Manufacturing process of integrally forged and pressed axle housing without welding seam

A manufacturing process, no weld technology, applied in the direction of railway car body parts, transportation and packaging, vehicle parts, etc., can solve the problem that the steel strength, compression resistance, flexural resistance and toughness can not meet the use or work requirements well, The insurance factor cannot be fully guaranteed, and the production efficiency of the axle housing is low, so as to achieve the effect of promoting the use value, improving the personal insurance factor, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The manufacturing process of the integrated forged axle housing without welding seam of the present invention will be described in detail below.

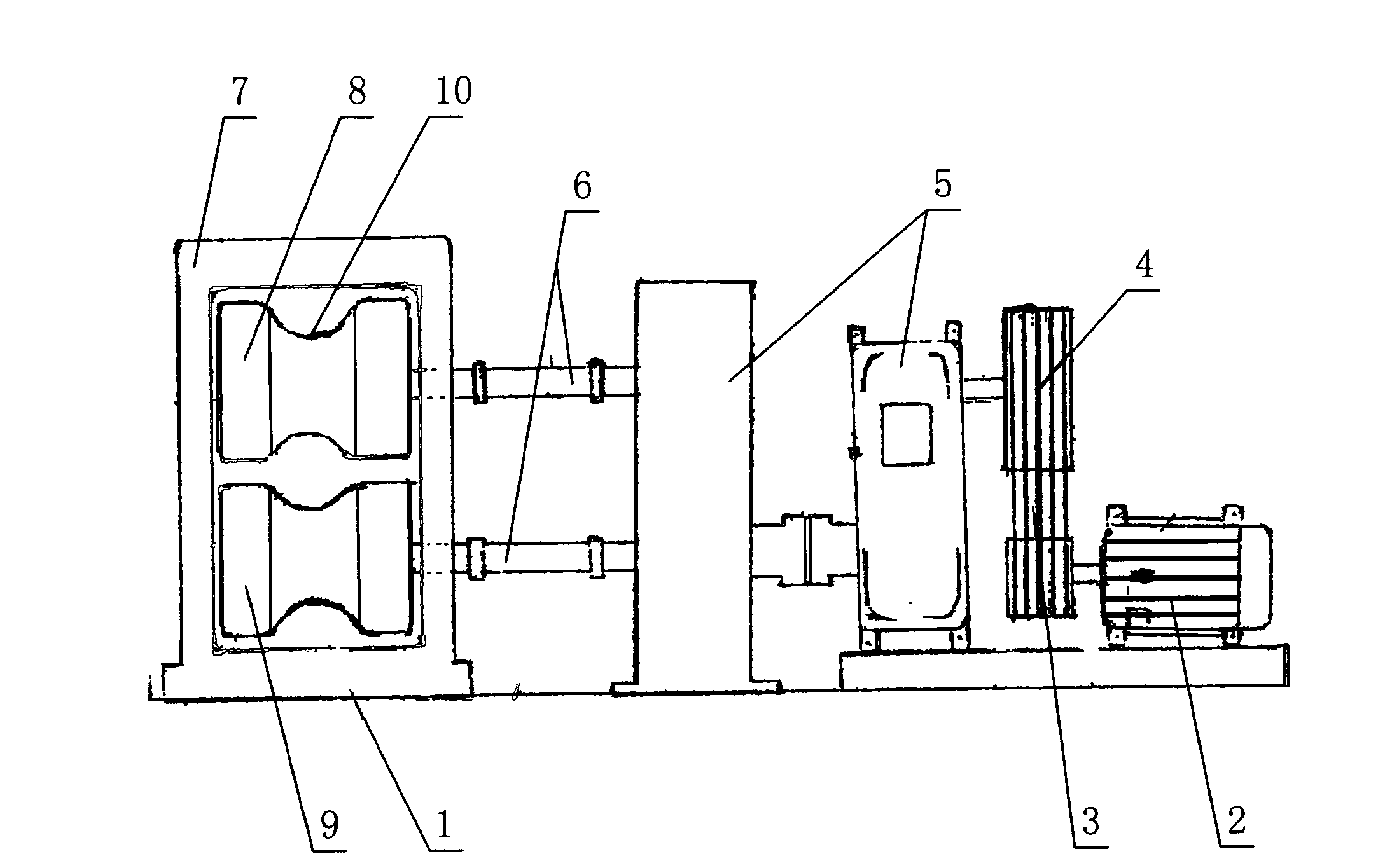

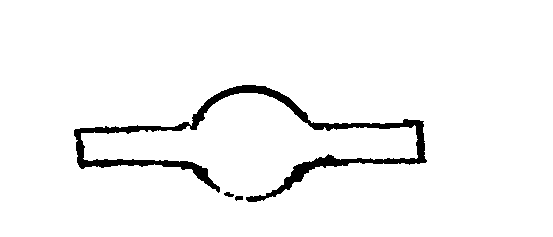

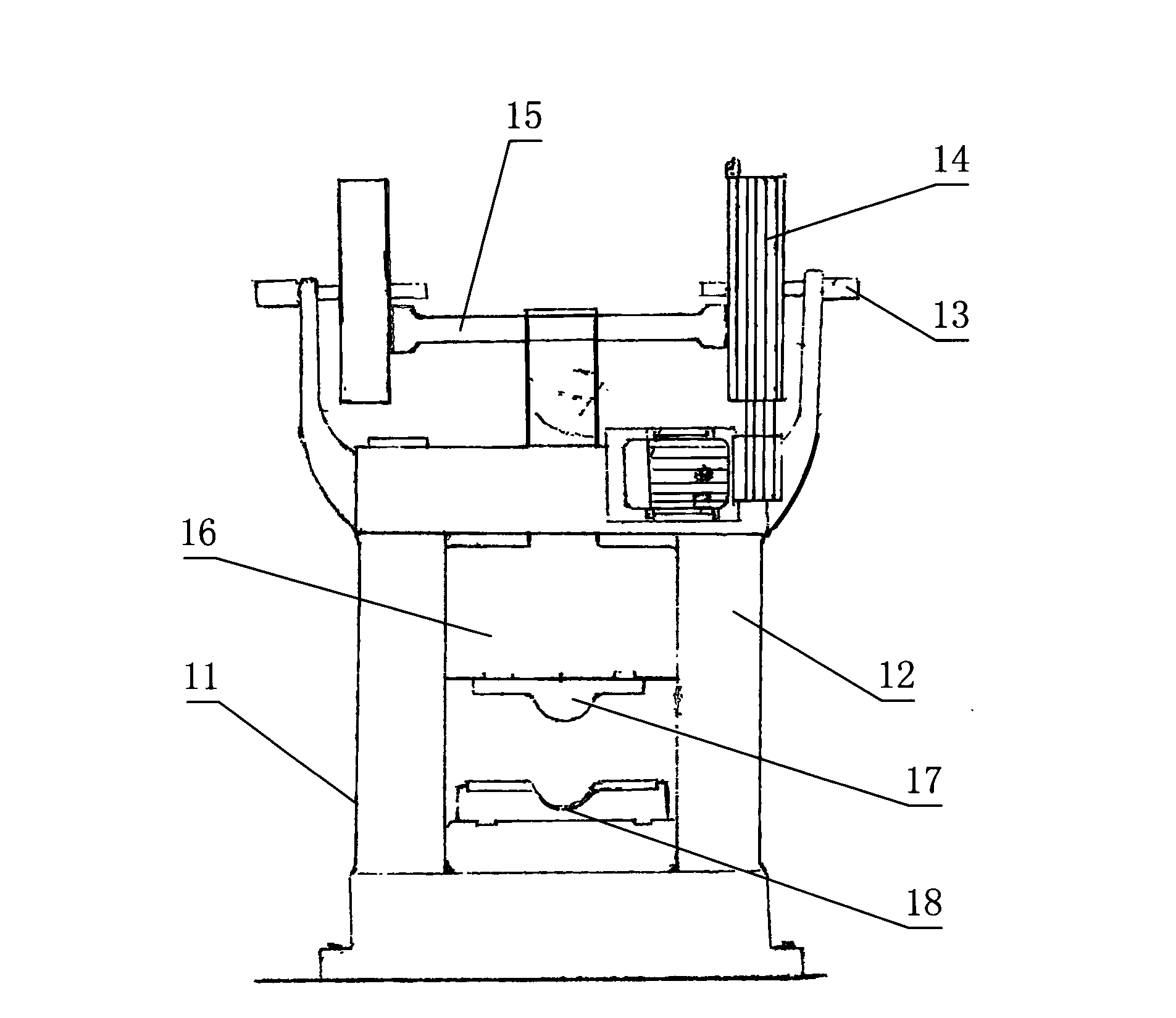

[0037] The welding seam-free integrated forging axle housing manufacturing process of the present invention includes the following steps: the primary blank is rolled and refined by a roll forging machine, and then the center pot is stamped with a friction press, the center pot is installed in the combined module, and the process is extruded by multiple heads. Extrusion molding machine, integral shaping with a comprehensive mold press, cutting off the flash burrs with a falling edge machine, taking out the precision forging blank of the center assembly module, and entering the normalizing furnace for aging and normalizing, after cooling, the flaw detection perspective, cold pressing correction, the whole is rough Cold processing, quenching and tempering heat treatment, all-round finishing after cooling, pressure test, painting, pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com