Method and device for differential leveling and rust removing of hot-rolled steel plate

A hot-rolled steel plate and flattening technology, which is applied in the direction of grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems that surface defects cannot be effectively eliminated, and achieve the effects of small footprint, good product quality, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

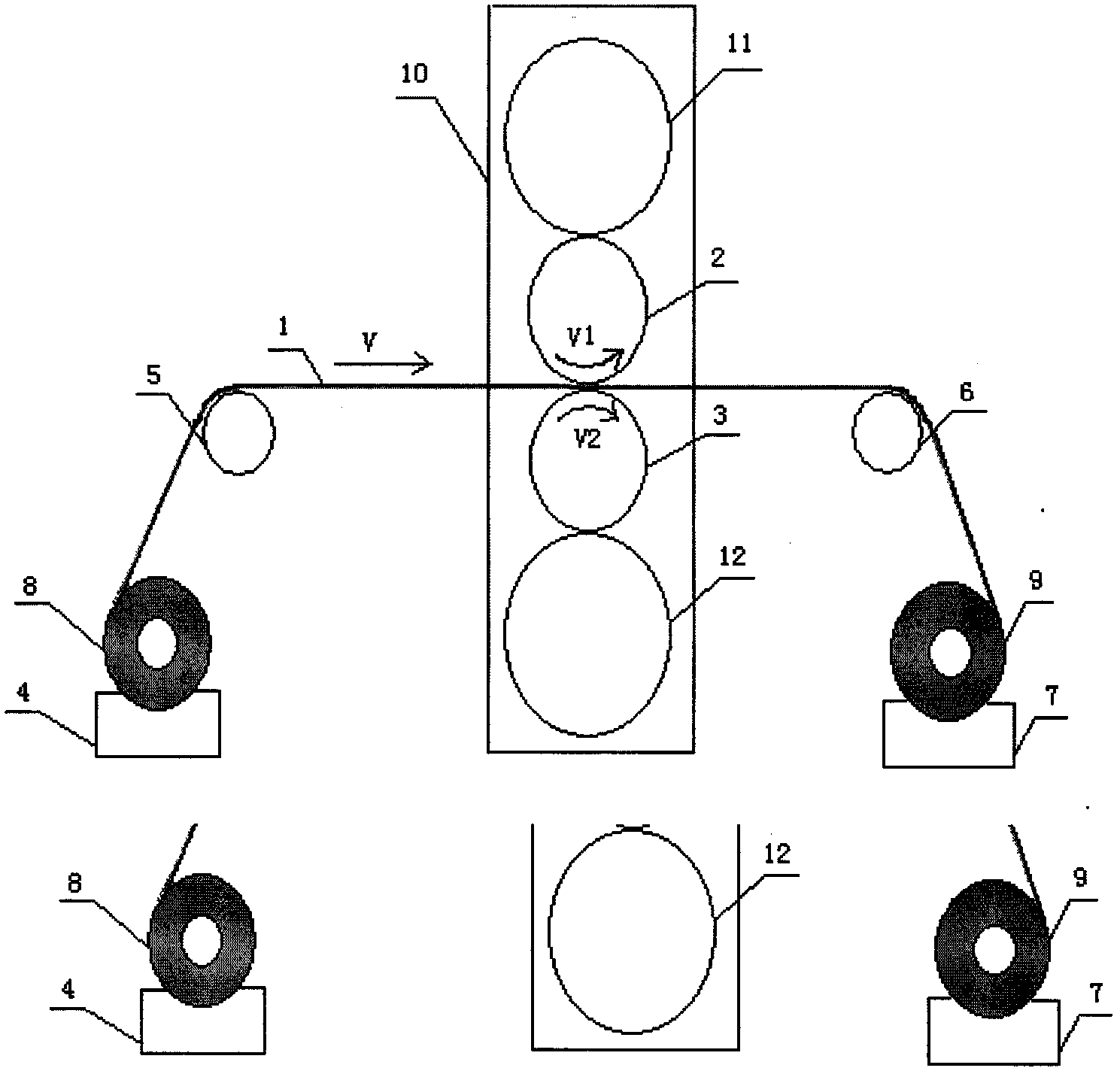

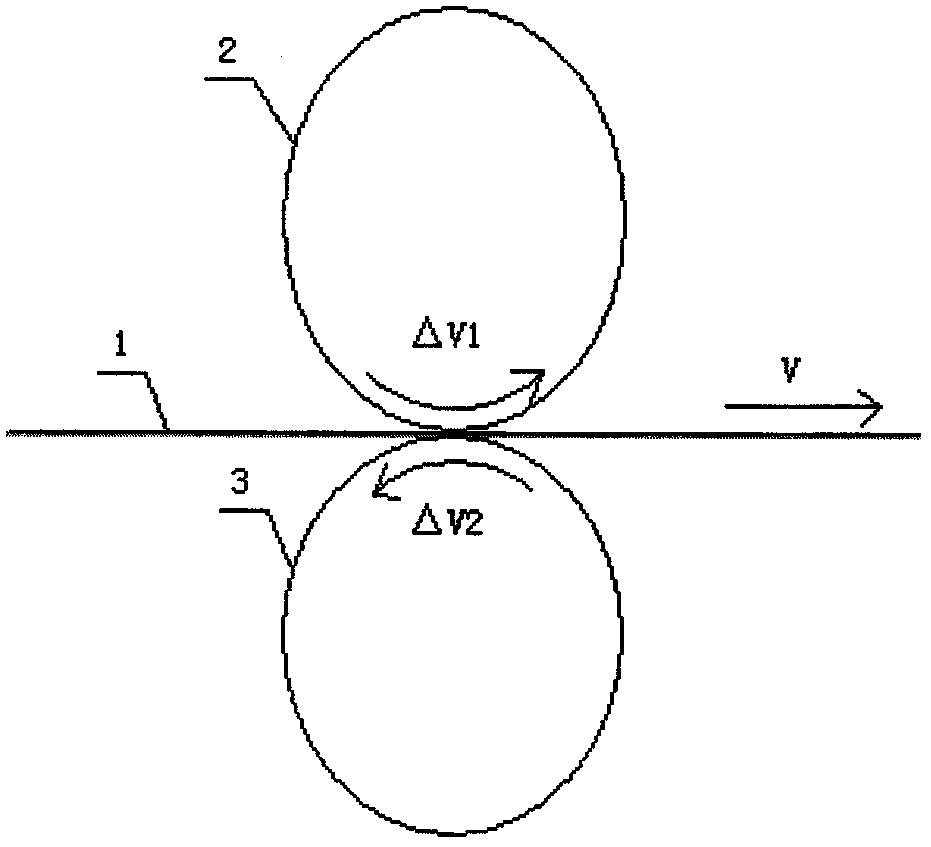

[0015] The device of differential smoothing and derusting of hot-rolled steel plate of the present invention is as figure 1 As shown, it includes a left coiler 4 , a right coiler 7 , a left guide roller 5 , a right guide roller 6 and a four-roll leveler 10 . The four-roller skin pass machine is equipped with an upper metal texturing roll 2, a lower metal texturing roll 3, an upper support roll 11 and a lower support roll 12. Between the upper metal texturing roll and the lower metal texturing roll is the channel for the hot-rolled steel plate 1, the upper support roll is located above the upper metal texturing roll, and the lower support roll is located below the lower metal texturing roll. The upper metal texturing roll 2 and the lower metal texturing roll 3 are wear-resistant forged steel rolls containing 5% metal chromium, with a diameter of 400 mm. The smooth cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com