High-strength and high-plasticity cast Mg-Ni-Y alloy and preparation method thereof

A mg-ni-y, high plasticity technology, applied in the field of magnesium alloy and its preparation, Mg-Ni-Y alloy and its preparation, can solve the problems of low elongation, decreased strength, low production efficiency, etc., to achieve alloy strength And elongation increase, reduce the process of homogenization treatment, reduce the effect of the generation of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

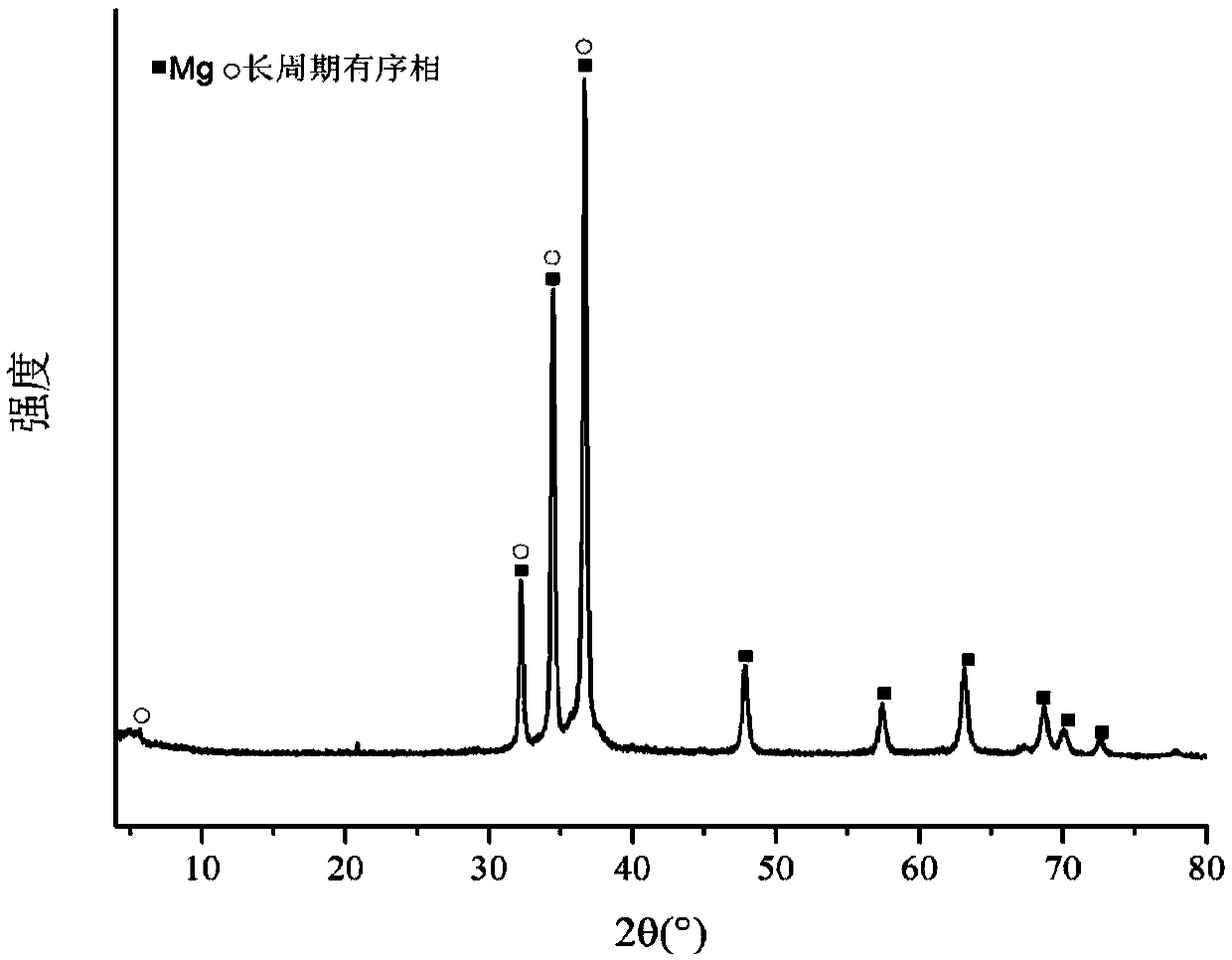

Embodiment 1

[0030] In this embodiment, a high-strength and high-plasticity casting Mg-Ni-Y alloy, the components of the alloy and their mass percentages are: 1.43wt.% Ni, 3.23wt.% Y, and the balance is Mg.

[0031] In this embodiment, a method for preparing a high-strength and high-plasticity cast Mg-Ni-Y alloy comprises the following steps:

[0032] a. Raw material preparation: the Ni of 1.43wt.% is respectively carried out by mass fraction, the Y of 3.23wt.% and the balance are the proportioning of magnesium to carry out raw material weighing batching;

[0033] b. Vacuumize the smelting furnace: adopt a vacuum suspension smelting furnace, place the Ni and Y raw materials prepared in the step a in the smelting furnace, and evacuate the smelting furnace for 10 to 25 minutes until the vacuum degree reaches 10 -4 Pa;

[0034] c. Smelting Ni-Y master alloy: After the vacuuming process of the smelting furnace in the step b is completed, fill the smelting furnace with argon until the pressure...

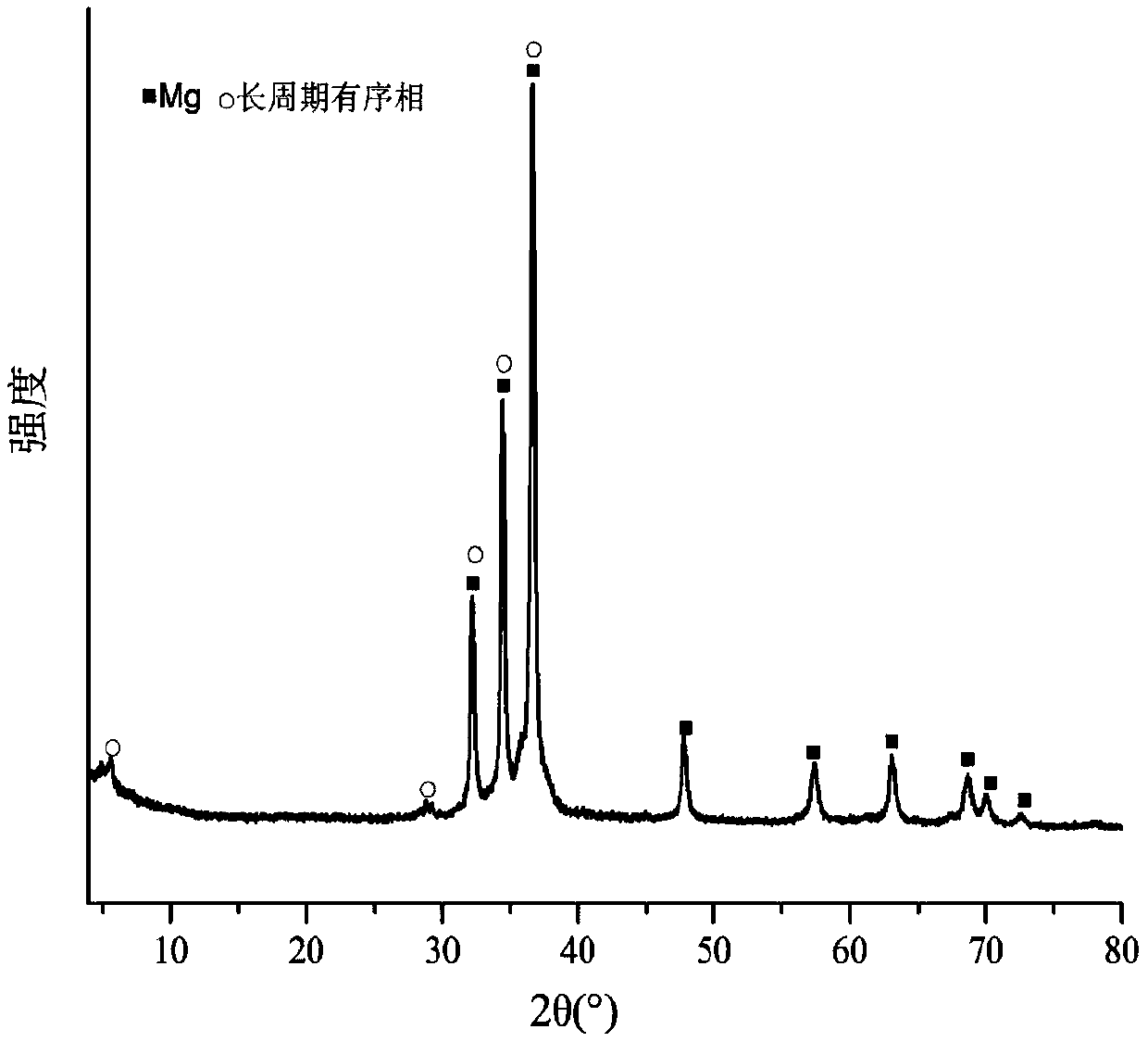

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, a high-strength and high-plasticity casting Mg-Ni-Y alloy, the alloy components and their mass percentages are: 2.33wt.% Ni, 5.27wt.% Y, and the balance is Mg.

[0042] In this embodiment, a method for preparing a high-strength and high-plasticity cast Mg-Ni-Y alloy comprises the following steps:

[0043] a. Raw material preparation: the Ni of 2.33wt.% is respectively carried out by mass fraction, the Y of 5.27wt.% and the balance are the proportioning of magnesium to carry out raw material weighing batching;

[0044] b. This step is the same as in Embodiment 1;

[0045] c. This step is the same as in Embodiment 1;

[0046] d. This step is the same as in Embodiment 1;

[0047] e. This step is the same as in Embodiment 1.

[0048] In the Mg-Ni-Y alloy ingot prepared in this example, Y and Ni form a long-period ordered phase and are dispersed in the Mg alloy matrix,...

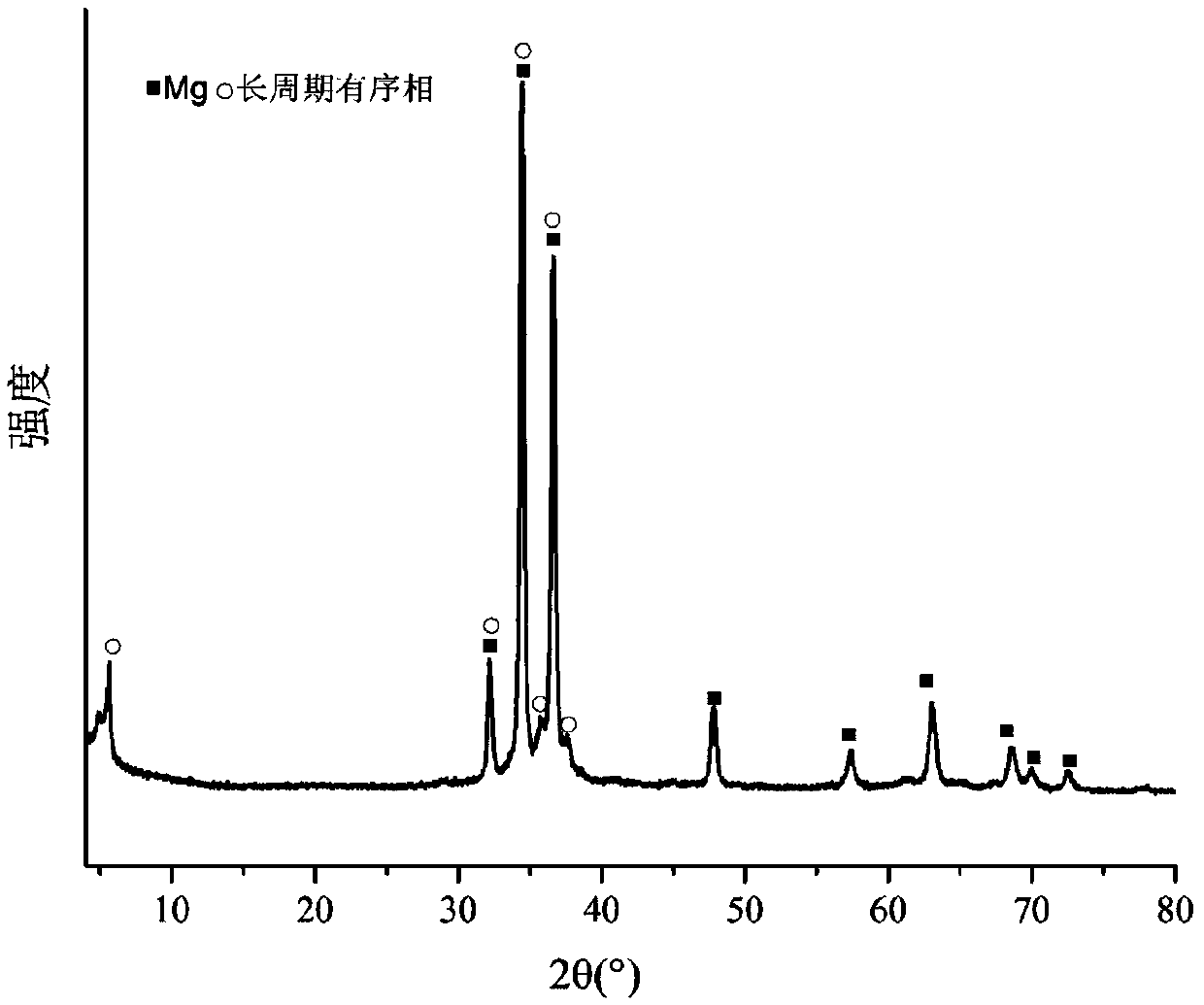

Embodiment 3

[0051] This embodiment is basically the same as the previous embodiment, and the special features are:

[0052] In this embodiment, a high-strength and high-plasticity casting Mg-Ni-Y alloy, the components of the alloy and their mass percentages are: 2.97wt.% Ni, 7.25wt.% Y, and the balance is Mg.

[0053] In this embodiment, a method for preparing a high-strength and high-plasticity cast Mg-Ni-Y alloy comprises the following steps:

[0054] a. Raw material preparation: the Ni of 2.97wt.% is respectively, the Y of 7.25wt.% and the balance are the proportioning of magnesium to carry out raw material weighing batching by mass fraction;

[0055] b. This step is the same as in Embodiment 1;

[0056] c. This step is the same as in Embodiment 1;

[0057] d. This step is the same as in Embodiment 1;

[0058] e. This step is the same as in Embodiment 1.

[0059] In the Mg-Ni-Y alloy ingot prepared in this example, Y and Ni form a long-period ordered phase and are dispersed in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com