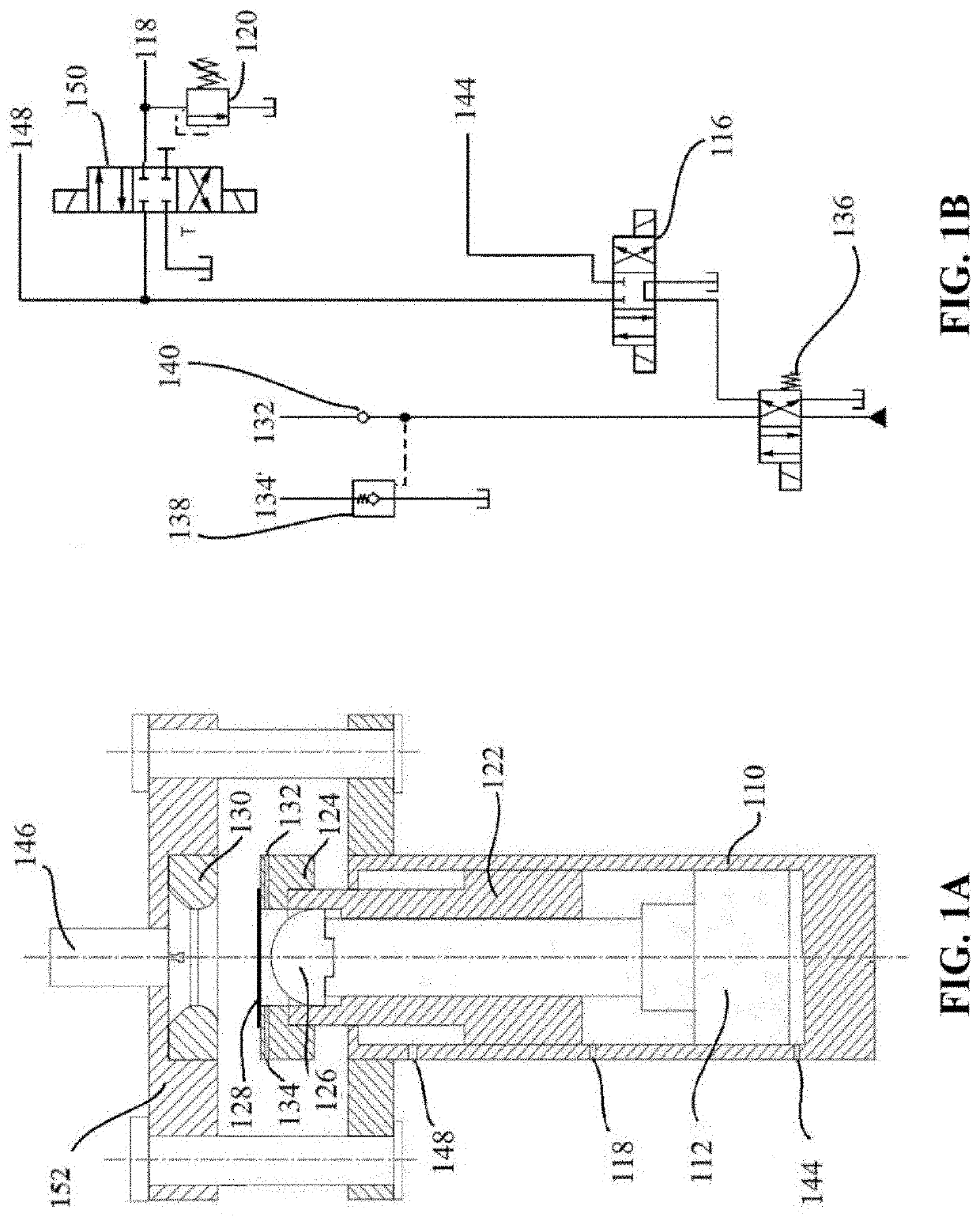

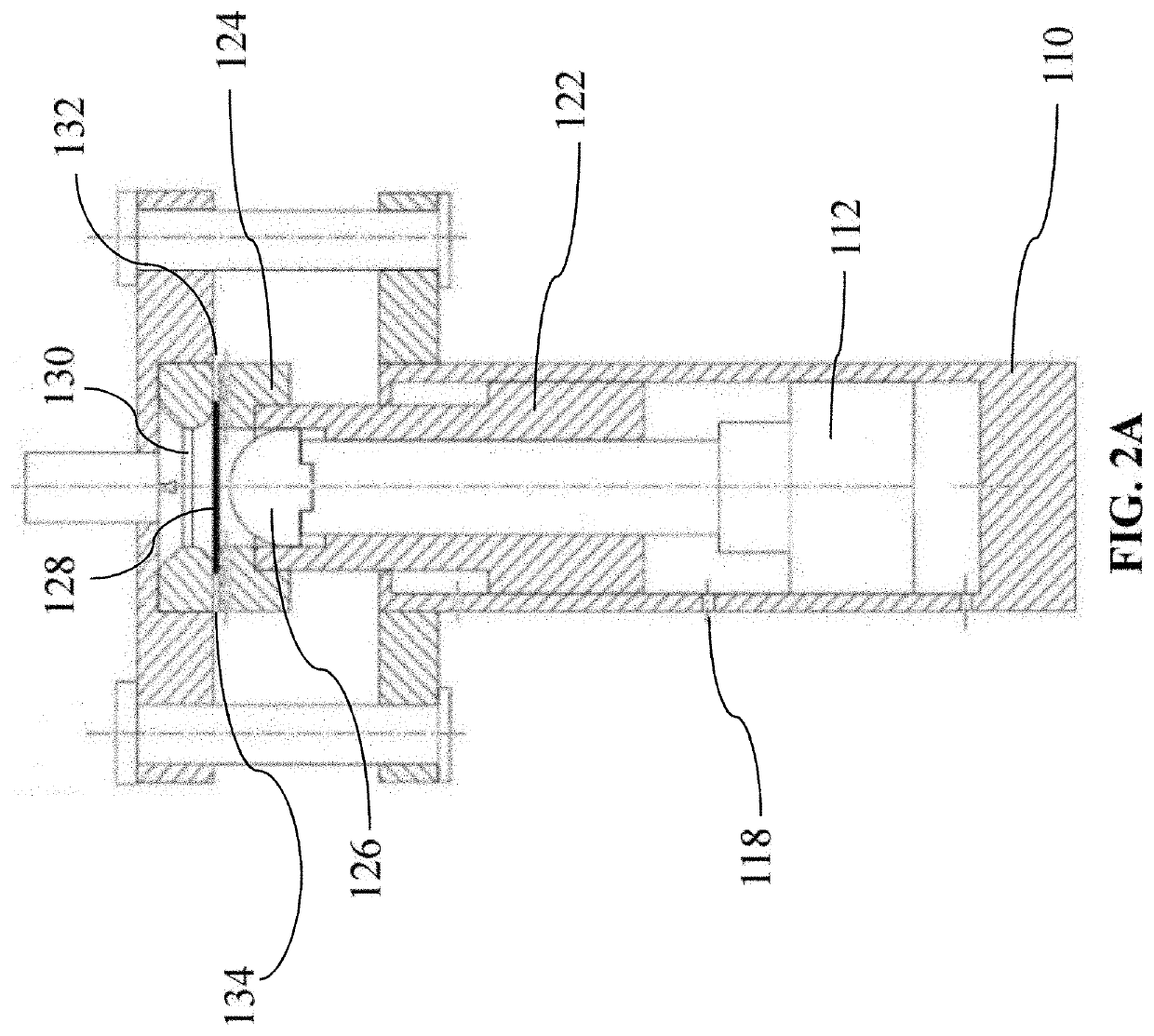

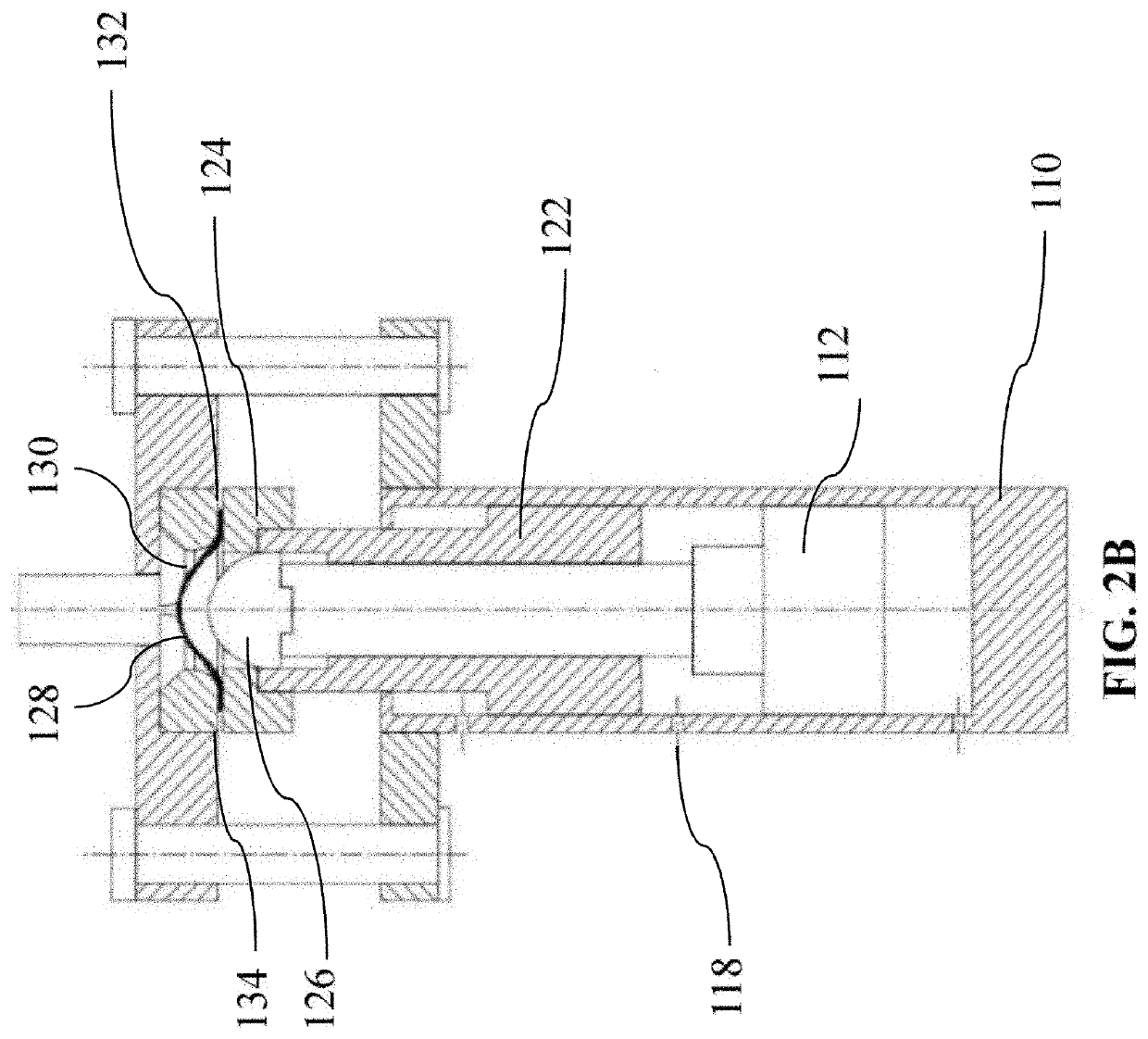

Apparatus for universal testing of metal sheet formability

ActiveUS10670501B2Material strength using tensile/compressive forcesInvestigating material ductilityMetal sheetPiston

A system for universal testing of metal sheet formability is described. The system discloses a cylinder barrel including two pistons for testing formability of the metal sheets. The driving force is provided by the hydraulic pressure of an incompressible fluid. The present application also describes an apparatus to perform various formability tests on metal sheets such as the bulge test, Nakazima test, Marciniak test, cupping test, and the blanking test. The system can also be used in hydroforming metal sheets.

Owner:JELOKHANI NIARAKI RASOUL +3

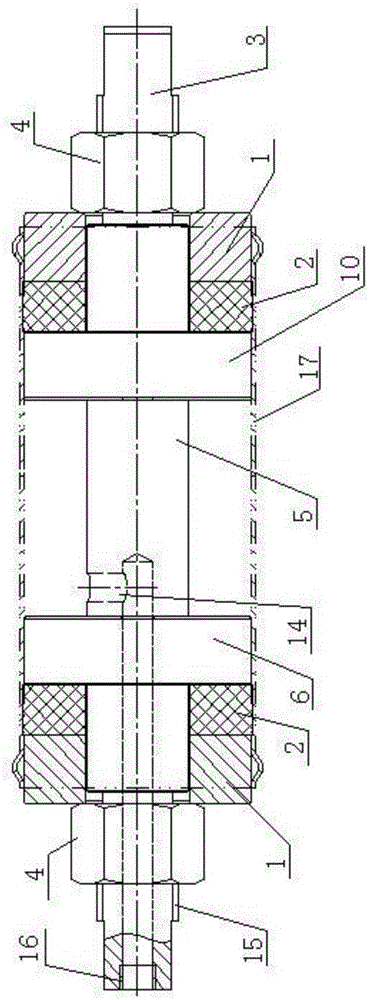

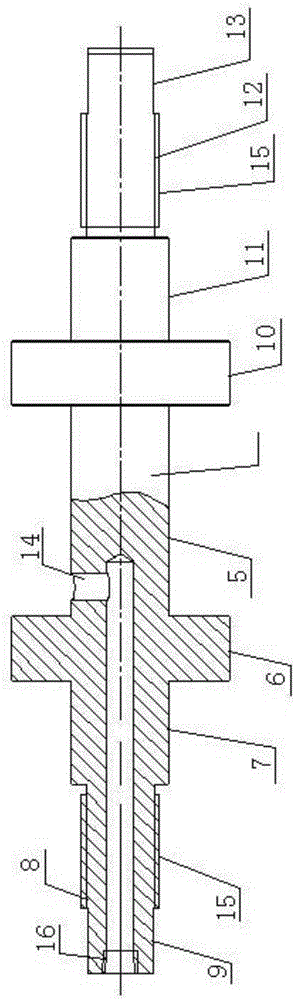

Short straight metal pressure pipe fitting bulge test apparatus

InactiveCN106338441AImprove sealingSimple structureMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumDumbbellPipe fitting

The invention discloses a short straight metal pressure pipe fitting bulge test apparatus, which belongs to the field of a machinery apparatus. The short straight metal pressure pipe fitting bulge test apparatus comprises pressure plates, flexible sealing pads, a mandrel and a nut, the mandrel is a dumbbell type, wherein an intermediate part is a first step, the steps from the second step to the ninth step are symmetrically arranged at the right end and the left end of the mandrel, the steps from the second step to the fifth step are arranged at the left end of the mandrel, the steps from the sixth step to the ninth step are arranged at the right end of the mandrel, the maximum axle diameters are less than or equal to the internal diameter of the to-be-measured pipe fitting, an inward pore is arranged on the first step, the pore extends to a random end part of the mandrel, the pressure plates and the flexible sealing pads are arranged on the third step and the seventh step, the outside threads are arranged on the fourth step and the seventh step, and the nut is cooperated with the corresponding step through the outside thread. The apparatus has the advantages of simple structure, safety and reliability, and convenient operation, and can effectively detect the sealing performance of the short straight metal pressure pipe fitting.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com