Foam resin laminated sound insulating plate and producing method thereof

A technology of foamed resin and manufacturing method, applied in the field of laminated boards, capable of solving problems such as weak resin adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the invention will be specifically described below with reference to the drawings.

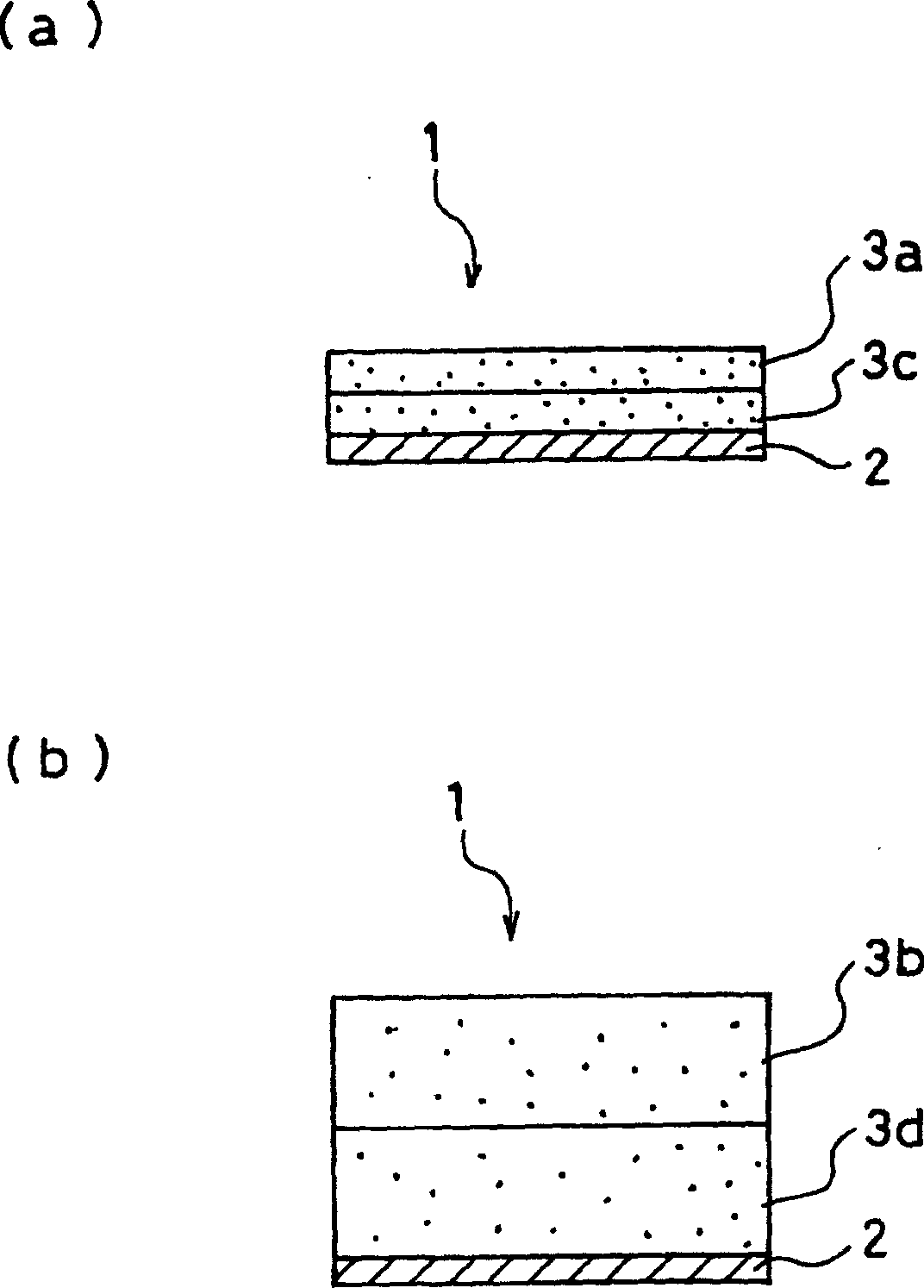

[0039] figure 1 A schematic diagram of a foamed resin laminated sound insulating panel 1 according to Example 1 of the present invention is shown. Such as figure 1 As shown in (a), this foamed resin laminated sound insulating board 1 is laminated sequentially with a foamable resin 3a that can be foamed when heated to the foaming temperature, a non-foamed resin 4 that does not foam even when heated, and a high-rigidity resin. The hard plate 2 (for example, steel plate, aluminum alloy plate, etc.) is integrated.

[0040] In the above-mentioned foamed resin laminated sound insulating panel 1, the foamable resin 3a and the non-foamed resin 4, and the non-foamed resin 4 and the hard board 2 are bonded by heat welding by heating and pressing. The temperature of this thermal fusion has been set lower than the foaming temperature of the foamable resin 3a, preferably lower than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com