Shear coupling grain boundary migration and crack interaction simulation method in binary alloy

A binary alloy, grain boundary migration technology, applied in special data processing applications, instruments, calculations, etc., can solve the problem of inability to accurately predict the healing or expansion of alloy micro-cracks, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to fully understand the purpose, features and effects of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

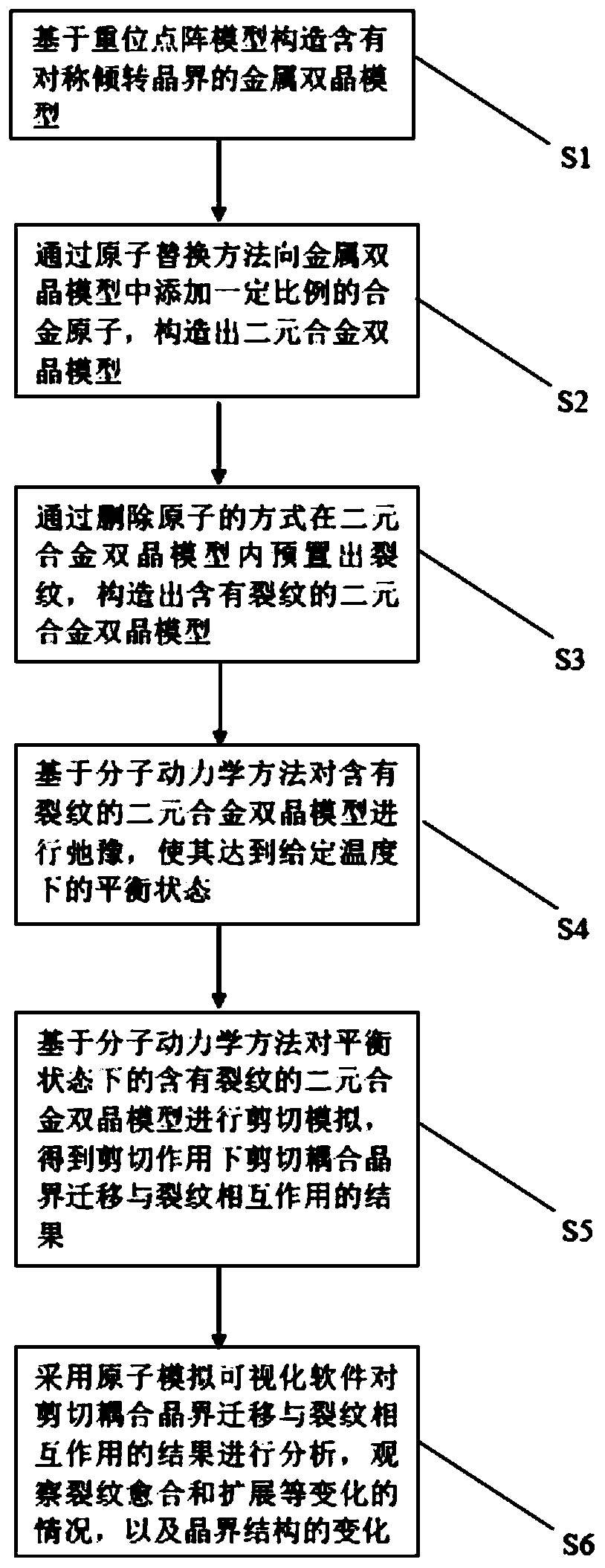

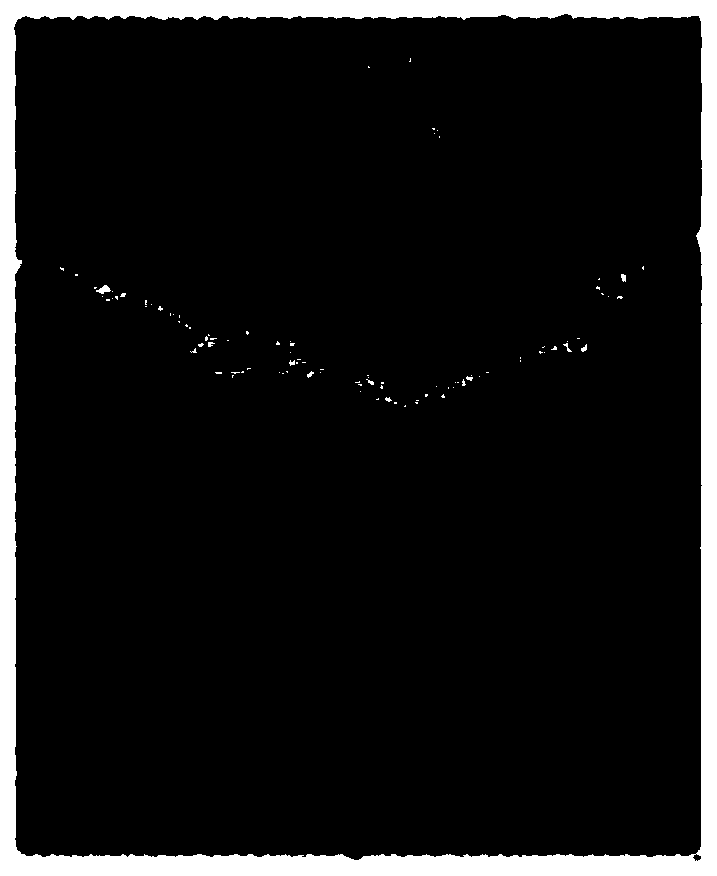

[0045] Such as figure 1 As shown, the present invention discloses a method for simulating the interaction between shear-coupled grain boundary migration and cracks in binary alloys. The method is based on the principle of molecular dynamics to establish an accurate interaction between shear-coupled grain boundary migration and cracks in binary alloys. The model can accurately predict the situation of crack healing or expansion during the interaction between the two, as well as the change of the grain boundary structure of the alloy.

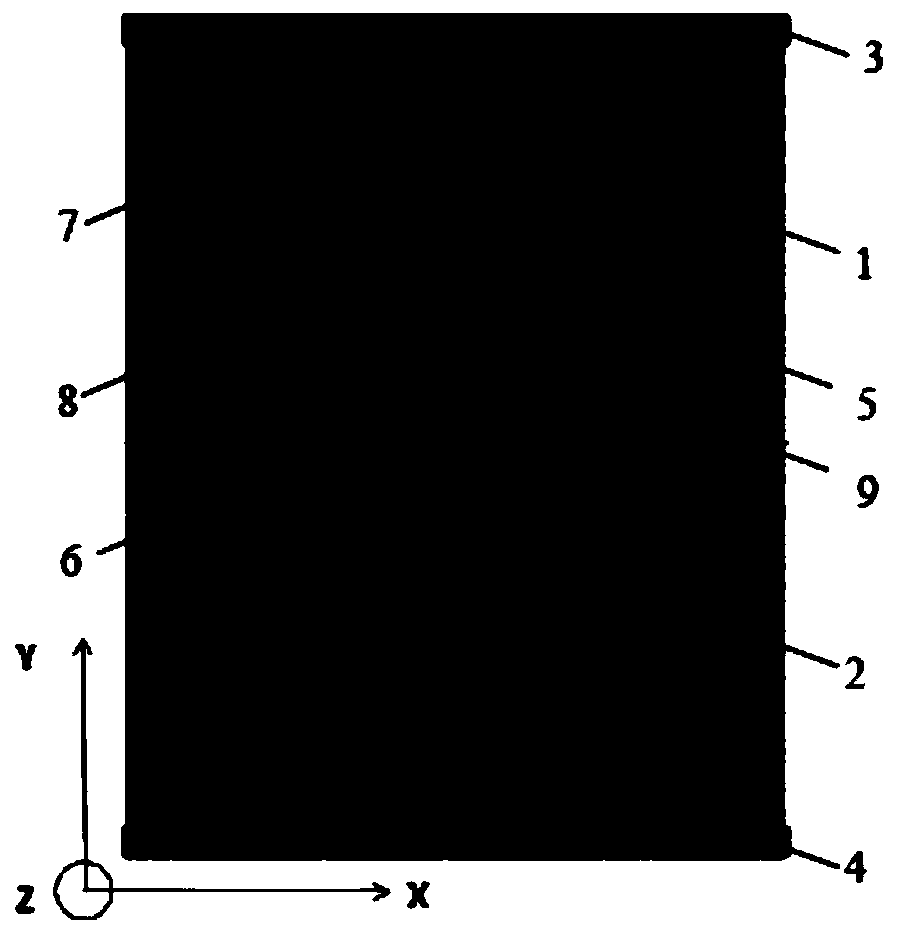

[0046] In the specific embodiment, the Σ9(221) grain boundary and crack interaction model in the iron-chromium alloy with a chromium content of 1% is taken as an example, specifically comprising the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com