Liquid sealed mount and method of assembling the same

An assembly method and liquid technology, applied in shock absorbers, mechanical equipment, springs, etc., can solve the problems of shell cracks, elastomer cracks, shell deformation, etc., to prevent leakage to the outside, achieve miniaturization, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

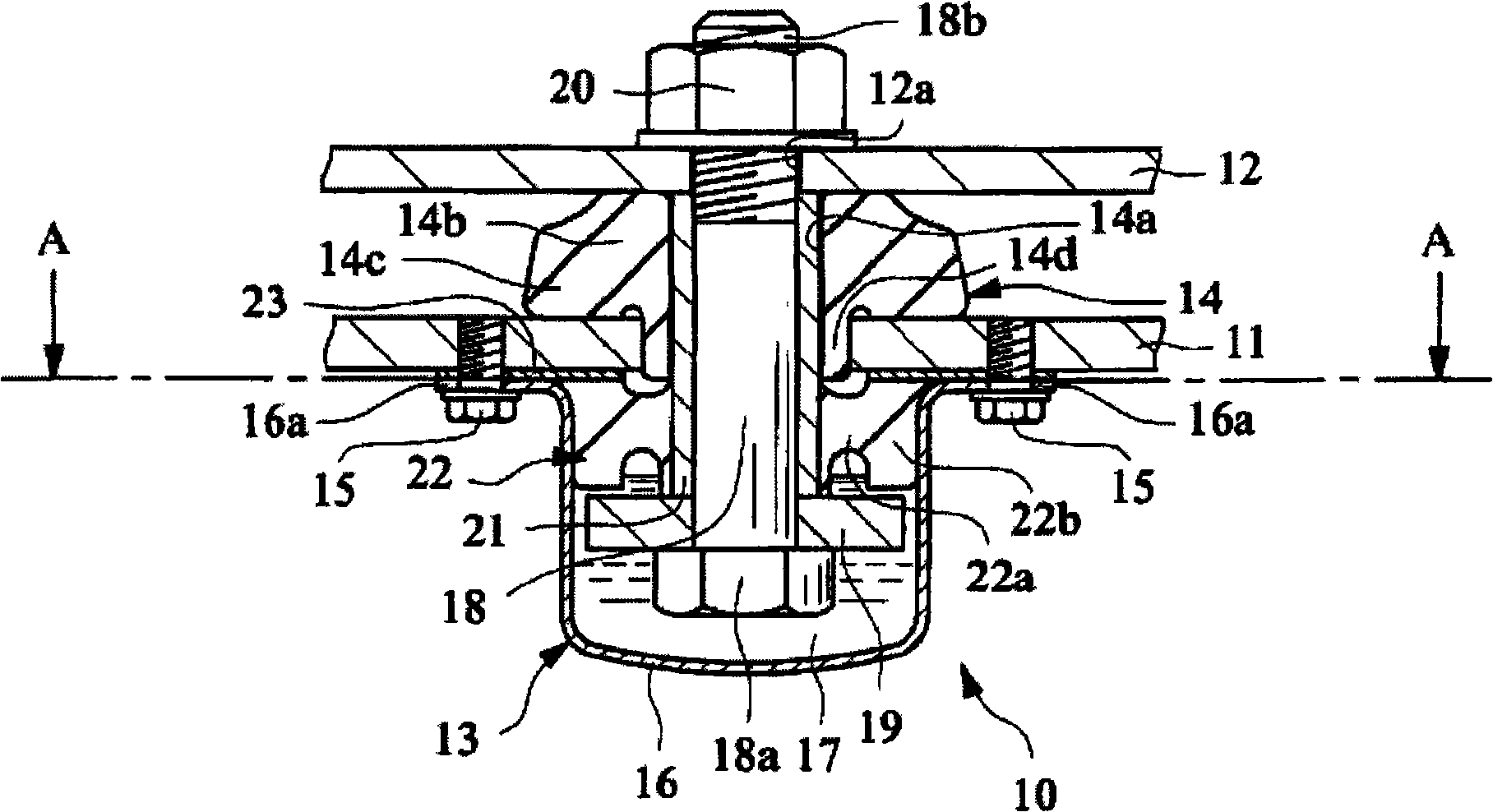

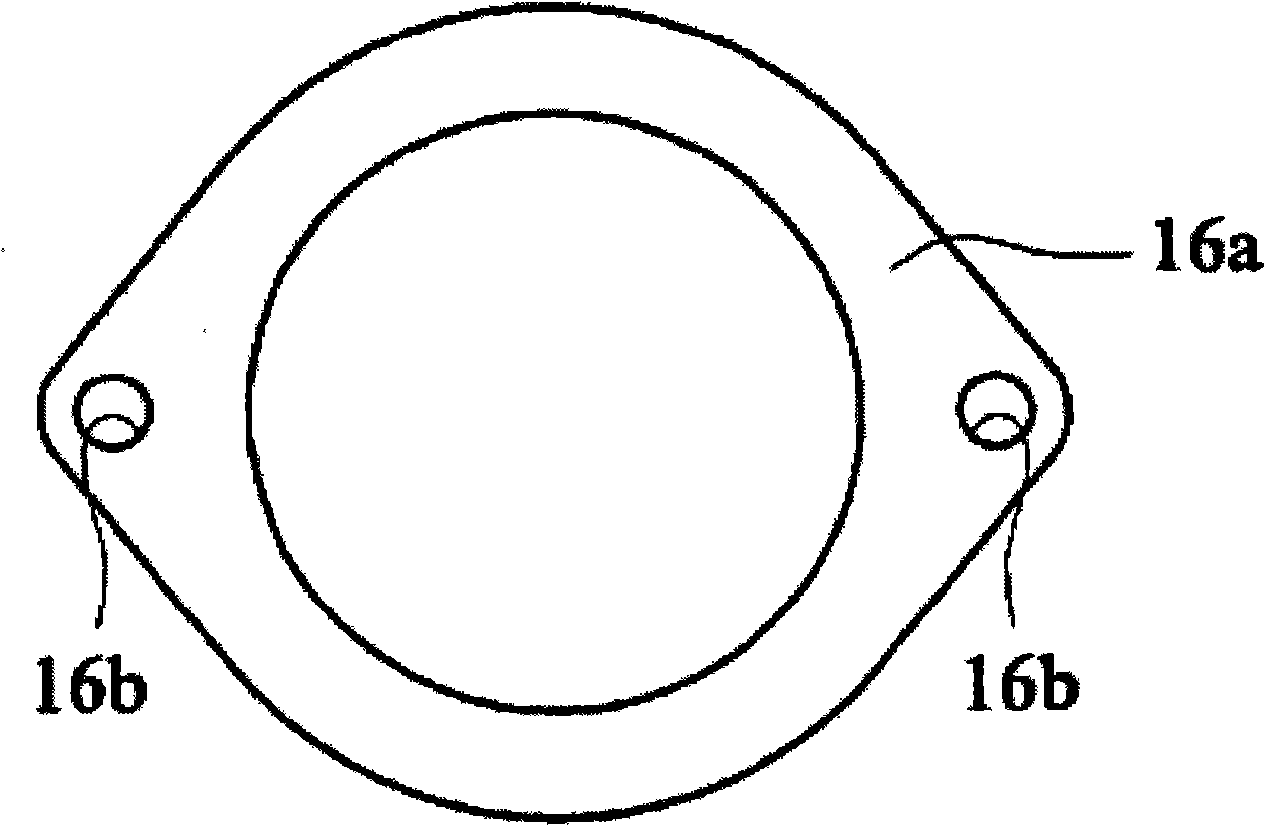

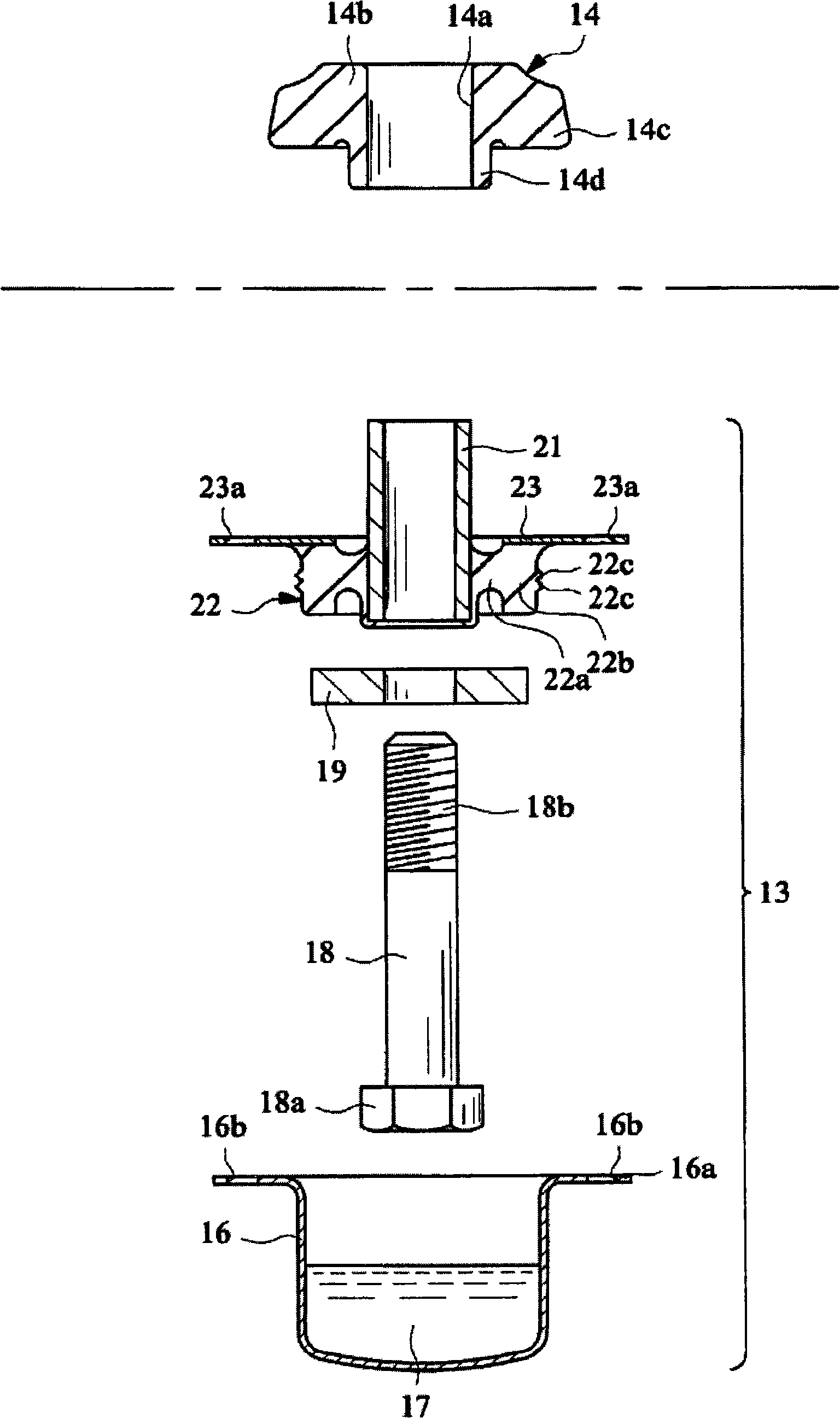

[0046] The following will refer to Figure 1-Figure 4 One embodiment of the present invention will be described in detail.

[0047] Such as figure 1 As shown, the liquid-enclosed bracket 10 is provided between the vehicle body frame (the other side member) 11 of the vehicle body (not shown in the figure) and the bottom wall side member (one side member) 12 of the cab (not shown in the figure). Among them, the vehicle body has crawler belts such as crawler traction devices used as a walking body in construction machinery such as a single-bucket excavator, and the cab is arranged on the frame 11 of the vehicle body. figure 1 In the upper part, the driver can ride. The liquid-filled bracket 10 absorbs and attenuates mutual vibration between the vehicle body frame 11 and the bottom wall side member 12 . The liquid-filled bracket 10 includes a vibration damping body (damping portion) 13 having a vibration damping function and a rubber ring-shaped elastic body (elastic body) 14 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com