Process for producing stainless steel diffusion-joined product

A diffusion bonding and manufacturing method technology, applied in the direction of manufacturing tools, welding/welding/cutting items, welding equipment, etc., can solve problems such as difficulty in obtaining joint strength, increased cost, and reduced corrosion resistance, and achieve joint strength and sealing Excellent, reduced manufacturing cost, low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Steel plates having the chemical compositions shown in Table 1 were prepared. D-1 to D-3 are steels with γmax less than 100, M-1 to M-2 are steels classified as so-called martensitic stainless steels, F-1 is ferritic single-phase steel, and A-1 is austenitic single-phase steel. Table 1 shows the thickness, surface finish, and surface roughness Ra of the steel sheet. Regarding the metal structure of each prepared steel plate, D-1 to D-3 are ferrite + carbide, M-1 to M-2 are ferrite phase + martensite phase, and M-3 is martensite single phase. Phase, F-1 is ferrite single phase, A-1 is austenite single phase.

[0092] [Table 1]

[0093]

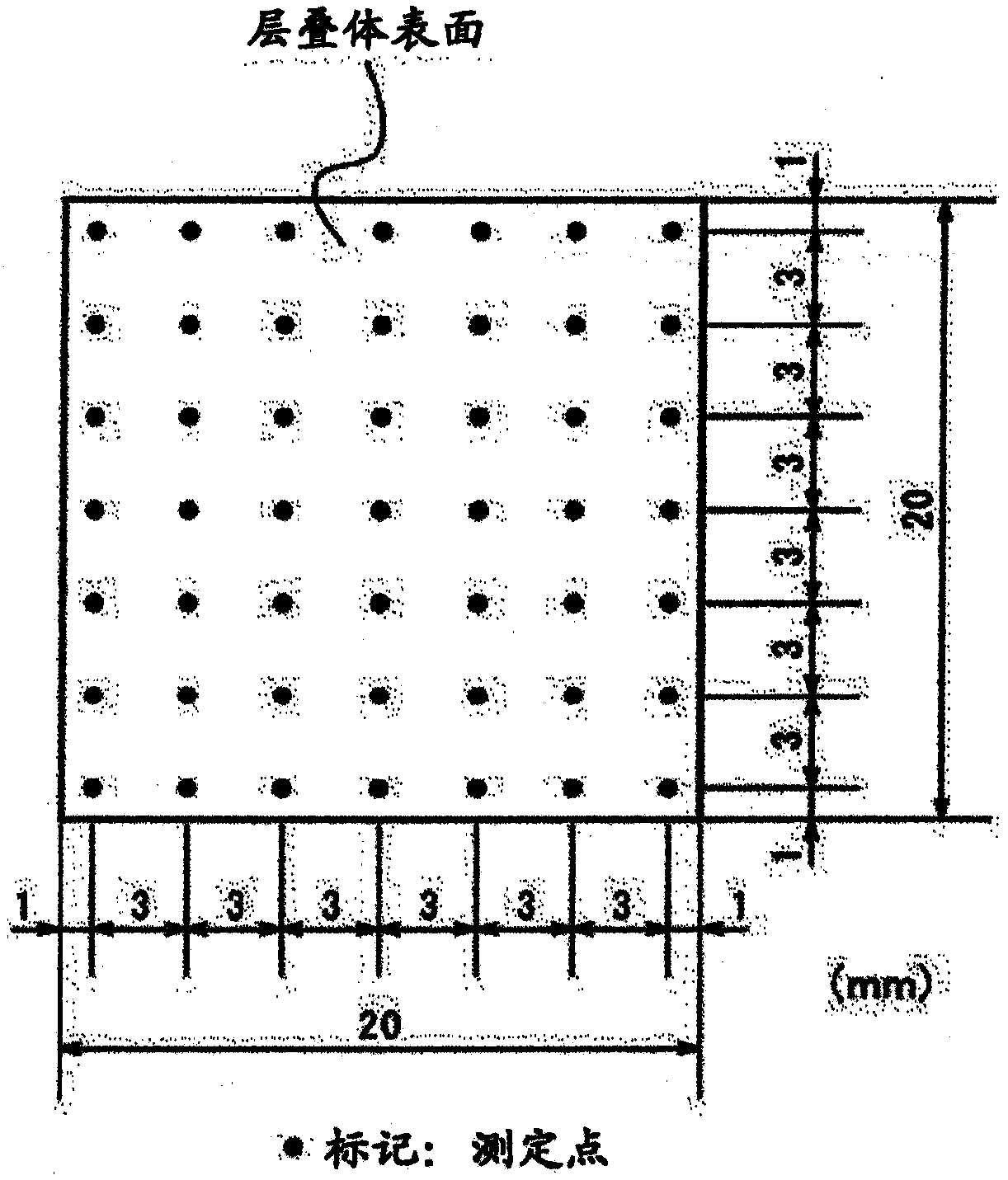

[0094] A flat test piece of 20 mm×20 mm was cut out from each steel plate, and two test pieces were superimposed in the following method to try diffusion bonding.

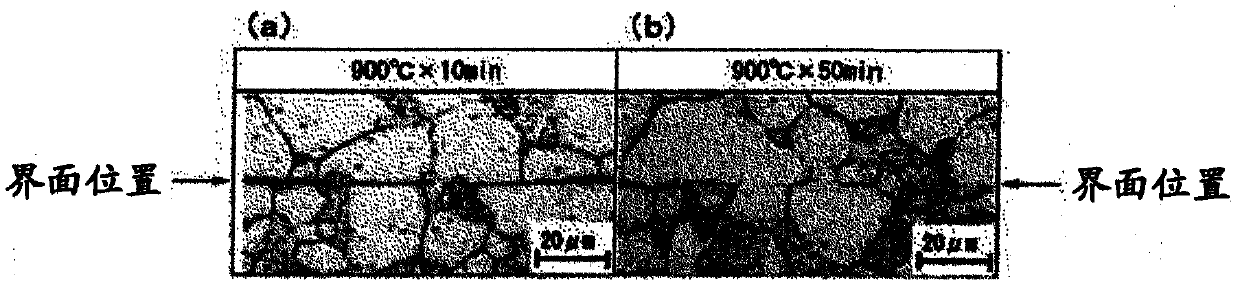

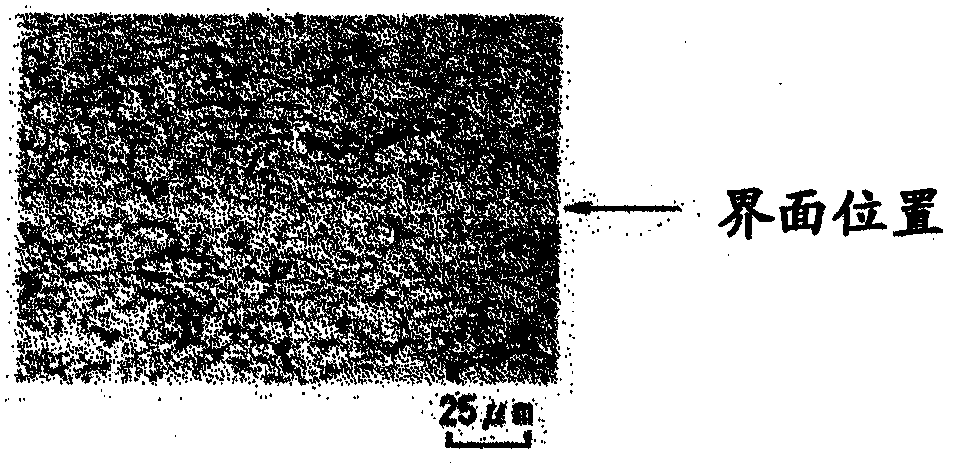

[0095] The two test pieces to be tried for diffusion bonding are stacked so that their surfaces are in contact with each other, and the surface pressure (contact surfa...

Embodiment 2

[0112] Smelting and hot-rolling the steel with the chemical composition shown in Table 3 to obtain a hot-rolled plate with a plate thickness of 3 to 4 mm, followed by annealing, pickling, cold rolling, finishing annealing, and pickling to obtain a plate A steel plate for testing with a thickness of 1.0mm. D-11 to D-15 are two-phase steels that are the object of the present invention, F-11 is a ferritic single-phase steel, and A-11 is an austenitic single-phase steel. Table 3 also describes the plate thickness, surface finish, and surface roughness Ra of the steel plate. Regarding the metal structure of each steel sheet, D-11 to D-15 are ferrite+carbide, F-11 is a ferrite single phase, and A-11 is an austenite single phase.

[0113] [table 3]

[0114]

[0115] A 100 mm square steel material (hereinafter referred to as "flat material") was produced by cutting from each test steel plate of steels D-11 to D-15. In addition, a steel material consisting of a frame with a width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com