Deforming magnesium alloy and preparation method thereof

A technology for deforming magnesium alloys and magnesium melts, applied in the field of metal materials, can solve problems such as insufficient heat resistance, mechanical properties need to be improved, and strength drops more, so as to promote the formation of precipitates and hinder basal plane dislocations. Slip, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing a deformed magnesium alloy, which includes the following steps: A) melting and alloying magnesium ingots, zinc ingots, gadolinium sources, neodymium sources, yttrium sources and zirconium sources, and obtaining a magnesium melt after refining, The magnesium melt includes 0.1wt%~10wt% of neodymium, 10wt%~12wt% of gadolinium, 3wt%~5wt% of yttrium, 0.5wt%~2wt% of zinc, 0.3wt%~0.8wt% of zirconium, The remaining magnesium and unavoidable impurities, the content of which is less than 0.02%; B) casting the magnesium melt and extruding it to obtain a deformed magnesium alloy.

[0028] In order to clearly illustrate the present invention, the experimental processes of step A and step B are described in detail below respectively.

[0029] According to the step A of the present invention, it is as follows: under a protective atmosphere, add magnesium ingots, zinc ingots and covering agent to the melting furnace, raise the ...

Embodiment 1

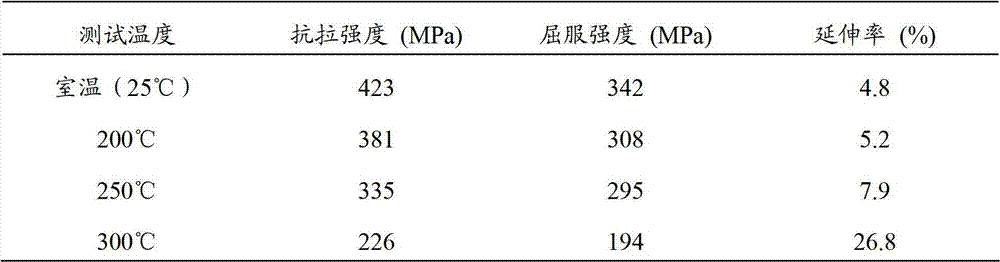

[0049] 1.1 Divide pure Mg ingots, pure Zn ingots, 20%Mg-Gd master alloys, 20%Mg-Y master alloys, 20%Mg-Nd master alloys and 30%Mg-Zr master alloys, remove scale and oil And drying, according to the element content Gd 10wt%, Y 4wt%, Zn 1wt%, Nd 0.5wt%, Zr 0.4wt%, the balance is the proportioning of Mg. Preparation of covering agent: 40wt% MgCl 2 , 20wt% KCl, 20wt% CaF and 20wt% BaCl 2 Mix to obtain covering agent; prepare refining agent: the KCl of 54wt%, the BaCl of 18wt% 2 , 24wt% Cacl 2 with 4wt% MgCO 3 Mix to get a refining agent.

[0050] 1.2 Under the protection of 99% carbon dioxide and 1% sulfur hexafluoride mixed gas, add the covering agent prepared in 1.1 with 2wt% alloy raw materials, the pure Mg ingot and pure Zn ingot weighed in 1.1 into the melting furnace, Raise the temperature to 750°C, add the Mg-Gd master alloy and Mg-Nd master alloy weighed in 1.1, stir for 2 minutes, raise the temperature to 780°C, add the Mg-Y master alloy and Mg-Zr master alloy, stir ...

Embodiment 2

[0055] 2.1 Divide pure Mg ingots, pure Zn ingots, 20%Mg-Gd master alloys, 20%Mg-Y master alloys, 20%Mg-Nd master alloys and 30%Mg-Zr master alloys, remove scale and oil And drying, according to the element content Gd 11wt%, Y 5wt%, Zn 1.5wt%, Nd 1wt%, Zr 0.8wt%, the balance is the ratio of Mg. Preparation of covering agent: 40wt% MgCl 2 , 20wt% KCl, 20wt% CaF and 20wt% BaCl 2 Mix to obtain covering agent; prepare refining agent: the KCl of 54wt%, the BaCl of 18wt% 2 , 24wt% Cacl 2 with 4wt% MgCO 3 Mix to get a refining agent.

[0056] 2.2 Under the protection of a mixed gas of 99% carbon dioxide and 1% sulfur hexafluoride, add the covering agent prepared in 2.1 with 2wt% alloy raw materials, the pure Mg ingot and pure Zn ingot weighed in 2.1 into the melting furnace, Raise the temperature to 730°C, add the Mg-Gd master alloy and Mg-Nd master alloy weighed in 2.1, stir for 2 minutes, raise the temperature to 780°C, add the Mg-Y master alloy and Mg-Zr master alloy, stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com