Seal and bulge test device of shell of gas flow meter

A technology of pressure test and gas flow, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the cumbersome process of installing and tightening bolts, affect the accuracy of the test, and labor intensity Large and other problems, to achieve good sealing, reduce labor intensity, and improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

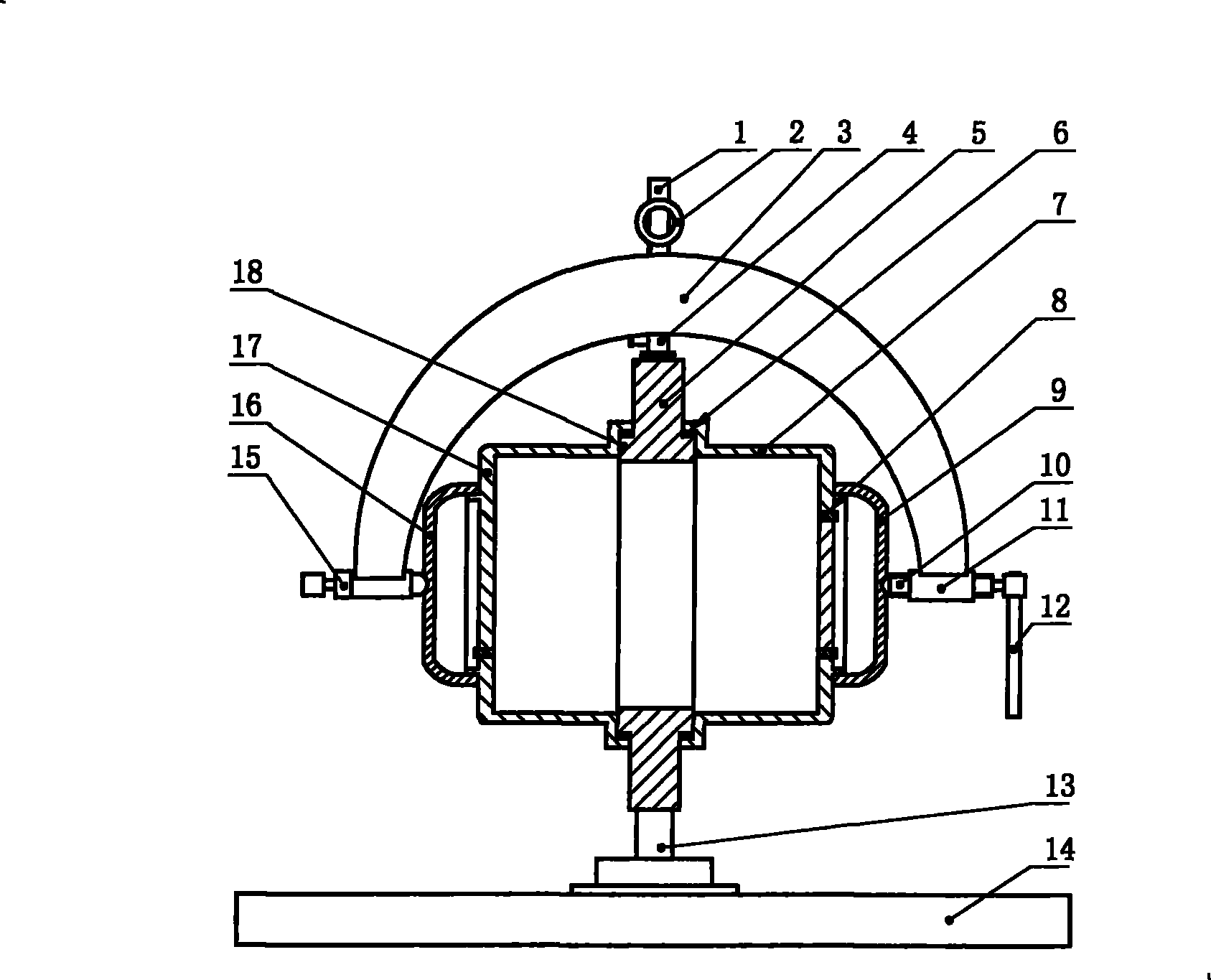

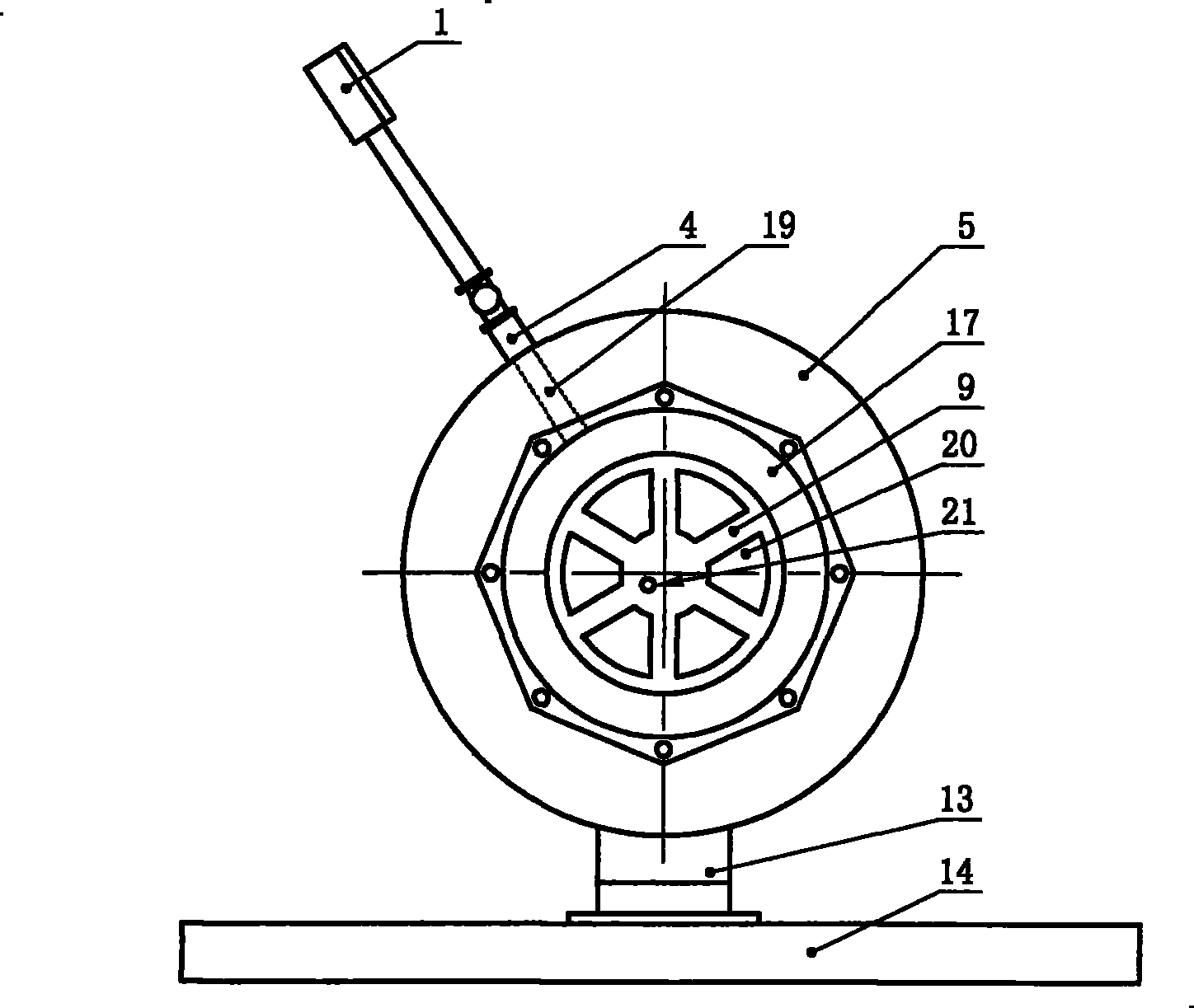

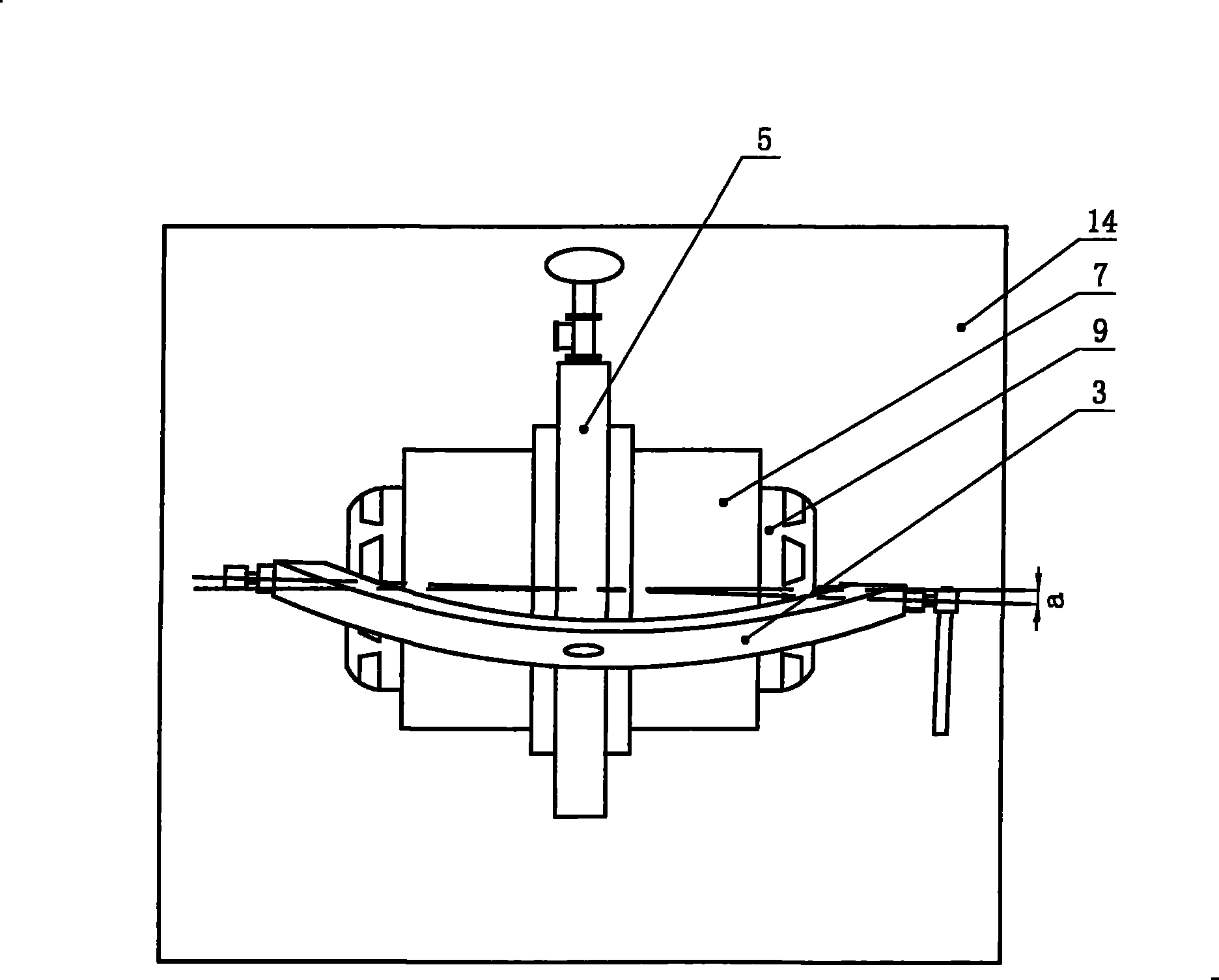

[0026] A gas flowmeter housing sealing pressure test device, composed of a base 14, an annular support 5, a fixture 3 and two pressing bowls 9,16. The annular support is vertically fixed on the upper surface of the base by the fixed table 13, and the radial air inlet 19 is formed on the annular support, and the radial air inlet is connected with the workpiece (i.e. the gas flowmeter two halves of the housing 7, 17) The internal spaces are connected. An air inlet pipe 4 is installed on the radial air inlet hole, and a pressure gauge 1 is installed on the air inlet pipe, so that the pressure state inside the two half shells can be observed conveniently. Both sides of the annular support are formed with mounting rings 18 that can be axially cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com