A method for rapid sintering of fully stabilized zirconia powder at low temperature and atmospheric pressure

A fully stable zirconia, rapid sintering technology, applied in the field of fine chemicals, can solve the problems of FSZ material production cost increase, long sintering cycle, etc., to ensure performance, solve densification and grain coarsening, and inhibit the growth of grains big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

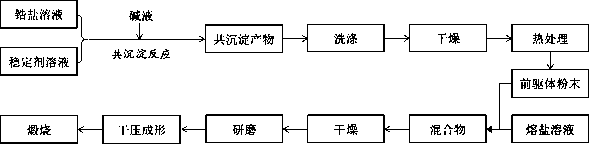

Embodiment 1

[0034] Such as figure 1 As shown, first set Y 2 o 3 Dissolve with concentrated nitric acid to form 0.2mol l -1 Stable and transparent Y(NO 3 ) 3 solution. At the same time, zirconium sulfate was dissolved in distilled water to form 0.2mol·l -1 Stable clear solution. The above two solutions are then combined according to (Y 3+ :Zr 4+ ) molar ratio of 3:97 for mixing, and adjust the pH value to 7 with ammonia water. Add a slightly excess saturated urea solution and heat to 75°C, causing the solution to completely precipitate and form a uniform and stable co-precipitation product; then, the coprecipitation product is washed, dried at 90°C and heat-treated at 600°C 2h, the precursor was obtained after natural cooling. Then the precursor was mixed with 0.6 mol·l -1 CaCl 2 -MgCl 2 Composite molten salt (CaCl 2 / MgCl 2 Molar ratio is 0.474:0.526) solution by (Ca 2+ +Mg 2+ ):Zr 4+ The example with a molar ratio of 5:95 was mixed evenly, dried and then ground and pass...

Embodiment 2

[0036] Such as figure 1 As shown, first set Y 2 o 3 Dissolve with concentrated nitric acid to form 0.2mol l -1 Stable and transparent Y(NO 3 ) 3 solution. Simultaneously ZrOCl 2 ·8H 2 O is dissolved in distilled water to form 0.2mol l -1Stable clear solution. Then the two solutions were mixed according to (Y 3+ :Zr 4+ ) molar ratio of 8:92 for mixing, and adding 4mol l -1 KOH solution, adjust the pH value to 10 to form a uniform and stable co-precipitation product; then, the co-precipitation product was washed, dried at 90°C and heat-treated at 800°C for 1h, and the precursor was obtained after natural cooling. Then the precursor was mixed with 0.6 mol·l -1 CaCl 2 -CaO composite molten salt (CaCl 2 / CaO molar ratio is 0.938:0.062) solution according to Ca 2+ :Zr 4+ The example with a molar ratio of 3:97 was mixed evenly, dried and then ground and passed through a 120-mesh sieve. It was pressed into a green body under a pressure system of 200Mpa and a holding t...

Embodiment 3

[0038] Such as figure 1 As shown, first set YC1 3 ·7H 2 O is dissolved in distilled water to form 0.2mol l -1 Stable and transparent YCl 3 solution. At the same time, zirconium sulfate was dissolved in distilled water to form 0.2mol·l -1 Stable clear solution. The above two solutions are then combined according to (Y 3+ :Zr 4+ ) in a molar ratio of 10:90, and adjust the pH value to 7 with ammonia water. Add a slightly excess saturated urea solution and heat to 75°C, causing the solution to completely precipitate and form a uniform and stable co-precipitation product; then, the coprecipitation product is washed, dried at 90°C and heat-treated at 700°C After 1.5h, the precursor was obtained after natural cooling. Then the precursor was mixed with 0.6 mol·l -1 BaCl 2 -CaCl 2 Composite molten salt (BaCl 2 / CaCl 2 Molar ratio is 0.359:0.641) solution according to (Ba 2+ +Ca 2+ ):Zr 4+ The example with a molar ratio of 3:97 was mixed evenly, dried and then ground an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com