Composite coating material applied to semi-metal iron-based brake pads and preparation method for composite coating material

A composite coating, brake pad technology, applied in metal material coating process, metal processing equipment, coating and other directions, can solve the problem of high price of new materials and preparation process, unstable friction performance of brake pads, and utilization of new brake pad materials. problems such as low rate, to achieve the effects of easy control of process parameters, beneficial environmental protection, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

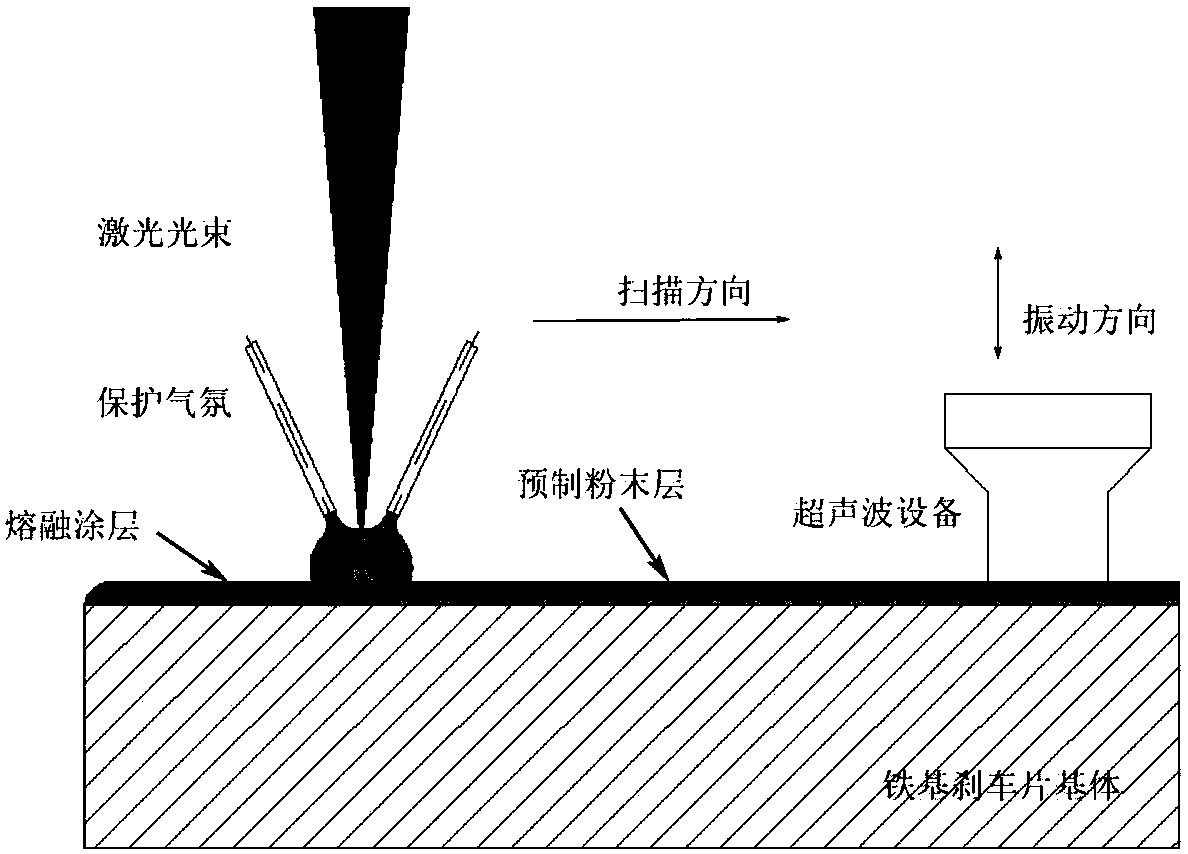

[0039] A composite coating material applied to semi-metallic iron-based brake pads, the preparation method of which comprises the following steps:

[0040] 1) Weigh nickel-chromium powder, chromium carbide cermet powder, ferrosilicon powder, vanadium-iron powder, aluminum powder and graphene as raw materials according to the mass ratio of 45:18:6:5:25:1;

[0041] 2) Place the weighed raw materials in a vibrating mixer for vibratory mixing. The vibration frequency used is 50 Hz, the vibration force is 9000 N, and the vibration time is 30 minutes. The raw materials are fully mixed, and then melted at high temperature to obtain molten Metal liquid; high-temperature melting process parameters: vacuum degree of high-temperature vacuum furnace <0.01MPa, protective gas is argon, temperature is 1800°C, holding time is 30min;

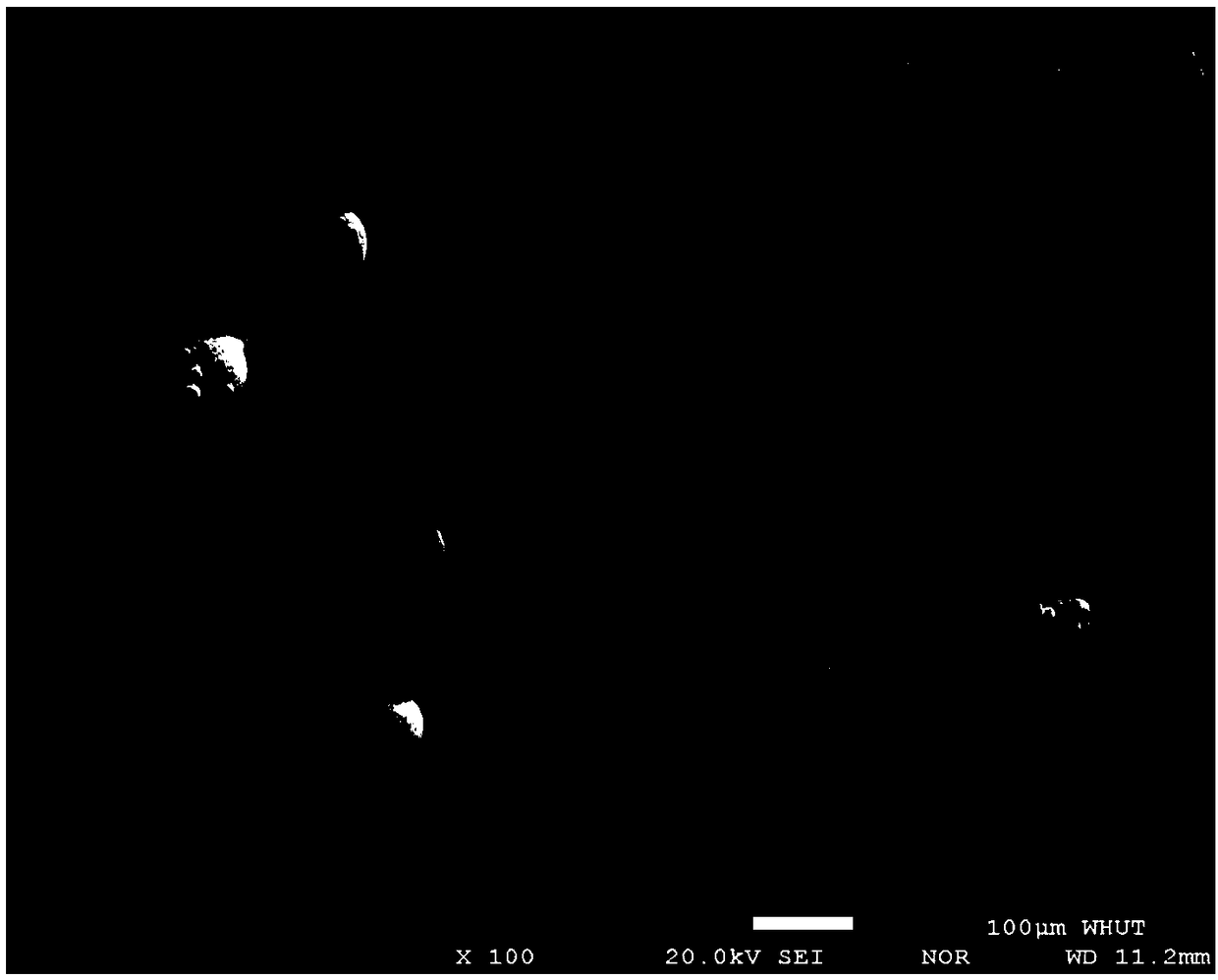

[0042] 3) The molten metal liquid obtained in step 2) is mixed and atomized with water and gas, and the diameter is controlled at 60-80 μm (as follows image 3...

Embodiment 2

[0048] A composite coating material applied to semi-metallic iron-based brake pads, the preparation method of which comprises the following steps:

[0049] 1) Weigh nickel-chromium powder, chromium carbide cermet powder, ferrosilicon powder, vanadium-iron powder, aluminum powder and graphene as raw materials according to the mass ratio of 40:16:7.5:5:30:1.5;

[0050] 2) Place the weighed raw materials in a vibrating mixer for vibratory mixing. The vibration frequency used is 50 Hz, the vibration force is 10000 N, and the vibration time is 30 minutes. The raw materials are fully mixed, and then melted at high temperature to obtain molten Metal liquid; high-temperature melting process parameters: vacuum degree of high-temperature vacuum furnace <0.01MPa, protective gas is argon, temperature is 1650°C, holding time is 40min;

[0051] 3) The molten metal liquid obtained in step 2) is mixed and atomized with water and gas, and the diameter is controlled at 70-90 μm (as follows im...

Embodiment 3

[0057] A composite coating material applied to semi-metallic iron-based brake pads, the preparation method of which comprises the following steps:

[0058] 1) Weigh nickel-chromium powder, chromium carbide cermet powder, ferrosilicon powder, vanadium-iron powder, aluminum powder and graphene as raw materials according to the mass ratio of 50:15:8:5:20:2;

[0059] 2) Place the weighed raw materials in a vibrating mixer for vibratory mixing. The vibration frequency used is 50 Hz, the vibration force is 11000 N, and the vibration time is 30 minutes. The raw materials are fully mixed and then melted at a high temperature to obtain a molten Metal liquid; high-temperature melting process parameters: vacuum degree of high-temperature vacuum furnace <0.01MPa, protective gas is argon, temperature is 1750°C, holding time is 35min;

[0060] 3) The molten metal liquid obtained in step 2) is mixed and atomized with water and gas, and the diameter is controlled at 85-100 μm (as follows im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com