Micro specimen and hydraulic bulge testing method

A technology of hydraulic bulging and test methods, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficult control, difficult theoretical analysis, and complex stress state of small disc samples , to achieve the effect of reducing measurement error, improving accuracy and reducing numerical gap

Active Publication Date: 2016-06-22

CHINA SPECIAL EQUIP INSPECTION & RES INST

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the force state of the small disc sample during the small punch test is complicated, and it is difficult to conduct effective theoretical analysis to obtain an analytical solution. Therefore, the research mainly focuses on the data accumulation of the test, and on the basis of the data accumulation, the small punch can be obtained. Empirical formulas relating rod test results to material mechanical properties, as well as simulating the test process through finite element calculations, and interpreting the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

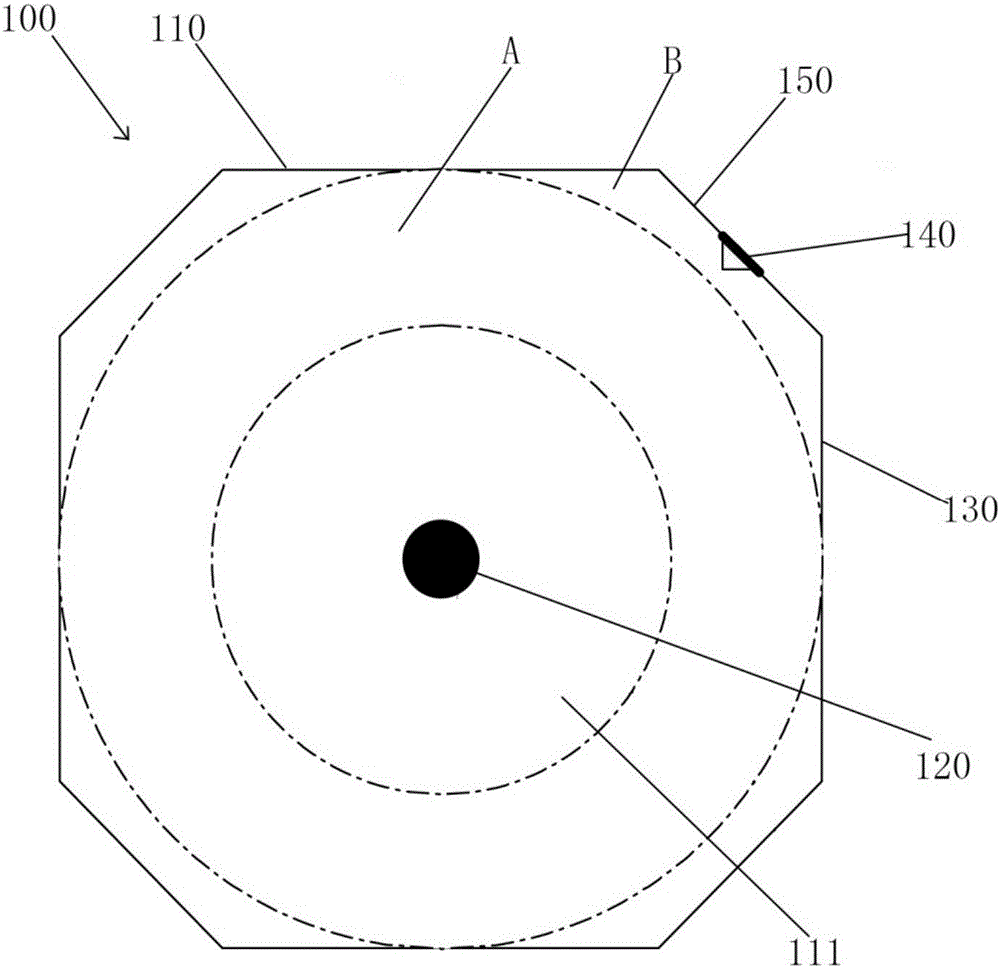

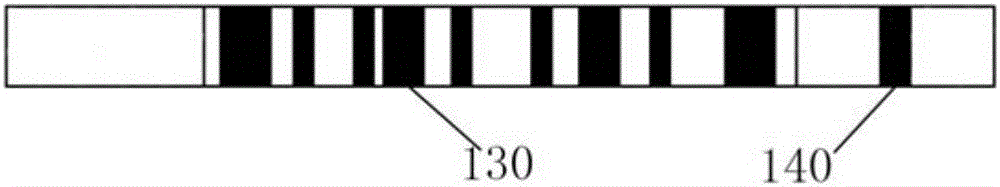

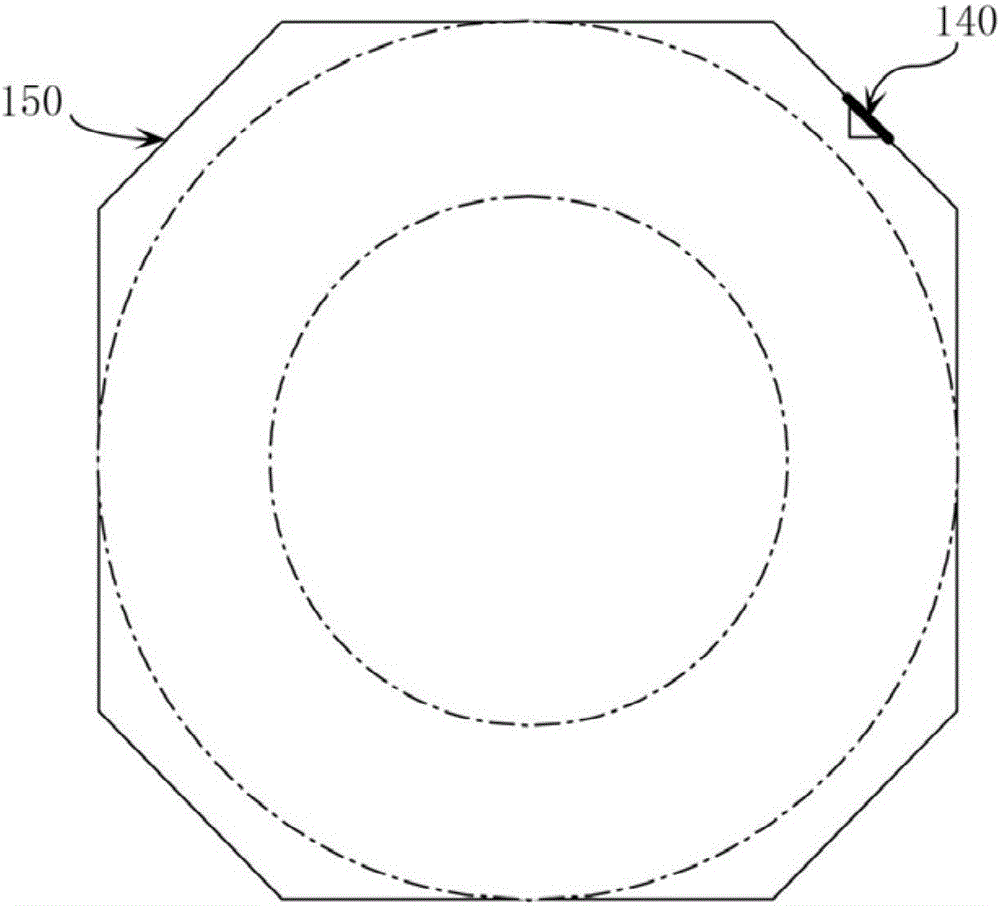

The invention relates to the field of metal material mechanical property testing, and provides a micro specimen and a hydraulic bulge testing method.The micro specimen comprises a specimen body which is a sheet body.A direction marker is arranged on the surface of the specimen body and is in or opposite to the bending direction of the specimen body.The influences of initial deformation of the micro specimen on testing results can be reduced, and the accuracy of hydraulic bulge testing results is improved.

Description

technical field [0001] The invention relates to the testing of mechanical properties of metal materials, in particular to a micro-sample and a hydraulic pressure inflation test method. Background technique [0002] Nuclear facilities, power plants and petrochemical equipment are highly dangerous facilities, so some structural designs of these facilities are designed according to relatively conservative principles. At the end of the 1970s, when the operating time of nuclear power plants in some countries was about to reach the design life, people were faced with the choice of stopping or continuing to operate. Therefore, it is necessary to test the mechanical properties of materials of in-service equipment structures. Since these materials have been operating under high temperature or radiation conditions for a long time, after a period of service, it is necessary to determine whether the properties of the materials have changed, so as to determine whether these structures c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12G01N3/06

Inventor 王汉奎徐彤寿比南张雪涛孙超

Owner CHINA SPECIAL EQUIP INSPECTION & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com