Strip steel production method for improving shape uniformity of steel cup mouth of welded gas cylinder

A production method and uniformity technology, applied in the field of metallurgical strip rolling, can solve the problems of uneven mechanical properties of hot-rolled strips, poor shape of the closing position, low surface hardness of strips, etc., so as to improve safety and aesthetics. , The effect of reducing the phase change difference and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

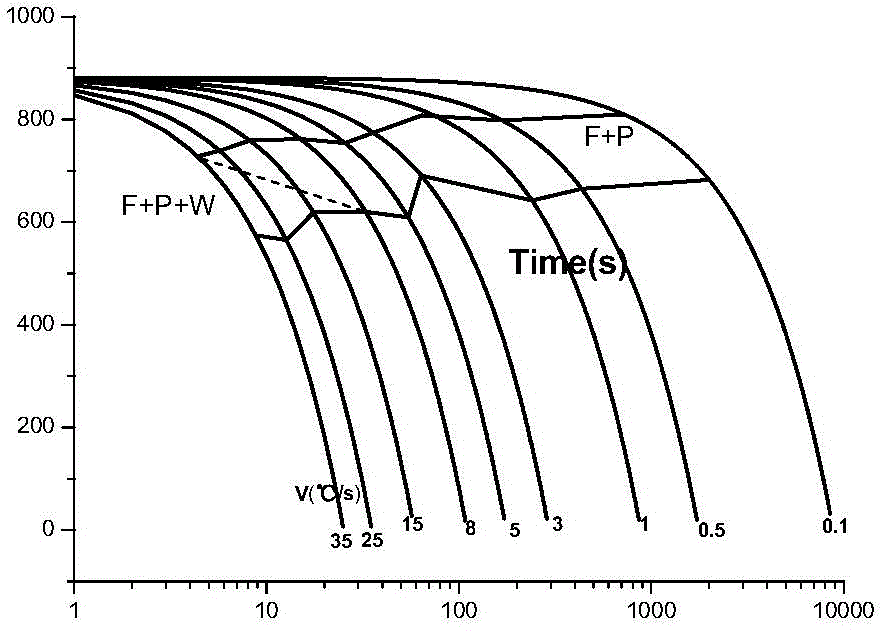

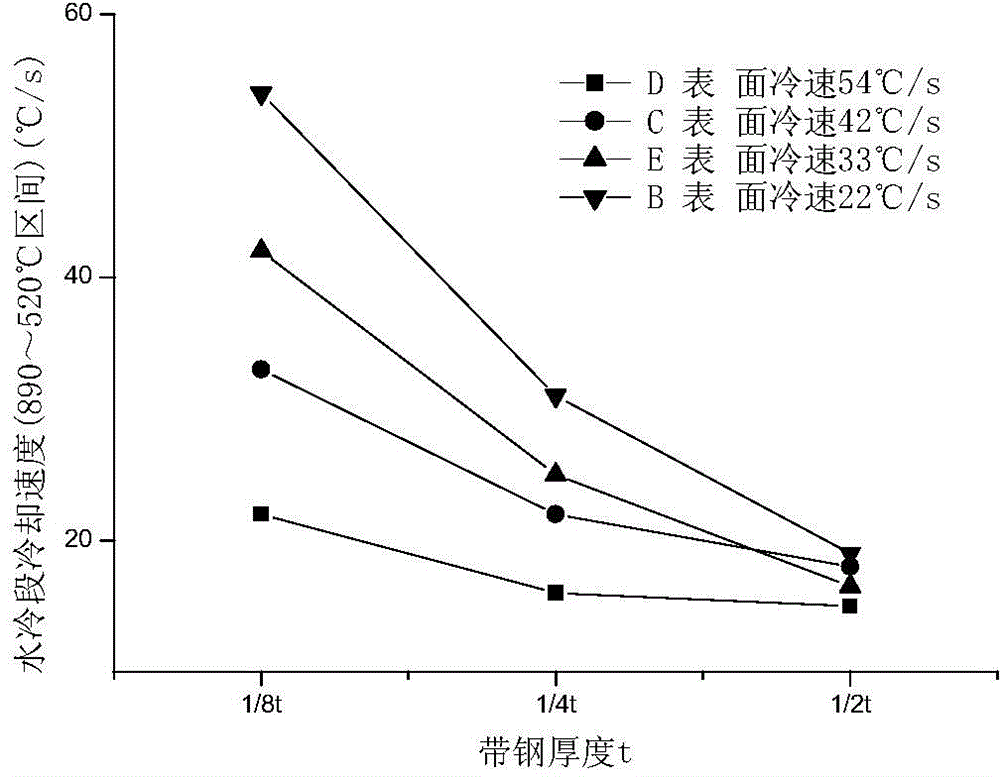

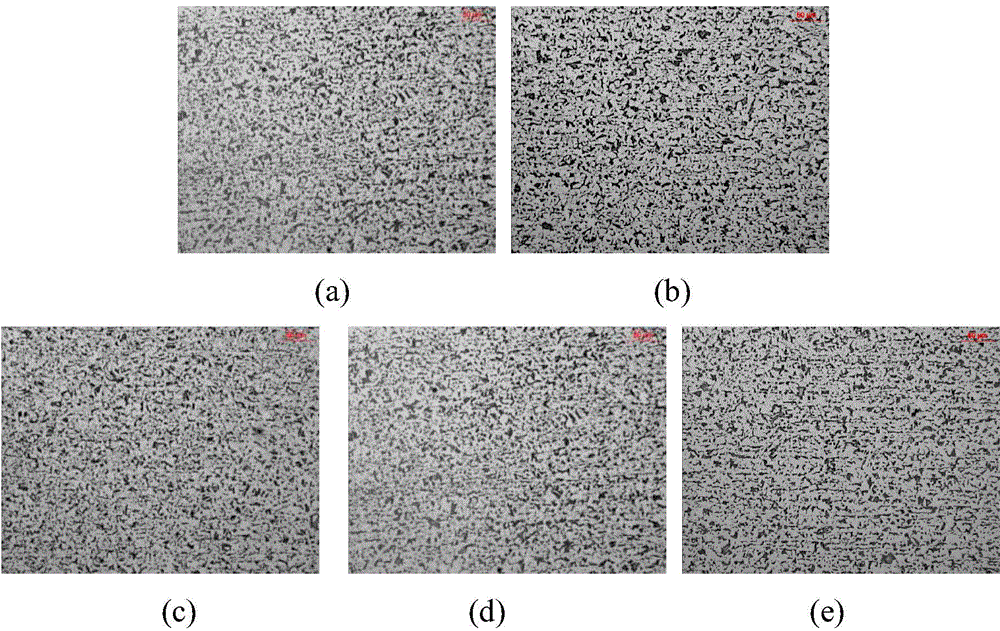

[0049] Example 1: Purified molten steel is obtained through smelting. Continuous casting is controlled by constant casting speed. Electromagnetic stirring, dynamic light reduction and other technologies are used to reduce slab component segregation, loose center, and evenly distribute inclusions to obtain a defect-free slab. The weight percentage of components is: C: 0.140%, Si: 0.0153%, Mn: 0.8012%, P: 0.0046%, S: 0.0028%, Als: 0.015%, Ti: 0.0118%. Heat the slab to 1240°C and keep it warm for 50 minutes to eliminate the temperature gradient of the slab. The rolling temperature of the final pass of rough rolling is 1060°C, the starting temperature of finish rolling is 975°C, the final rolling temperature is 892°C, and the thickness range is 2.01mm-3.0mm. The laminar flow cooling adopts deceleration cooling, edge shielding, and combined cooling mode: ①The laminar cooling rate is reduced by 26% on the original basis; ②The side stroke of the edge shielding is 186mm; ③Laminar flow...

Embodiment 2

[0051] Example 2: Purified molten steel is obtained through smelting. Continuous casting is controlled by constant casting speed. Electromagnetic stirring, dynamic light reduction and other technologies are used to reduce slab composition segregation, loose center, and evenly distribute inclusions to obtain a defect-free slab. The composition weight percentage range is: C: 0.1539%, Si: 0.0294%, Mn: 0.8745%, P: 0.0098%, S: 0.0032%, Als: 0.024%, Ti: 0.0179%. Heat the slab to 1196°C and keep it warm for 45 minutes to eliminate the temperature gradient of the slab. The rolling temperature of the final pass of rough rolling is 1042°C, the starting temperature of finish rolling is 971°C, the final rolling temperature is 885°C, and the thickness range is 3.01mm-6.0mm. Laminar cooling adopts reduced-speed cooling, edge shielding, and combined cooling mode: ①The laminar cooling rate is reduced by 20% on the original basis; ②The stroke of one side of the edge shielding is 150mm; ③Lamina...

Embodiment 3

[0053] Example 3: Purified molten steel is obtained through smelting, constant casting speed control is adopted for continuous casting, segregation of slab composition and loose center are reduced through technologies such as electromagnetic stirring and dynamic light reduction, and inclusions are evenly distributed to obtain a non-defective slab. The weight percentage range of the components is: C: 0.170%, Si: 0.0348%, Mn: 1.00%, P: 0.0108%, S: 0.0028%, Als: 0.0349%, Ti: 0.02%. Heat the slab to 1175°C and keep it warm for 40 minutes to eliminate the temperature gradient of the slab. The rolling temperature of the final pass of rough rolling is 1030°C, the starting temperature of finish rolling is 964°C, the final rolling temperature is 878°C, and the thickness range is 6.01mm-14.0mm. The laminar flow cooling adopts deceleration cooling, edge shielding, and combined cooling mode: ①The laminar cooling rate is reduced by 16% on the original basis; ②The side stroke of the edge sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com