Tool cathode and method for improving flatness of electrolytic milling bottom surface

A tool cathode and flatness technology, which is applied in the field of electrolytic grinding compound processing, can solve the problems of easy breakage of tool insulation materials, insulation failure, limited application scope, etc., to shorten the preparation cycle, enhance the dissolution rate and improve the flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

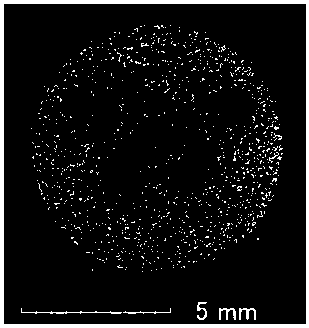

[0028] In this example, the Figure 8 For the cathode of the tool shown, no water holes are opened on the cathode end of the tool. Figure 5 The velocity vector diagram of the electrolyte in the bottom gap is given. It can be seen that the electrolyte flowing into the bottom gap from the side gap gradually forms a converging flow, and finally a high flow velocity area appears in the middle area of the processed bottom surface of the workpiece, while the flow velocity in the two sides areas is relatively lower. Apparently, compared with the areas on both sides of the processed bottom surface, the electrolyte update and the discharge of processed products in the middle area are faster due to the higher flow rate of the electrolyte. Therefore, under the action of stray current, the electrochemical anodic dissolution rate in the middle area of the processed bottom surface of the workpiece is higher than that on both sides, and finally a concave cross-sectional shape is formed...

Embodiment 2

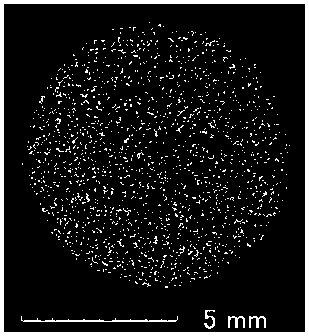

[0030] In this example, the Figure 7 The tool cathode shown, the tool cathode as Figure 4 As shown, five water outlet holes are opened on the end face. Figure 6 The velocity vector diagram of the electrolyte in the bottom gap is given. It can be seen that the electrolyte sprayed out of the water outlet hole on the cathode end face of the tool significantly changes the flow state of the electrolyte in the bottom gap, so that the electrolyte that originally flows to the middle area of the processed bottom surface of the workpiece converges. Instead, the liquid flows quickly to the two sides of the workpiece, resulting in a low flow rate area in the middle of the processed bottom surface of the workpiece. Since the electrolyte flow in the middle area of the processed bottom surface of the workpiece is inhibited, the electrolyte renewal and product discharge are slower than those in the two sides. Under the action of stray current, the electrochemical anodic dissolution r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com