Device for sintering transparent ceramics by induction heating

A technology of transparent ceramics and induction heating, applied in lighting and heating equipment, muffle furnaces, furnaces, etc., can solve the problems of brittleness, high power consumption, and high sintering costs in vacuum tungsten wire sintering furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

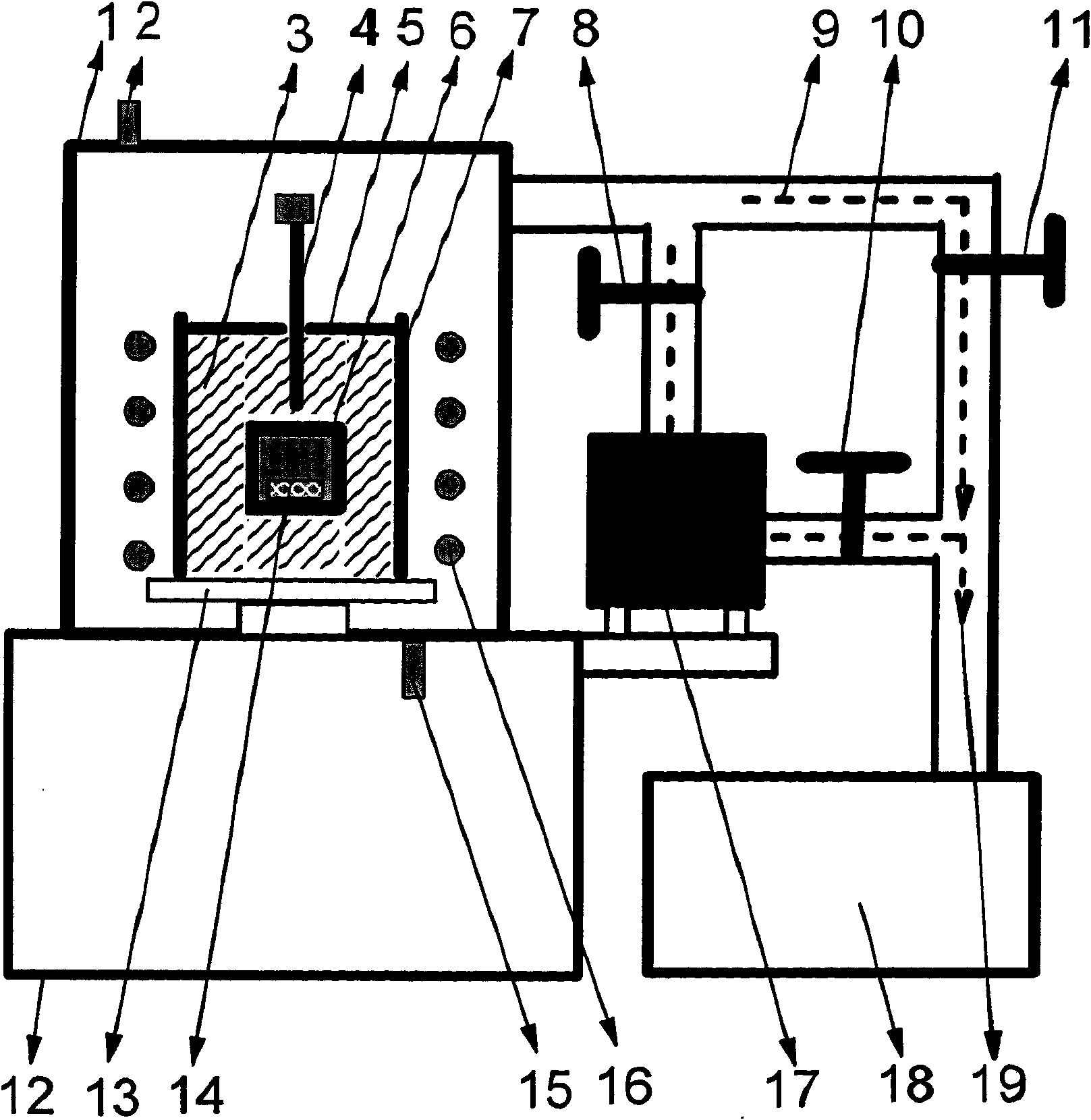

[0023] Place the Nd:YAG ceramic body to be sintered in a covered tungsten crucible 6 (as a heating element for induction heating) and then embed it in zirconia heat insulating sand 3. The tungsten crucible 6 should be at the center of the induction coil to ensure For the uniformity of temperature field, cover the quartz glass cover 5 above the zirconia sand 3, and place the end of the thermocouple 4 for temperature measurement close to the outer wall of the tungsten crucible (6).

[0024] Close the furnace door and turn on the circulating cooling water.

[0025] Turn on the mechanical pump 18, open the third baffle valve 11 to evacuate the furnace chamber through the bypass gas path 9.

[0026] When the air pressure in the furnace is ≤10Pa, open the second baffle valve 10, turn on the power switch of the molecular pump, and start the molecular pump 17. When the molecular pump reaches the rated operating frequency, the third damper valve 11 is closed, the first damper valve 8 ...

Embodiment 2

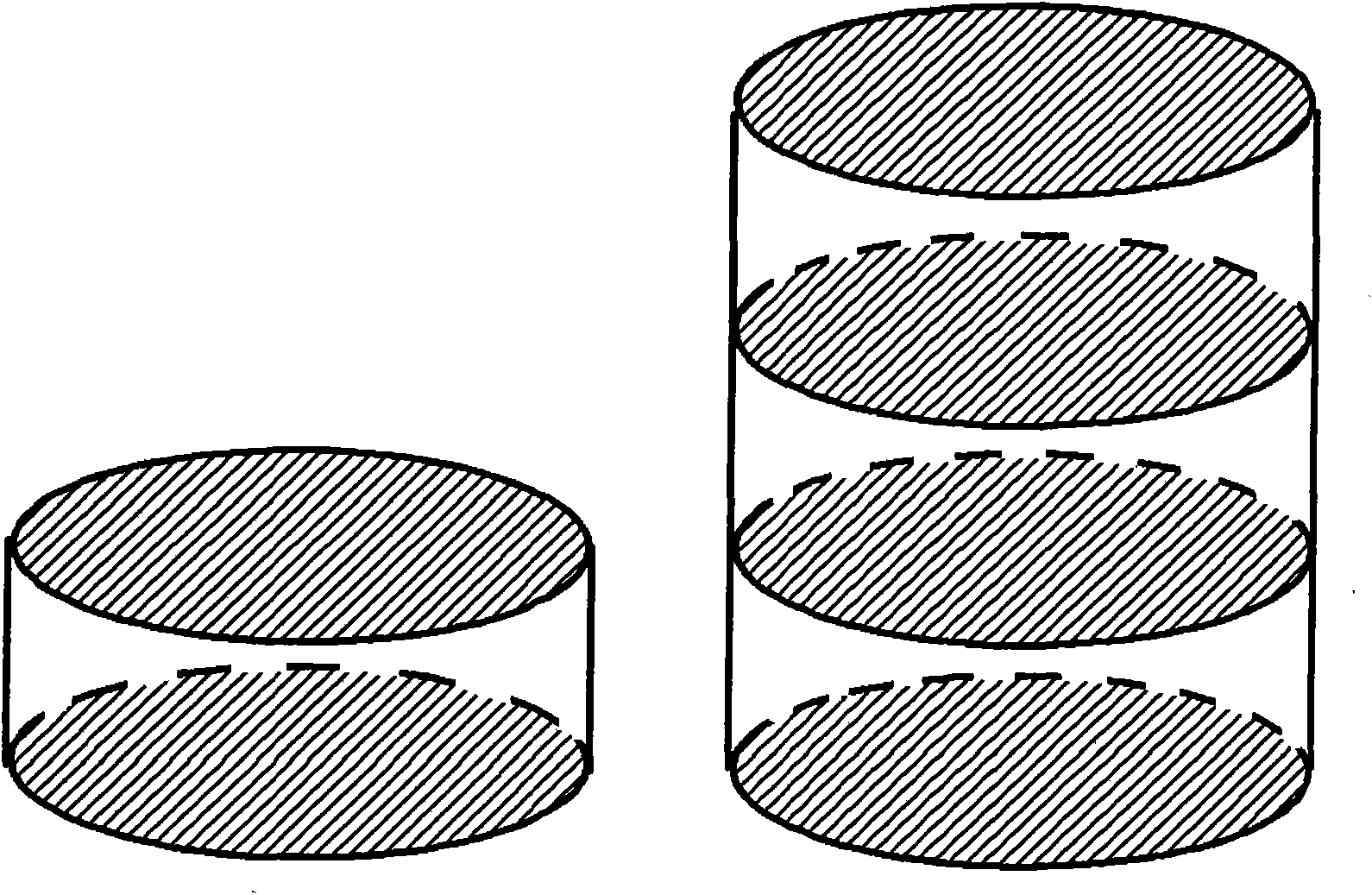

[0033] The multi-block Yb:YAG ceramic body to be sintered is placed in an iridium crucible or a plurality of stacked iridium buckets 6 as a heating element for induction heating, such as figure 2 As shown, it is embedded in the zirconia insulating sand 3; the iridium crucible or the iridium barrel 6 should be placed in the center of the induction coil to ensure the uniformity of the temperature field; the quartz glass cover 5 is covered above the zirconia sand 3; the thermocouple 4. One end of the temperature measurement is close to the outer wall of the iridium barrel 6 .

[0034] Close the furnace door and turn on the circulating cooling water.

[0035] Turn on the mechanical pump 18, open the third baffle valve 11 to evacuate the furnace chamber through the bypass gas path 9.

[0036] When the air pressure in the furnace is ≤10Pa, open the second baffle valve 10, turn on the power switch of the molecular pump, and start the molecular pump 17. When the molecular pump reac...

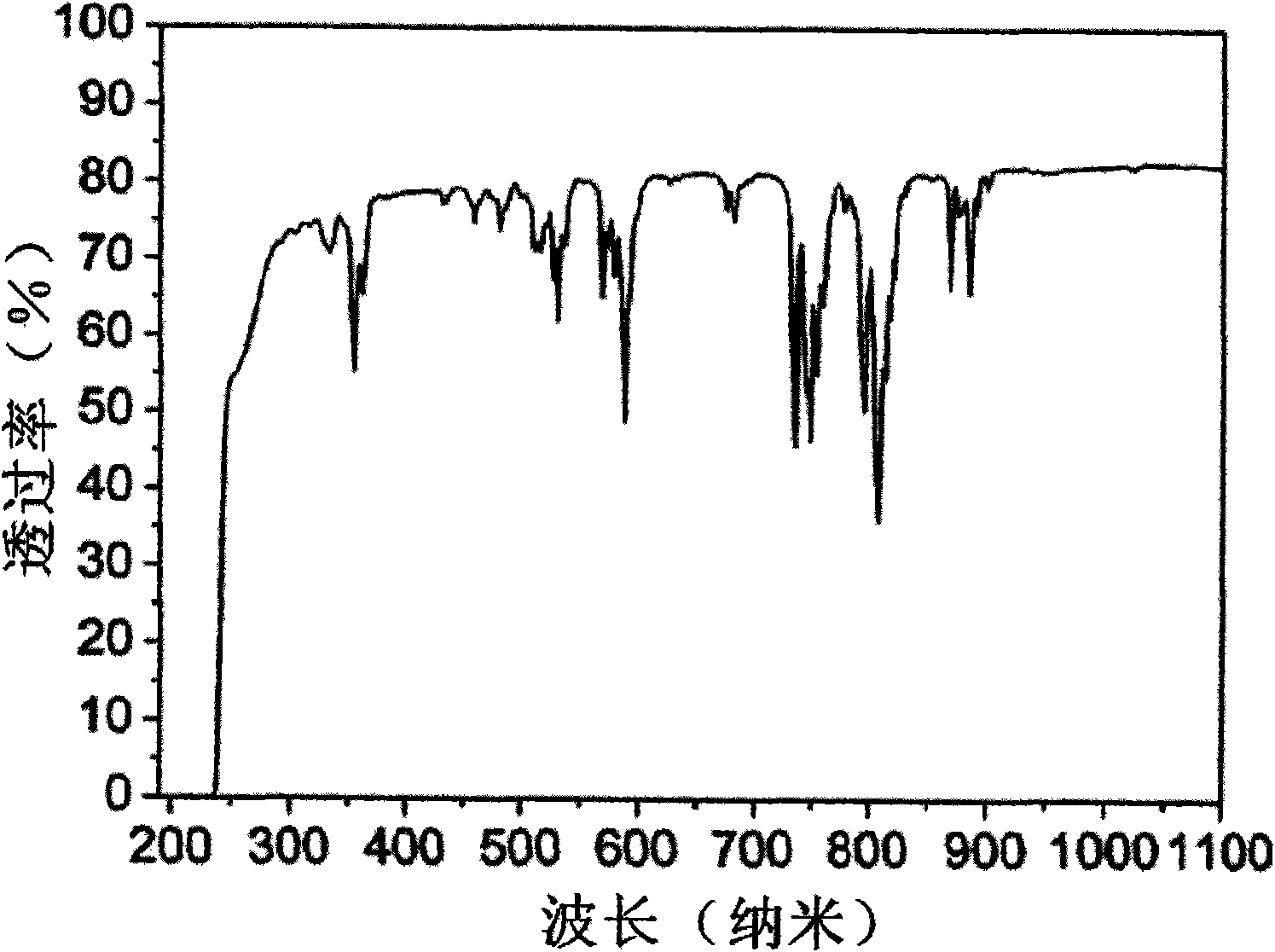

Embodiment 3

[0041] The Yb:Y to be sintered 2 o 3The ceramic body is placed in the graphite crucible 6 (as a heating element for induction heating) and then embedded in the porous graphite 3 (as a thermal insulation material); the graphite crucible 6 should be placed at the center of the induction coil to ensure the uniformity of the temperature field; The top of the graphite 3 is covered with a quartz glass cover 5; the temperature measuring end of the thermocouple 4 is placed close to the outer wall of the graphite crucible 6 .

[0042] Close the furnace door and turn on the circulating cooling water.

[0043] Turn on the mechanical pump 18, open the third baffle valve 11 to evacuate the furnace chamber through the bypass gas path 9.

[0044] When the air pressure in the furnace is ≤10Pa, open the second baffle valve 10, turn on the power switch of the molecular pump, and start the molecular pump 17. When the molecular pump reaches the rated operating frequency, the third damper valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com