Acetone gas sensor based on NiO / ZnO heterostructure hollow ball sensitive material and preparation method thereof

A gas sensor and sensitive material technology, applied in the direction of analyzing materials, material resistance, and material analysis through electromagnetic means, can solve the problems of low sensitivity, high detection temperature, etc., and achieve high sensitivity, good repeatability, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

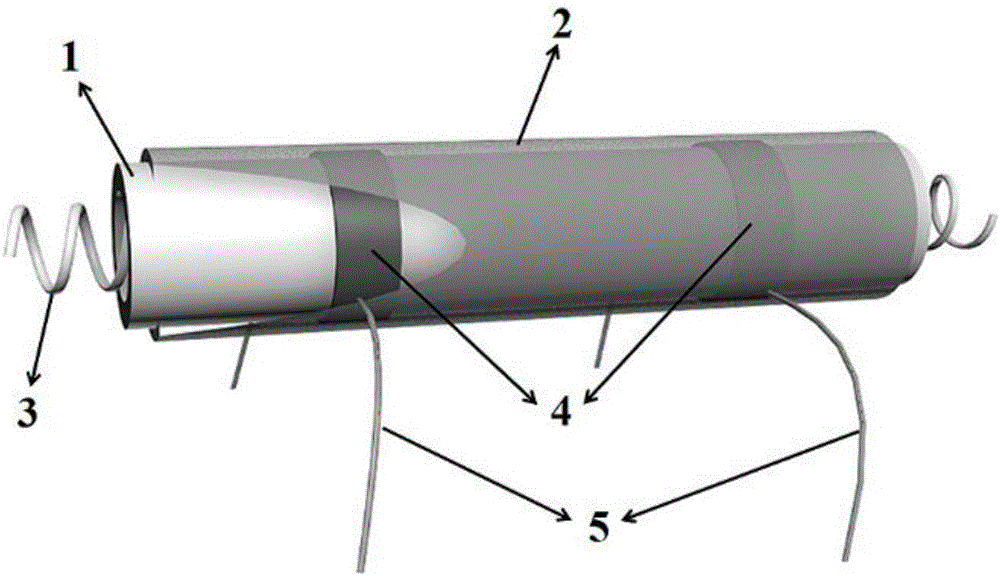

[0041] Using NiO / ZnO heterostructure hollow spheres as sensitive materials to make acetone sensors, the specific manufacturing process:

[0042] 1. First, 1.10g of Zn(CH 3 COO) 2 2H 2 O and 0.06g Na 3 C 6 h 5 o 7 2H 2 Dissolve O in 200mL of deionized water, and keep stirring until it is completely dissolved; then slowly add 5mL of ammonia water to it until the solution is clear;

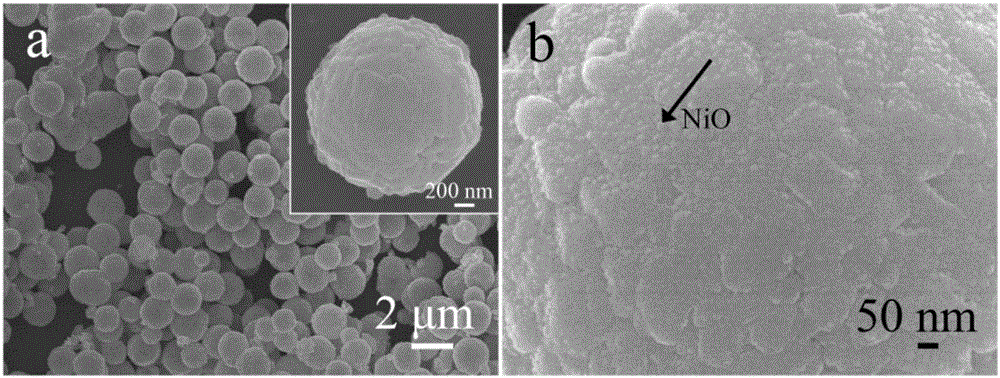

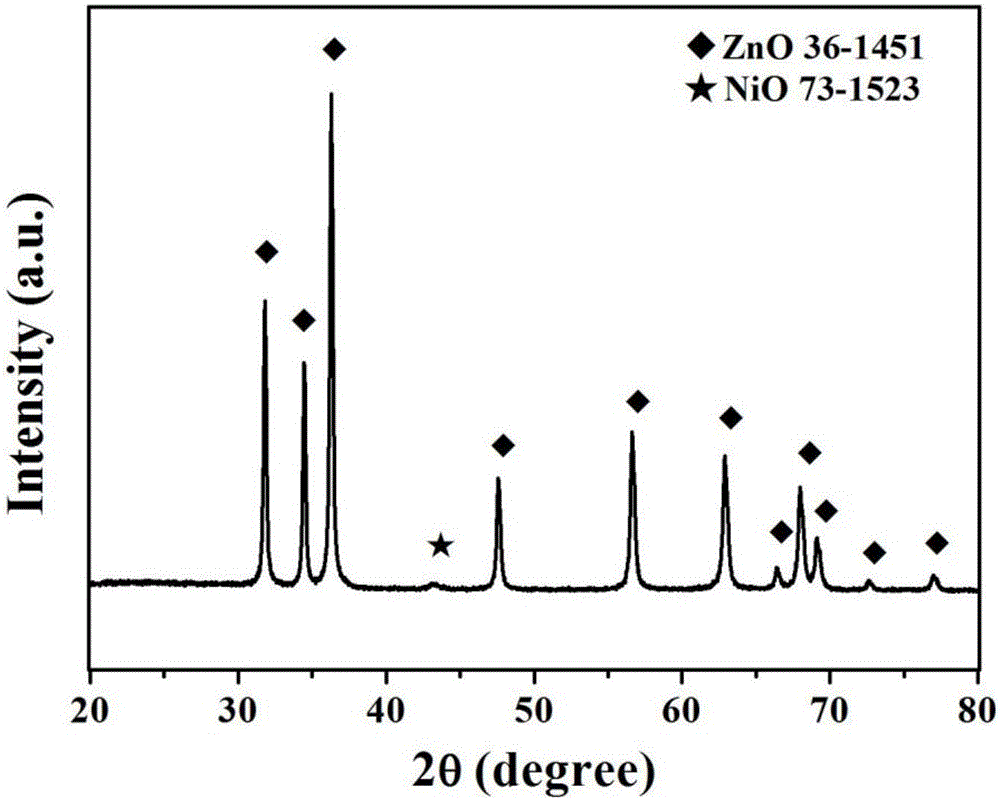

[0043] 2. React the above solution for 40 minutes under the condition of microwave power 300W and 90°C, take it out, cool it down to room temperature naturally, wash the formed precipitate with deionized water and ethanol for several times, and then dry it at room temperature before cooling it at 500°C Calcined at lower temperature for 2 hours, thus obtained ZnO hollow sphere powder assembled by ZnO nanoparticles;

[0044] 3. Take 50mg of the above ZnO hollow sphere powder and add it to a mixed solvent composed of 3mL ethylene glycol and 7mL ethanol, ultrasonically and stir for 20 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com