Aluminum alloy applied to electric vehicle charging and preparation method thereof

An aluminum alloy and electric vehicle technology, applied in the field of aluminum alloy preparation, can solve the problems of poor plasticity and heat resistance, unable to obtain fine and uniform crystalline aluminum alloy, etc., achieve excellent mechanical properties, increase fluidity, and ensure plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

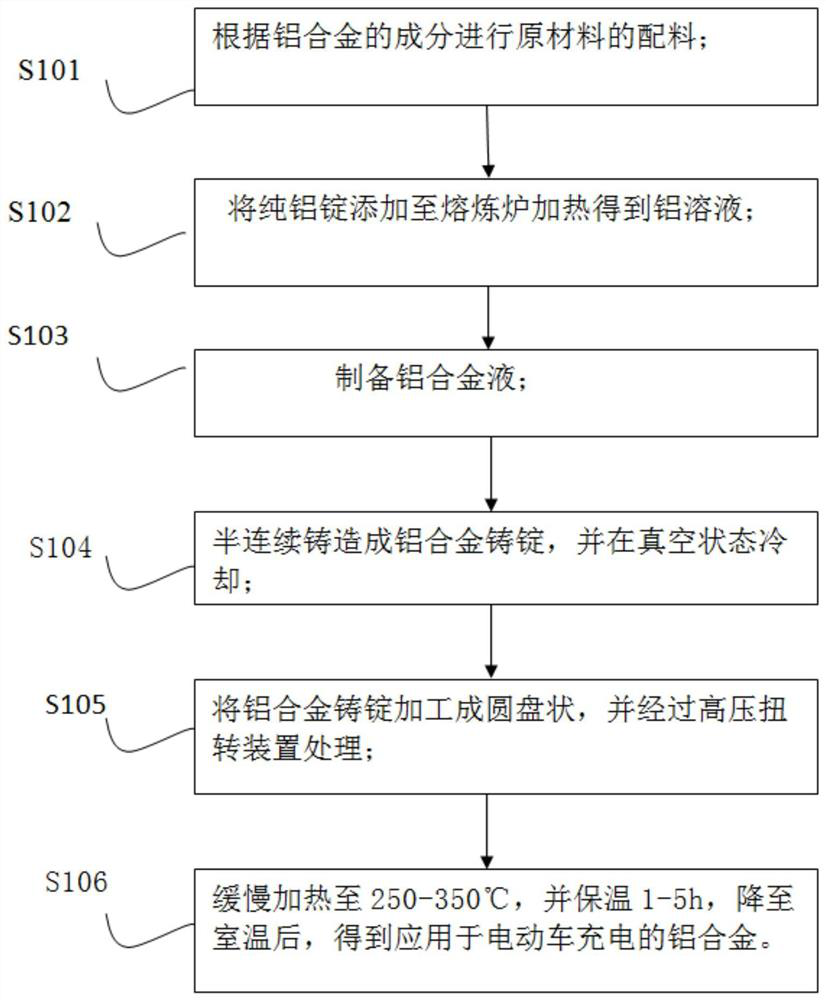

[0042] In addition, the present invention also provides a method for preparing an aluminum alloy used in electric vehicle charging, comprising the following steps:

[0043] S1. According to the composition of aluminum alloy, the ingredients of raw materials are carried out;

[0044] S2. Adding pure aluminum ingots into a melting furnace and heating to 700-750° C. to obtain an aluminum solution;

[0045] S3. Lower the temperature to 650-690° C., and add the remaining raw materials to the aluminum solution in turn under the condition of stirring. After completely dissolving, remove the slag and keep it warm for 30-60 minutes to obtain the aluminum alloy solution;

[0046] S4. Semi-continuously casting the molten aluminum alloy into an aluminum alloy ingot at a casting temperature of 730-750° C., cooling slowly, and maintaining a vacuum state during the cooling process, with a vacuum degree lower than 5 torr;

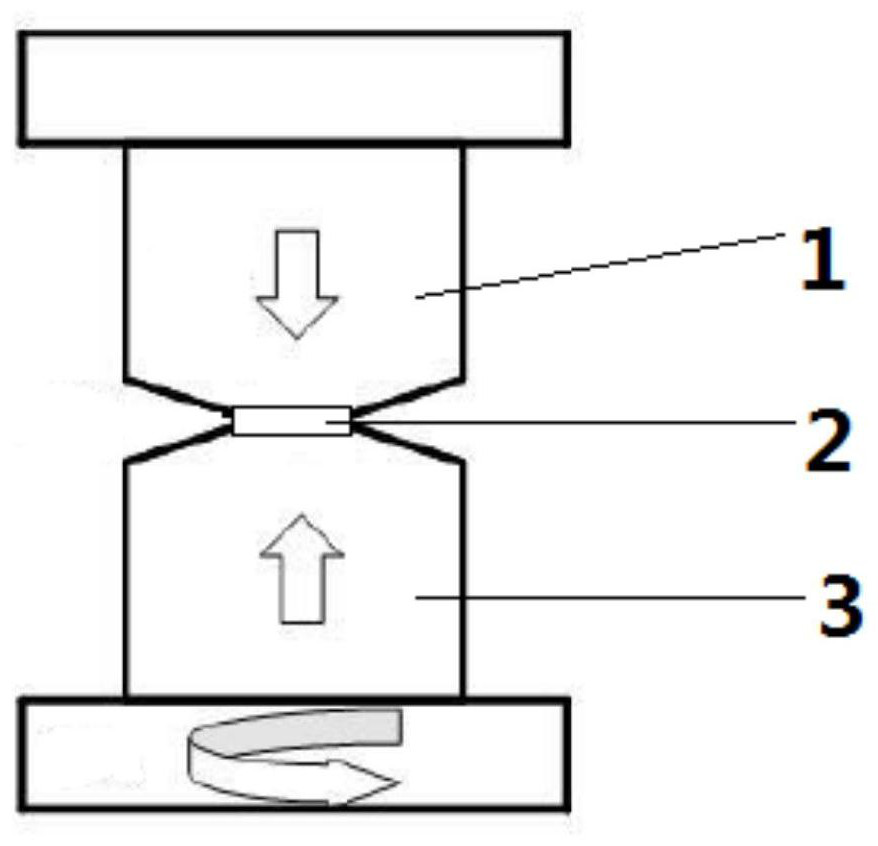

[0047] S5, processing the cooled aluminum alloy ingot into a disc sh...

Embodiment 1

[0052] This embodiment is used to illustrate the preparation method of the aluminum alloy used for electric vehicle charging of the present invention,

[0053] The aluminum alloy includes the following components by weight percent: Zn: 1.12%, Mn: 1.0%, Mg: 9.0%, Cr: 0.1%, Ni: 0.3%, Ti: 0.12%, and trace elements: 0.4%, impurity elements≤0.5%, the balance is Al, and the trace elements are B, Re, Zr, and the mass percentage ratio of B, Re, Zr is 8:1:3;

[0054] The method comprises the steps of:

[0055] S1. Raw materials are mixed according to the composition of the aluminum alloy; specifically: the raw materials are: Zn ingots, AlMn alloys, Mg ingots with a purity of 99.9%, Al ingots, AlCr, AlNi, Ti ingots, and trace element aluminum-based master alloys ;

[0056] S2, adding pure aluminum ingots into the melting furnace and heating to 750°C to obtain aluminum solution;

[0057] S3. Lower the temperature to 690°C, and add the remaining raw materials to the aluminum solution s...

Embodiment 2

[0062] This embodiment is used to illustrate the preparation method of the aluminum alloy used for electric vehicle charging of the present invention,

[0063] The aluminum alloy includes the following components by weight percentage: Zn: 0.55%, Mn: 0.8%, Mg: 8.0%, Cr: 0.4%, Ni: 0.3%, Ti: 0.12%, and trace elements: 0.4%, impurity elements≤0.5%, the balance is Al, and the trace elements are B, Re, Zr, and the mass percentage ratio of B, Re, Zr is 1:1:3;

[0064] The method comprises the steps of:

[0065] S1. Raw materials are mixed according to the composition of the aluminum alloy; specifically: the raw materials are: Zn ingots, AlMn alloys, Mg ingots with a purity of 99.9%, Al ingots, AlCr, AlNi, Ti ingots, and trace element aluminum-based master alloys ;

[0066] S2, adding pure aluminum ingots into the melting furnace and heating to 700°C to obtain aluminum solution;

[0067] S3. Lower the temperature to 650°C, and add the remaining raw materials to the aluminum solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com