Short straight metal pressure pipe fitting bulge test apparatus

A pressing test and pressure tube technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of unsealing, difficulty in pressing short straight metal pressure pipe fittings, etc., and achieve effective sealing , The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

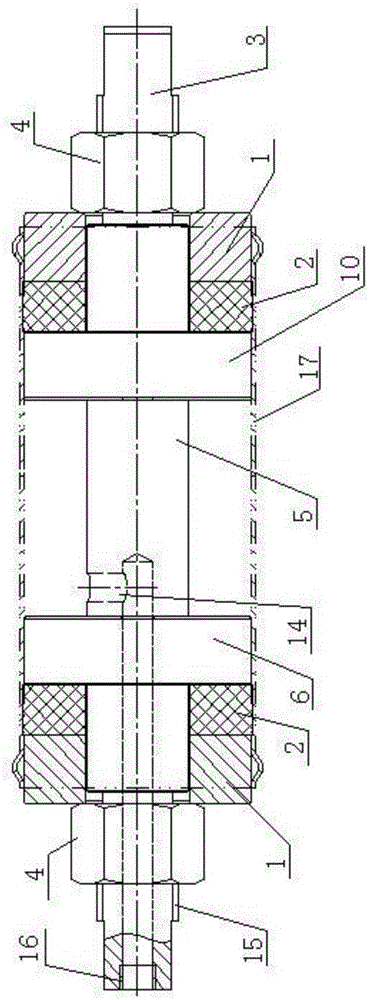

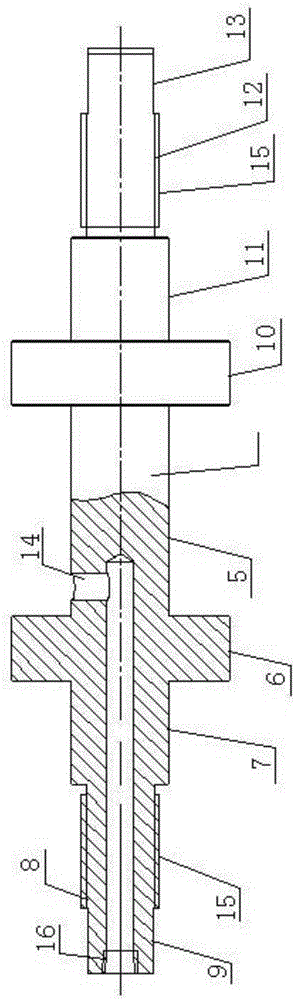

[0015] Such as figure 1 and figure 2 The shown short straight metal pressure pipe fitting compression test device includes a pressure plate 1, a flexible gasket 2, a mandrel 3 and a nut 4, the mandrel 3 is dumbbell-shaped, the middle part is a first step 5, and the mandrel 3 The right end and the left end are symmetrically provided with the second to the ninth steps, the left end of the mandrel 3 is the second to the fifth steps 6, 7, 8, 9, and the right end of the mandrel 3 is the sixth to the ninth steps 10, 11 , 12, 13, the maximum shaft diameter is less than or equal to the inner diameter of the pipe fitting 17 to be tested, the first step 5 is provided with an inward air hole 14, and the air hole 14 extends to the end of the left end of the mandrel 3, the third and seventh steps Both 7 and 11 are provided with a pressure plate 1 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com