Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

364 results about "Nickel Chromium Alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium Nickel is one of numerous metal alloys sold by American Elements under the trade name AE Alloys™. Generally immediately available in most volumes, AE Alloys™ are available as bar, ingot, ribbon, wire, shot, sheet, and foil.

Etchant and replenishment solution therefor, and etching method and method for producing wiring board using the

ActiveUS20050109734A1Suppress too much dissolutionExcessive dissolutionDecorative surface effectsPrinted circuit aspectsDissolutionMetallic Nickel

An etchant of the present invention includes an aqueous solution containing hydrochloric acid, nitric acid, and a cupric ion source. An etching method of the present invention includes bringing the etchant into contact with at least one metal selected from nickel, chromium, nickel-chromium alloys, and palladium. Another etching method of the present invention includes bringing a first etchant that includes an aqueous solution containing at least the following components A to C (A. hydrochloric acid; B. at least one compound selected from the following (a) to (c): (a) compounds with 7 or less carbon atoms, containing a sulfur atom(s) and at least one group selected from an amino group, an imino group, a carboxyl group, a carbonyl group, and a hydroxyl group; (b) thiazole; and (c) thiazole compounds; and C. a surfactant) into contact with a surface of the metal, and then bringing a second solution that includes an aqueous solution containing hydrochloric acid, nitric acid, and a cupric ion source into contact with the surface of the metal. According to the etchant and the etching methods of the present invention, it is possible to etch at least one metal selected from nickel, chromium, nickel-chromium alloys, and palladium quickly and suppress excessive dissolution of copper.

Owner:MEC CO LTD

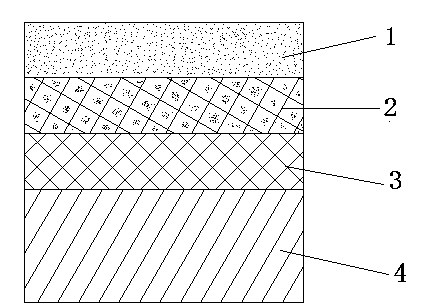

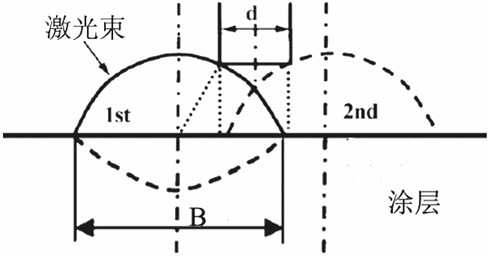

Self-lubricating solid composite material and preparation method of self-lubricating solid coating

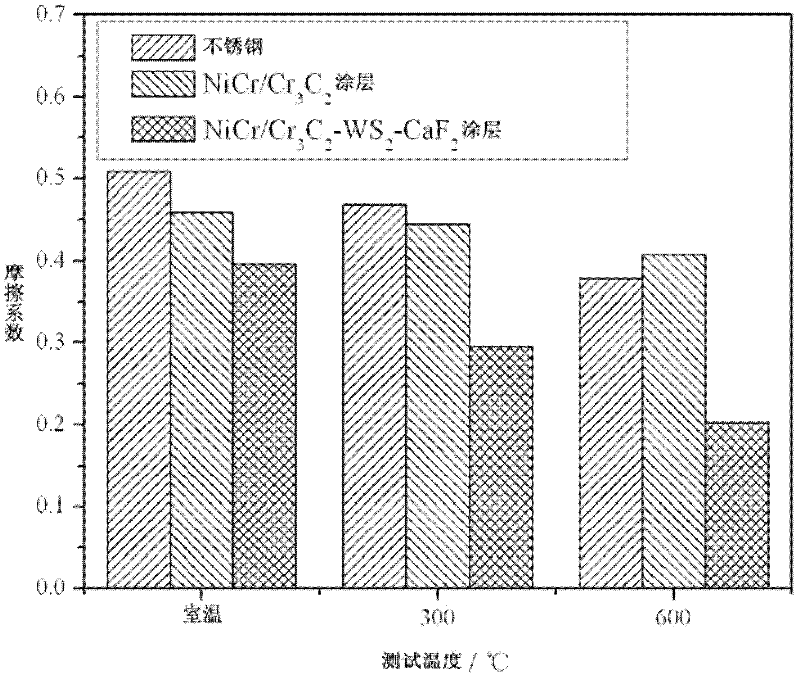

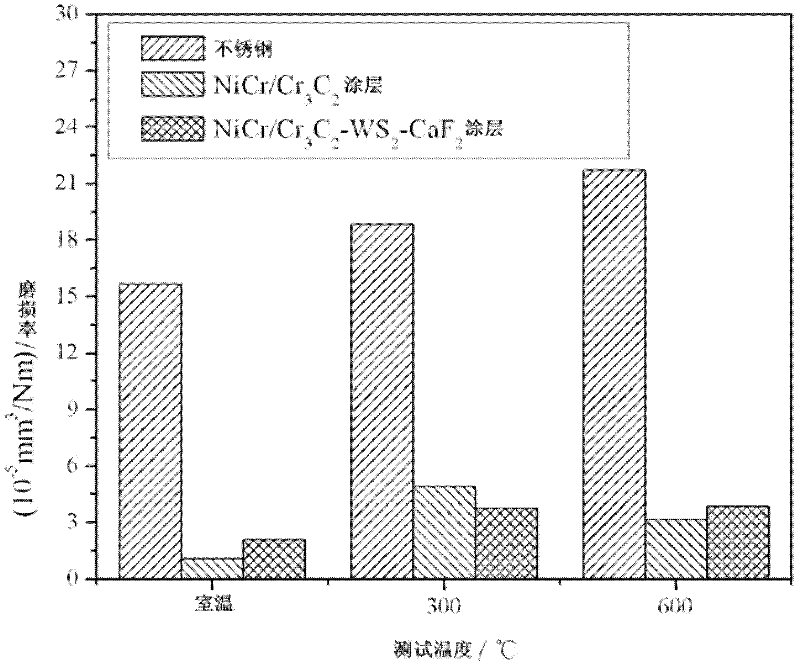

ActiveCN102363853AImprove wear resistanceReduce coefficient of frictionMetallic material coating processesMelting tankChromium carbide

The invention provides a self-lubricating solid composite material, which comprises 15-30 wt% of nickel-chromium alloy, 40-60 wt% of chromium carbide, 10-20 wt% of tungsten disulfide and 10-20 wt% of calcium fluoride. The invention also provides a preparation method of a self-lubricating solid coating. By a laser cladding method, the self-lubricating solid coating is formed on a matrix material. The self-lubricating solid composite material can be firstly coated on the matrix material and forms a coating by laser cladding; and also the matrix material can be firstly irradiated by a laser beam to form a molten pool, and then the self-lubricating solid composite material is sent into the molten pool and is continuously irradiated to form the coating. The prepared self-lubricating solid coating has excellent wear resistance and good lubrication performance within the temperature range of room temperature to 600 DEG C, and can satisfy the usage requirement under severe working conditions.

Owner:SUZHOU UNIV

Alloy steel and article made therefrom

A relatively high strength high toughness medium Carbon Copper-Nickel-Chromium alloy steel and method that eliminates and / or reduces the use of scarce, expensive alloying elements and is lower in cost than existing high strength high toughness alloy steels with comparable strength and toughness properties. In a first embodiment, the alloy steel is comprised of by weight about 0.40–1.00% Copper, about 2.50–8.00% Nickel, and about 0.80–3.50% Chromium. In a second embodiment the alloy steel is comprised of by weight about 0.55–0.70% Copper, about 1.0–6.0% Nickel, and about 1.0–2.2% Chromium.

Owner:CARPENTER TECH CORP

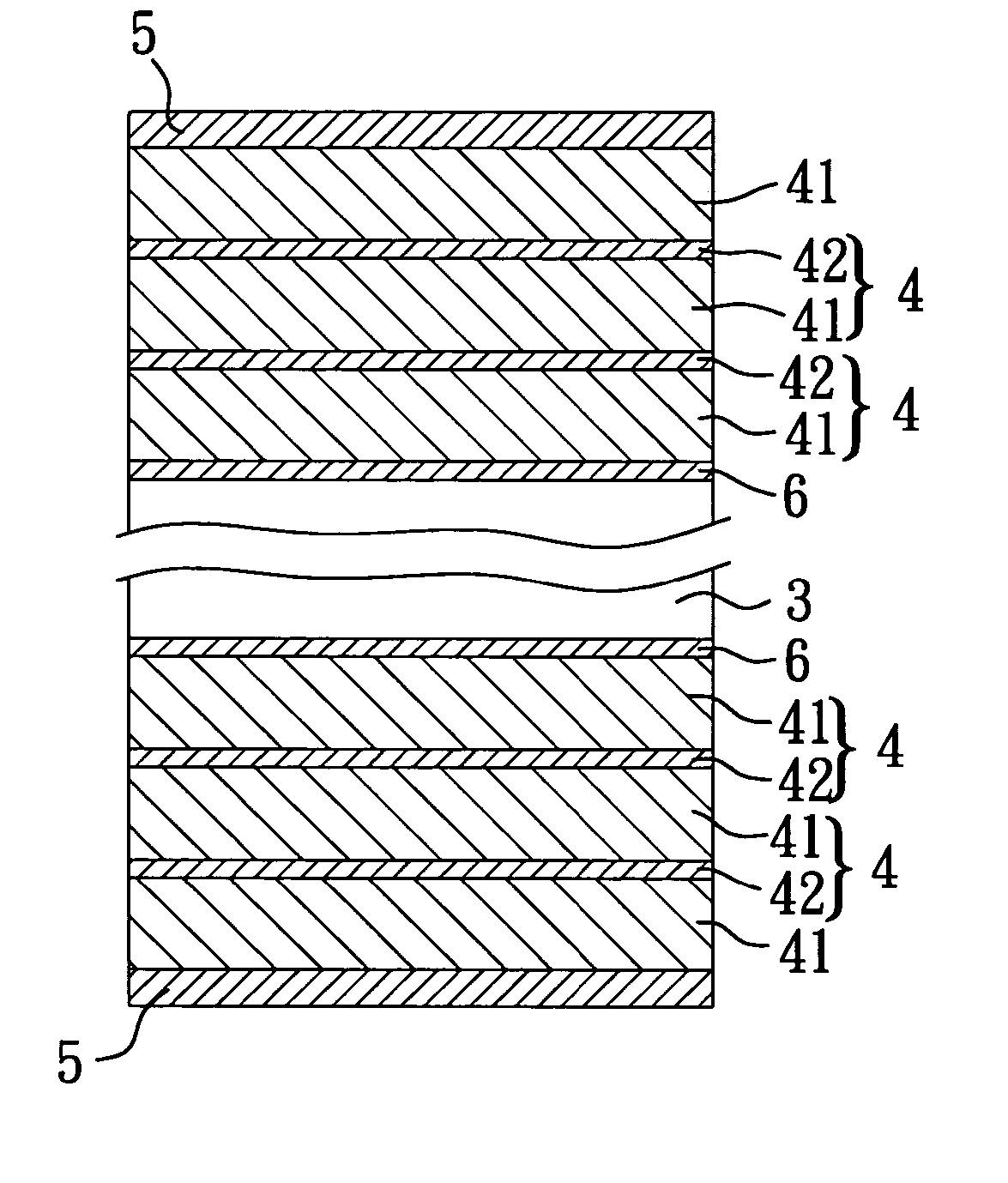

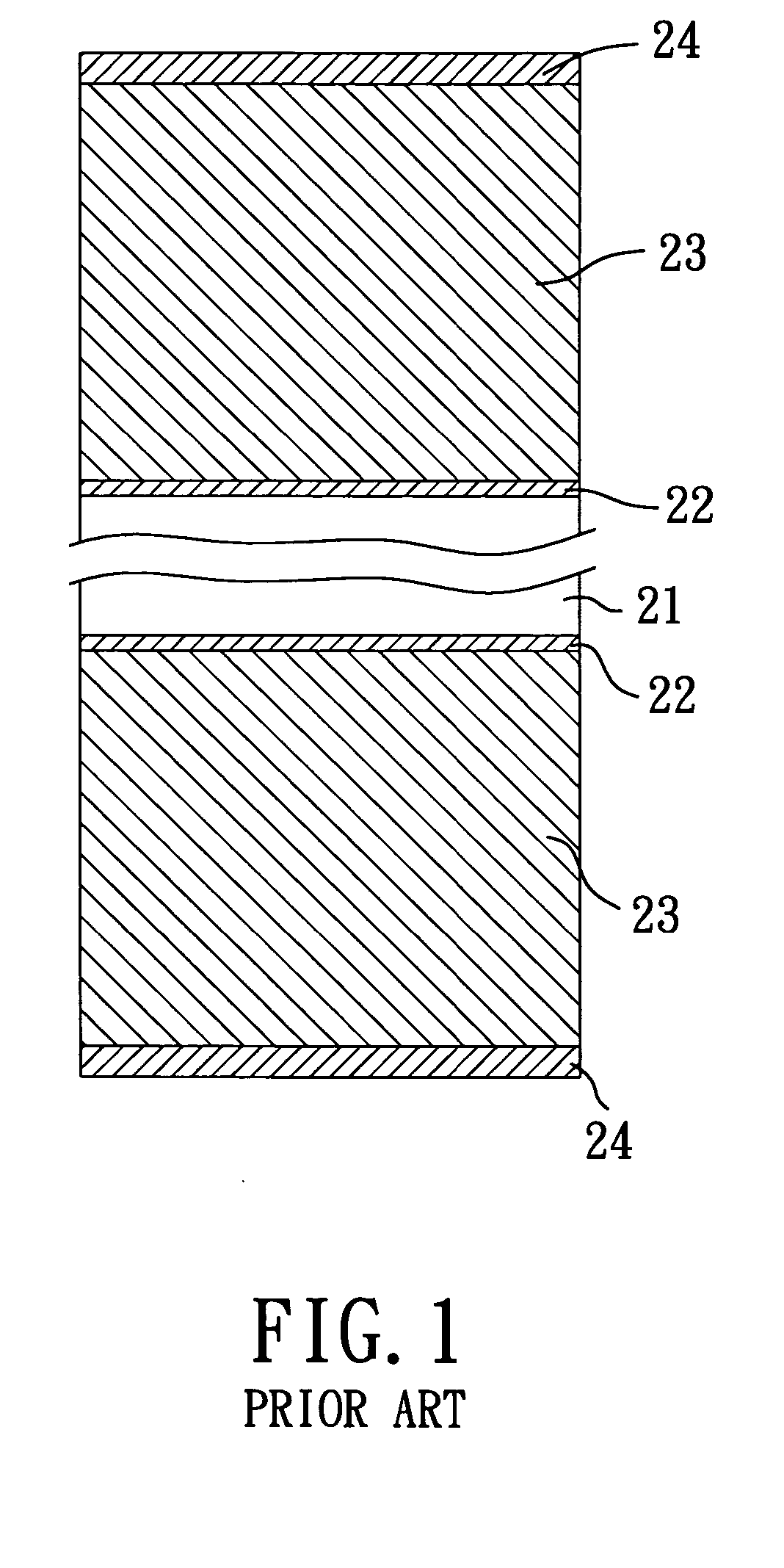

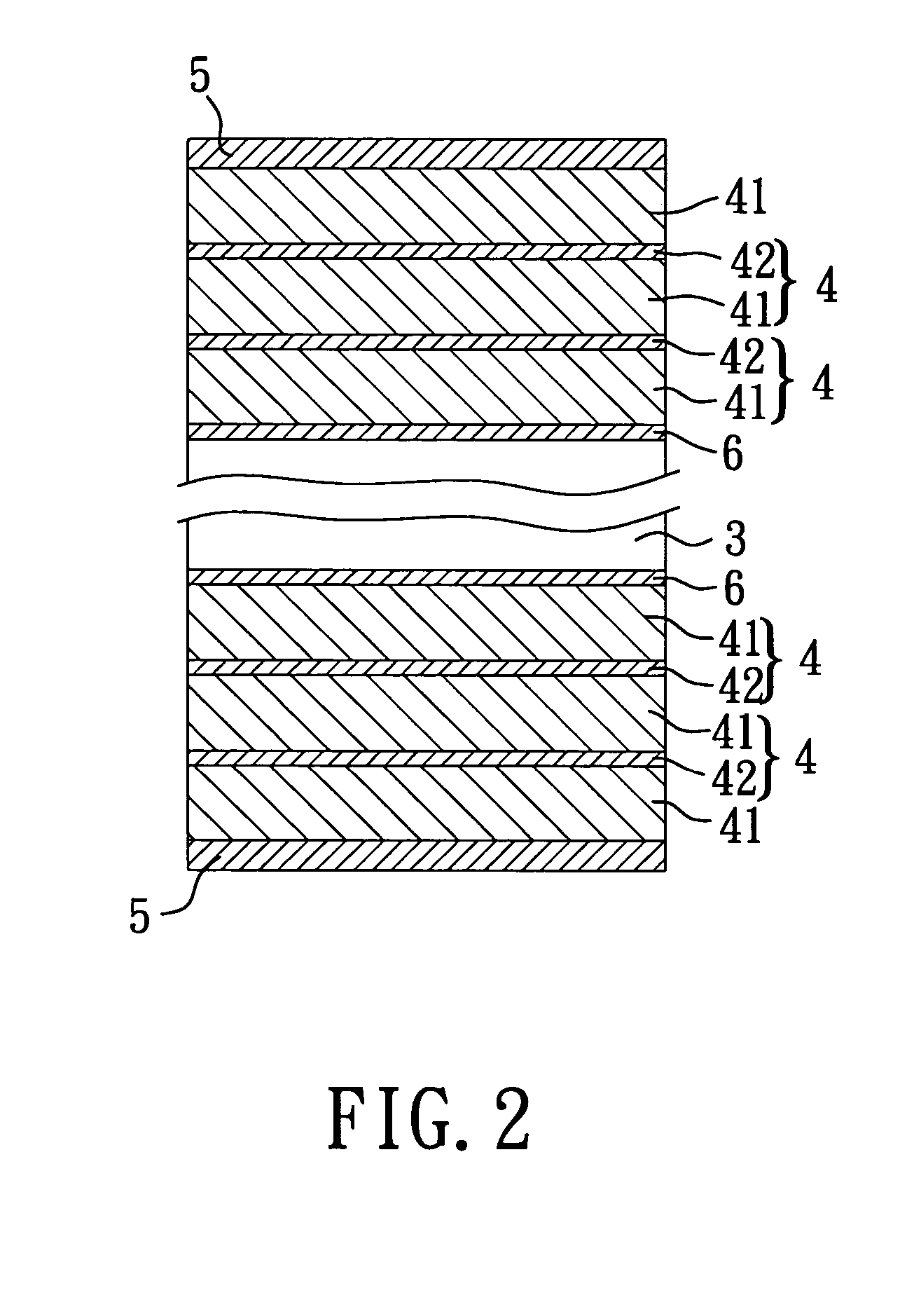

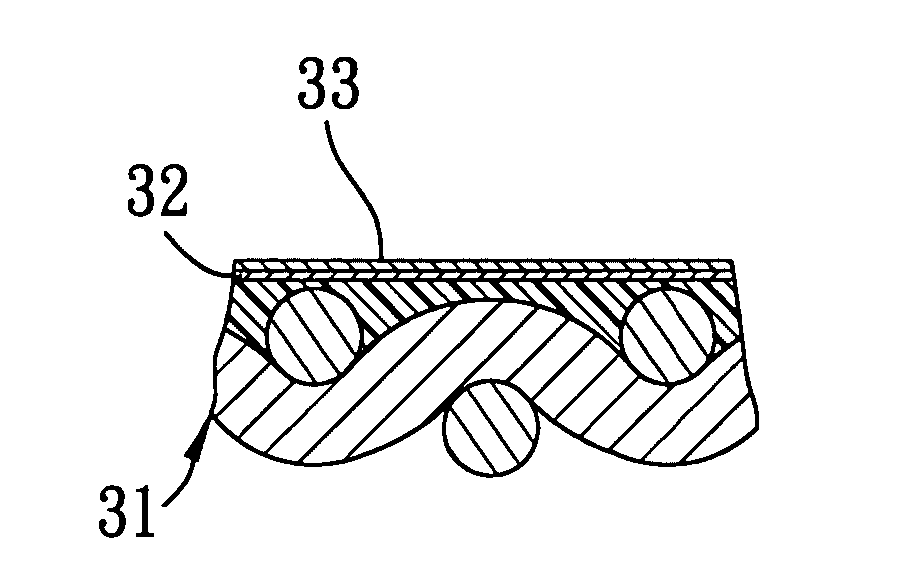

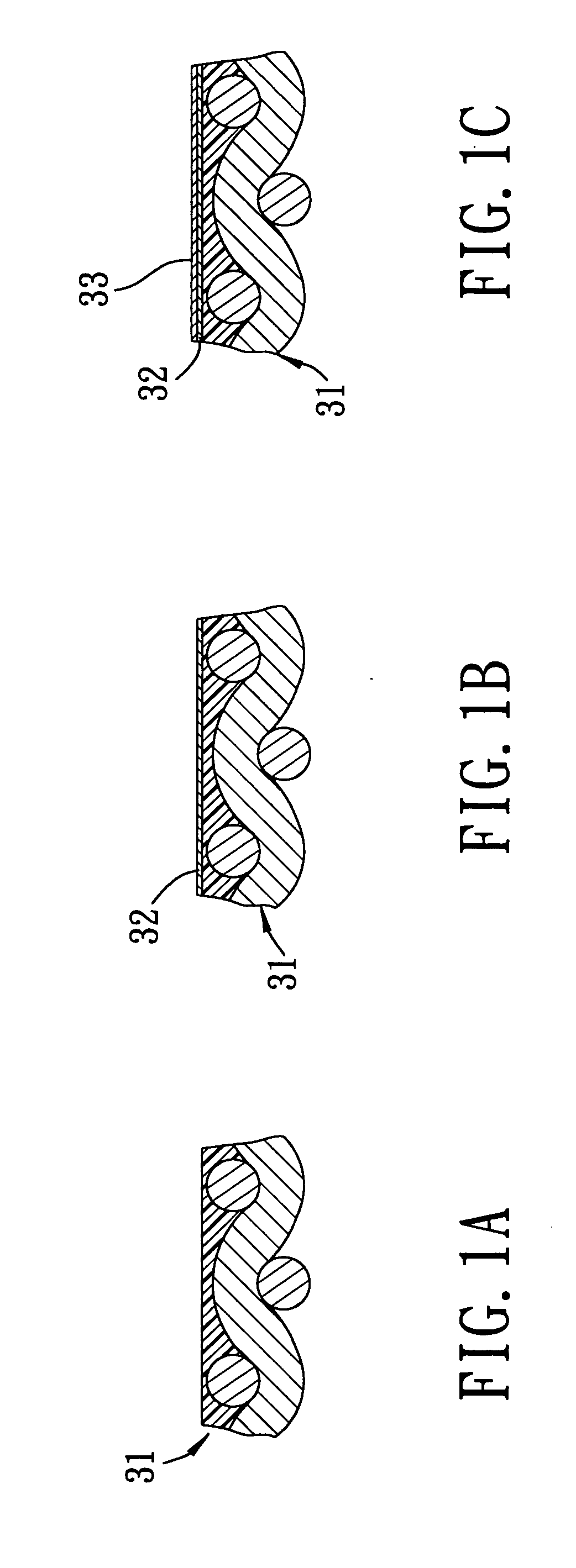

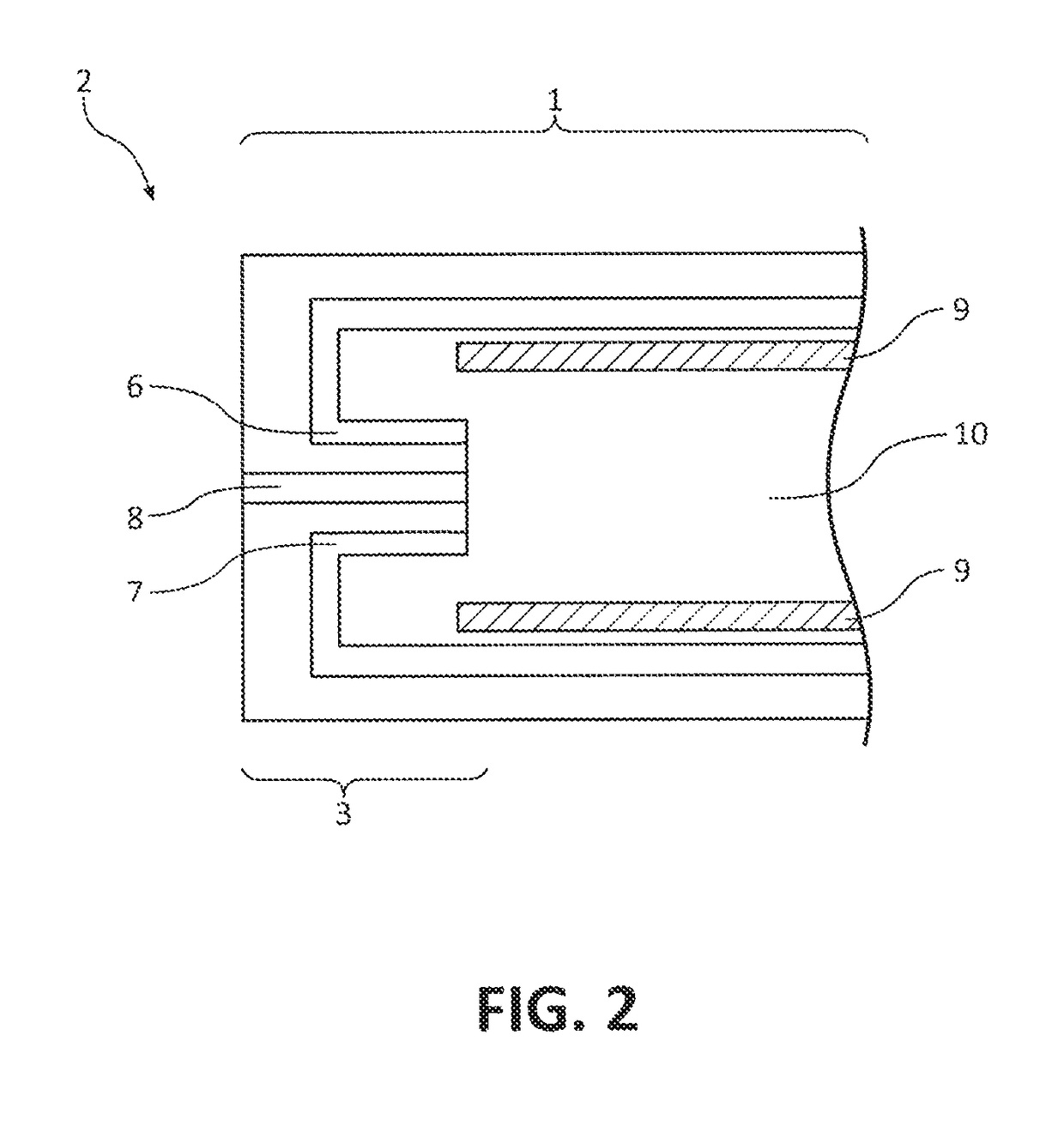

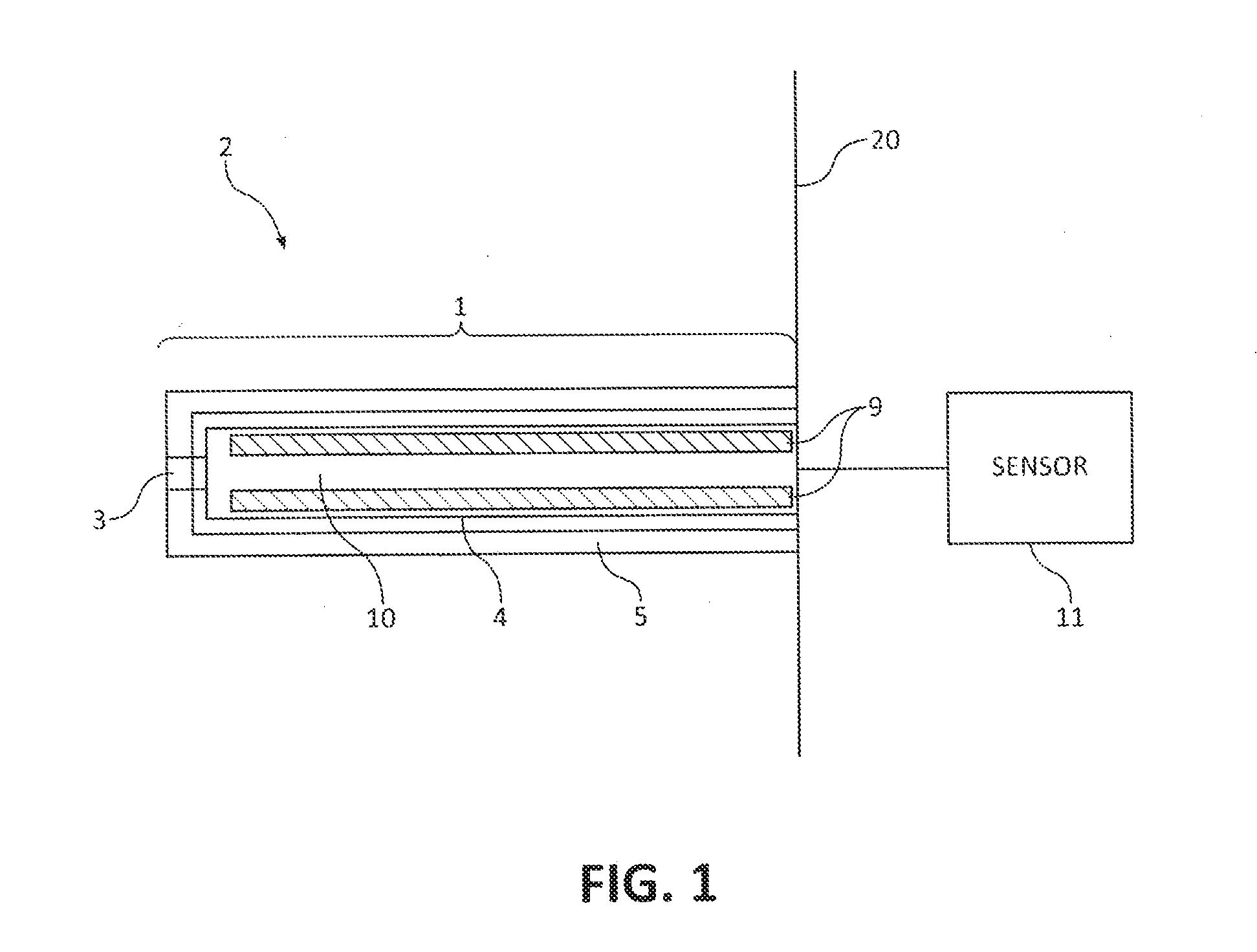

Electromagnetic radiation shielding fabric

InactiveUS20050042960A1Magnetic/electric field screeningSynthetic resin layered productsOptoelectronicsTitanium

An electromagnetic radiation shielding fabric includes a fabric substrate, a first interfacial layer formed on the fabric substrate, and at least a radiation shielding unit formed on the first interfacial layer and including two shielding layers, each of which is made from a first metal, and a second interfacial layer interposed between the shielding layers and made from a second metal. The first metal is selected from the group consisting of copper, silver, gold, and aluminum. The second metal is selected from the group consisting of nickel, chromium, nickel-chromium alloy, and titanium.

Owner:HELIX TECH

Multielement high-nickel chromium wear-resistant cast iron and its prepn process

InactiveCN1706976AImprove antioxidant capacityImprove wear resistanceChemical compositionWear resistant

The present invention is multielement high-Ni-Cr wear resistant alloy cast iron and its preparation process. The multielement high-Ni-Cr wear resistant cast iron consists of: C 1.2-3.2 wt%, Cr 12-27 wt%, Mn 0.5-1.5 wt%, Si 0.3-1.5 wt%, Mo 0.2-2.2 wt%, Ni 0.2-2.0 wt%, Cu 0.5-1.2 wt%, S not more than 0.07 wt%, P not more than 0.07 wt% and modifier 0.2-0.5 wt%, except Fe. By means of altering the components of the alloy cast iron, wear resistant alloy cast iron with high antioxidant performance and high wear resisting performance and different operation temperature range, -20 to +300 deg.c, 300 to 700 deg.c, 700 to 900 deg.c, etc may be produced for different uses. Compared with common alloy cast iron, the multielement high-Ni-Cr wear resistant alloy cast iron may produce parts with 1.5-3.5 times longer service life.

Owner:宝钢集团上海梅山有限公司

Composite powder coated by ultramicro or Nano metal powder, and preparation method

A superfine or nano-class metallic powder clad composite powder is composed of a core particle made of the metal (Ni or stainless steel), the carbide (tungsten carbide or chromium carbide), alloy (NiCr), self-smelting alloy (NiCrBSi), or their composition, and a cladding layer made of superfine or nano-class metal particles (Al, Mo, or Co). It can be used for hot spray coating or powder metallurgy. Its preparing process is also disclosed.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

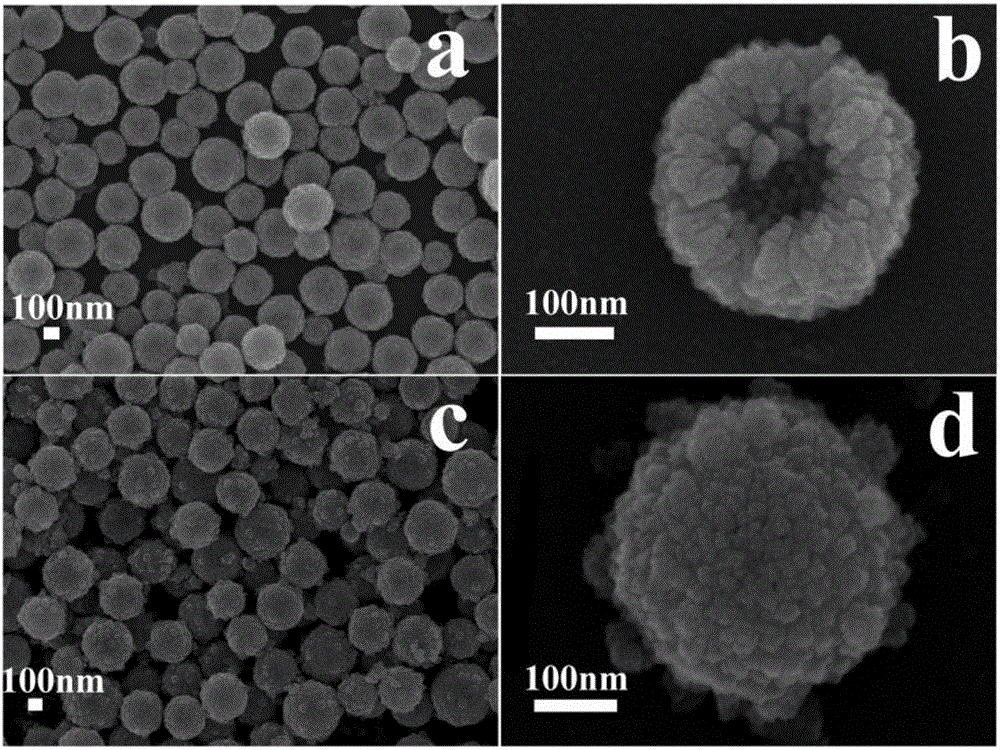

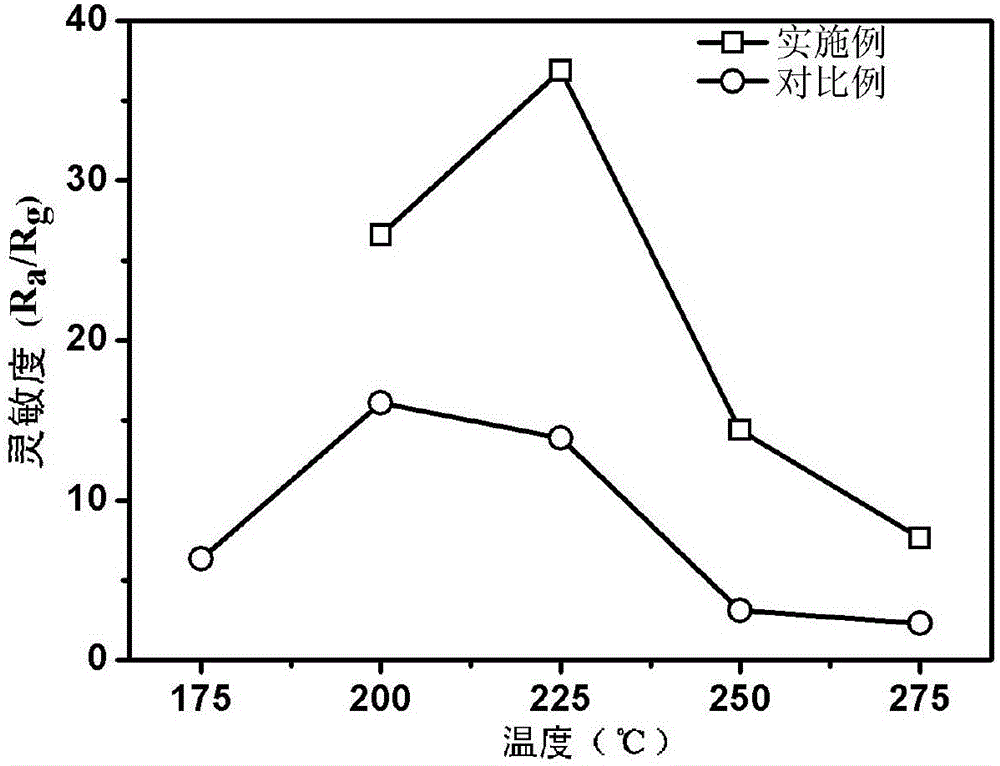

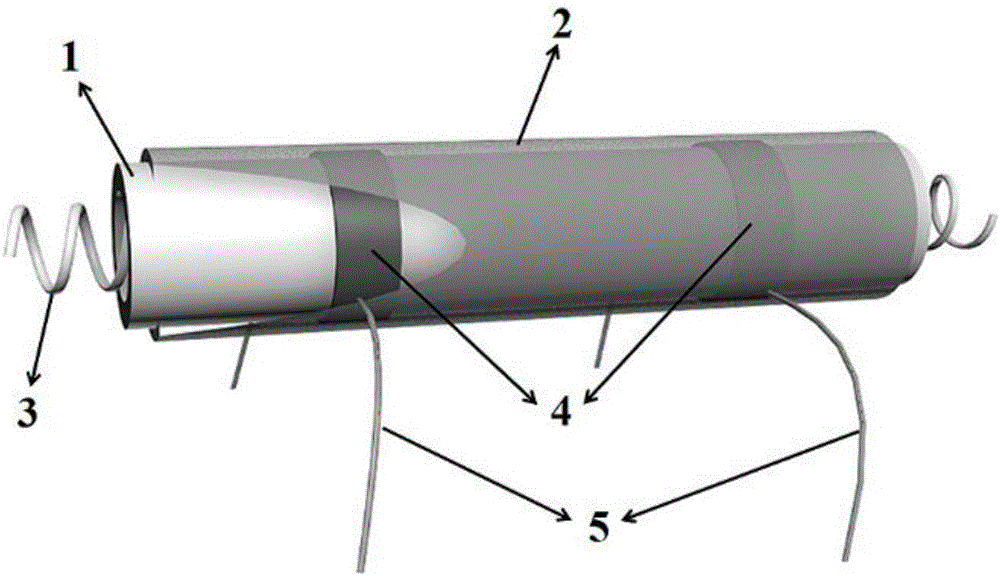

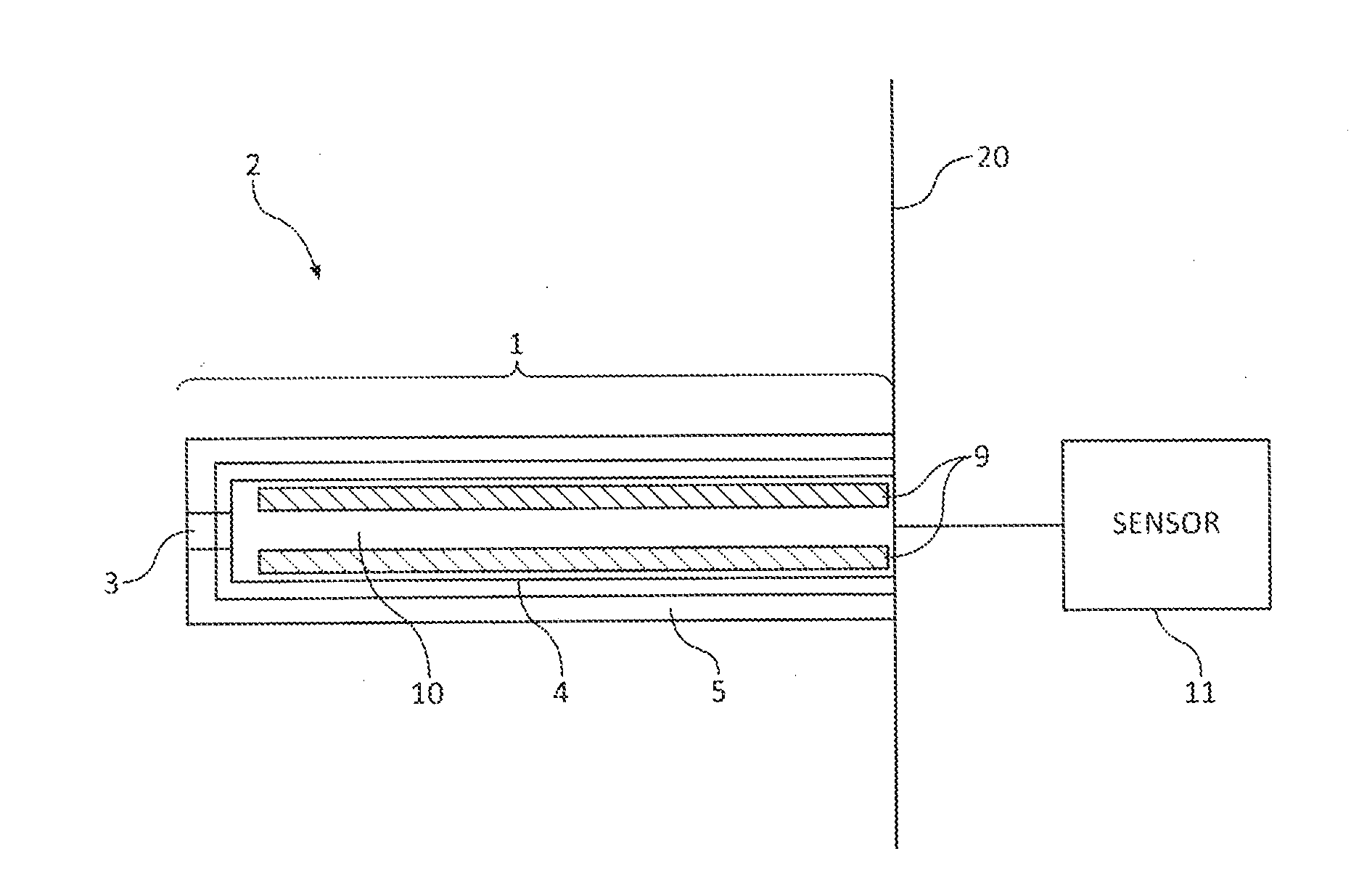

Ethanol sensor based on hollow spherical SnO2/CeO2 heterostructural composite oxide and preparation method thereof

ActiveCN105136867AThe synthesis method is simpleLow costMaterial resistanceHigh volume manufacturingTwo step

The invention belongs to the technical field of semiconductor oxide gas sensor, and specifically relates to a hollow spherical SnO2 / CeO2 heterostructural composite oxide ethanol gas sensor and a preparation method thereof. A hollow spherical SnO2 / CeO2 heterostructural composite oxide sensitive material prepared through a two-step hydrothermal method is used. With utilization of a heterostructure formed between SnO2 and CeO2 and synergistic catalysis action of SnO2 and CeO2 on ethanol, the gas sensitive characteristic of the sensor on ethanol is effectively improved. In addition, the adopted sensor structure is composed of a commercially available Al2O3 insulation ceramic tube with two annular gold electrodes, a semiconductor sensitive material coating the annular gold electrodes and the Al2O3 insulation ceramic tube, and a nickel-chromium alloy heating coil passing through the Al2O3 insulation ceramic tube. The ethanol gas sensor is simple in device process, small in size and suitable for mass production, thereby having broad application prospects in detection of the ethanol content.

Owner:JILIN UNIV

Method for making an electromagnetic radiation shielding fabric

A method for making an electromagnetic radiation shielding fabric includes the steps of forming a radiation shielding metal layer on a fabric substrate through sputtering deposition techniques, and forming a protective metal layer on the radiation shielding metal layer. The radiation shielding metal layer is made from a first metal selected from the group consisting of copper and silver. The protective metal layer is made from a second metal selected from the group consisting of nickel, chromium, nickel-chromium alloy, and titanium. The aforesaid sputtering deposition is conducted at a power ranging from 300 to 1000 watts and a deposition time ranging from 17 to 90 seconds.

Owner:HELIX TECH

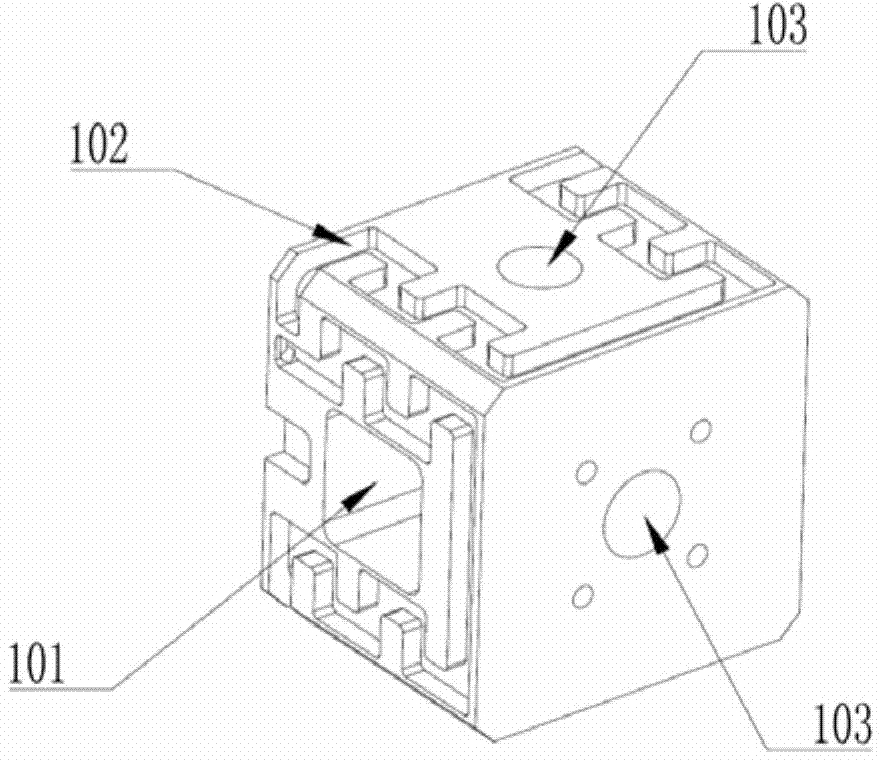

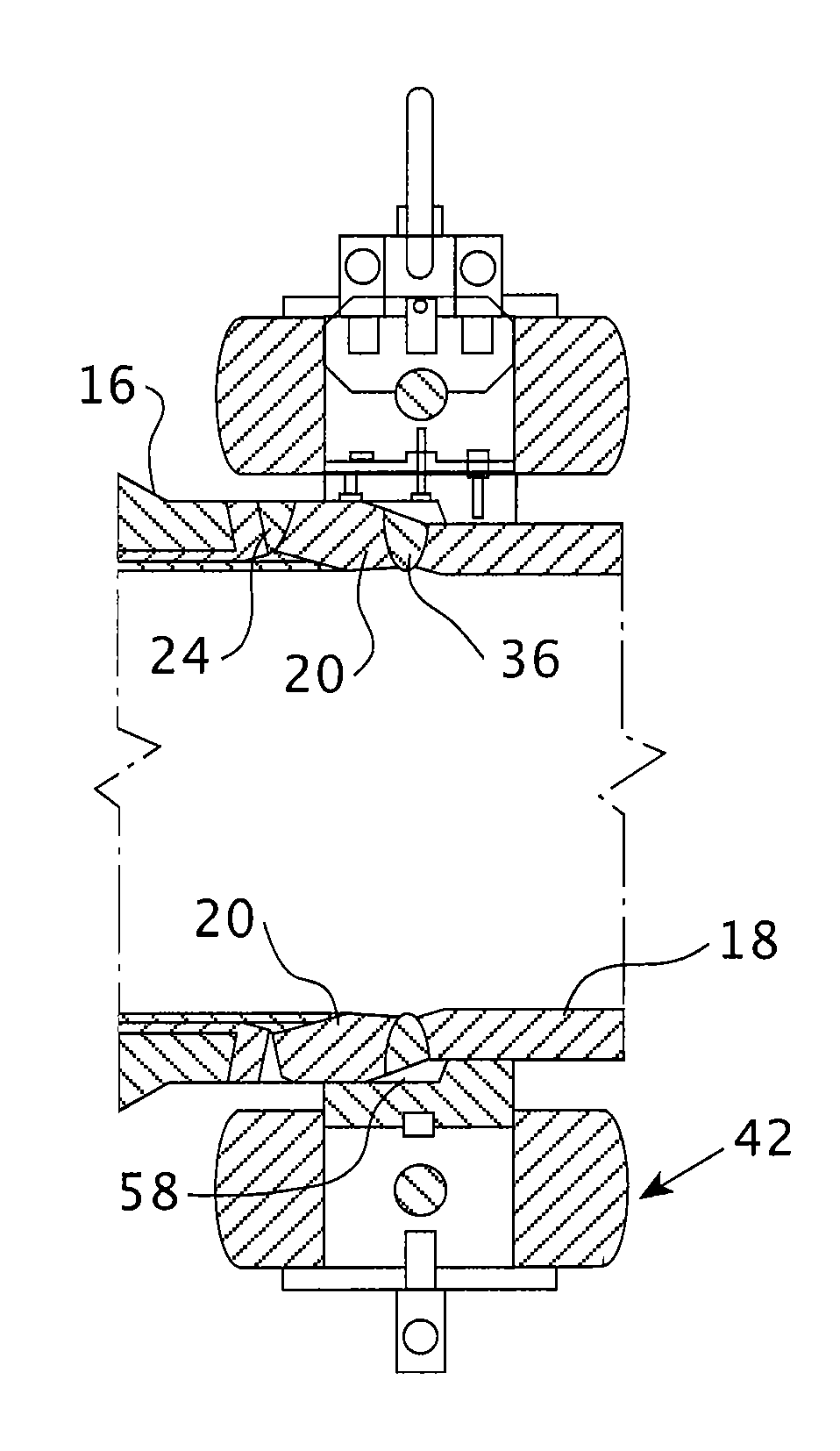

Non-magnetic heating device for nuclear magnetic resonance gyroscope

ActiveCN104505273AImprove heating efficiencyHeating evenlyContact operating partsOhmic-resistance heatingNMR - Nuclear magnetic resonanceGyroscope

The invention provides a non-magnetic heating device for a nuclear magnetic resonance gyroscope. The device consists of a heating body, a heating wire, a heat insulating framework and magnetic compensation coils, wherein the heating body is made of a non-magnetic high-heat-conductivity material, and is of a hollow structure; an atomic gas chamber is placed into the heating body for being uniformly heated; the four faces of the outer side of the heating body are provided with heating grooves; the nickel-chromium alloy non-magnetic heating wire can be placed into the heating grooves positively or reversely, thereby constructing a spatial symmetrical non-magnetic heating structure under the constraints of the heating grooves; after the heating body and the heating wire are fixedly assembled, the combination is fixed in the polytetrafluoroethylene heat insulating framework; three groups of winding grooves are formed in the heat insulating framework for winding enameled wires, thereby constructing three groups of orthogonal Helmholtz magnetic compensation coils for compensating a residual magnetic field. Compared with the prior art, the non-magnetic heating device has the advantages of compact structure, easiness in assembly, easiness in implementing engineering, high heating uniformity, high heating efficiency and high heating magnetic field counteracting capability.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

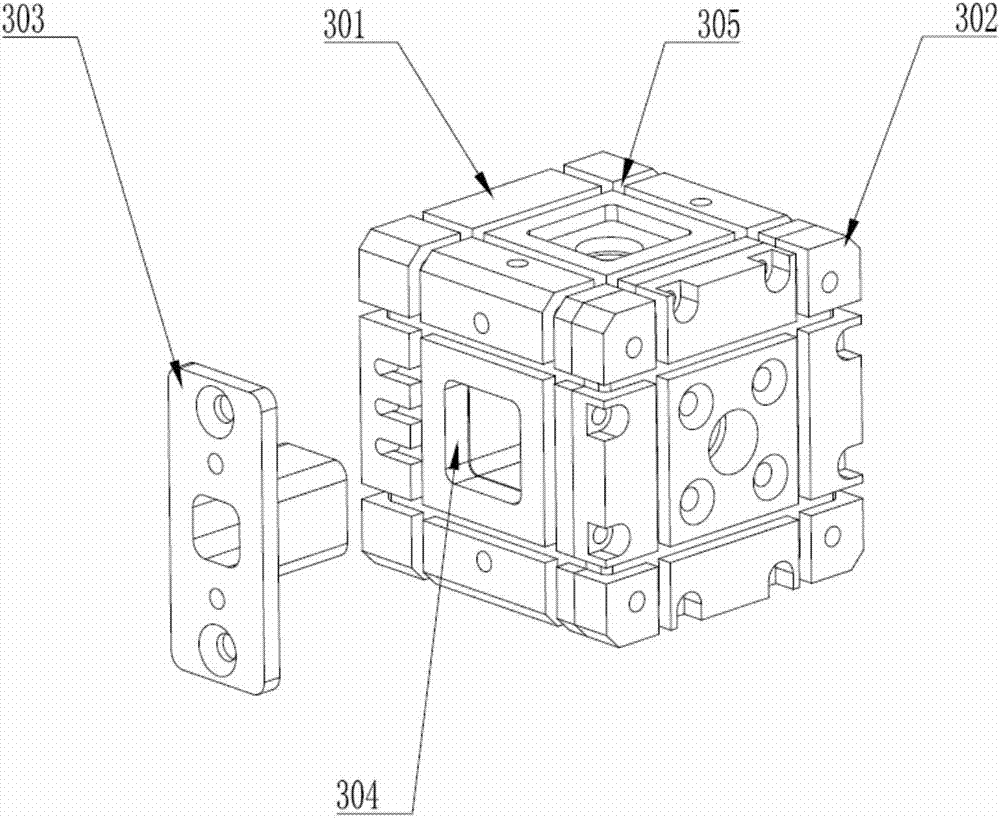

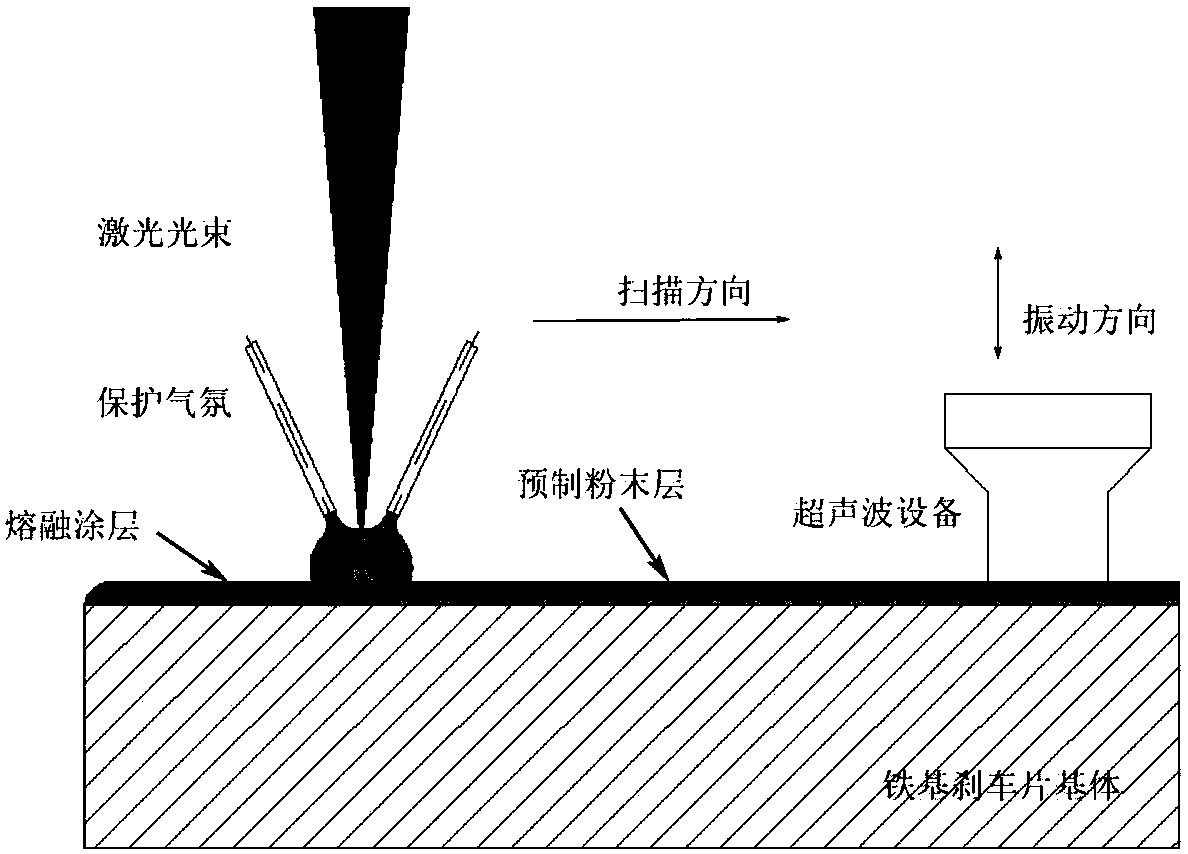

Composite coating material applied to semi-metal iron-based brake pads and preparation method for composite coating material

ActiveCN108127123AStable brakingImprove toughnessTransportation and packagingMetal-working apparatusWater vaporFerrosilicon

The invention discloses a composite coating material applied to semi-metal iron-based brake pads. The composite coating material is formed by nickel-chrome alloy powder, chromium carbide powder, ferrosilicon, ferrovanadium, aluminite powder and graphene being subjected to high temperature melting, water vapor mixing atomization, bonding batter-mixing brushing and laser melting. The raw materials comprise the ingredients of, in percentage by mass, 12-50% of nickel-chromium, 15-28% of chromium carbide, 6-10% of ferrosilicon, 5-8% of ferrovanadium, 20-40% of aluminum and 1-2% of graphene. By means of the composite coating material applied to the semi-metal iron-based brake pads and a preparation method for the composite coating material, a metal alloy powder coating formed on the surface of the semi-metal iron-based brake pads has good physical and mechanical performance and has good friction performance and thermal stability under high temperature conditions, and dust after friction is convenient to treat, furthermore, process parameters are easy to control in the preparation process, and the composite coating material applied to the semi-metal iron-based brake pads and the preparation method for the composite coating material are suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Thermostable and corrosion-resistant cast nickel-chromium alloy

A nickel-chromium casting alloy comprising up to 0.8% of carbon, up to 1% of silicon, up to 0.2% of manganese, 15 to 40% of chromium, 0.5 to 13% of iron, 1.5 to 7% of aluminum, up to 2.5% of niobium, up to 1.5% of titanium, 0.01 to 0.4% of zirconium, up to 0.06% of nitrogen, up to 12% of cobalt, up to 5% of molybdenum, up to 6% of tungsten and from 0.01 to 0.1% of yttrium, remainder nickel, has a high resistance to carburization and oxidation even at temperatures of over 1130° C. in a carburizing and oxidizing atmosphere, as well as a high thermal stability, in particular creep rupture strength.

Owner:SCHMIDT CLEMENS

High-temperature alloy base self-lubricating composite material and surface pattern treatment method thereof

InactiveCN101078072AExtended service lifeReduce coefficient of frictionBearing componentsLaser beam welding apparatusSurface patternSuperalloy

A kind of high temperature alloy group self-lubricating compound material and the method to pattern surface of it. The components and the mass percent of them are as following: Ni: 28.8-56.8%, Fe: 10.0-30.0%, Cr: 7.2-14.2%, W: 5.0- 15.0%, C: 3.0-6.0%, Si: 0.8%-1.2%, MoS2: 5.0%-15.0%. The method to pattern it' s surface contains the following steps: The surface of the nickel chromium alloy group self-lubricating compound material sample after being hot pressed and mould will be polished. A gammaray laser will be used to corrase micropore on the surface, the focus of the focusing lens will be adjusted to 40-60mm, the facula diameter at the focus is 0.15- 0.20mm, the impulse duration will be adjusted to 450-500ns, the laser bean will process micropore according to ring shape from outside to inside. The surface after being corrased and polished will be lubricated by daubing the fat of solid layered dry lubricant. The alloy group material not only owns high mechanical strength but also owns high temperature self-lubricating ability. The coefficient of friction can be decreased, the application life can be prolonged, and low attrition abrasion in wide temperature range can also be realized by patterning the surface.

Owner:NANJING UNIV OF SCI & TECH

Penetration brazing preparation method of high-content wolfram carbide gradient wear-resisting coating

The invention provides a penetration brazing preparation method of a high-content wolfram carbide gradient wear-resisting coating, comprising the following steps: sequentially sticking a plurality of layers metal wire net flexible compound cloth containing wolfram carbide WC or wolfram carbide-cobalt WC-Co and nickel-chromium alloy powder Ni-Cr on a metal base body by using an epoxy resin binding agent; and carrying out penetration brazing in a vacuum furnace. Compared with the prior art, the Rockwell hardness of a researched coating with the WC content of 70% is HRC64-70 and the wear resistance is obviously improved.

Owner:NANCHANG INST OF TECH

Wear resistant coating for piston rings

InactiveUS20050260436A1Improved scuff resistanceImprove wear resistanceMolten spray coatingPiston ringsChromium carbidePowder mixture

A wear resistant coating for protecting surfaces undergoing sliding contact is disclosed. The wear resistant coating is applied by high velocity plasma process deposition of a powdered blend of the coating constituents. The powdered blend includes a nickel-chromium alloy, chromium carbide, and molybdenum. The molybdenum powder has a particle size of less than about 45 microns. The disclosed coating should find use as a bearing surface on piston rings, cylinder liners, and other components of a power cylinder assembly of an internal combustion engine.

Owner:MAHLE ENGINE COMPONENTS USA

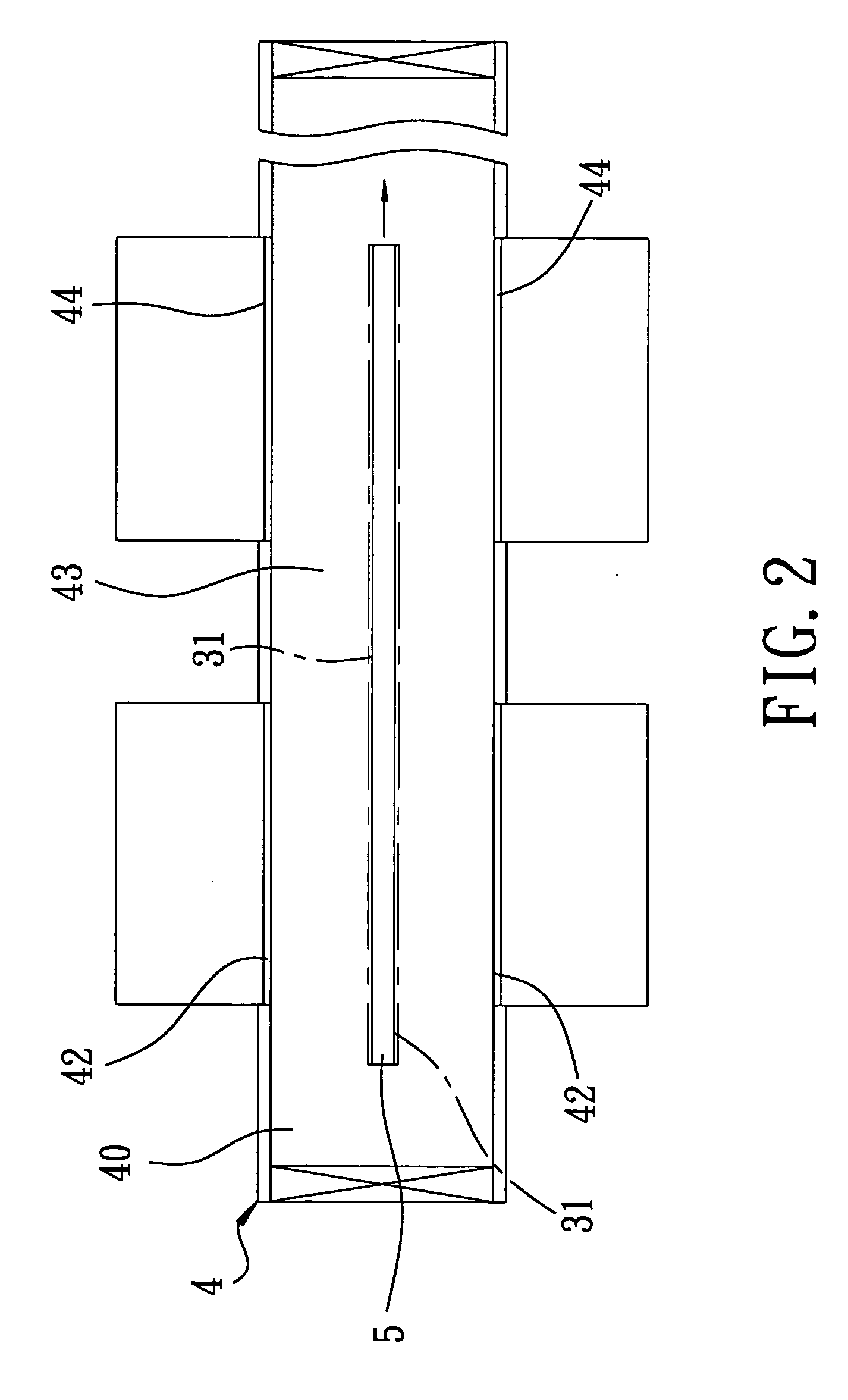

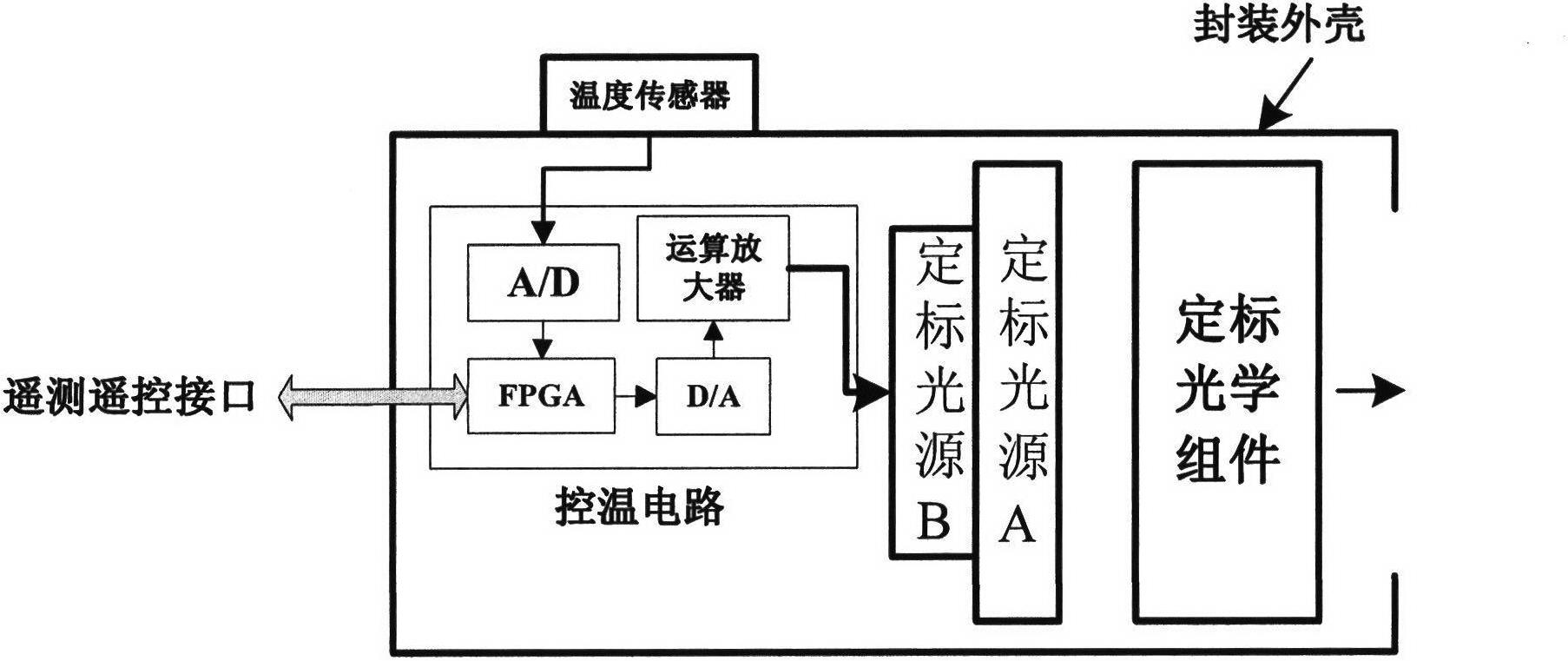

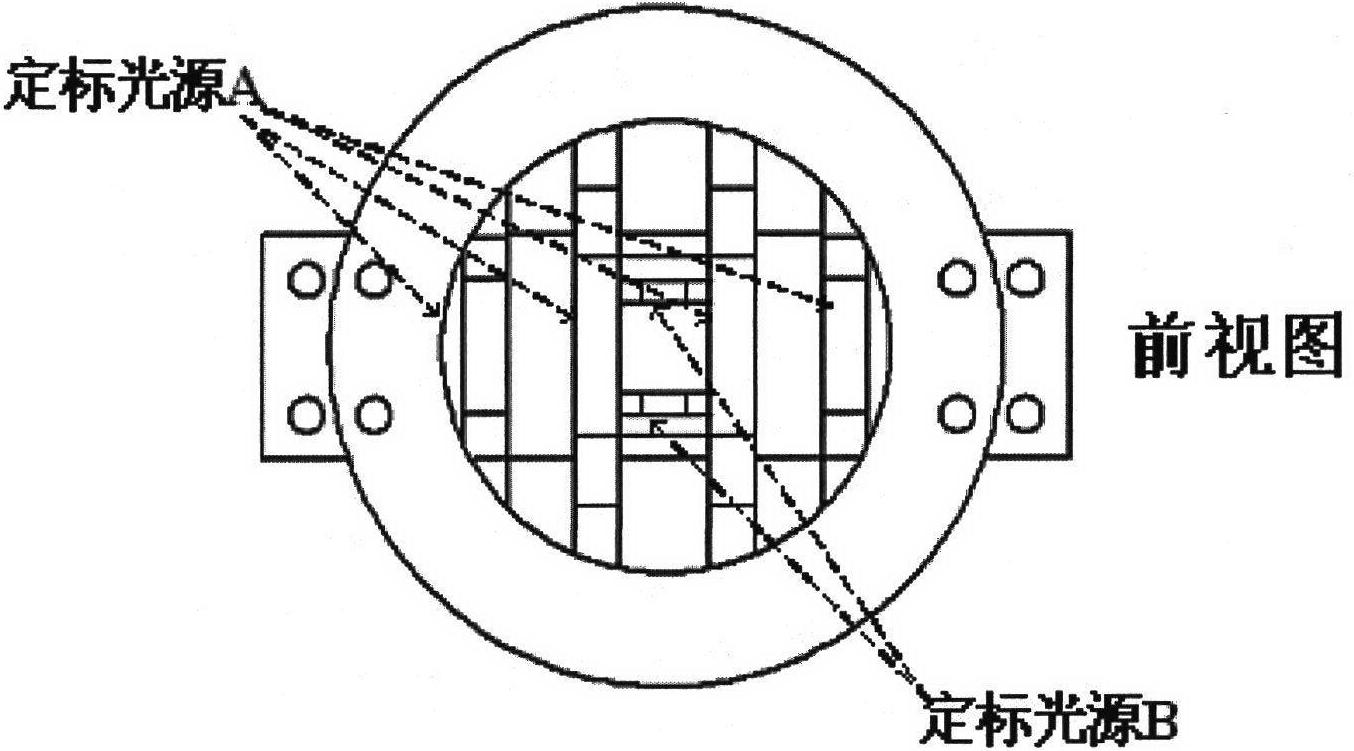

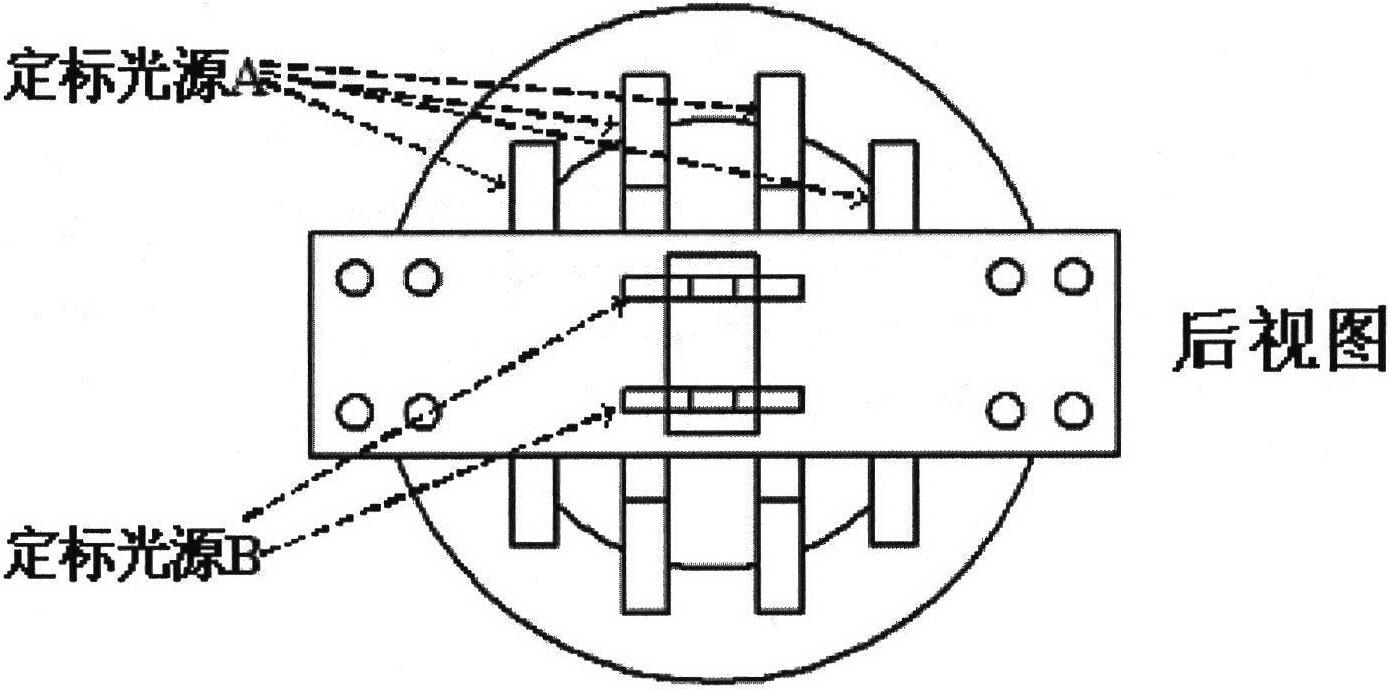

Infrared-spectrum satellite full-dynamic range multipoint radiance calibration device and calibration method

ActiveCN102685546AImprove calibration accuracyImprove stabilityTelevision system detailsColor television detailsInfraredProgrammable logic device

The invention relates to an infrared-spectrum satellite full-dynamic range multipoint radiance calibration device and an infrared-spectrum satellite full-dynamic range multipoint radiance calibration method, and belongs to the technical field of remote sensing quantitative application. The calibration device is fixed in a camera optical system to be calibrated. A satellite supplies power to a temperature control circuit. The calibration device comprises the temperature control circuit, a calibration light source, a calibration optical component, a temperature sensor and a package, wherein the temperature control circuit, the calibration light source and the calibration optical component are packaged by the package; and the temperature control circuit comprises a programmable logic device, an analogue / digital converter, a digital / analogue converter and an operational amplifier. The temperature control circuit can provide different irradiance values for a focal plane, and the calibration light source adopts a nickel-chromium alloy and a combined design, so that high stability and radiation capability under the heating of current of different levels are ensured, an irradiance level covering a full dynamic range can be generated, and satellite calibration accuracy is directly improved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Thin film resistor etch

InactiveUS20050003673A1Electric discharge tubesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceFilm resistance

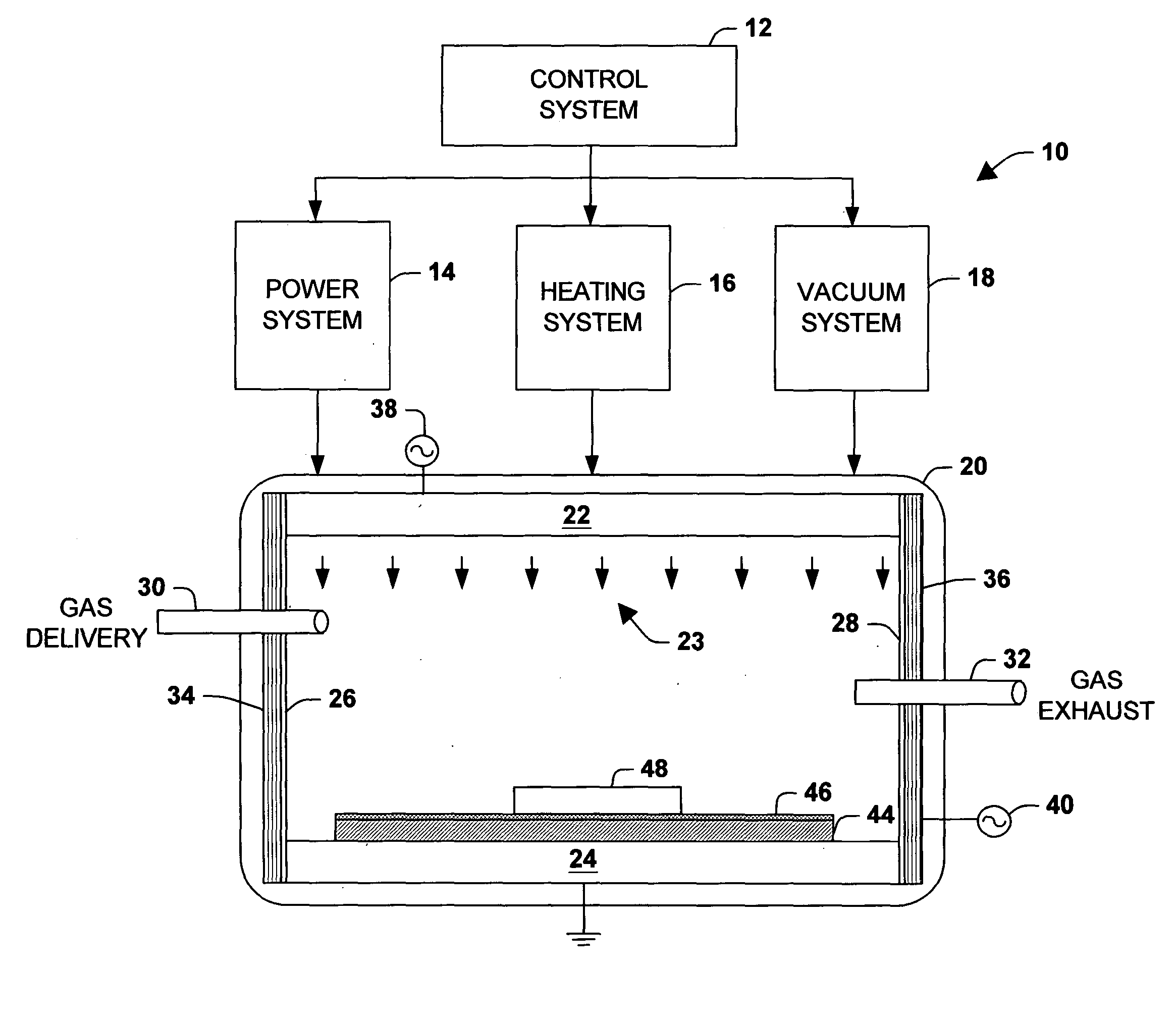

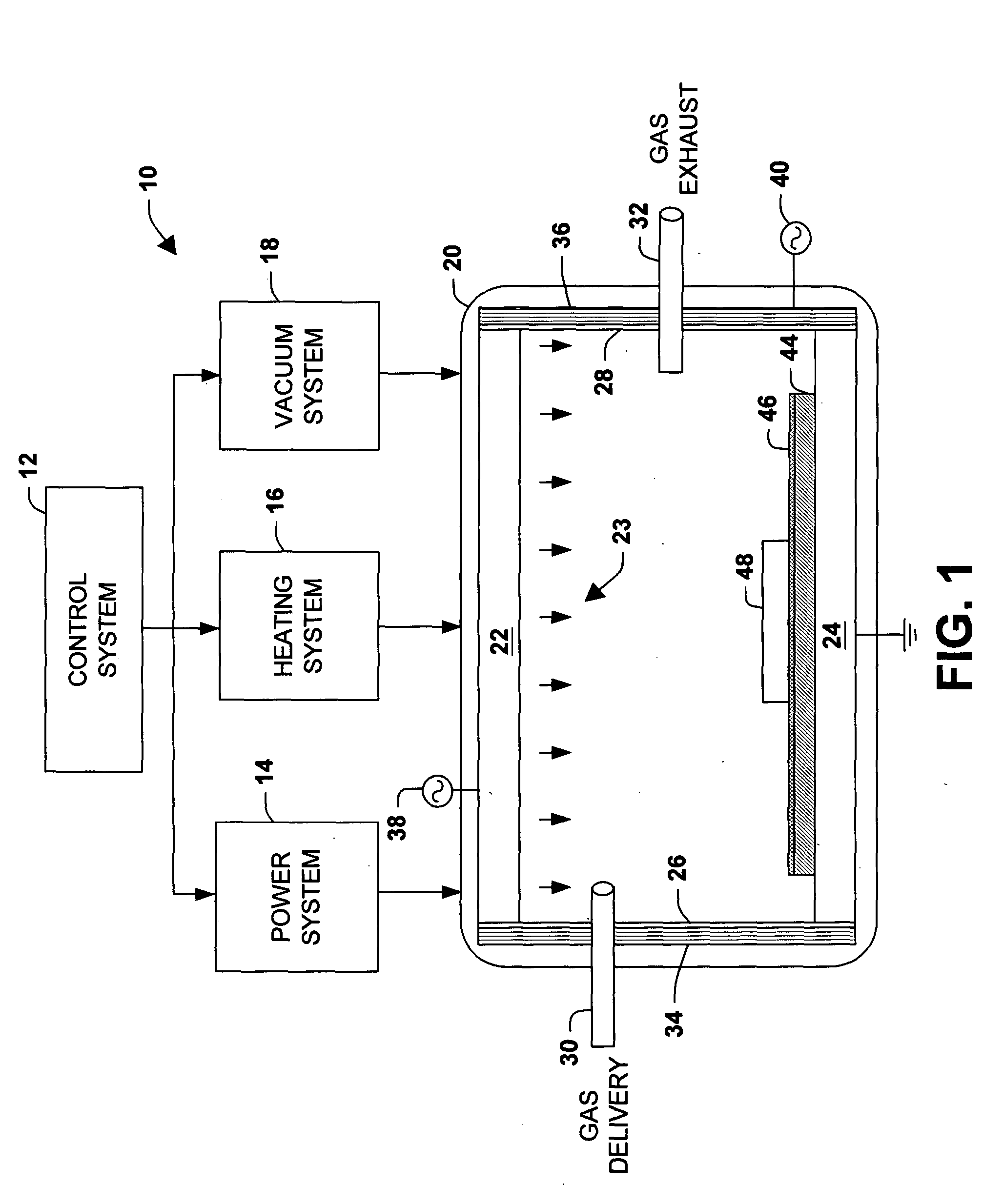

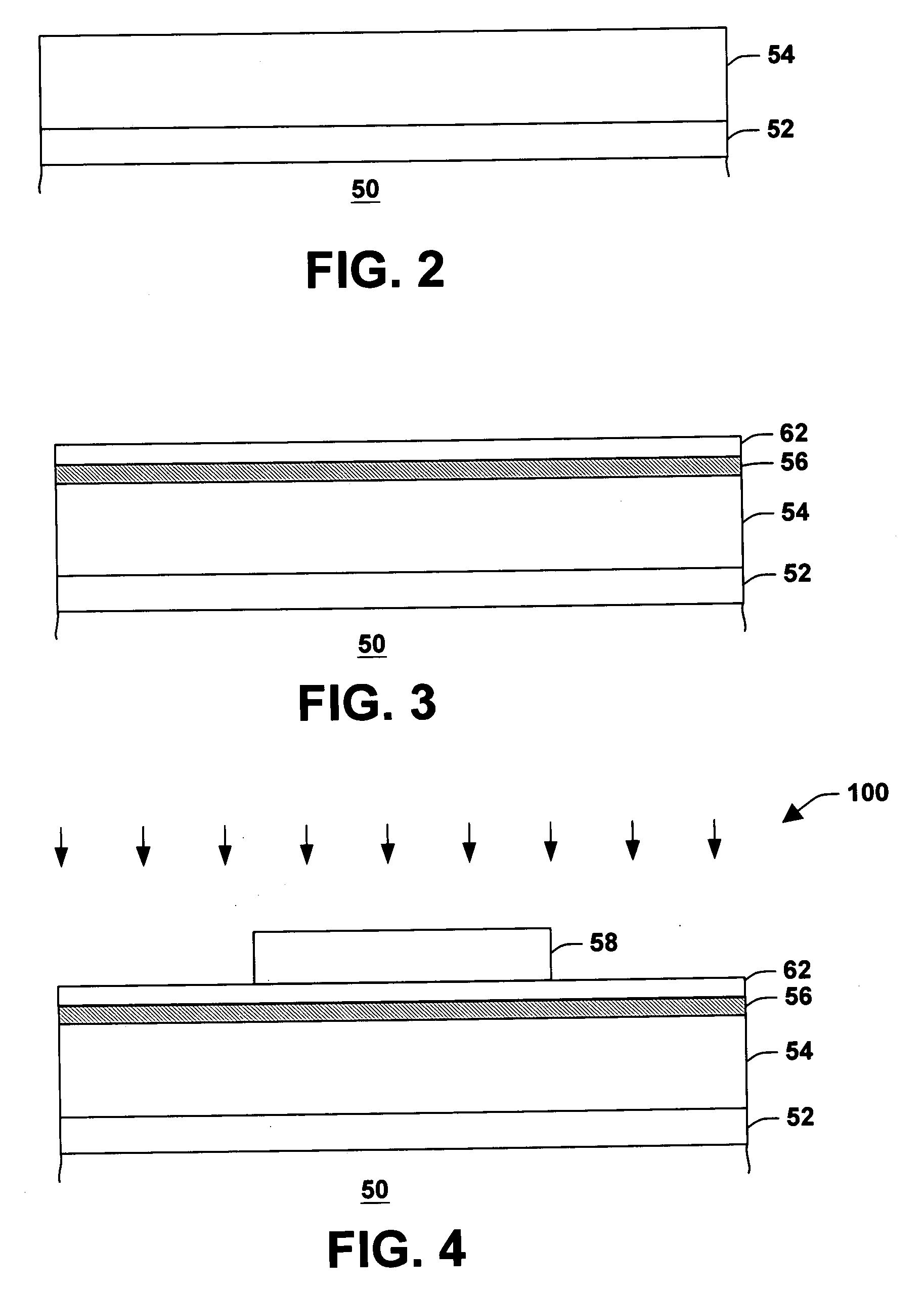

A thin film resistor is formed by employing a plasma etch on a resistor material layer. The resistor material layer can be fabricated employing a nickel chromium (NiCr) alloy, or nickel chromium aluminum (NiCrAl) alloy. A plasma etch is performed in a magnetically enhanced low pressure environment with a chlorine chemistry mixture. The magnetically enhanced low pressure environment and the sufficiently selective chlorine chemistry provide a substantially controlled plasma etch of the resistor material layer to form the thin film resistor. In-situ thickness measurements or an endpoint optical emission system can be employed to determine when to halt the etching process to mitigate damage associated with etching of the layer underlying the thin film resistor.

Owner:TEXAS INSTR INC

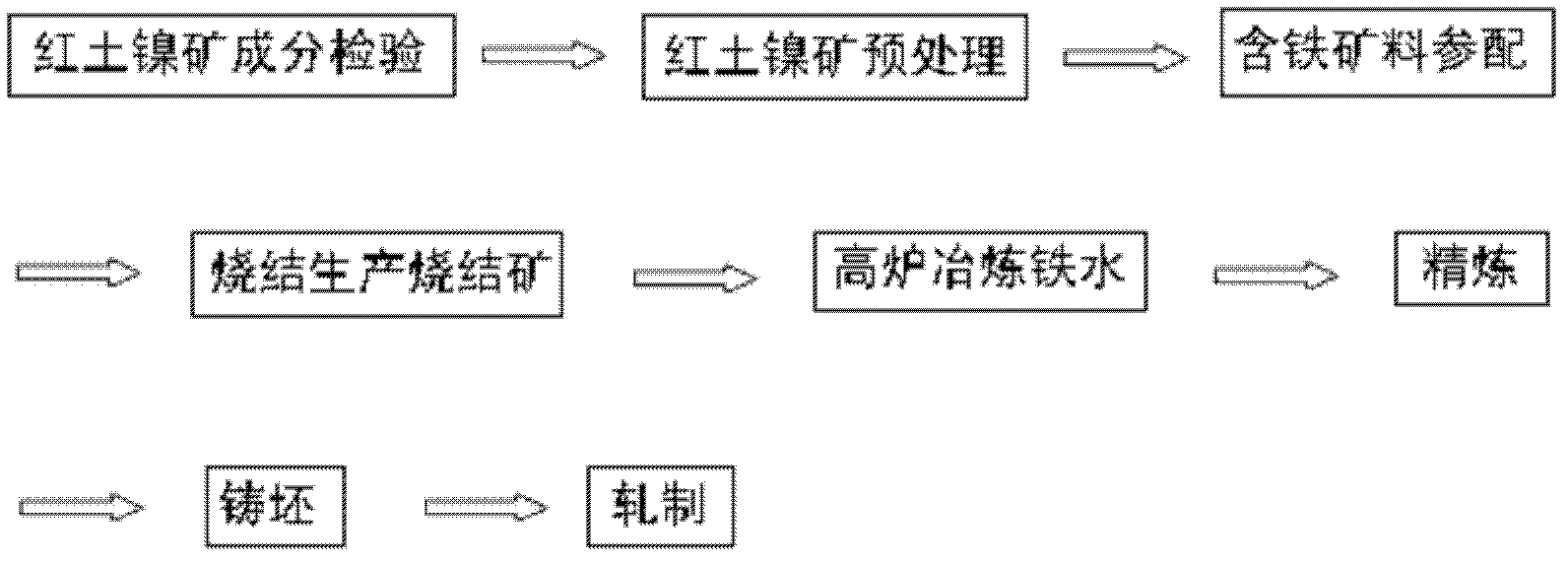

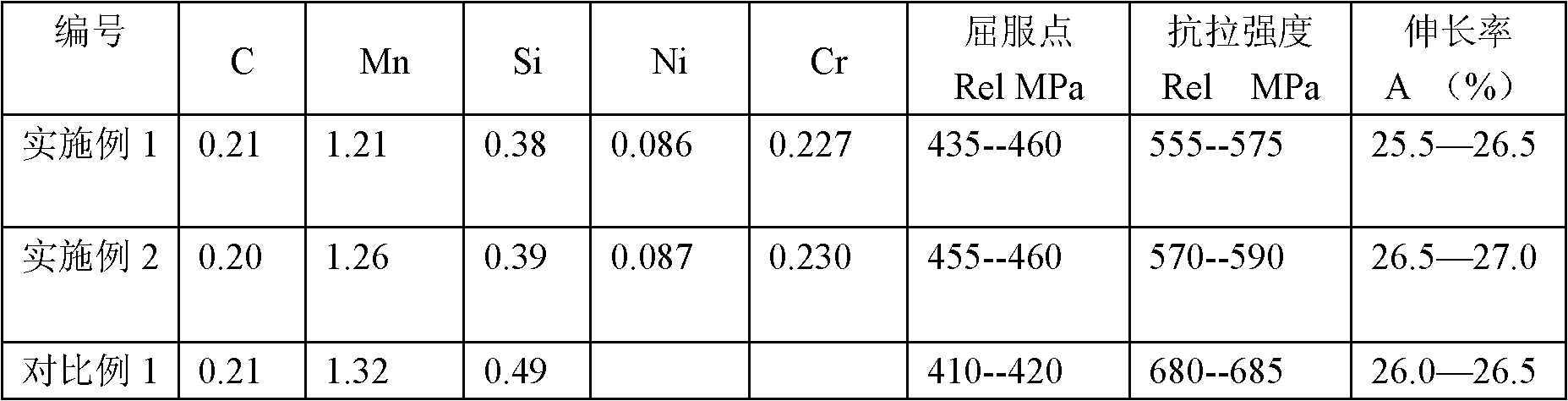

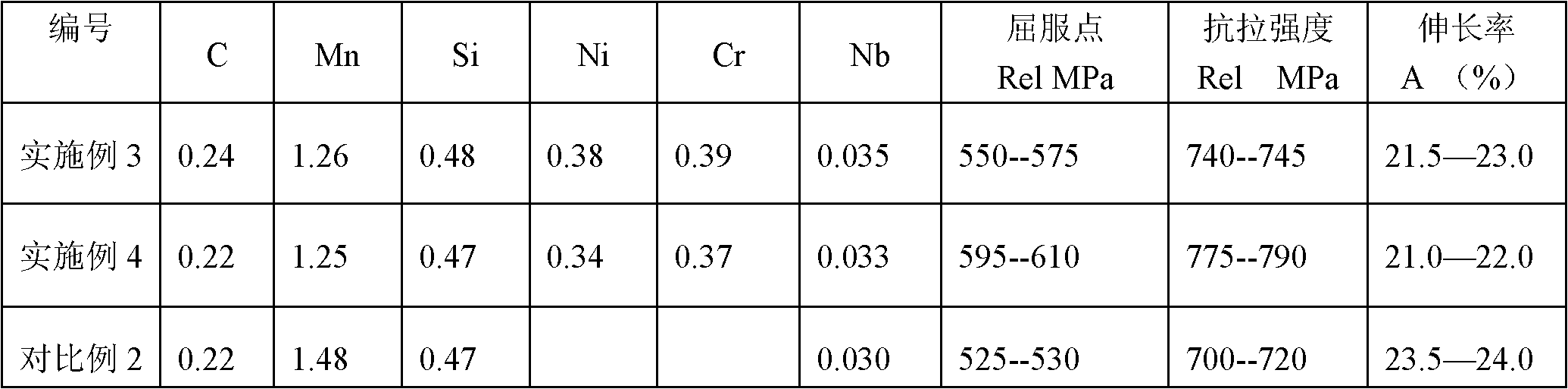

Preparation method of nickel-chrome alloy steel

The invention relates to a preparation method of nickel-chrome alloy steel, which comprises the following steps of ore sintering, sinter smelting, refining and casting; the iron-containing ore material comprises, on a weight basis, 10-100% of laterite-nickel ore and 0-90% of iron ore. The invention also relates to the alloy steel obtained by the preparation method, and alloy steel bars obtained by the alloy steel through further rolling. The invention adopts cheap laterite-nickel ore resources instead of the whole or part of the iron ore resources for the preparation of the alloy steel and steel bars; not only a lot of iron in the laterite-nickel ore is effectively used, but also the nickel, chromium elements in the laterite-nickel ore are made full use of; the production process is simplified; the cost is reduced; and the performance of the steel is significantly improved.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

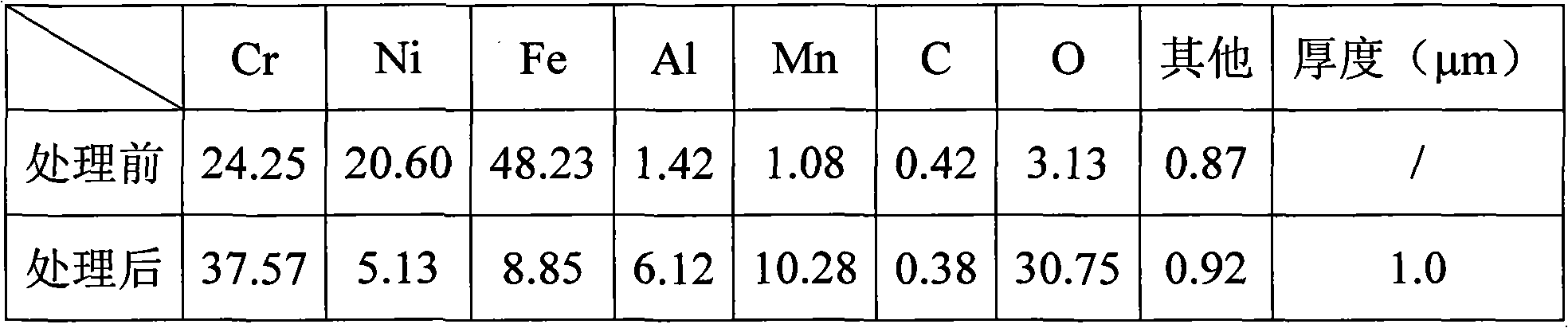

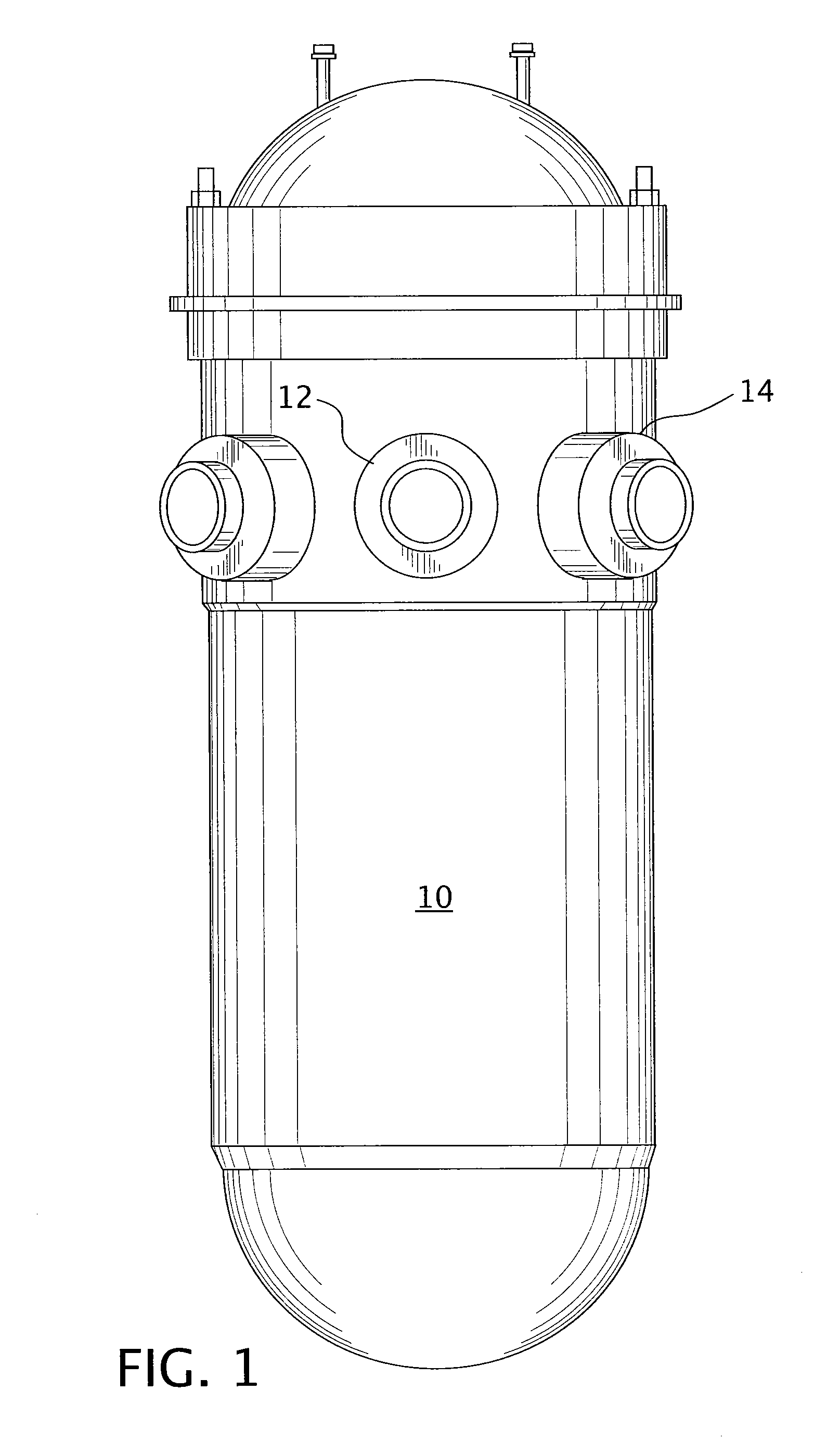

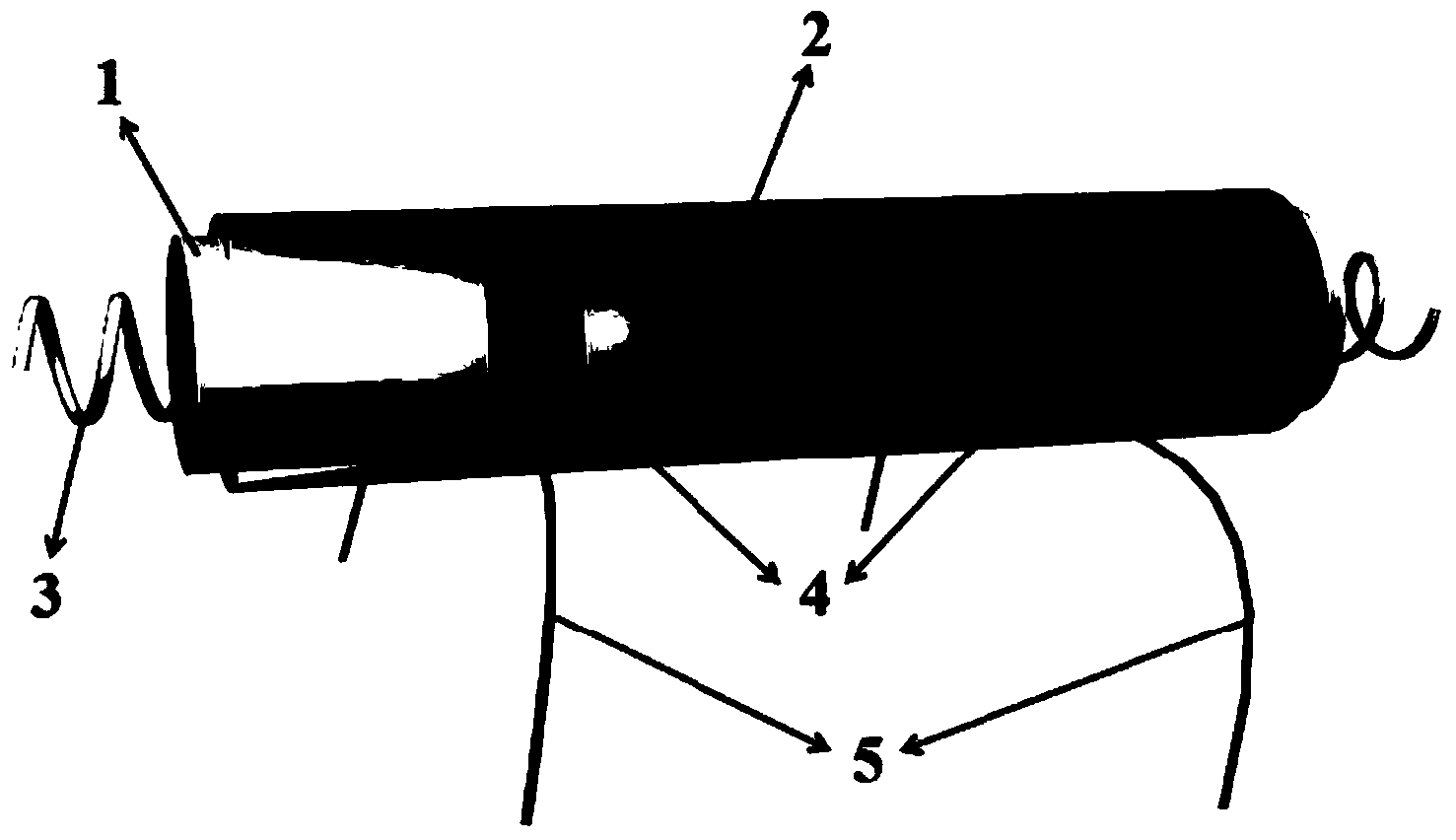

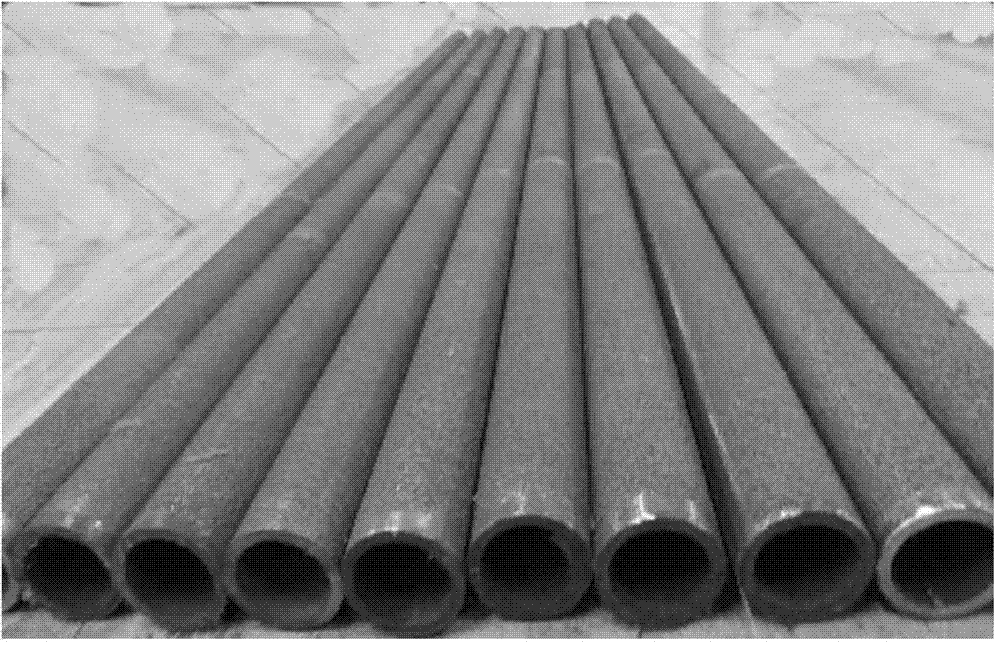

Cracking furnace tube for retarding coking and carburizing of ethylene cracking furnace tube, and manufacturing method thereof

ActiveCN102399571AInhibit cokingInhibition of carburizationThermal non-catalytic crackingCarbon numberPetroleum

The present invention relates to a cracking furnace tube for retarding coking and carburizing of an ethylene cracking furnace tube, and a manufacturing method thereof. According to the present invention, the inner surface of the cracking furnace tube is provided with a layer of an oxide film, wherein the oxide film comprises at least one element selected from Cr, Ni, Fe, Mn, Al, Si and B; the manufacturing method comprises: directly adding at least one element selected from Al, Si or B to a nickel-chromium alloy containing elements of Cr, Ni, Fe, Mn and C during the conventional cracking furnace tube manufacturing process to prepare the tube, then carrying out a heat treatment for the resulting tube under low oxygen partial pressure atmosphere to generate a layer of the metal and / or nonmetal oxide thin film on the inner surface of the tube; when the cracking furnace tube of the present invention is adopted for producing olefin with low carbon number by the petroleum hydrocarbon cracking furnace, the deposition of the coke on the inner wall of the furnace tube can be reduced by more than 70%.

Owner:CHINA PETROLEUM & CHEM CORP +2

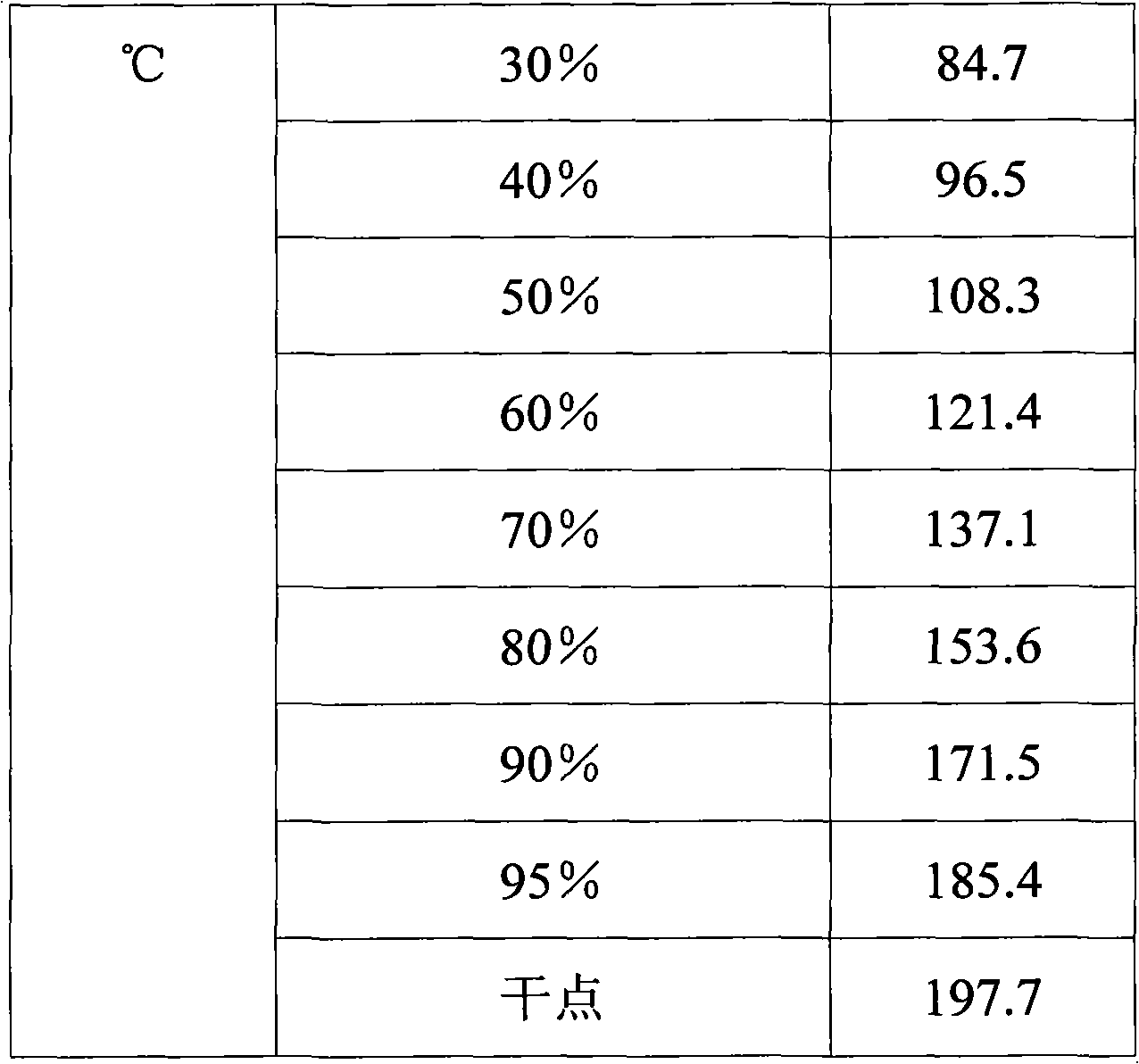

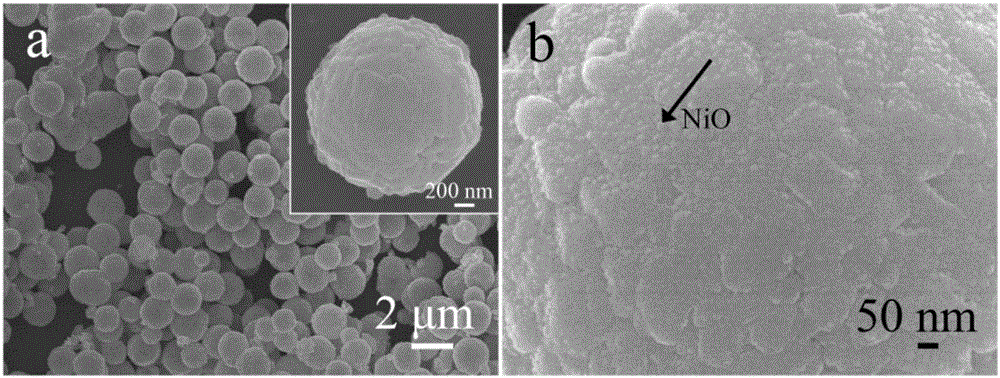

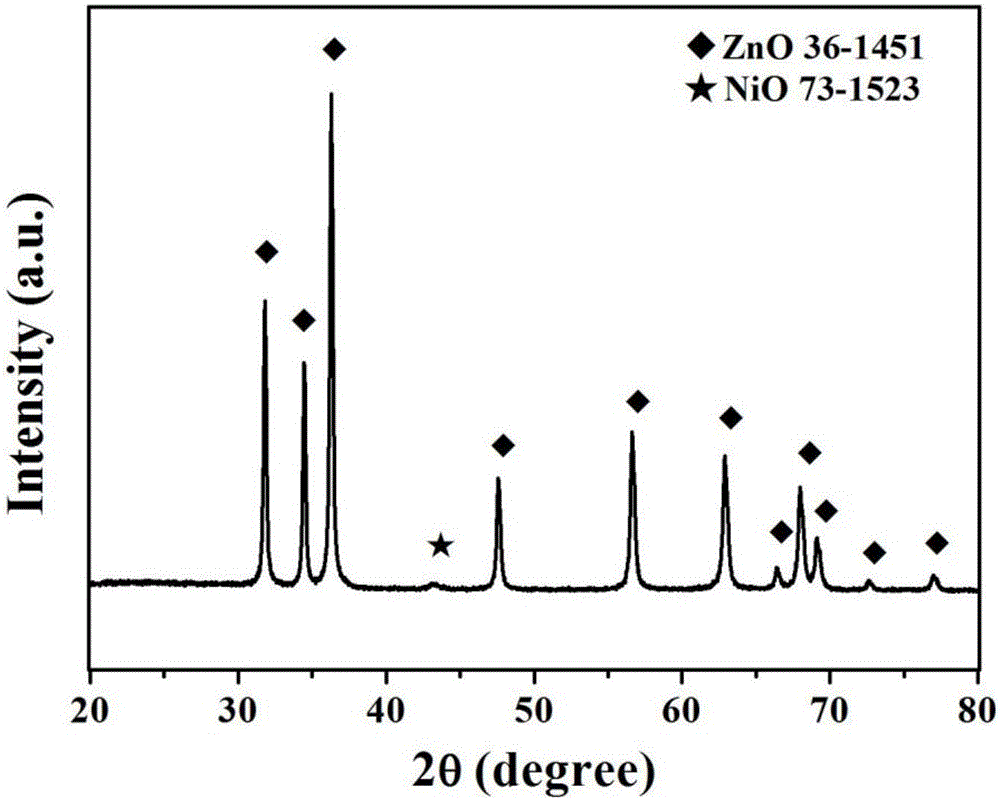

Acetone gas sensor based on NiO / ZnO heterostructure hollow ball sensitive material and preparation method thereof

ActiveCN106124573AGood dispersionEasy transferMaterial resistanceHigh volume manufacturingNanoparticle

The invention relates to an acetone gas sensor based on a NiO / ZnO heterostructure hollow ball sensitive material and a preparation method thereof, and belongs to the technical field of semiconductor oxide gas sensors. The invention uses a NiO-ZnO heterostructure hollow ball sensitive material prepared by microwave assisted method and solvothermal method. The catalytic effect of NiO nanoparticles on organic gas and the heterogeneous structure between the two can effectively improve the sensitivity of the sensor to acetone. In addition, the sensor structure adopted by the invention comprises a commercially available Al2O3 insulating ceramic tube with 2 annular gold electrodes, a semiconductor sensitive material coated on annular gold electrodes and the Al2O3 insulating ceramic tube, and a nickel chromium alloy heating coil passing through the Al2O3 insulating ceramic tube. The device has the advantages of simple process and small size, and is suitable for mass production, so it has broad application prospects in the detection of acetone content in microenvironment.

Owner:JILIN UNIV

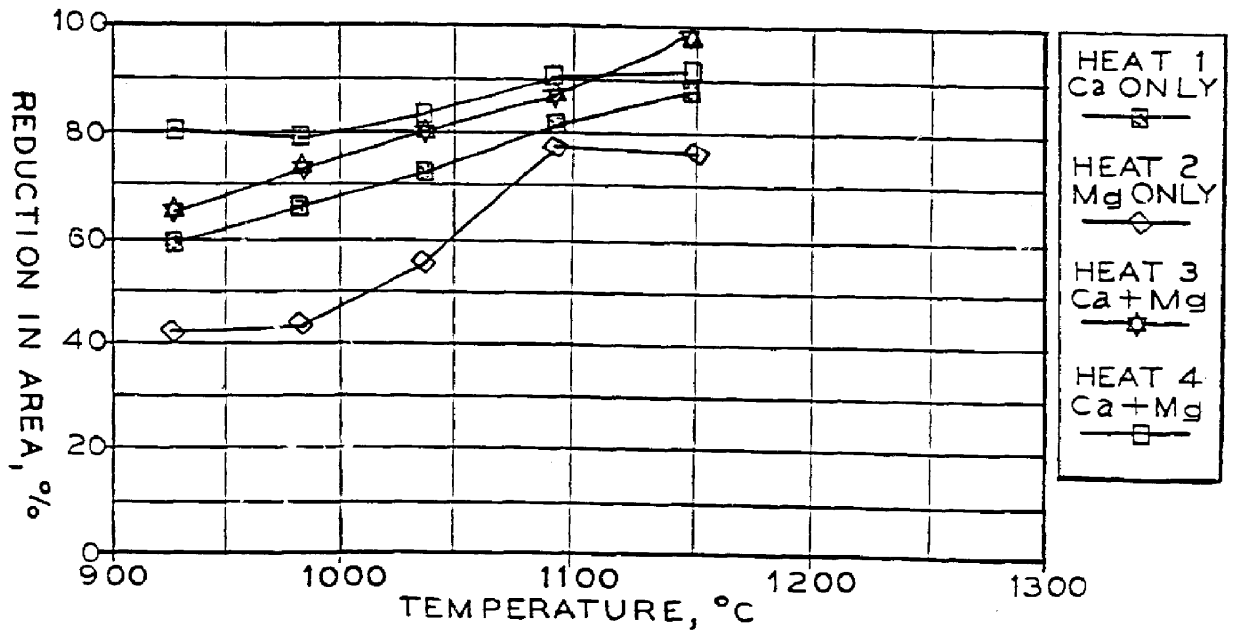

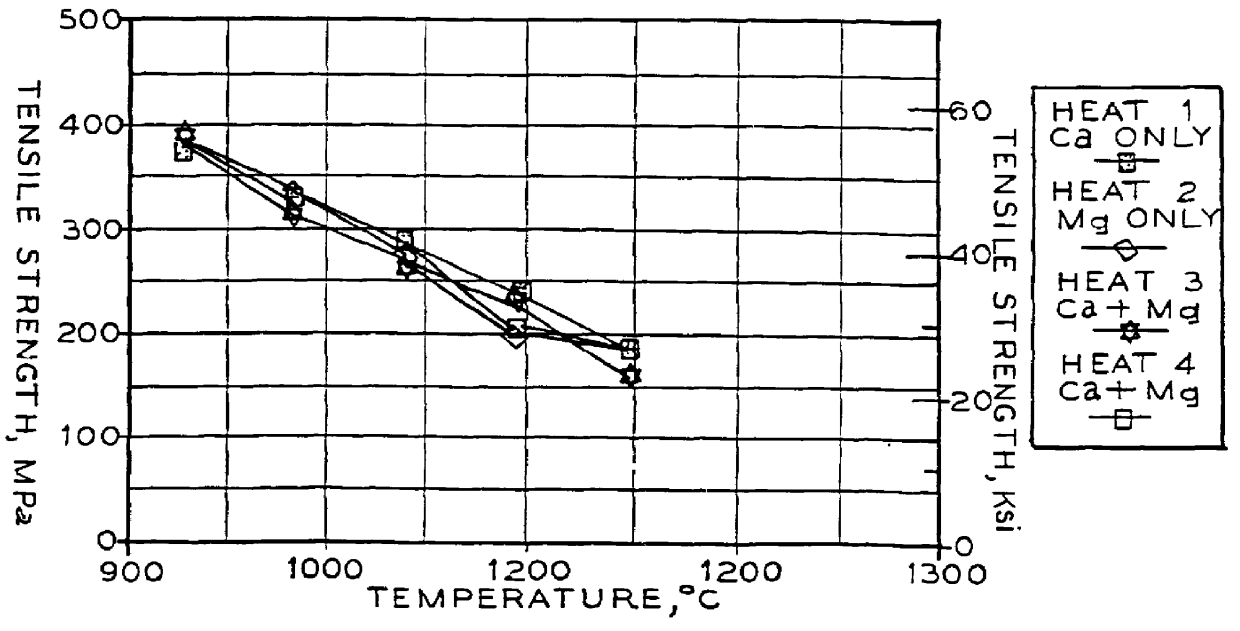

Hot working high-chromium alloy

Hot working a nickel-chromium alloy that contains by weight percent, 42 to 65 chromium, 0.002 to 0.1 calcium, 0.002 to 0.1 magnesium, 0 to 2 aluminum, about 0 to 5 cobalt, 0 to 3 copper, 0 to 5 iron, 0 to 5 manganese, 0 to 3 molybdenum, 0 to 3 niobium, 0 to 2 silicon, 0 to 3 tantalum, 0 to 5 titanium, 0 to 5 tungsten, 0 to 5 vanadium, 0 to 1 zinc, 0 to 0.2 carbon 0 to 0.1 silver, 0 to 0.1 cerium, 0 to 0.1 phosphorus, 0 to 0.1 sulfur, less than 0.005 total boron, rare earths and zirconium and balance nickel and incidental impurities, at a temperature of at least 800 DEG C. improves formability for alpha -phase chromium alloys.

Owner:HUNTINGTON ALLOYS CORP (US)

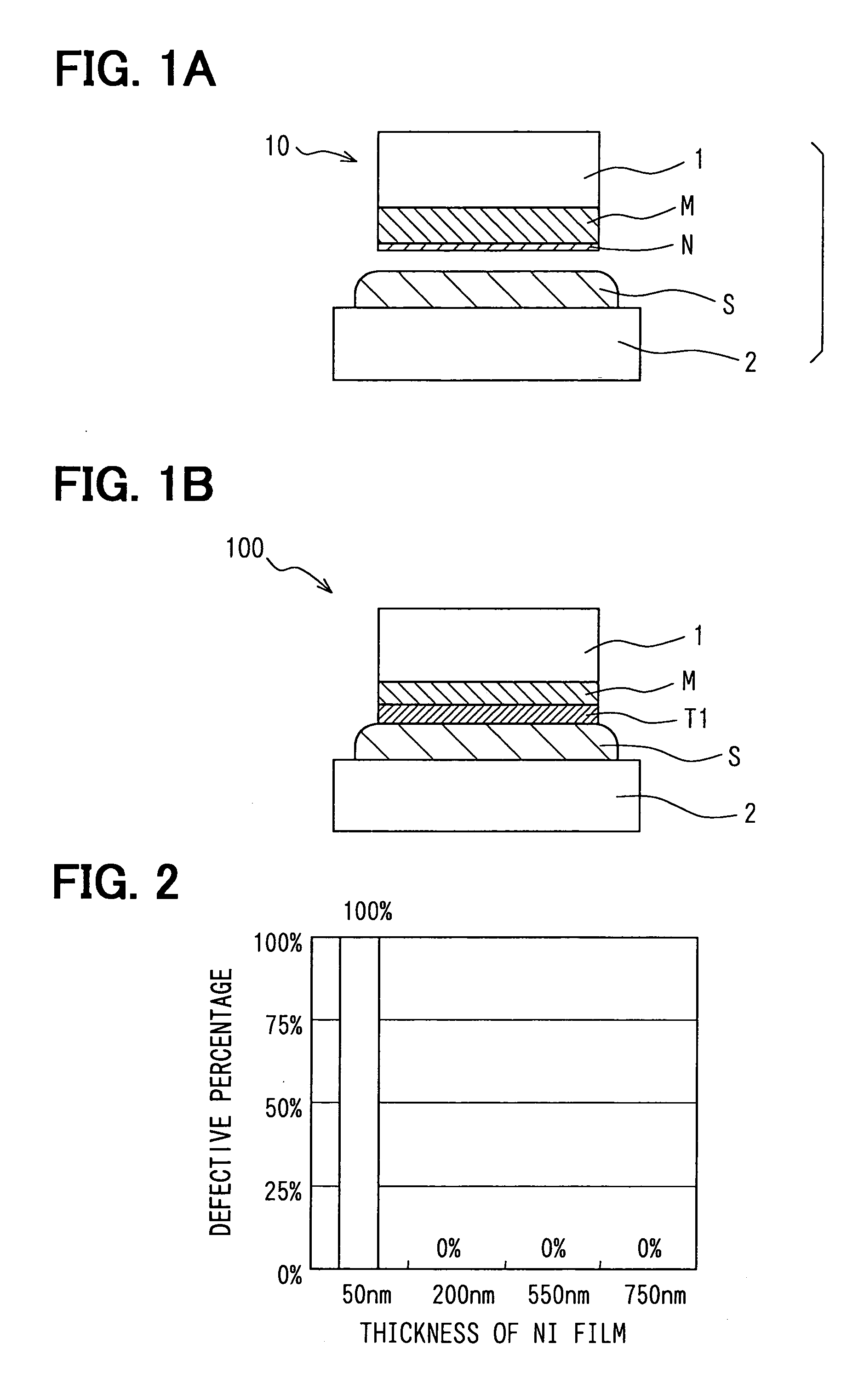

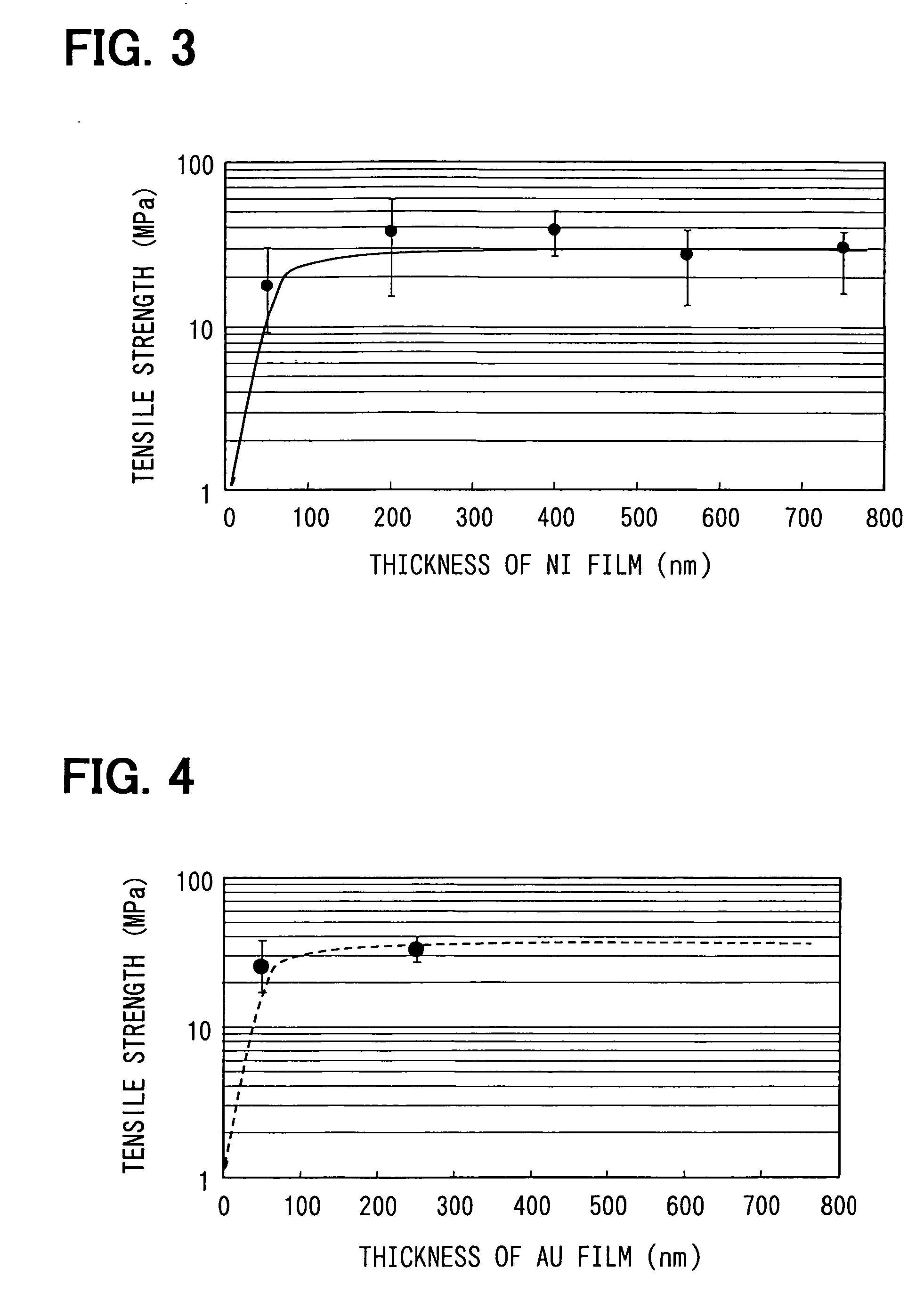

Semiconductor device having tin-based solder layer and method for manufacturing the same

ActiveUS20060049521A1Simple manufacturing processLower device costSemiconductor/solid-state device detailsSolid-state devicesTitaniumSemiconductor

Owner:DENSO CORP

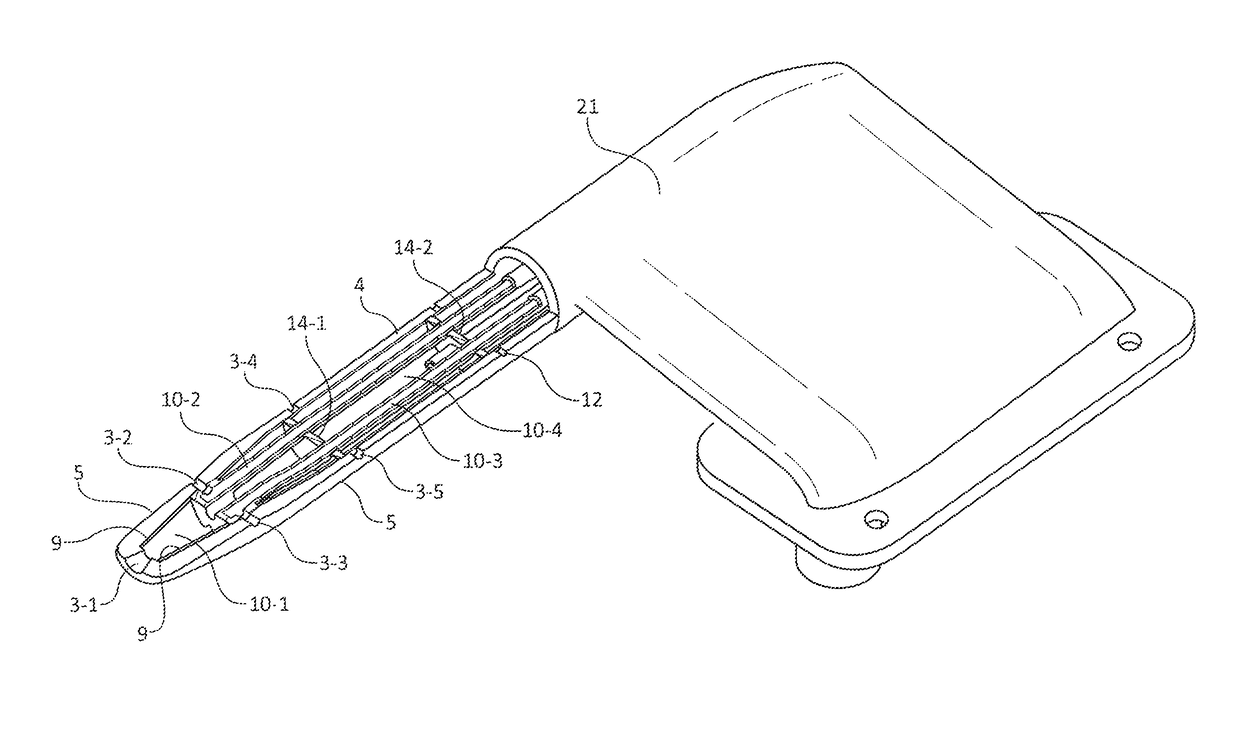

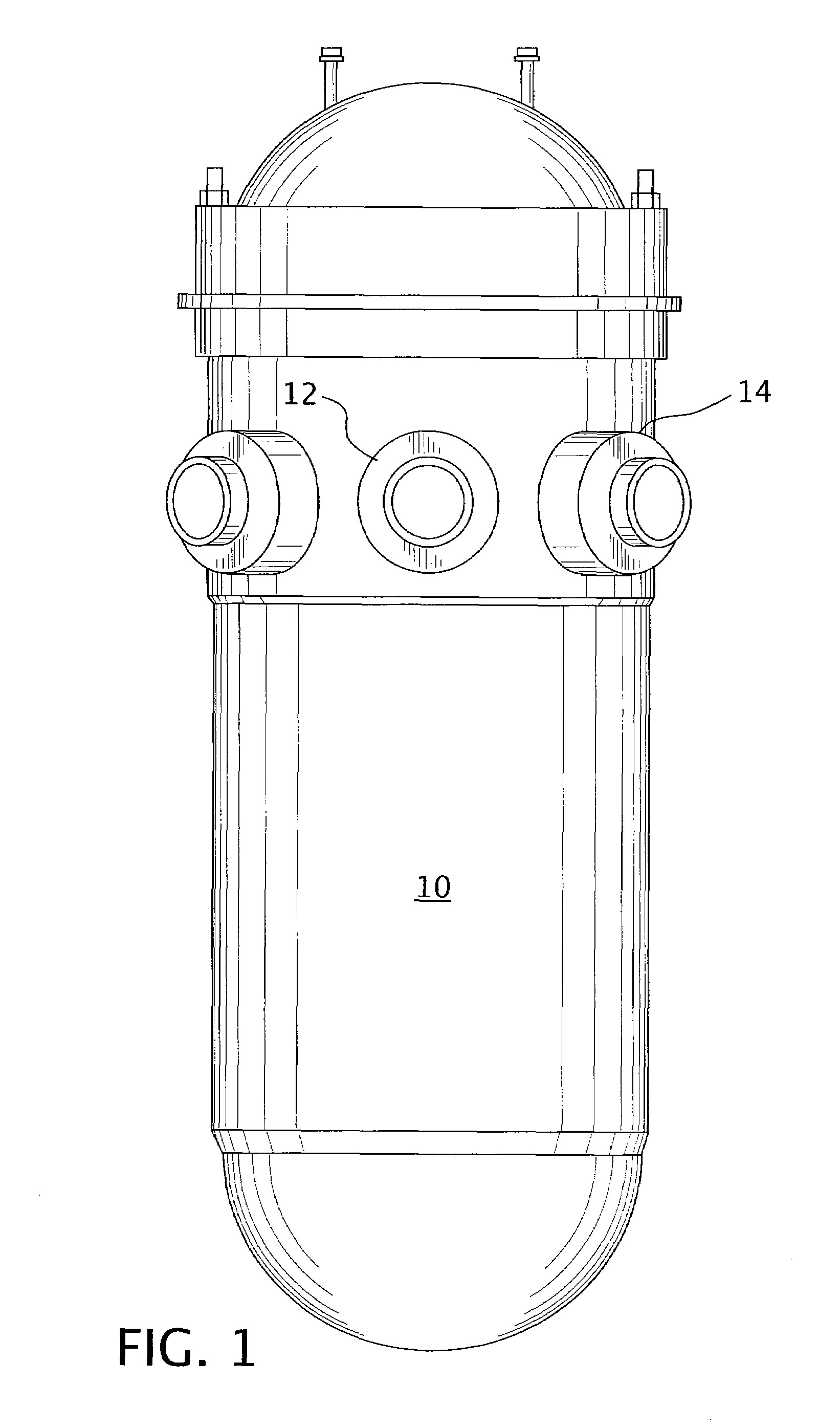

Corrision-resistant heated air data probe

ActiveUS9772345B2Measurement apparatus componentsIndication/recording movementConductive materialsNickel alloy

An air data probe is disclosed. The air data probe may include a probe body having an interior cavity and coated by a protective shell. A sensing port may be disposed in the air data probe and may extend through the probe body. The sensing port may also be lined by the protective shell. The protective shell may be made of an austenitic nickel-chromium alloy, or stainless steel, or any relatively corrosion resistant material. The probe body may be made of nickel, or a nickel alloy, or any relatively thermally conductive material. The protective shell may be joined to the probe body by additive manufacturing, such as laser cladding. In this manner, an air data probe capable withstanding high temperatures without corrosion and yet also being relatively thermally conductive is disclosed.

Owner:ROSEMOUNT AEROSPACE

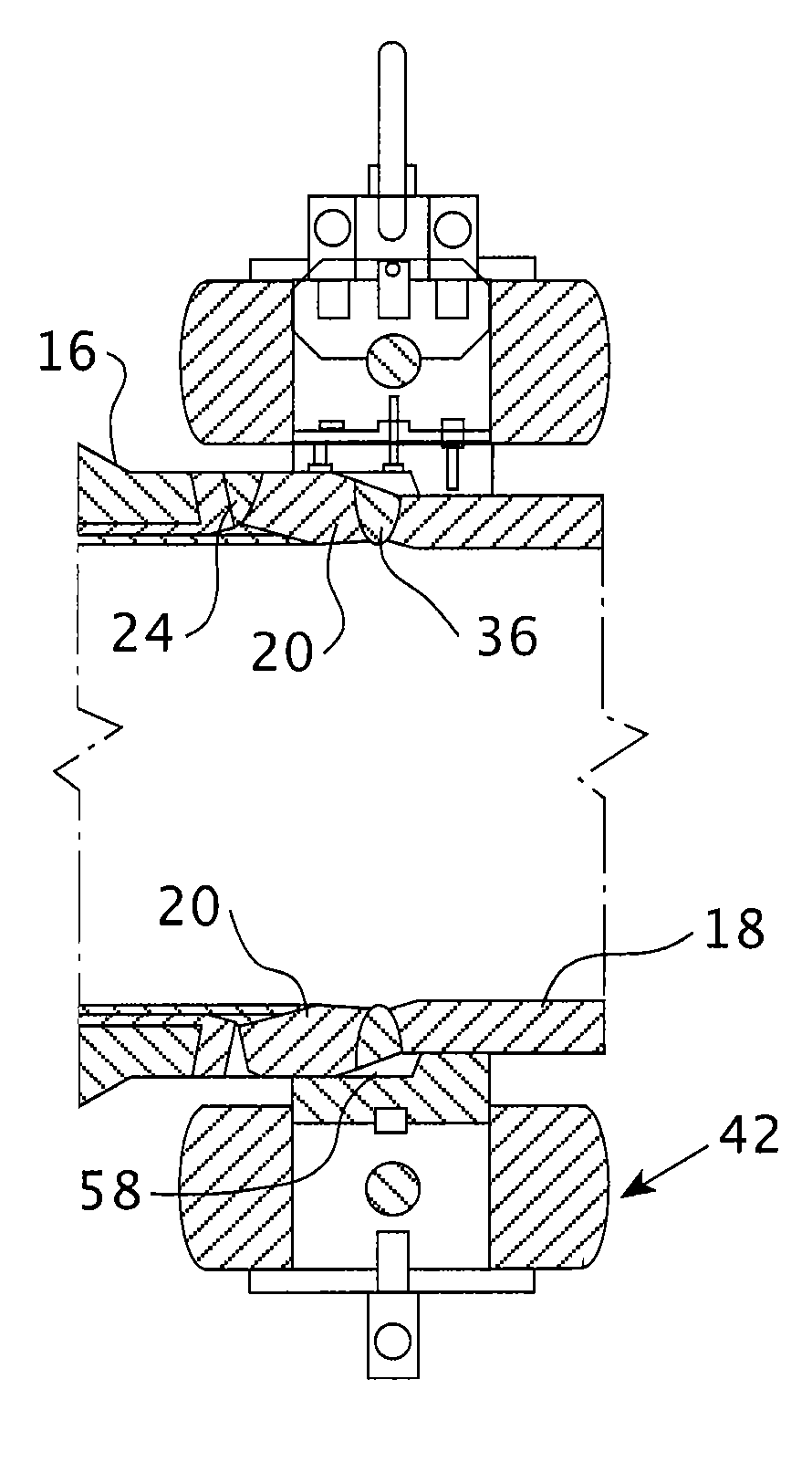

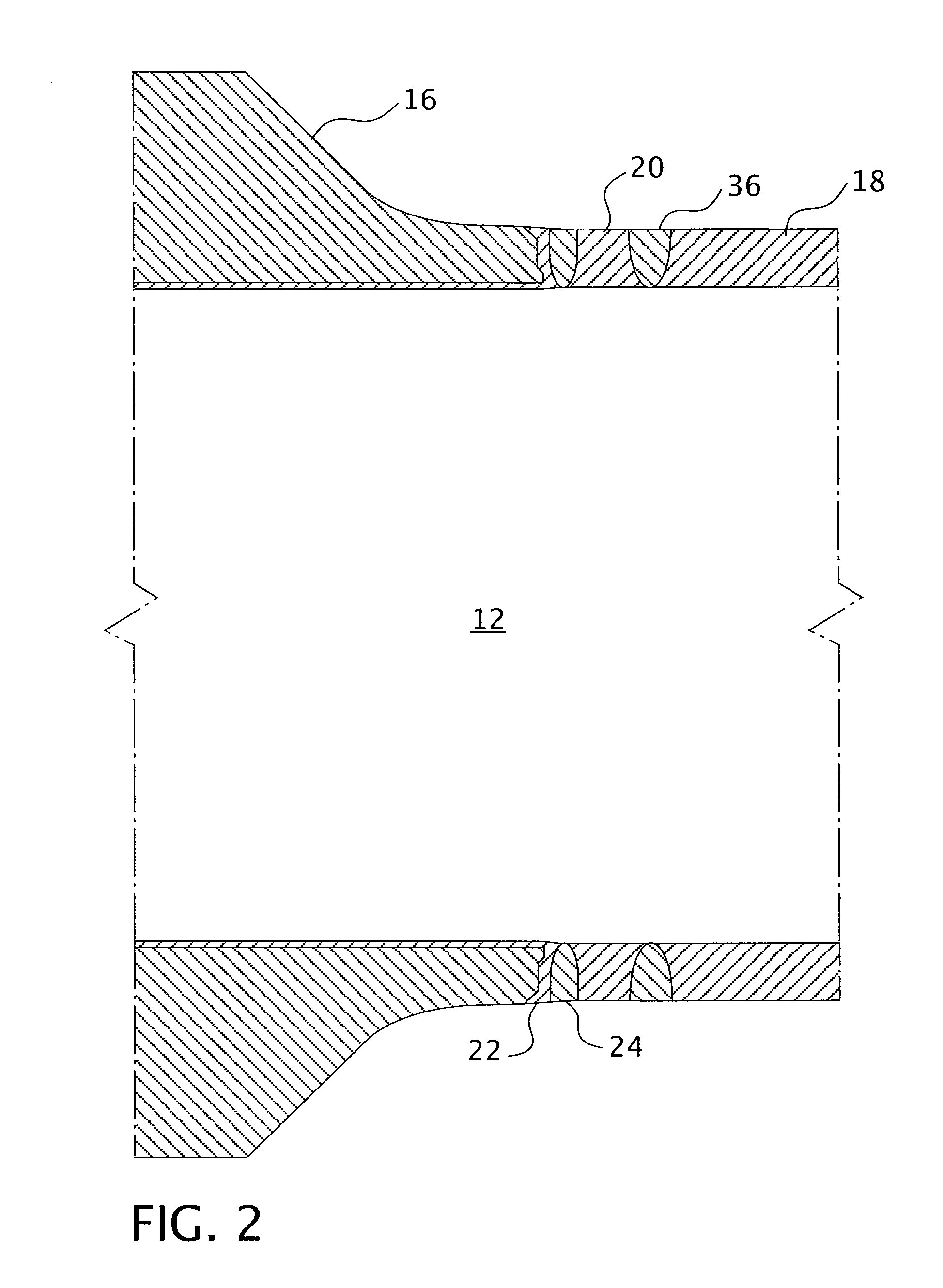

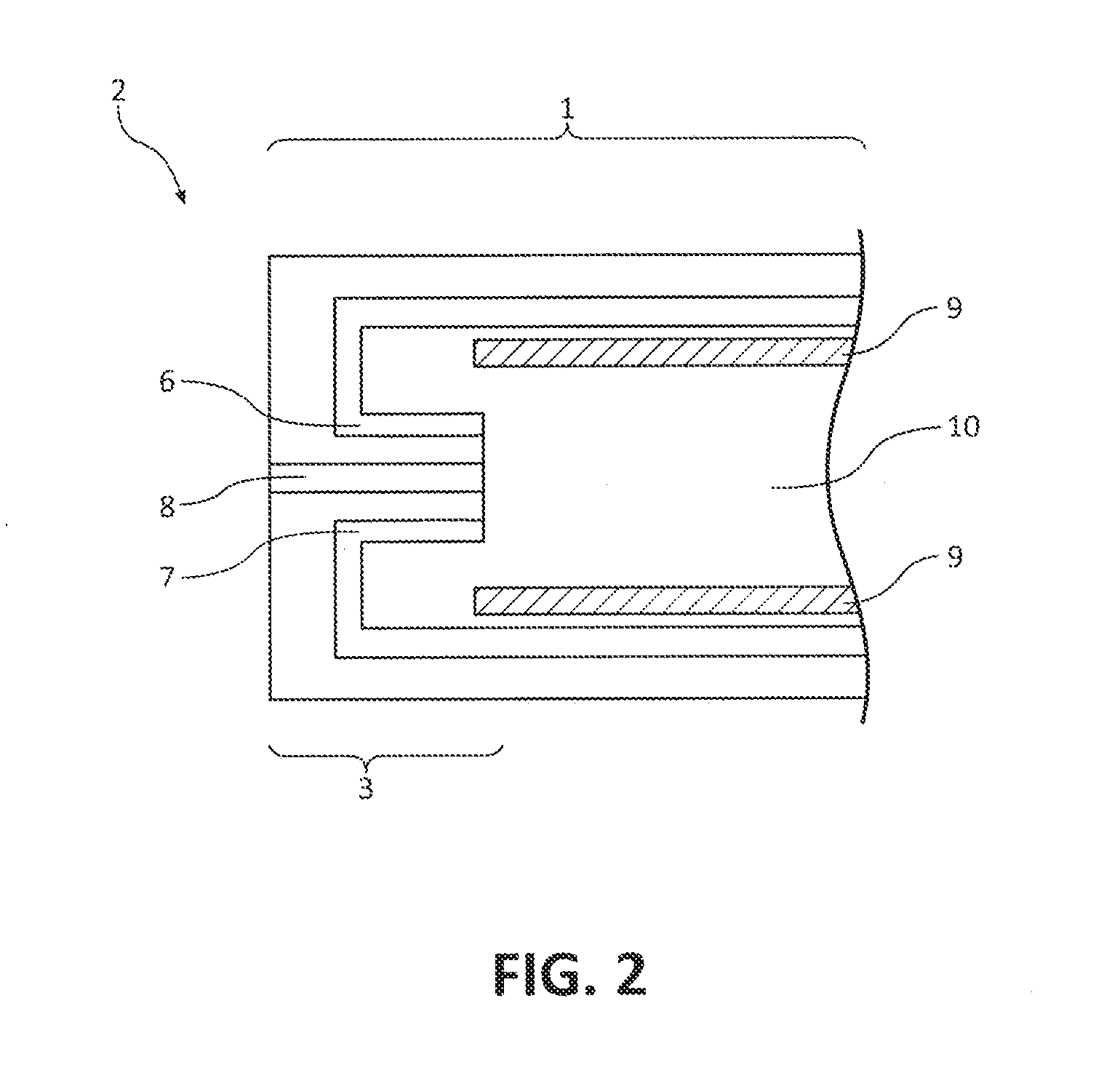

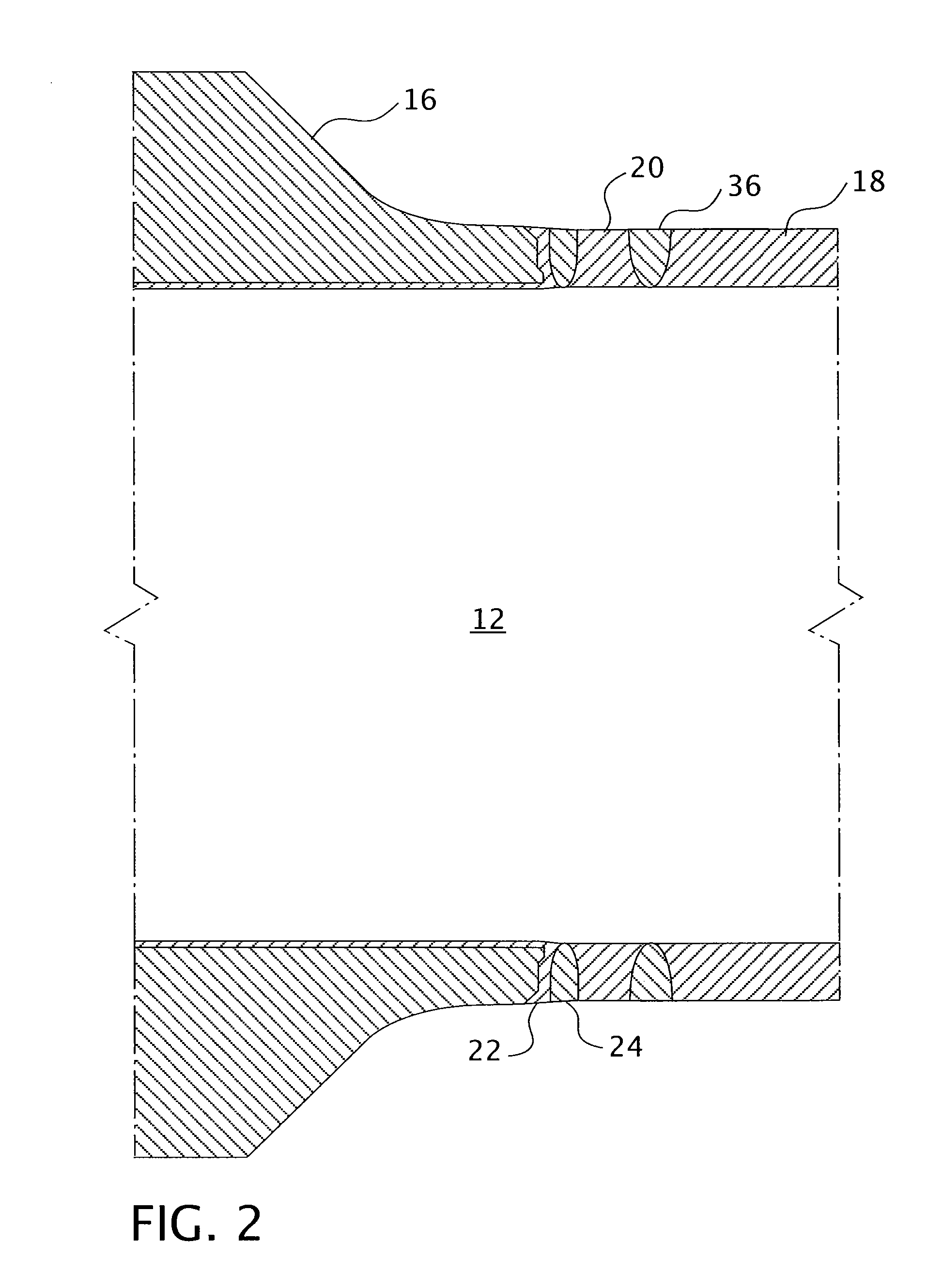

Mechanical stress improvement process

ActiveUS20080110229A1Avoid it happening againReduce overall outer diameterFurnace typesEmergency protection arrangementsPressurized water reactorNuclear engineering

A process for reducing residual tensile stresses in high nickel-chromium alloy nozzle safe-end welds of pressurized water reactor nuclear pressure vessels such as are found at the reactor vessel inlet and outlet nozzles and the pressurizes surge, spray, safety and relief nozzles. The process involves the application of radial compression on the outside surface of the nozzle's safe-end and / or connecting coolant piping, to reduce the outside diameter at the mid-point of the piping element to which the load is applied to between about 0.2% and about 3%. The radially compressive load applied by this process is imparted using a mechanical device that can be employed at the vessel manufacturer's facility or at a nuclear power plant after welding of the nozzle safe-end to the coolant piping or before either after plant commissioning of operation.

Owner:NUVISION ENG INC

Preparation method for inconel alloy based self-lubricating corrosion and wear resistant coating

InactiveCN102424943AFulfill the needs of serviceTightly boundMolten spray coatingCoated surfaceThermal spraying

The invention discloses a preparation method for an inconel alloy based self-lubricating corrosion and wear resistant coating. The method comprises the steps of: spraying Ni-based diamond alloy powder on a matrix so as to obtain a primary coating; scanning the primary coating with a laser beam so as to obtain a final coating. In the invention, through laser scanning treatment, a dense antifriction lubricating oxide film is formed on the coating surface of an inconel alloy workpiece, and the coating is dense and is closely combined with the matrix interface. The method of the invention meets the service demand of the coating in a high wearing and corrosive medium, and the laser scanning treatment also greatly improves its surface hardness. The method of the invention broadens the engineering application scope of thermal spraying coatings, and provides a new method for developing cogeneric high-end products.

Owner:ANHUI TIANYI HEAVY IND

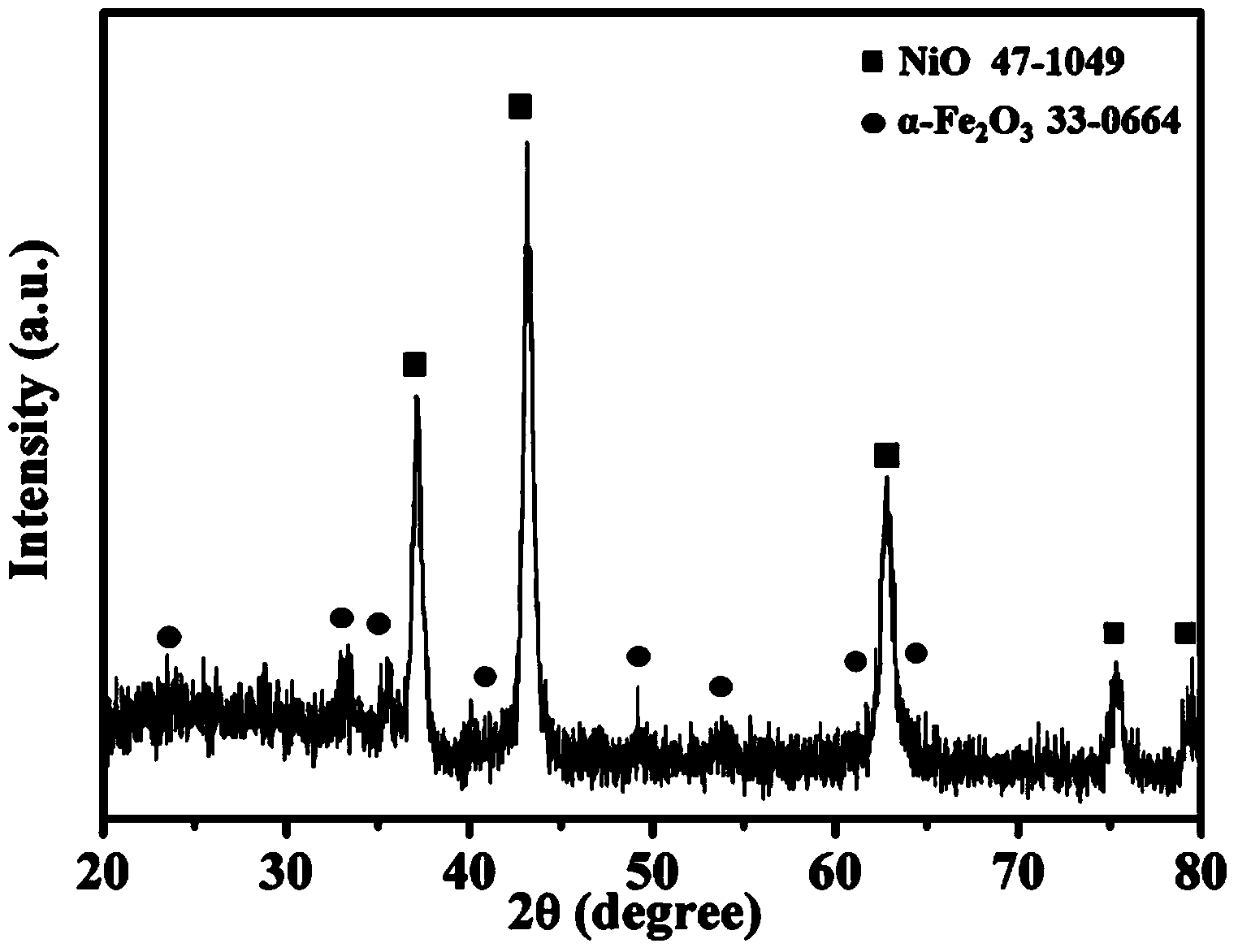

Toluene sensor based on alpha-Fe2O3/NiO heterostructure nanotube and preparation method of toluene sensor

InactiveCN104391012AImprove reaction efficiencyHigh sensitivityMaterial resistanceHigh volume manufacturingToluene

The invention discloses a toluene sensor based on an alpha-Fe2O3 / NiO heterostructure nanotube and a preparation method of the toluene sensor, and belongs to the technical field of semiconductor oxide gas sensors. The sensor adopts an alpha-Fe2O3 / NiO heterostructure nanotube sensitive material made with a two-step hydrothermal method, and the sensitive characteristic of the sensor to toluene is improved effectively through a heterostructure formed between alpha-Fe2O3 and NiO and synergetic catalysis action of the alpha-Fe2O3 and NiO to toluene; and besides, the sensor structurally comprises a commercially available Al2O3 insulating ceramic tube provided with two annular gold electrodes, semiconductor sensitive materials applied on the annular gold electrodes and the Al2O3 insulating ceramic tube as well as a nickel-chromium alloy heating coil penetrating through the Al2O3 insulating ceramic tube. The device is simple in process, small in size and suitable for volume production, therefore having wide application prospect in detection of toluene content in a microenvironment.

Owner:JILIN UNIV

Double silver low-emissivity coated glass based on composite dielectric layer

ActiveCN1569713AStrong infrared reflection abilityLow surface emissivityVacuum evaporation coatingSputtering coatingArgon atmosphereLow emissivity

The device disclosed by the invention comprises (from glass substrate outward) glass / dielectric layer / silver layer / protection layer / composite dielectric layer / silver layer / protection layer / dielectric layer, wherein the dielectric layer being SnO2, sputtered in oxygen-argon atmosphere through the tin target of the AC cathode, the silver layer being Ag, sputtered in argon atmosphere through the DC flat target, the protection layer being NiCr, sputtering nickel-chromium alloy in argon atmosphere through the DC flat target.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +1

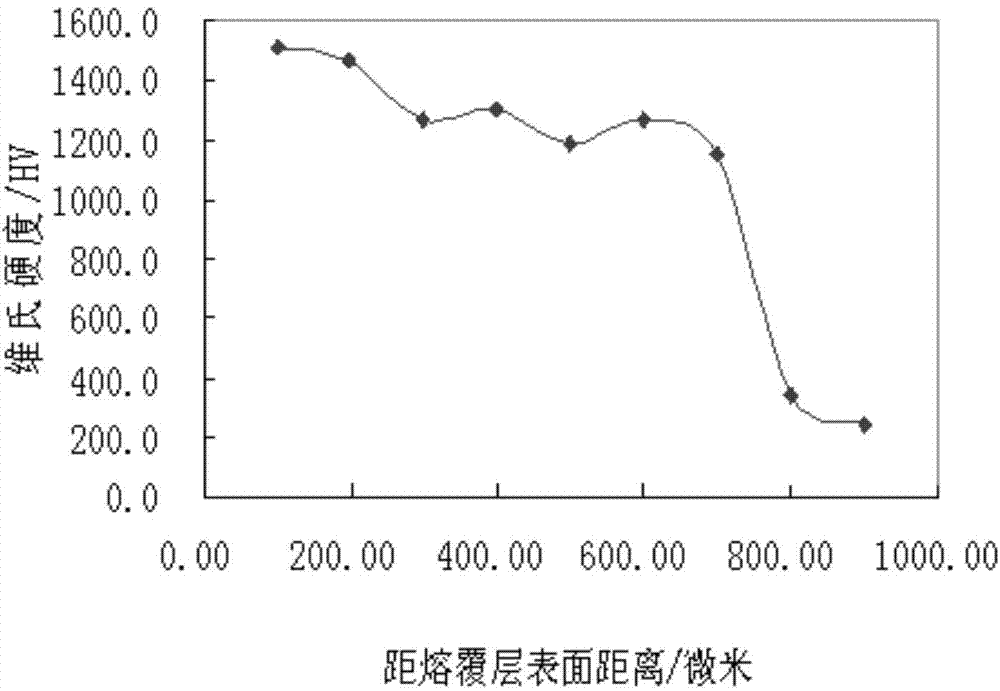

Powder material for boiler tube high temperature resistance and wear resistance protecting and preparation method thereof

InactiveCN103878363AHigh hardnessImprove wear resistanceMetallic material coating processesSurface engineeringWear resistant

The invention relates to powder material for boiler tube high temperature resistance and wear resistance protecting and a preparation method thereof, and belongs to the technical field of surface engineering. The power material comprises the following components, by weight percentage, 10-20% of titanium-nickel alloy powder, 1.5-3.5% of graphite powder, 0.5-1% of silica powder, 8-25% of nickel-chromium alloy powder Ni80Cr20, 5-10% of iron boride powder and the balance of tri-chromium dicarbide powder. The preparation method comprises the following steps that power material is prepared, mix powder is formed, liquid-containing binders are prepared, sizing agents are prepared from the mix powder, prilling is completed through spray drying, and finished product powder is prepared from screening the prilling powder and is used for preparing a cladding layer. The metal cladding layer with high wear resistant duplex ceramic is formed through laser cladding, and the hardness ranges from 1100 HV to 1600 HV, so that the powder material for boiler tube high temperature resistance and wear resistance protecting and the preparation method thereof has the advantages that efficiency of the laser cladding is higher, loss of powder spattering is low, grain of the cladding layer is tiny, wear resistance of the cladding layer is high and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Corrision-resistant heated air data probe

ActiveUS20160291051A1Measurement apparatus componentsIndication/recording movementConductive materialsNickel alloy

An air data probe is disclosed. The air data probe may include a probe body having an interior cavity and coated by a protective shell. A sensing port may be disposed in the air data probe and may extend through the probe body. The sensing port may also be lined by the protective shell. The protective shell may be made of an austenitic nickel-chromium alloy, or stainless steel, or any relatively corrosion resistant material. The probe body may be made of nickel, or a nickel alloy, or any relatively thermally conductive material. The protective shell may be joined to the probe body by additive manufacturing, such as laser cladding. In this manner, an air data probe capable withstanding high temperatures without corrosion and yet also being relatively thermally conductive is disclosed.

Owner:ROSEMOUNT AEROSPACE

Mechanical stress improvement process

ActiveUS7389669B2Avoid it happening againFurnace typesEmergency protection arrangementsPressurized water reactorNuclear engineering

A process for reducing residual tensile stresses in high nickel-chromium alloy nozzle safe-end welds of pressurized water reactor nuclear pressure vessels such as are found at the reactor vessel inlet and outlet nozzles and the pressurizes surge, spray, safety and relief nozzles. The process involves the application of radial compression on the outside surface of the nozzle's safe-end and / or connecting coolant piping, to reduce the outside diameter at the mid-point of the piping element to which the load is applied to between about 0.2% and about 3%. The radially compressive load applied by this process is imparted using a mechanical device that can be employed at the vessel manufacturer's facility or at a nuclear power plant after welding of the nozzle safe-end to the coolant piping or before either after plant commissioning of operation.

Owner:NUVISION ENG INC

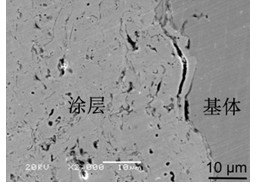

Nickel chromium alloy for sealing face of nuclear power valve

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com