In-situ synthesized aluminum carbide reinforced aluminum matrix composite material and preparation method thereof

A composite material and a technology for reinforced aluminum matrix, which is applied in the field of in-situ synthesis of aluminum carbide Al4C3 reinforced aluminum matrix composite material and its preparation, which can solve the problems such as thermal stability and high temperature mechanical properties of composite materials that are not given, and achieve improved interface lubrication. Effects of wet and interfacial bond strength, high tensile strength and thermal stability, high room temperature strength and high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

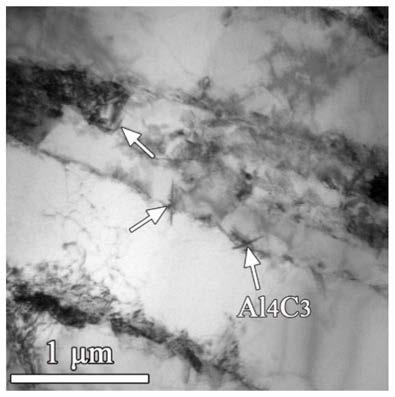

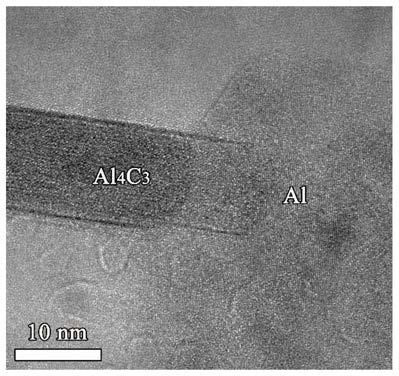

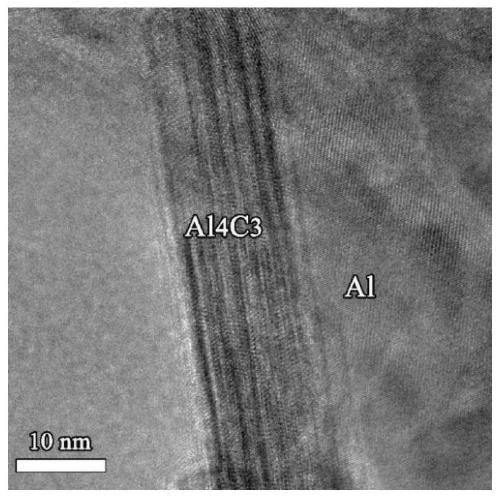

[0028] This embodiment provides a kind of in situ synthesis Al 4 C 3 Reinforced aluminum matrix composites, including aluminum powder and graphene powder, the volume fraction of graphene powder is 0.8%, and aluminum powder and graphene powder generate nanoscale Al with dispersed distribution through in-situ reaction 4 C 3 , nanoscale Al 4 C 3 It is distributed in the composite material in two forms, one of which is that the two ends of the rod-shaped shape grow into the two aluminum grains respectively, pinning two adjacent aluminum grains, and the other is that the two ends of the rod-shaped shape grow along the crystal grains. Boundary arrangement can effectively prevent dislocation and grain boundary migration.

[0029] In-situ synthesis of Al in the foregoing examples 4 C 3 Reinforced aluminum matrix composites can be prepared by the following methods, including the following specific steps:

[0030] S1: Choose aluminum powder with a ball diameter of 200 mesh and gr...

Embodiment 2

[0035] This embodiment provides a kind of in situ synthesis Al 4 C 3 Reinforced aluminum matrix composites, including aluminum powder and graphene powder, the volume fraction of graphene powder is 1.5%, and aluminum powder and graphene powder generate nanoscale Al with dispersed distribution through in-situ reaction 4 C 3 , nanoscale Al 4 C 3 It is distributed in the composite material in two forms, one of which is that the two ends of the rod-shaped shape grow into the two aluminum grains respectively, pinning two adjacent aluminum grains, and the other is that the two ends of the rod-shaped shape grow along the crystal grains. Boundary arrangement can effectively prevent dislocation and grain boundary migration.

[0036] In-situ synthesis of Al in the foregoing examples 4 C3 Reinforced aluminum matrix composites can be prepared by the following methods, including the following specific steps:

[0037] S1: Select aluminum powder with a ball diameter of 200 mesh and grap...

Embodiment 3

[0045] This embodiment provides a kind of in situ synthesis Al 4 C 3 Reinforced aluminum matrix composites, including aluminum powder and graphene powder, the volume fraction of graphene powder is 2%, and aluminum powder and graphene powder generate nanoscale Al with dispersed distribution through in-situ reaction 4 C 3 , nanoscale Al 4 C 3 It is distributed in the composite material in two forms, one of which is that the two ends of the rod-shaped shape grow into the two aluminum grains respectively, pinning two adjacent aluminum grains, and the other is that the two ends of the rod-shaped shape grow along the crystal grains. Boundary arrangement can effectively prevent dislocation and grain boundary migration.

[0046] In-situ synthesis of Al in the foregoing examples 4 C 3 Reinforced aluminum matrix composites can be prepared by the following methods, including the following specific steps:

[0047] S1: Select aluminum powder with a spherical diameter of 1-2 μm and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com