B-containing high-formability extremely thin hot-rolled pickling plate and preparation method thereof

A hot-rolled pickling and formability technology, which is applied in the field of hot-rolled pickling sheets with high formability and ultra-thin specifications containing B and its preparation, can solve the problem of less than 400MPa, the lowest and effective solid solution B content is reduced, Mn and Ti The problem of low content is eliminated, and the effect of eliminating the yield plateau, suppressing the transverse fold defect and improving the surface quality is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

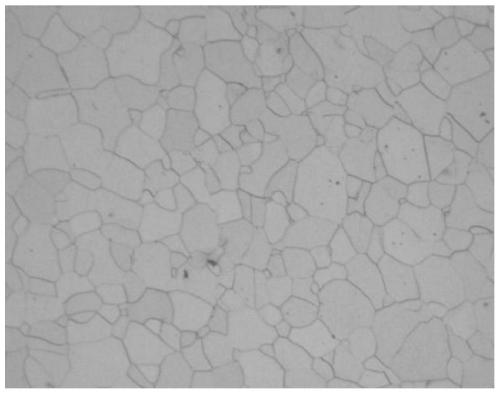

Image

Examples

preparation example Construction

[0021] The preparation method of the B-containing high-formability ultra-thin specification hot-rolled pickling plate of the present invention mainly includes the following steps: steel billet→hot continuous rolling→hot-rolled raw material uncoiling→drawing and leveling unit breaking scale→pickling, characterized in that: the hot The heating temperature of the billet in the continuous rolling step is 1200°C to 1280°C; the start rolling temperature of the finish rolling in the hot continuous rolling step is 1080°C to 1150°C; the finish rolling temperature in the hot continuous rolling step is 860°C °C to 920 °C; the coiling temperature in the hot continuous rolling step is 540 to 600 °C.

[0022] In the present invention, when the stretching and leveling unit breaks the scale, the elongation of the stretching and leveling unit is controlled to be 1.0% to 2.0%. will get worse.

[0023] The start rolling temperature of the finish rolling in the hot continuous rolling step of the...

Embodiment 1

[0028] The 2050 hot rolling unit (7-stand continuous rolling finishing unit) is used to produce ultra-thin specification hot-rolled pickling plates with high surface quality and high formability containing B ultra-low C+Ti micro-alloying treatment. The chemical composition weight percent of the starting billet is: [C]: 0.0031%, [Si]: 0.19%, [Mn]: 0.86%, [P]: 0.004%, [S]: 0.001%, [B]: 0.0026%, [Ti]: 0.056%, [Als]: 0.044%, [N]: 0.0028%, [O]: 0.0028%, and the rest is Fe and unavoidable impurities.

[0029]The preparation method is: billet heating → descaling → rough rolling → finishing rolling → laminar cooling → coiling → cooling the steel coil to room temperature (≤40°C) → uncoiling of hot-rolled raw materials → laser welding → scale breaking by the stretching and leveling unit → pickling →rinsing→drying→online leveling→edge trimming→online oiling→baling→packing and storage. The thickness of the steel billet is 230mm. After being heated at 1240°C, it is descaled after being re...

Embodiment 2

[0033] The 2050 hot rolling unit (7-stand continuous rolling finishing unit) is used to produce ultra-thin specification hot-rolled pickling plates with high surface quality and high formability containing B ultra-low C+Ti micro-alloying treatment. The chemical composition weight percent of the starting billet is: [C]: 0.0017%, [Si]: 0.14%, [Mn]: 0.95%, [P]: 0.002%, [S]: 0.002%, [B]: 0.0048%, [Ti]: 0.036%, [Als]: 0.028%, [N]: 0.0020%, [O]: 0.0030%, and the rest is Fe and unavoidable impurities.

[0034] The preparation method is: billet heating → descaling → rough rolling → finishing rolling → laminar cooling → coiling → cooling the steel coil to room temperature (≤40°C) → uncoiling of hot-rolled raw materials → laser welding → scale breaking by the stretching and leveling unit → pickling →rinsing→drying→online leveling→edge trimming→online oiling→baling→packing and storage. The thickness of the steel billet is 230mm. After being heated at 1240°C, it is descaled after being r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com