A kind of preparation technology of heat-resistant mg-sr-zn-y alloy

A preparation process and alloy technology, which is applied in the field of preparation technology of heat-resistant Mg-Sr-Zn-Y alloys, can solve the problems of decreased creep resistance, poor heat resistance, and difficulty of meeting magnesium alloys, and achieve high heat resistance. high performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

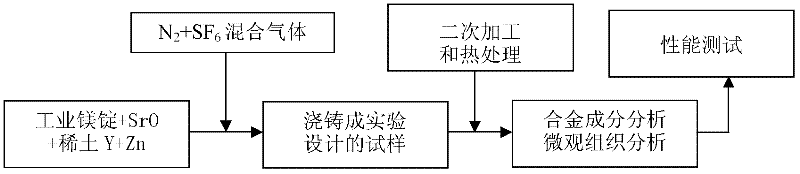

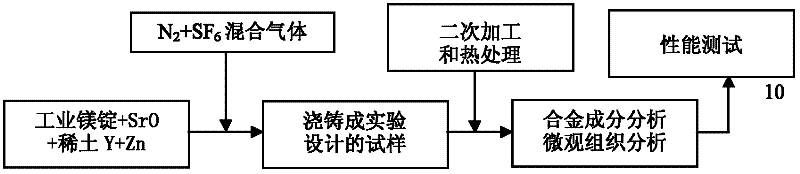

[0012] In conjunction with the accompanying drawings, the preparation process of the present invention is described in detail:

[0013] First, the purchased SrCO 3 The powder is prepared into SrO, and the process is to keep the temperature at 1250°C for 3h. The reaction mechanism is: SrCO 3(s) =SrO (s) +CO 2(g) , the final Sr content is 5% (mass ratio, the same below). In order to prevent the oxidative combustion of the melt, sulfur hexafluoride (SF 6 ) gas protection. Secondly, turn on the power of the pit furnace, put the crucible into the melting furnace to heat, put the preheated magnesium block and strontium oxide powder into the crucible to heat up and melt, and open the protective gas when the magnesium ingot starts to melt. Then, after the magnesium block is completely melted, stir it, remove the slag and let it stand to make the melt homogeneous, then raise the temperature to 810°C for refining for 30 minutes, cool down to 750°C, add 1% rare earth Y in sequence,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com