Nanometer quasi-eutectic enhanced Mg-Zn-Y alloy preparation method

An alloy and quasicrystal technology, applied in the field of magnesium alloy manufacturing, can solve problems such as less research, and achieve the effect of enhancing plastic workability and significant benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

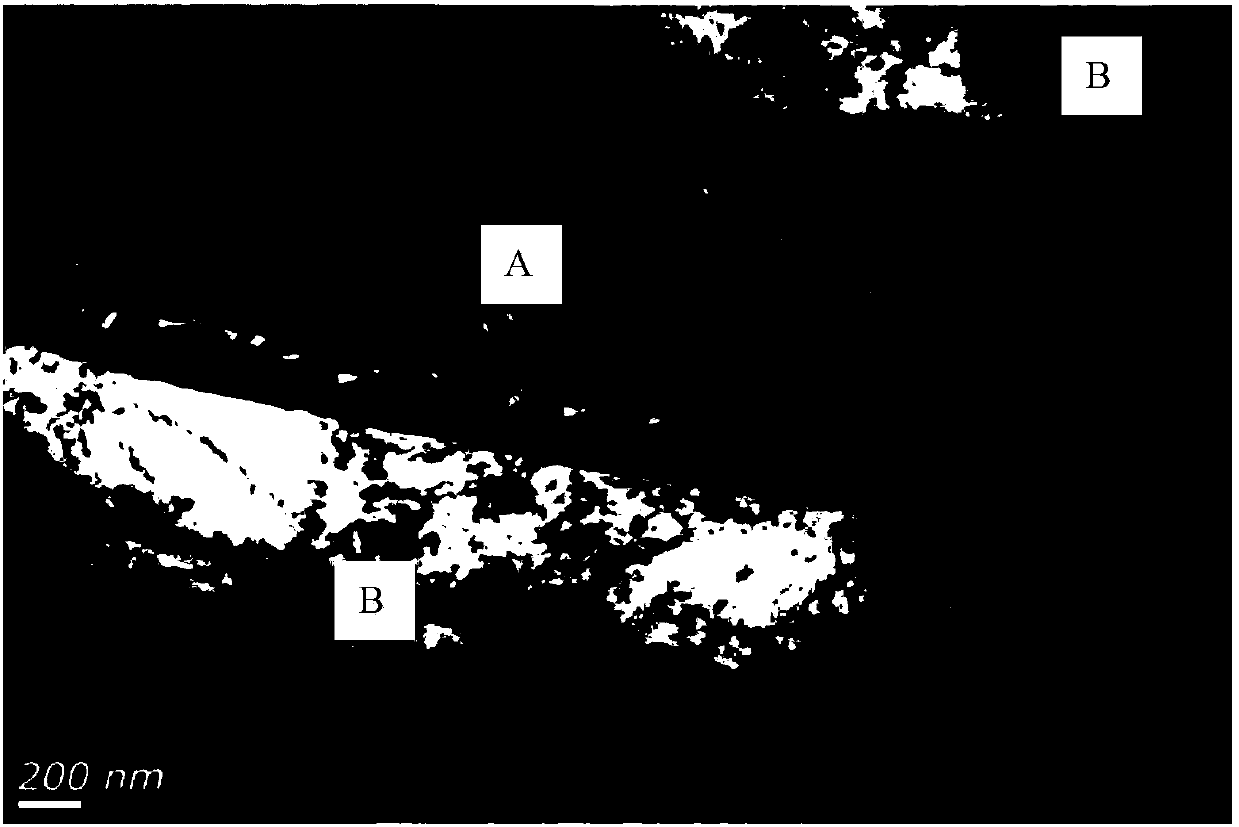

[0030] A preparation method of nano-eutectic crystal reinforced Mg-Zn-Y alloy, the steps are as follows:

[0031] A. Prepare the cast Mg-Zn-Y alloy according to the set atomic percentage ratio of each constituent element; the set atomic percentages of each constituent element are: 3% Zn, 0.5% Y , and the rest are Mg;

[0032] B, the as-cast Mg-Zn-Y alloy prepared in step A is annealed at 400 DEG C for 12h, and cooled with the furnace;

[0033] C. After the annealed Mg-Zn-Y alloy obtained in step B is kept at 320° C. for 4 hours, hot extrusion is carried out, the extrusion temperature is 320° C., and the extrusion ratio is 20:1;

[0034] D. Place the hot-extruded Mg-Zn-Y alloy obtained in step C in a heat treatment furnace, heat up to 560° C. with the furnace, keep it warm for 10 minutes, and then quench it with water at 60° C. Quasicrystalline reinforced Mg-Zn-Y alloys.

[0035] The specific operation of preparing the as-cast Mg-Zn-Y alloy in step A described in this exampl...

Embodiment 2

[0039] A preparation method of nano-eutectic crystal reinforced Mg-Zn-Y alloy, the steps are as follows:

[0040] A. Prepare the cast Mg-Zn-Y alloy according to the set atomic percentage ratio of each constituent element; the set atomic percentages of each constituent element are: 1.5% Zn, 0.25% Y , and the rest are Mg;

[0041] B. Anneal the as-cast Mg-Zn-Y alloy prepared in step A at 400° C. for 12 hours, and cool with the furnace.

[0042] C. After the annealed Mg-Zn-Y alloy obtained in step B is kept at 320°C for 4h, hot extrusion is carried out, the extrusion temperature is 320°C, and the extrusion ratio is 20:1;

[0043] D. Place the hot-extruded Mg-Zn-Y alloy obtained in step C in a heat treatment furnace, heat up to 580° C. with the furnace, keep it warm for 10 minutes, and then quench it with water at 60° C. to obtain nano-copolymer Quasicrystalline reinforced Mg-Zn-Y alloys.

[0044] The specific operation of preparing the as-cast Mg-Zn-Y alloy in step A described...

Embodiment 3

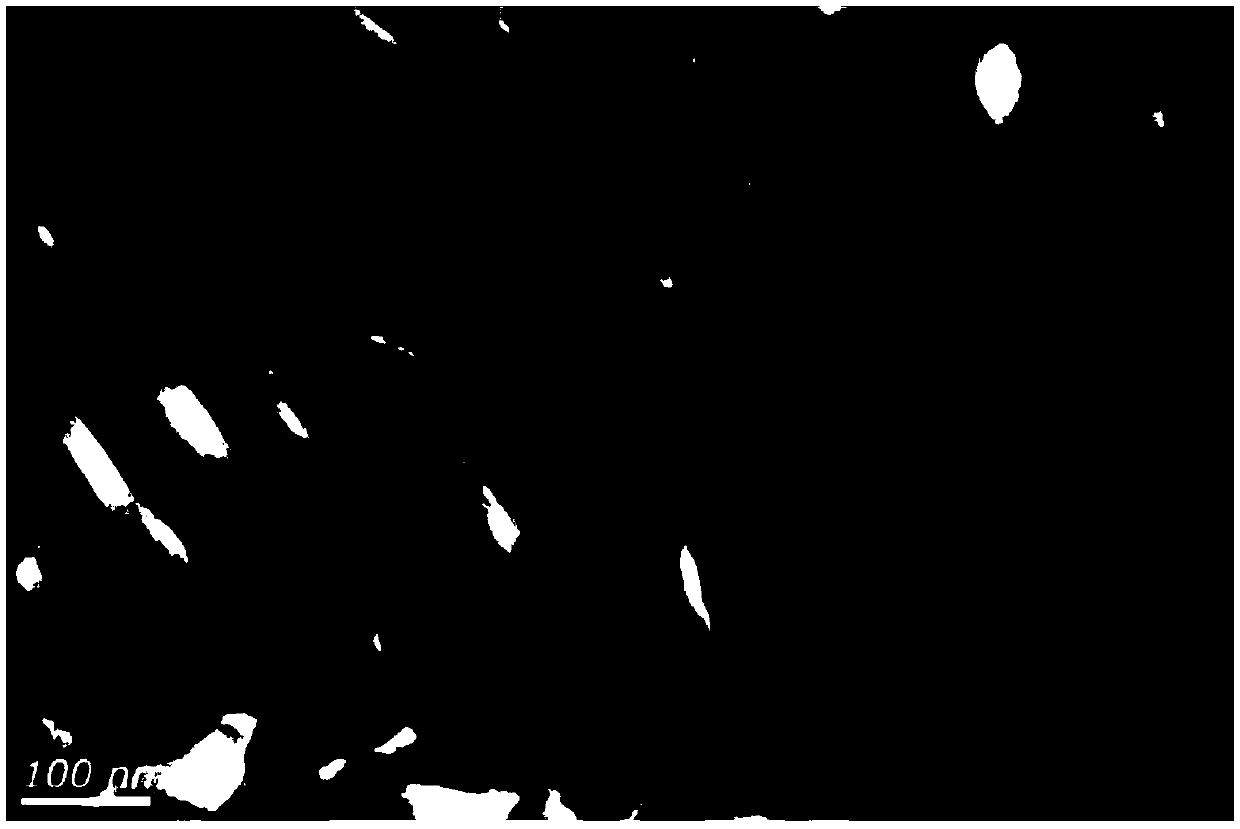

[0047] A preparation method of nano-eutectic crystal reinforced Mg-Zn-Y alloy, the steps are as follows:

[0048] A. Prepare the cast Mg-Zn-Y alloy according to the set atomic percentage ratio of each constituent element; the set atomic percentages of each constituent element are: 0.5% Zn, 0.08% Y , and the rest are Mg;

[0049] B, the as-cast Mg-Zn-Y alloy prepared by step A is annealed at 380 ℃ for 20h, and cooled with the furnace;

[0050] C. After the annealed Mg-Zn-Y alloy obtained in step B is kept at 300° C. for 4 hours, hot extrusion is carried out, the extrusion temperature is 300° C., and the extrusion ratio is 9:1;

[0051] D. Place the hot-extruded Mg-Zn-Y alloy obtained in step C in a heat treatment furnace, heat up to 550° C. with the furnace, keep it warm for 20 minutes, and then quench it with water at 30° C. to obtain nano-copolymer Quasicrystalline reinforced Mg-Zn-Y alloys.

[0052] The specific operation of preparing the as-cast Mg-Zn-Y alloy in step A d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com