High-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire

A gas-shielded, flux-cored wire technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as the inability to guarantee the use of low-temperature steel, poor low-temperature impact toughness and crack resistance, and poor arc stability. , to achieve the effect of improving slag coverage and slag removal, improving thermal crack resistance and welding arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A kind of high strength and low temperature resistant TiO 2 Department of CO 2 Gas-shielded low-hydrogen flux-cored welding wire, which uses low-P, S low-carbon steel strips as the wire wrapping, uses flux-cored transition alloys, and is manufactured using the general-purpose flux-cored wire manufacturing process, with a filling ratio of 10%-20 %.

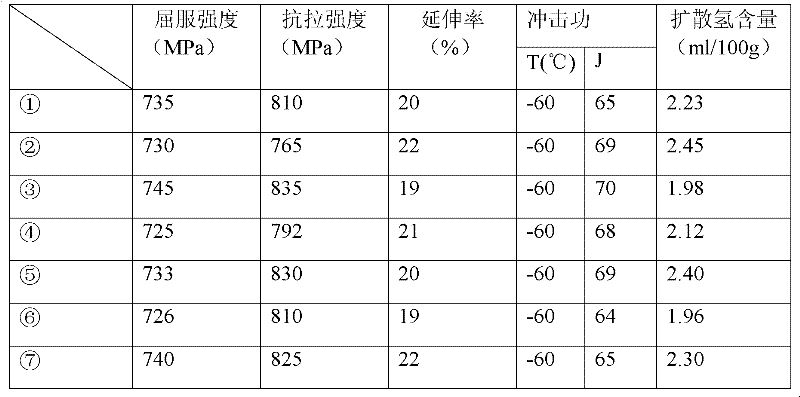

[0037] Select cold-rolled steel strips, and use the welding wires with the mass components (accounting for the wt% of the welding wire) listed in Table 1 respectively. The wire diameter is 1.2mm. CO2 gas protection, voltage 28V, current 250A, dry elongation 18mm, moving speed 250mm / min. The mechanical properties and diffusible hydrogen (mercury method) content of the welds obtained by using the above welding wires are shown in Table 2.

[0038] It can be seen that the tensile strength of the deposited weld metal obtained by using the welding wire of the present invention can reach more than 760MPa, the low-temperature imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com