Al-RE-Y alloy refiner and continuous casting and rolling preparation method thereof

A continuous casting and rolling, refining agent technology, applied in metal rolling and other directions, can solve the problems of environmental pollution, easy residual salt impurities, etc., and achieve the effects of simplified process, simple and easy control of smelting process, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

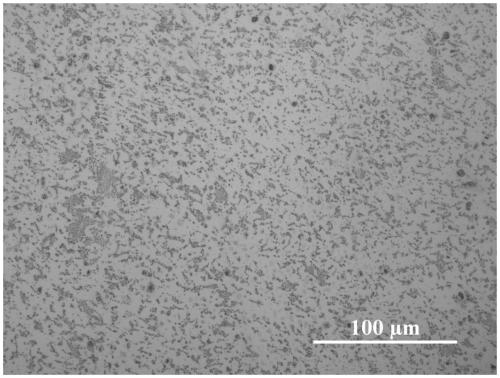

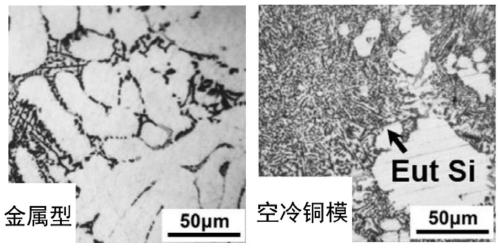

Image

Examples

Embodiment 1

[0044] The weight percent of an Al-RE-Y alloy refiner is: according to the theoretical ratio, 3.2wt% Ce, 0.8wt% Y, and the rest are Al elements and inevitable impurity elements.

[0045] Its preparation method is:

[0046] (1) After properly considering the burning loss, calculate the amount of required raw materials according to the above-mentioned Al-RE-Y alloy composition and stoichiometric ratio; remove the oxide layer and remove the industrial pure aluminum ingot, Al-20Ce and Al-10Y master alloy Dry and preheat to 180-220°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy;

[0047] (2) After melting the industrial pure aluminum ingots accounting for 20-25% of the melting furnace height into a molten pool at 720-750°C, add the remaining aluminum ingots;

[0048] (3) After the aluminum ingots are completely melted, raise the temperature to 740-750°C, add Al-20Ce and Al-10Y master alloys in 2 to 4 times, keep...

Embodiment 2

[0053] The weight percent of an Al-RE-Y alloy refiner is: according to the theoretical ratio, 8wt% La, 4wt% Y, and the rest are Al element and inevitable impurity element.

[0054] Its preparation method is:

[0055] (1) After properly considering the burning loss, calculate the amount of required raw materials according to the above-mentioned Al-RE-Y alloy composition and stoichiometric ratio; remove the oxide layer and remove the industrial pure aluminum ingot, Al-20La and Al-10Y master alloy Dry and preheat to 180-220°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy;

[0056] (2) After melting the industrial pure aluminum ingots accounting for 20-25% of the melting furnace height into a molten pool at 720-750°C, add the remaining aluminum ingots;

[0057] (3) After the aluminum ingots are completely melted, raise the temperature to 740-750°C, add Al-20La and Al-10Y master alloys in 2 to 4 times, and keep t...

Embodiment 3

[0062] The weight percent of an Al-RE-Y alloy refiner is: according to the theoretical ratio, 4wt% La, 4wt% Ce, 3wt% Y, and the rest are Al elements and inevitable impurity elements.

[0063] Its preparation method is:

[0064] (1) After properly considering the burning loss, calculate the amount of required raw materials according to the above-mentioned Al-RE-Y alloy composition and stoichiometric ratio; mix industrial pure aluminum ingots, Al-20La, Al-20Ce and Al-10Y master alloys Remove the oxide layer and dry and preheat to 180-220°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy;

[0065] (2) After melting the industrial pure aluminum ingots accounting for 20-25% of the melting furnace height into a molten pool at 720-750°C, add the remaining aluminum ingots;

[0066] (3) After the aluminum ingot is completely melted, raise the temperature to 740-750°C, add Al-20La, Al-20Ce and Al-10Y master alloys in 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com