A kind of cualmn shape memory alloy and preparation method thereof

A memory alloy and alloy ingot technology is applied in the fields of CuAlMn shape memory alloy and its preparation, shape memory alloy and its preparation, and achieves the effects of efficient preparation, favorable for directional growth, and simple directional annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

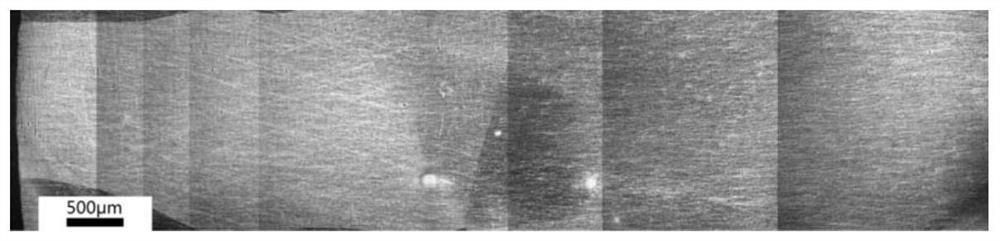

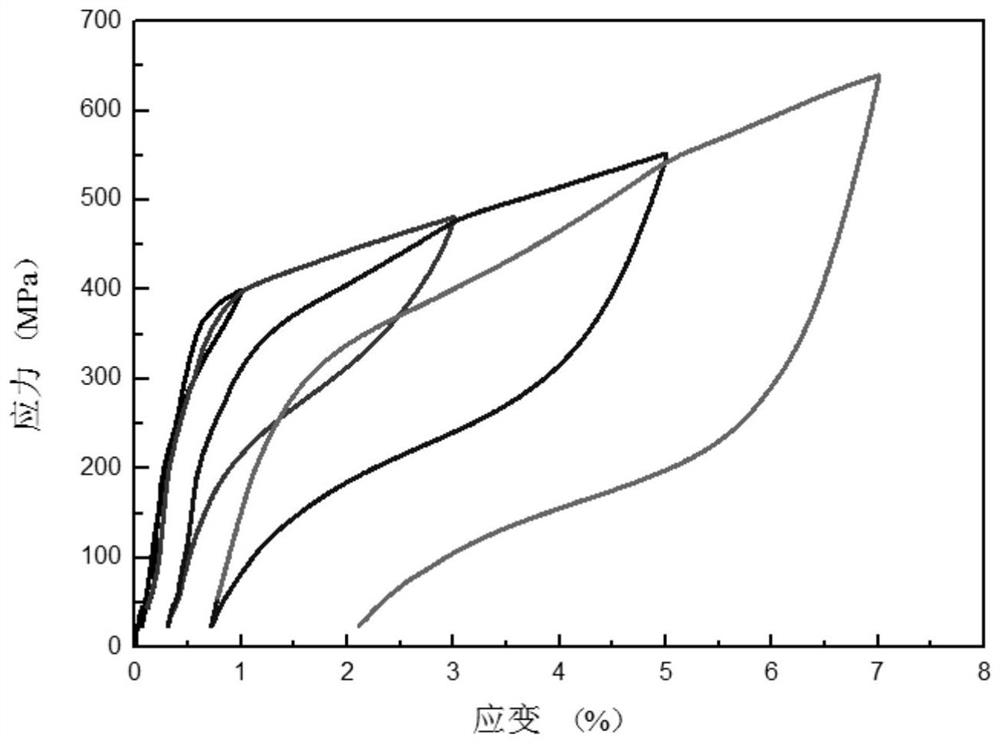

[0045] The molar percentages are: Al 17.0%, Mn 12.0%, Cu 71.0%. Weigh oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.99%. times, and finally get alloy ingots. The alloy ingots were hot rolled to a thickness of 20 mm and then cold rolled to a thickness of 10 mm. Install the rolled sample on the pull rod connected to the servo motor in the directional annealing furnace, close the directional annealing furnace cover, and evacuate to ~10-3Pa, and the upper end of the sample is consistent with the hot zone. The temperature of the hot zone is 900°C, the width of the hot zone is 20mm, the temperature gradient is 120°C / mm, and the moving speed of the shape memory alloy material relative to the hot zone is 15μm / s. Subsequently, the orientation zone was quenched at 900°C to obtain a columnar crystal CuAlMn shape memory alloy with a grain length of more than 5mm and a width of more than 1mm. figure 1 shown. Then the cyclic tensile test was car...

Embodiment 2

[0047] The molar percentages are: Al 18.0%, Mn 12.0%, Cu 70.0%. Weighing oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity greater than 99.9% are placed in a copper crucible, vacuumed, and arc smelted , repeated smelting 5-6 times to obtain alloy ingots. The alloy ingot was heated to 800°C and hot-rolled to a thickness of 2 mm, and then cold-rolled to a thickness of 1 mm. Install the rolled sample on the pull rod connected to the servo motor in the directional annealing furnace, the upper end of the sample is consistent with the hot zone, close the directional annealing furnace cover, and evacuate to ~10-3Pa. The temperature of the hot zone is adjusted to 900°C, the width of the hot zone is 20mm, and the temperature gradient is 100°C / mm, so that the moving rate of the alloy material relative to the hot zone is 30 μm / s to pass through the above temperature field. Then the CuAlMn shape memory alloy is quenched to obtain the columnar crystal shap...

Embodiment 3

[0049] The molar percentages are: Al 17.5%, Mn 12.0%, Cu 70.5%. Weigh oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.99%. times, and finally get alloy ingots. Alloy ingots were extruded into alloy rods up to 10 mm in diameter. Then install the sample on the pull rod connected to the servo motor in the directional annealing furnace, close the directional annealing furnace cover, and evacuate to ~10-3Pa, and the upper end of the sample is consistent with the hot zone. The temperature of the hot zone is 900°C, the thickness of the hot zone is 10mm, the temperature gradient is 85°C / mm, and the moving rate of the shape memory alloy material relative to the hot zone is 20 μm / s. The single crystal CuAlMn shape memory alloy is obtained by directional annealing. The sample was taken out and placed in a muffle furnace and heated to 500°C for 10 minutes, then heated to 900°C for 60 minutes, then cooled to 500°C for 10 minutes, and after 4 cycles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com