A kind of high-temperature embrittlement-resistant free-cutting aluminum alloy and preparation method thereof

An aluminum alloy and high temperature resistance technology, which is applied in the field of high temperature embrittlement free-cutting aluminum alloy and its preparation, can solve the problems of human health and ecological environment hazards, insufficient heat resistance, high temperature brittleness, etc., to achieve increased strength, The effect of increasing the recrystallization temperature and improving the high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

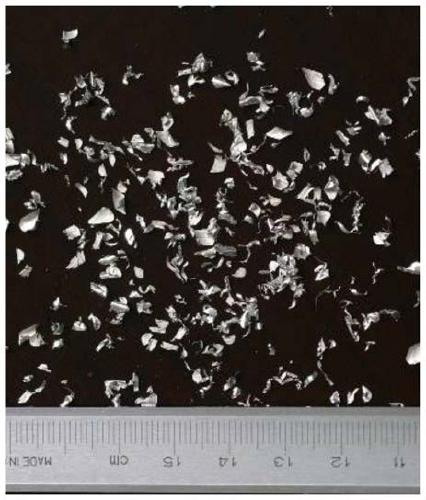

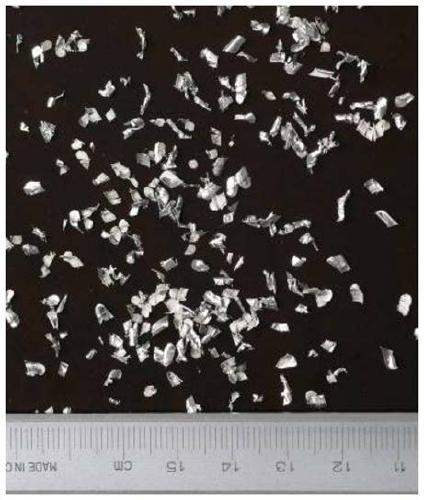

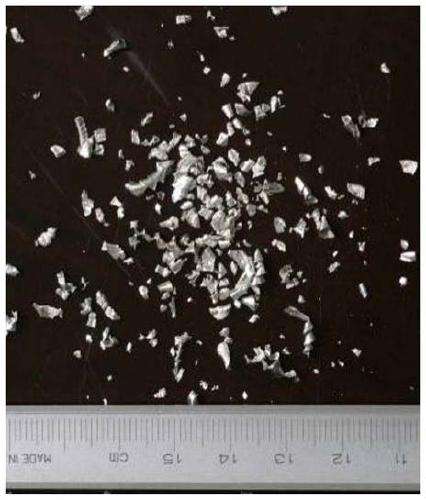

Image

Examples

preparation example Construction

[0050] The preparation method of the high-temperature embrittlement-resistant free-cutting aluminum alloy provided by the present invention is characterized in that it comprises the following steps:

[0051] Step 1: Select aluminum ingots, magnesium ingots, bismuth ingots, tin ingots, aluminum-silicon alloys, aluminum-manganese alloys, aluminum-copper alloys, aluminum-iron alloys, aluminum-chromium alloys, and aluminum-strontium alloy rods according to the composition and mass percentage of aluminum alloys and Al-Ti-B alloy rods as raw materials for batching;

[0052] Step 2: Heat and melt the aluminum ingot at 720-730°C, then add magnesium ingot, bismuth ingot, tin ingot, aluminum-silicon alloy, aluminum-manganese alloy, aluminum-copper alloy, aluminum-iron alloy and aluminum-chromium alloy, stir and melt to form aluminum alloy liquid;

[0053] The third step: use high-purity inert gas and sodium-free refining agent to carry out degassing and impurity removal treatment on al...

Embodiment 1

[0074] The aluminum alloy is composed of the following mass percentage components: Mg 1.1%, Si 0.8%, Mn 0.4%, Cu0.18%, Fe 0.16%, Cr 0.12%, Sr 0.045%, Ti 0.035%, B 0.007%, Sn 0.5% , Bi 0.4%, the balance is Al and unavoidable impurity elements, the individual content of impurity elements is ≤0.05%, and the total amount of impurity elements is ≤0.15%. The preparation method of aluminum alloy comprises the following steps:

[0075] The first step: according to the composition and mass percentage of aluminum alloy, select aluminum ingot with 99.7% aluminum content, magnesium ingot with 99.8% magnesium content, bismuth ingot with 99.9% bismuth content, tin ingot with 99.9% tin content, AlSi20 alloy, AlMn10 alloy, AlCu50 alloy, AlFe20 alloy, AlCr5 alloy, AlSr5 alloy rod and AlTi5B1 alloy rod are used as raw materials for batching;

[0076] Step 2: Heat and melt the aluminum ingot at 725°C, then add magnesium ingot, bismuth ingot, tin ingot, AlSi20 alloy, AlMn10 alloy, AlCu50 alloy, ...

Embodiment 2

[0085] The aluminum alloy is composed of the following mass percentages: Mg 1.2%, Si 0.6%, Mn 0.5%, Cu0.15%, Fe 0.2%, Cr 0.1%, Sr 0.05%, Ti 0.03%, B 0.006%, Sn 0.6% , Bi 0.3%, the balance is Al and unavoidable impurity elements, the individual content of impurity elements is ≤0.05%, and the total amount of impurity elements is ≤0.15%. The preparation method of aluminum alloy comprises the following steps:

[0086] The first step: according to the composition and mass percentage of aluminum alloy, select aluminum ingot with 99.7% aluminum content, magnesium ingot with 99.8% magnesium content, bismuth ingot with 99.9% bismuth content, tin ingot with 99.9% tin content, AlSi20 alloy, AlMn10 alloy, AlCu50 alloy, AlFe20 alloy, AlCr5 alloy, AlSr5 alloy rod and AlTi5B1 alloy rod are used as raw materials for batching;

[0087] Step 2: Heat and melt the aluminum ingot at 730°C, then add magnesium ingot, bismuth ingot, tin ingot, AlSi20 alloy, AlMn10 alloy, AlCu50 alloy, AlFe20 alloy a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com