Preparation method of nickel-chrome alloy steel

An alloy steel and nickel-chromium technology, which is applied to low-alloy steel and its preparation, and the medium field containing nickel-chromium, can solve the problems of not being comprehensively utilized, and achieve the effects of good economic benefits, improved strength, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 HRB400 hot-rolled ribbed steel bar

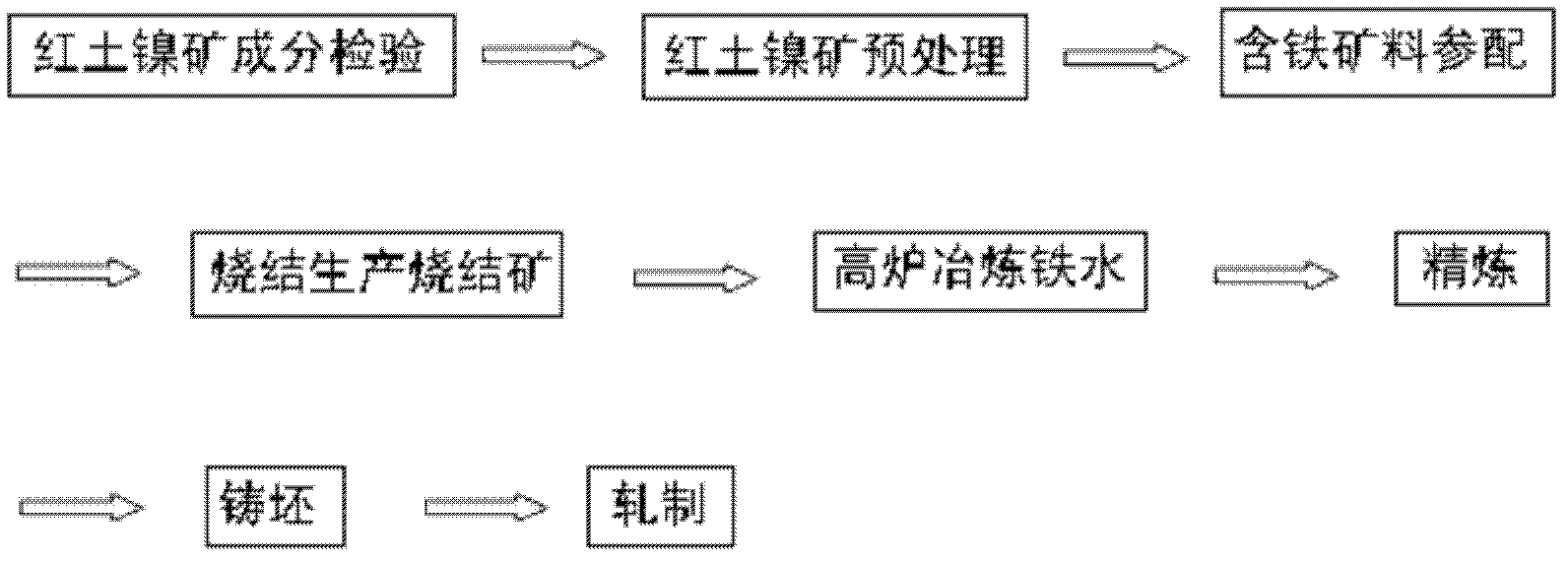

[0033] The production process is as follows:

[0034] (1) select the laterite nickel ore containing nickel 1.0%, chromium 1.2%, iron 50% for use, first through drying equipment drying for subsequent use;

[0035] (2) The dried laterite nickel ore and the iron ore containing 61% iron are mixed according to the weight ratio of 1.5:8.5, and 90% iron-containing ore, 5% quicklime and 5% coal powder are added according to the weight for batching , control the water content to 9.5-10wt%, mix and pelletize, and then carry out cloth and sintering. The temperature of the ignition furnace of the sintering machine is controlled at 1050-1100°C, the temperature of the exhaust gas is controlled at 130-150°C, and the negative pressure of the bellows is controlled at -12kpa~ -13kpa, get sintered ore;

[0036] (3) The sintered ore is smelted in a blast furnace, and the obtained molten iron contains 0.12% of nickel and 0.3% of chromium; ...

Embodiment 2

[0044] Embodiment 2HRB400 hot-rolled ribbed steel bar

[0045] The production process is as follows:

[0046] (1) select the laterite nickel ore containing nickel 1.0%, chromium 1.5%, iron 50% for use, first through drying equipment drying for subsequent use;

[0047] (2) sintering the dried laterite nickel ore and iron ore containing 61% iron according to the weight ratio of 1.5:8.5;

[0048] (3) Smelting the sintered ore in a blast furnace, and the obtained molten iron contains 0.15% nickel and 0.45% chromium;

[0049] All the other steps and technology are with embodiment 1.

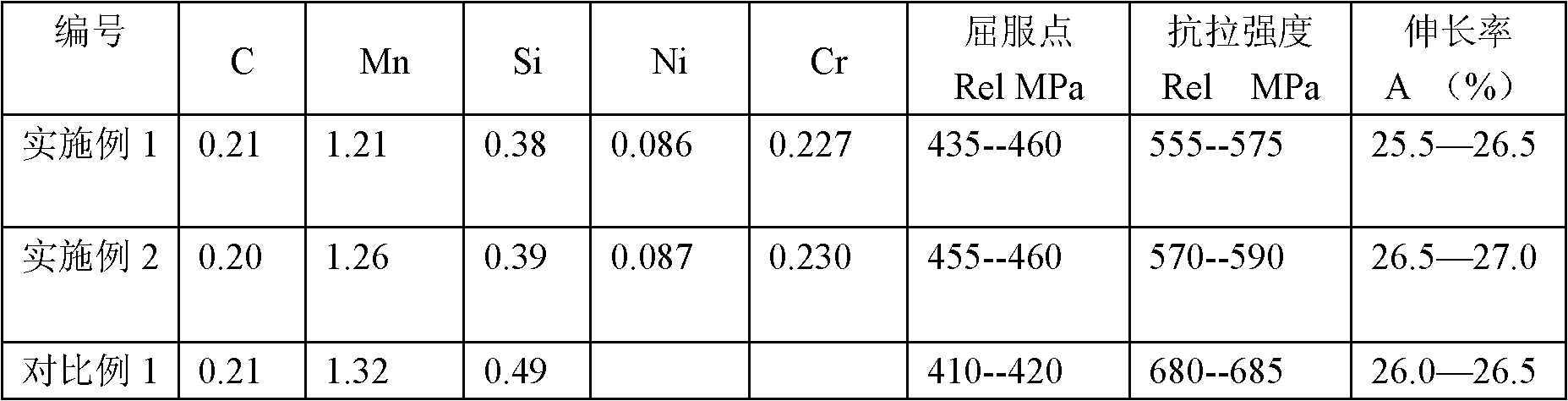

[0050] The specific ingredients are shown in Table 2

[0051] Table 2

[0052] the element

[0053] The carbon equivalent calculated according to the carbon equivalent calculation formula Ceq=C+Mn / 6+(Cr+V+Mo) / 5+(Cu+Ni) / 15 complies with the provisions of GB1499.1.

Embodiment 3

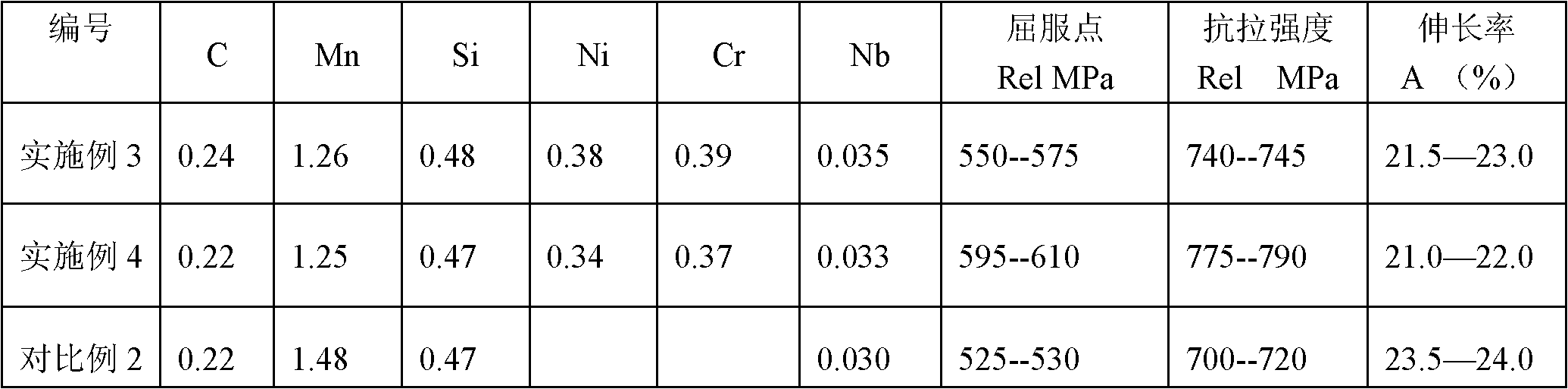

[0059] Embodiment 3HRB500 high-strength 500MPa earthquake-resistant and weather-resistant steel bar

[0060] The production process is as follows:

[0061] (1) select the laterite nickel ore containing nickel 0.8%, chromium 1.1%, iron 50% for use, first through drying equipment drying for subsequent use;

[0062] (2) The dried laterite nickel ore and iron ore containing 61% iron are mixed according to the weight ratio of 7:3, and 90% iron-containing ore, 5% quicklime, and 5% coal powder are added according to the weight for batching , control the water content to 9.5-10wt%, mix and pelletize, and then carry out cloth and sintering. The temperature of the ignition furnace of the sintering machine is controlled at 1050-1100°C, the temperature of the exhaust gas is controlled at 130-150°C, and the negative pressure of the bellows is controlled at -12kpa~ -13kpa, get sintered ore;

[0063] (3) Smelting the sintered ore in a blast furnace, and the obtained molten iron contains 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com