Thick X80 hot rolled coil for phi 1422mm ultra large diameter spiral submerged arc welded pipe and manufacturing method of thick X80 hot rolled coil

A technology of submerged arc welded pipe and super large diameter, which is applied in the field of thick gauge X80 hot-rolled coil and its manufacturing, can solve the problems of DWTT performance not meeting the requirements, high operating system input cost, low single-pass reduction rate, etc. Effects of strain-induced grain boundary migration, excellent tensile properties and low-temperature toughness, and large pass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0047] A thick gauge X80 hot-rolled coil for Φ1422mm ultra-large-diameter spiral submerged arc welded pipe. The chemical composition weight percentage of the hot-rolled coil is shown in Table 1. The billet size is 230mm×1650mm, and the hot-rolled coil size is 21.4mm×1550mm.

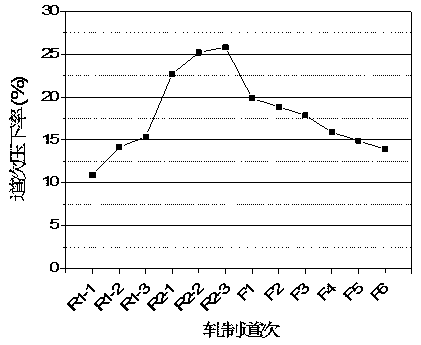

[0048] Its production process is: KR method stirring pre-desulfurization→LD top-bottom composite blowing→LF deep desulfurization→RH deep degassing→calcium treatment→continuous casting→slab reheating→rough rolling→finish rolling→cooling and coiling after rolling The heating temperature of the casting slab is 1170°C, the thickness of the rough rolling intermediate billet is 65.7mm, the cumulative reduction rate of the finish rolling is 67.5%, and the cooling rate after rolling is 30°C / s. The specific process parameters are shown in Table 2. The reduction rate and distribution law of each pass in the rolling stage are shown in figure 1 .

[0049] Table 1 Weight percentage of chemical composition of hot roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com