Large-strain nickel-chromium alloy ultrafine filament monofilament continuous annealing device

A nickel-chromium alloy and annealing device technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

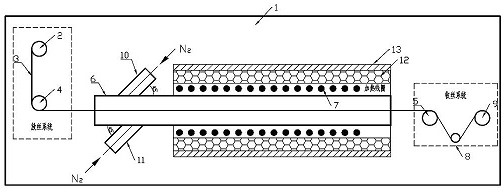

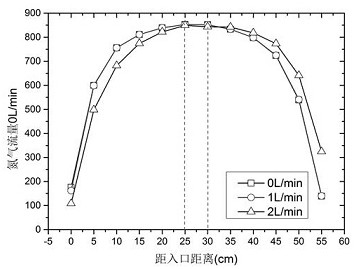

[0026] Turn on electricity and set the heat treatment temperature to 850°C, feed high-purity nitrogen gas into the quartz tube 6 from the first gas inlet 10 and the second gas inlet 11 respectively, and the flow rates are about 0L / min, 1L / min and 2L / min respectively, pre- Heat for half an hour. Thermocouples are used to measure the temperature in the quartz tube 6. The effective heating length of the quartz tube 6 is 55cm. The measurement point is measured from the entrance of the ultra-fine wire in the effective heating area. The distance is 5cm. 12 points of temperature are tested in total. The measurement results are as follows: figure 2 shown. When about 1L / min of high-purity nitrogen gas is injected from the two gas injection ports at 45° and 225°, the air can be isolated to create a symmetrical and stable temperature field. Compared with the temperature field without protective gas (0L / min), the temperature field has no obvious temperature difference, and the temperatu...

Embodiment 2

[0028] Turn on the power and set the heat treatment temperature to 930°C and the winding tension to 1g, respectively pass high-purity nitrogen gas into the quartz tube 6 from the first gas inlet 10 and the second gas inlet 11, the flow rate is about 1L / min, preheat for half an hour . Insert the wire reel wound with drawn NiCr alloy wire with a diameter of about 21.14 μm (the strain amount is about 46.6%) on the pay-off wheel 2, and pull the NiCr alloy wire 3 through the guide wheel 4 to change from vertical direction to horizontal direction , the NiCr alloy wire is passed through the quartz tube 6 with a threading tool, and after the guide wheel 5 and the tension adjustment wheel 8 change directions, the NiCr alloy wire is stuck on the coil on the wire receiving wheel 9 . Drive the take-up and take-off system to control the take-up speed to 30 rpm (the residence time in the quartz tube 6 is about 7.3s), and annealed NiCr alloy wire is obtained.

[0029] Stress-strain test ana...

Embodiment 3

[0031] Drawing and reducing the NiCr alloy wire after the annealing in Example 2, electrifying and setting the heat treatment temperature as 930° C. and the wire drawing tension as 1 g, and passing into the quartz tube 6 from the first gas inlet 10 and the second gas inlet 11 respectively. High-purity nitrogen, the flow rate is about 1L / min, preheat for half an hour. Clamp the wire reel wound with a drawn NiCr alloy wire with a diameter of about 14.91 μm (the strain amount is about 40.3%) on the pay-off wheel 2, and pull the NiCr alloy wire 3 through the guide wheel 4 to change from the vertical direction to the horizontal direction , the NiCr alloy wire is passed through the quartz tube 6 with a threading tool, and after the guide wheel 5 and the tension adjustment wheel 8 change directions, the NiCr alloy wire is stuck on the coil on the wire receiving wheel 9 . Drive the take-up and take-up system, control the take-up speed to 30 rpm (the residence time in the quartz tube 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com