Volumetric capacity-variable constant-pressure maintenance device of pressure vessel

A technology for pressure vessels and holding devices, which is applied to pressure vessels, electric fluid pressure control, fixed-capacity gas storage tanks, etc. It can solve problems such as pressure oscillations and response lags, and achieve the effect of simple operation, practicality and convenience of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

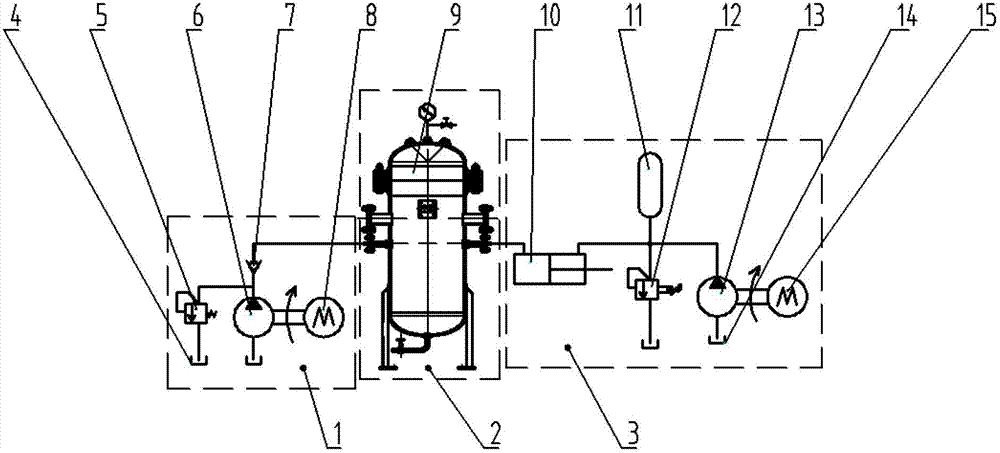

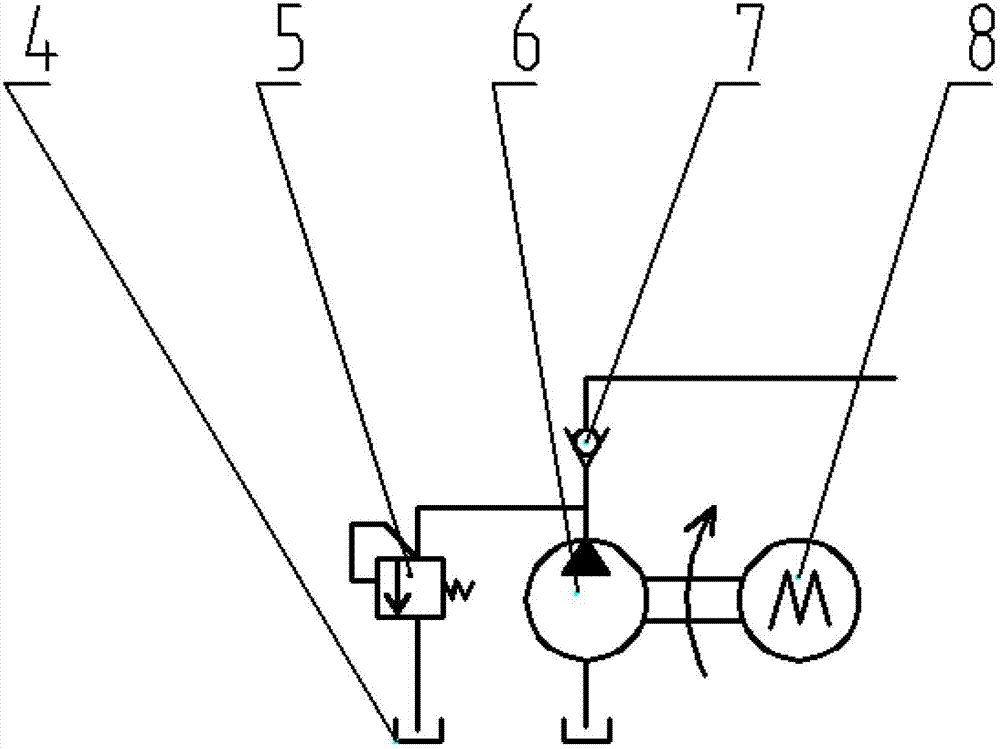

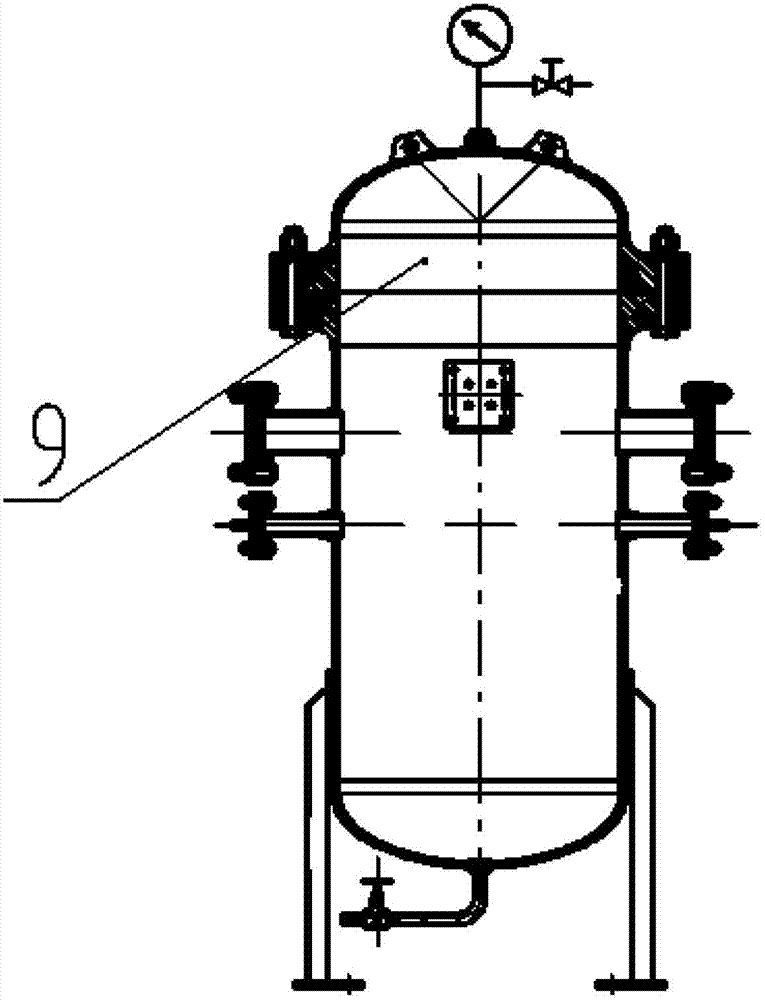

[0025] combine Figure 1~4 , the device is composed of three parts: pressure vessel system 2, pressurization system 1 and variable volume constant pressure maintenance system 3. The pressure vessel system is mainly a pressure vessel 9, and also includes some accessories such as instrument valves; the pressurization system 1 is composed of a pressure test pump 6 for pumping water pressure, an overflow valve 5 and a one-way valve 7; a variable volume constant pressure maintenance system 3 It consists of piston hydraulic cylinder 10, accumulator 11, overflow valve 12, hydraulic pump 13 and oil tank 14. The pressurization system 1 communicates with one side of the pressure vessel system 2 through a high-pressure rubber hose, and the variable-volume constant pressure maintenance system 3 communicates with the other side of the pressure vessel system 2 through a high-pressure hose. The pressure vessel 9 communicates with the rodless chamber of the piston hydraulic cylinder 10, and ...

Embodiment approach 2

[0029] combine Figure 5 , Another implementation mode created by the present invention: the piston rod of the piston hydraulic cylinder 10 is fixedly connected to the nut 16, and the nut 16 cooperates with the lead screw 17. Leading screw 17 two ends are connected to base plate by bearing, bearing seat, and leading screw 17 stretches out the axle and is connected with the shaft of motor 18 by shaft coupling (the motor front can add speed reducer). The screw 17 is rotated by the motor 18, and the rotation of the screw 17 is transformed into the linear motion of the nut 16. The nut 16 moves left and right together with the piston to realize the pressure adjustment of the pressure vessel 9 . The pressure in the pressure vessel 9 is transmitted to the controller 20 through the pressure sensor 21. The controller 20 detects and compares the signals, and then controls the motor driver 19. The motor driver 19 drives the motor 18 to rotate at a certain direction and speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com