Optimized presetting method for steel strip-flattening technological parameter

A technology of process parameter optimization and process parameter, applied in the direction of contour control, etc., can solve the problems of unqualified flat strip steel plate shape, unstable production process, large randomness, etc., to improve mechanical properties, improve performance and plate shape quality, Eliminates the effect of yielding platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The optimization preset method of strip steel leveling process parameter of the present invention is further described in detail as follows:

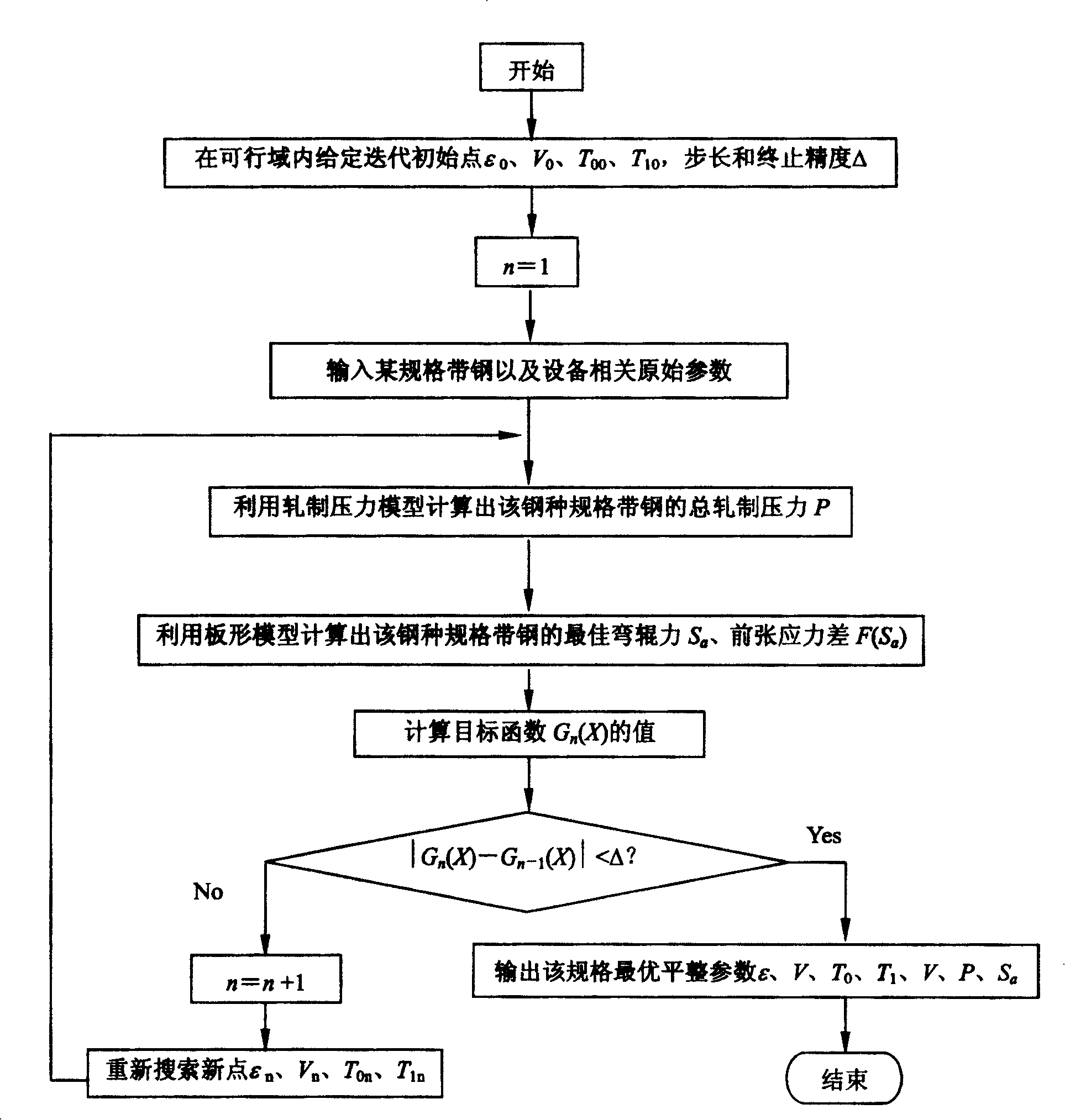

[0056] A. Determination of objective function for leveling process parameters optimization

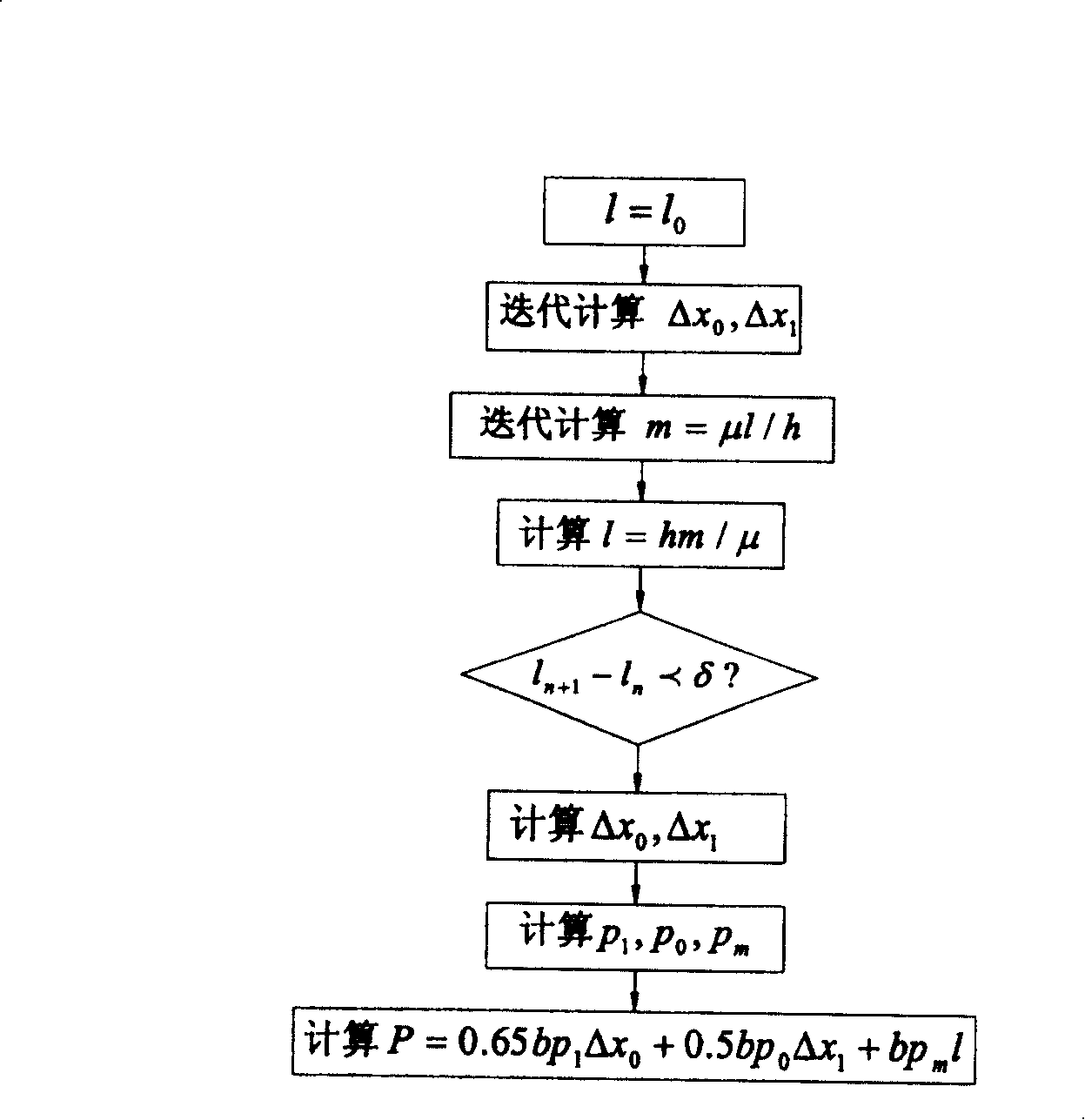

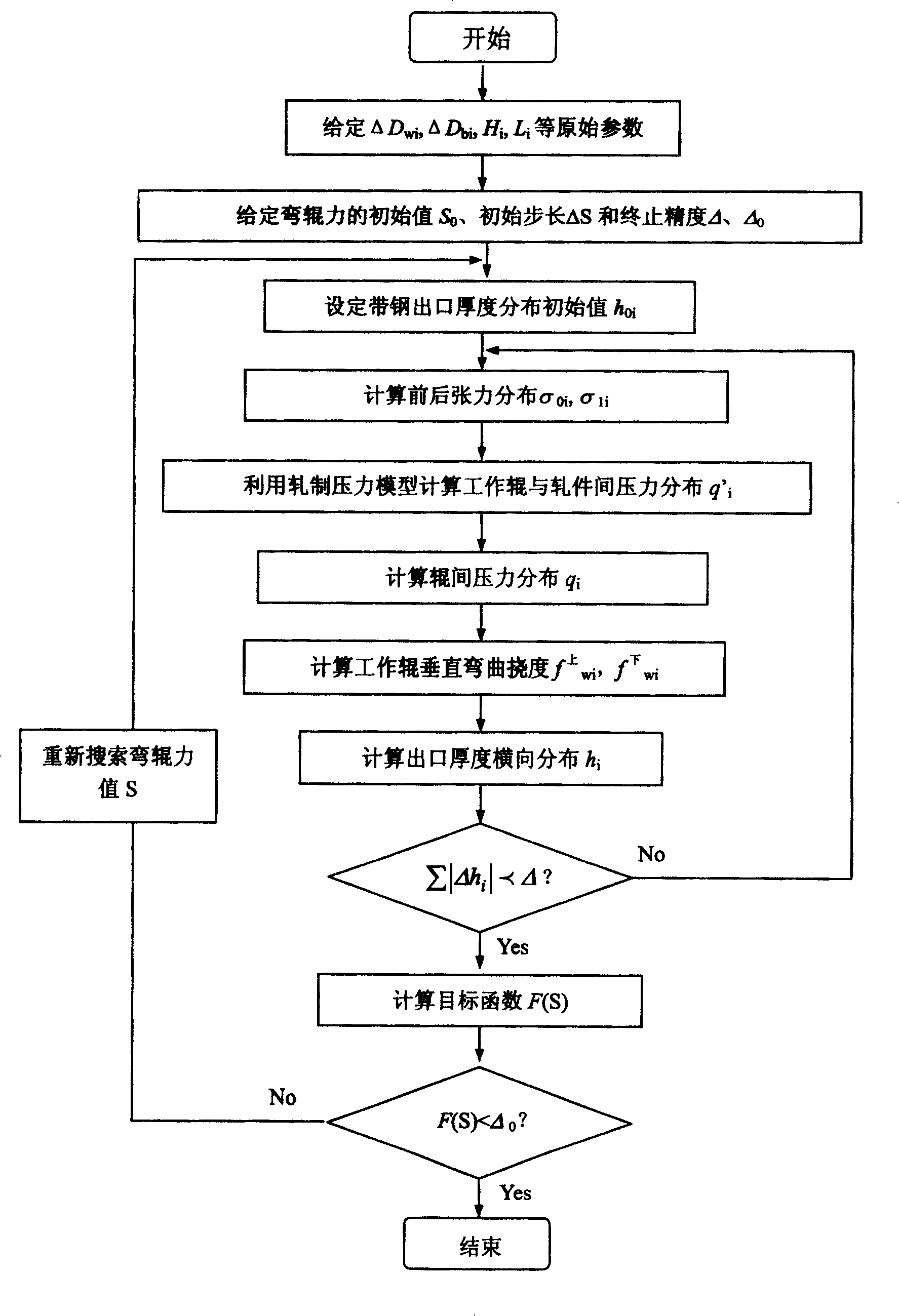

[0057] According to the rolling theory, under certain conditions such as incoming strip steel, pass roll shape and roll surface shape, the pass elongation ε, pass speed V, entrance tension (back tension) T 0 and outlet tension (front tension) T 1 etc. determine the rolling pressure P, and when ε, V, T 0 , T 1 When P and P are constant, there must be an optimal bending force S (corresponding to the bending force with the most uniform transverse distribution of tensile stress at the exit of the strip), so that the exit shape of the strip is the best. Among them, the relationship between V and rolling pressure P is: the leveling speed affects the friction coefficient and deformation resistance of the leveling deformation zone, and then af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com