Electric melting furnace, electric melting method and method for producing rock wool by using electric smelting red mud

An electric melting and electrode technology, which is applied in the field of electric melting furnace and electric melting red mud to produce rock wool, can solve the problems of large voltage and current fluctuations, increased production costs, and misoperation of electrical equipment, and achieve the effect of arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

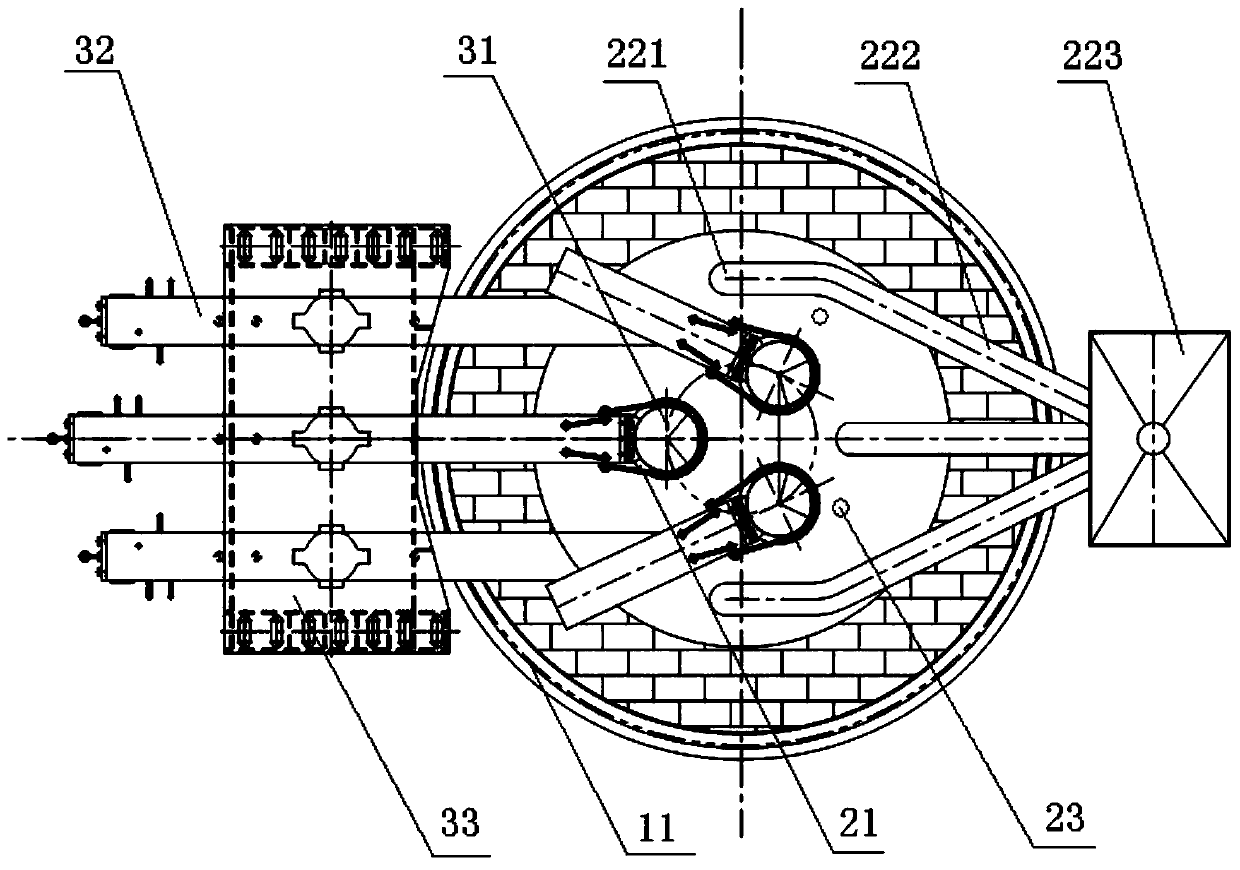

[0094] Such as figure 1 As shown, the present invention provides an electric melting furnace, including an electric melting furnace body, a control system 4 and a power supply system, the control system 4 is electrically connected to the power supply system, the power supply system includes an ignition device 3, and the electric melting furnace The body is structurally matched with the ignition device 3 , and the ignition device 3 includes a graphite electrode 31 and an electrode automatic adjustment mechanism 33 .

[0095] The graphite electrode 31 is a three-phase graphite electrode 31, and the discharge points of the three-phase graphite electrode 31 are electrically connected with resistance wires respectively; The three-phase graphite electrodes 31 are electrically connected, and the electrode lifting mechanism 331 drives the three-phase graphite electrodes 31 to lift. The main body of the electric melting furnace is provided with a channel for the graphite electrode 31 ...

Embodiment 2

[0106] On the basis of Example 1, in order to adapt the electric melting furnace to the production of inorganic fibers, especially the production of rock wool based on red mud, the following improvements are made, as Figure 1-3 As shown, the electric melting furnace body includes a furnace body 1 and a furnace cover 2; a furnace top distribution device 22 is arranged in the furnace body 1, and the furnace top distribution device 22 communicates with a feeding device through a material conveying device; The side wall of the furnace body 1 is provided with a discharge opening; the furnace cover 2 is provided with a passage hole for the graphite electrode 31 to pass through.

[0107] Wherein the inner hearth of the furnace body 1 is preferably cylindrical. The design inner diameter is preferably 360 cm, and the melting capacity is 5-8 tons per hour, preferably 6 tons.

[0108] The first layer of the furnace body 1 bottom and circumference is made of asbestos board from the outs...

Embodiment 3

[0137] According to the above embodiments, in order to solve the problem of unbalanced three-phase current when the existing electric melting furnace starts arcing, the present invention provides an electric melting method, which uses the electric melting furnace to process materials, and the steps mainly include:

[0138] 1) Preparation before operation;

[0139] 2) Fabric;

[0140] 3) charge preheating;

[0141] 4) molten pool generation;

[0142] 5) The ignition device 3 ignites and starts the arc;

[0143] 6) Maintain production, form melting rated current, melting rated voltage, melting rated power, and operate stably;

[0144] 7) Output stream, when the molten liquid level reaches the set height, open the discharge port, let the molten liquid stream flow out and lead it to the next material processing process.

[0145] Specifically, the pre-operation preparation in step 1) includes three steps: equipment acceptance, pre-operation drying and post-drying inspection; wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com