Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Hydrogen flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen Flux Monitoring. One of the common corrosion products of iron or steel in a neutral or acidic medium is atomic hydrogen. Normally, these highly reactive species combine with other hydrogen atoms to produce a relatively harmless molecule, hydrogen gas (H 2).

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN101003749AStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

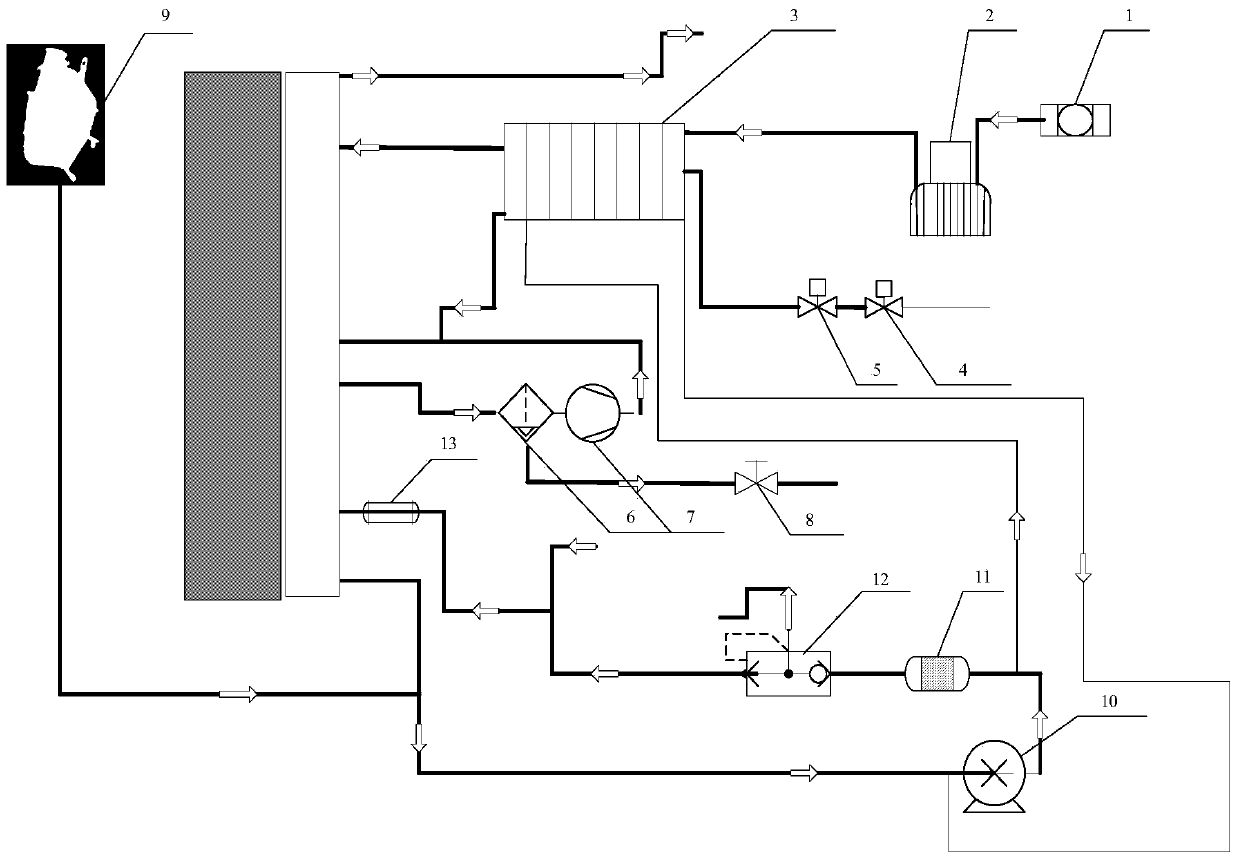

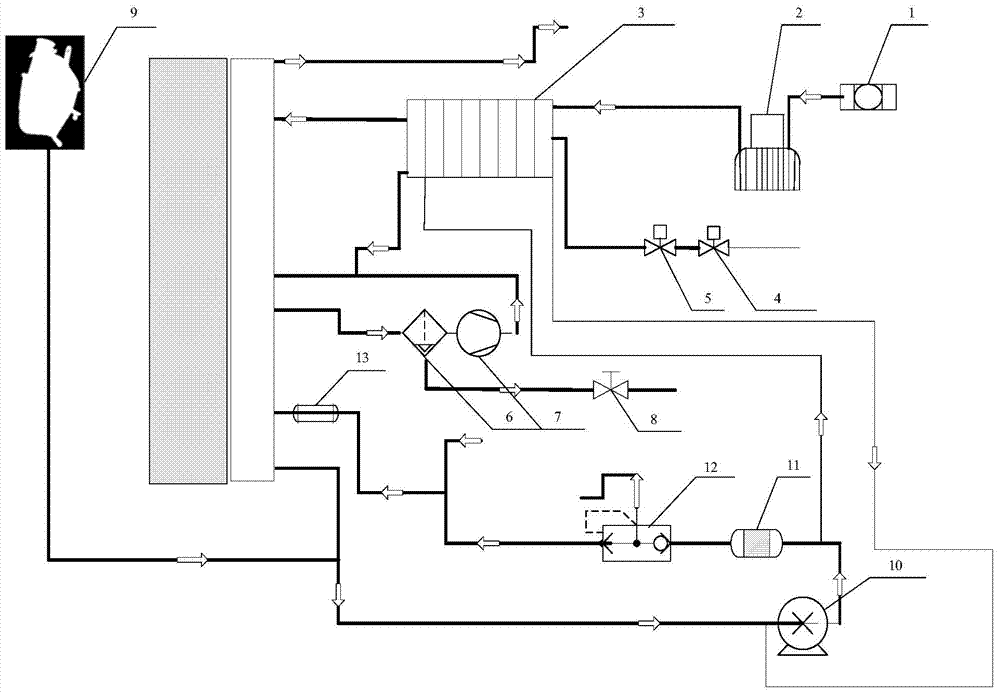

Fuel cell engine system

ActiveCN103474686AReduce energy consumptionReduce volumeFuel cell auxillariesFuel cell detailsCirculator pumpEngineering

The invention discloses a fuel cell engine system, comprising a fuel cell stack, a distribution assembly, a hydrogen supply unit, an air supply unit, a cooling unit and a heat exchanger, wherein a humidifier of the air supply unit is omitted; the hydrogen supply unit comprises a hydrogen reflux part; the hot end of the heat exchanger is air fluid while the cold end of the heat exchanger is provided with two independent fluids, namely a hydrogen fluid and a cooling cycle fluid; the hot end inlet of the heat exchanger is connected with a vent of an air compressor while the hot end outlet is connected with an air inlet of the fuel cell stack; the two fluid inlets of the cold end of the heat exchange are respectively connected with a control valve outlet of a hydrogen storage tank outlet and a cooling cycle pump outlet; the two fluid outlets of the cold end of the heat exchanger are respectively connected with the fuel cell stack hydrogen inlet and cooling cycle pump inlet. The fuel cell engine system has the beneficial effects that the air cooler and the hydrogen preheater are combined, and hydrogen flux is used for replacing the air side humidifier, thus simplifying the system, reducing the size and weight of the parts, and reducing the system energy consumption.

Owner:SUNRISE POWER CO LTD

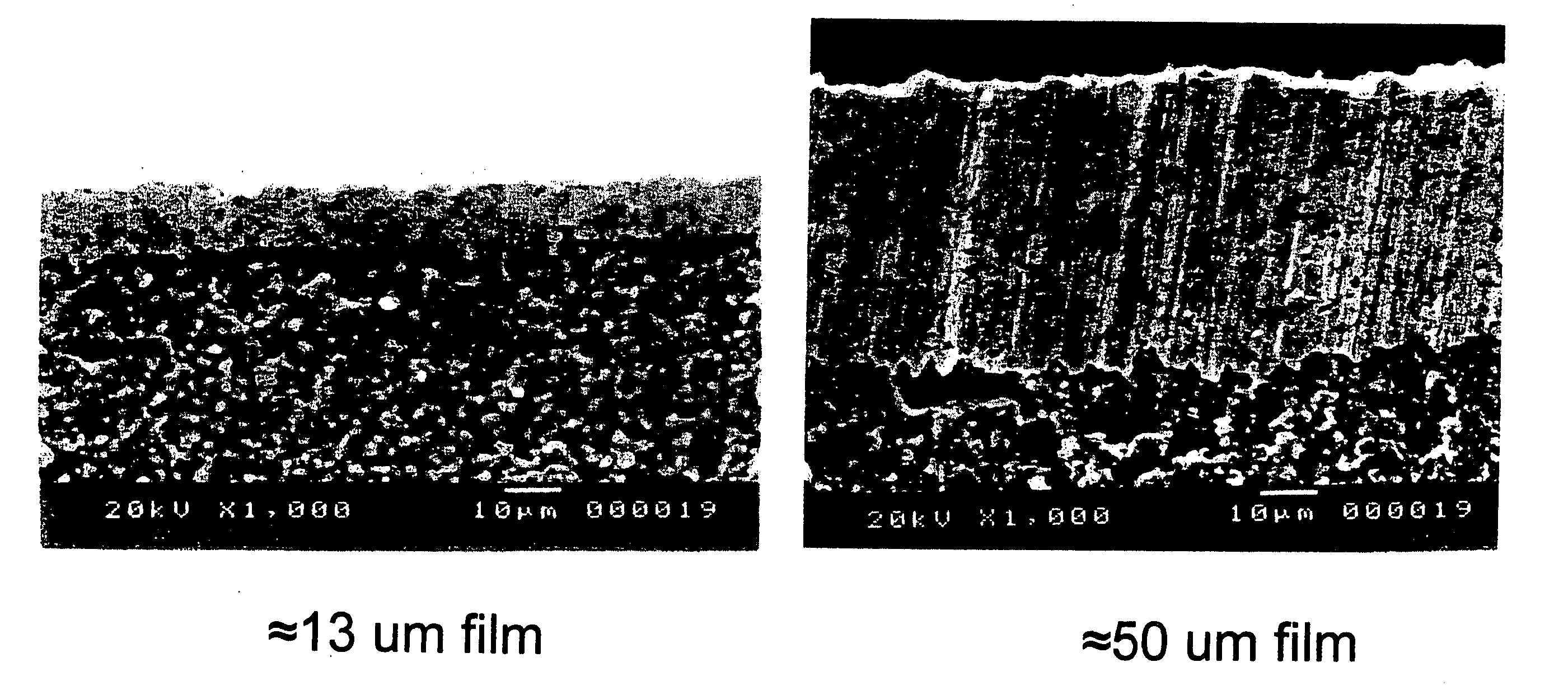

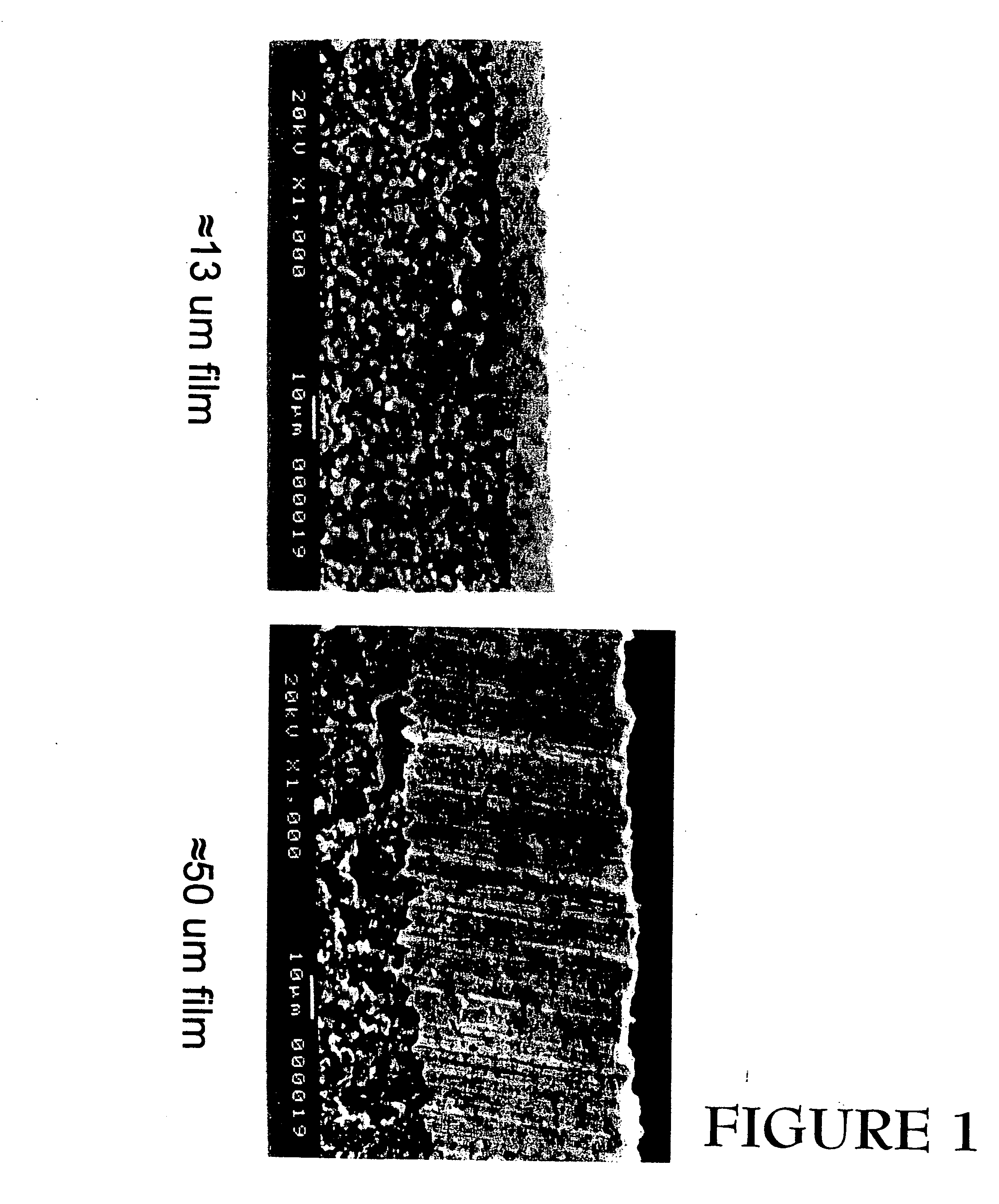

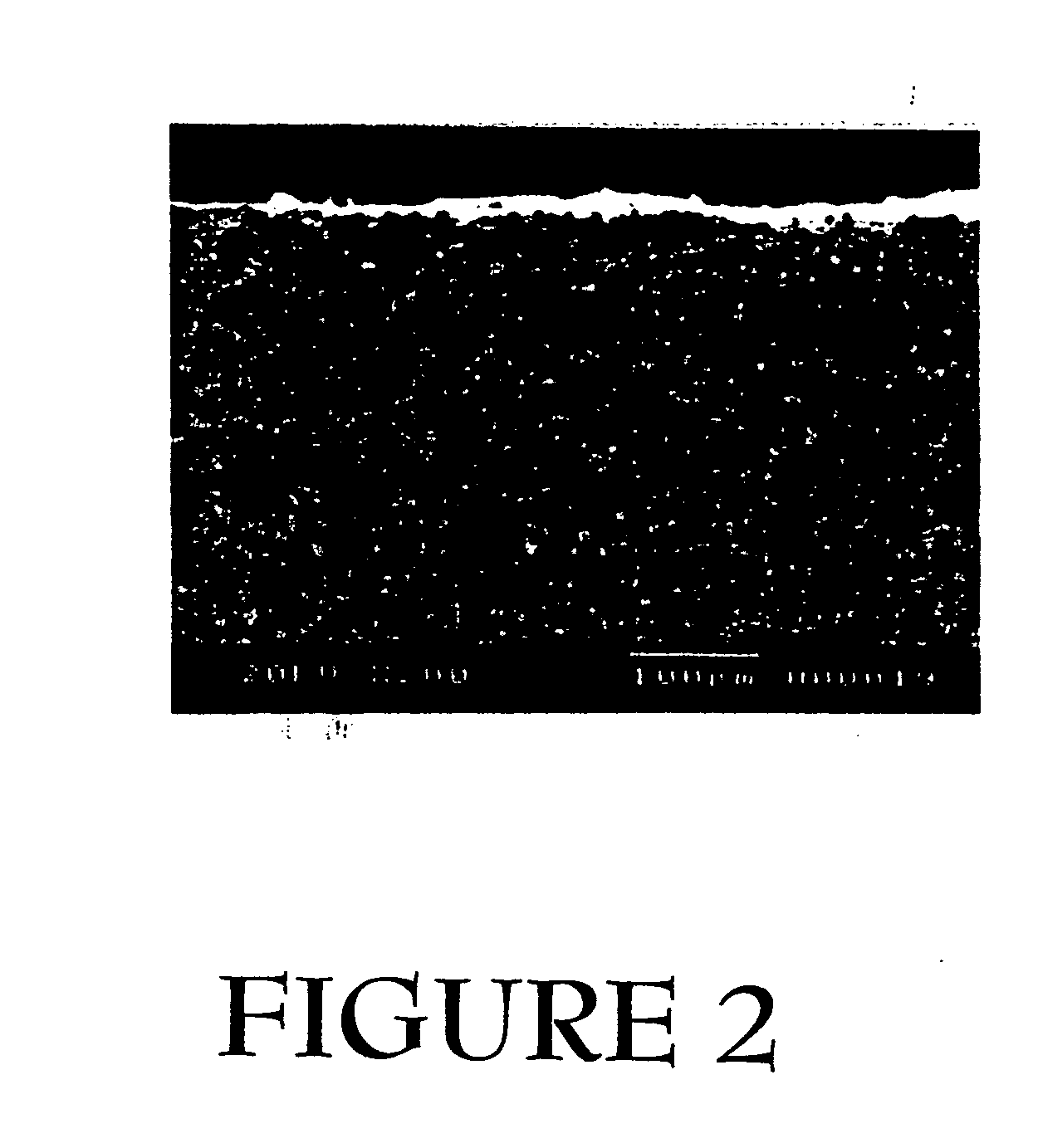

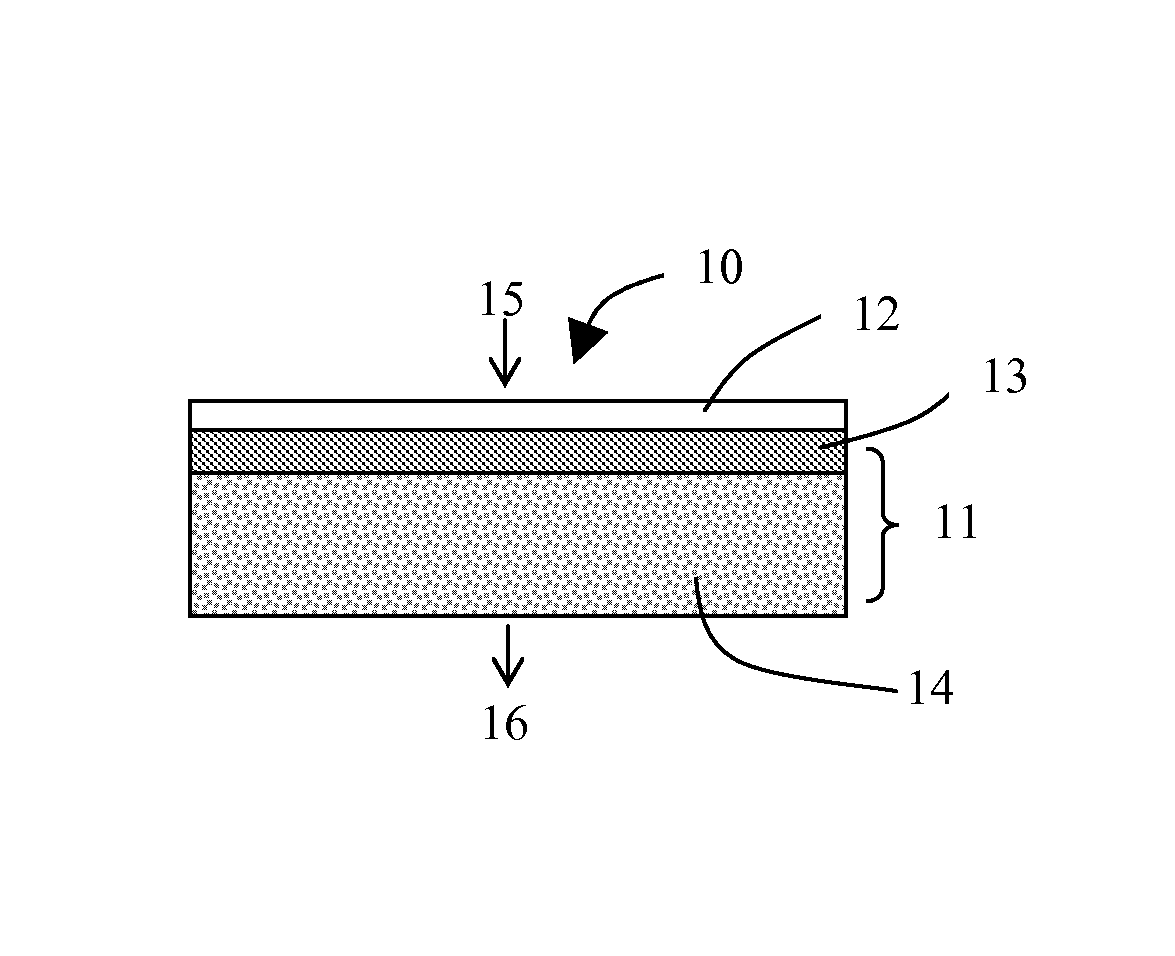

Method for fabricating a hydrogen separation membrane on a porous substrate

A hydrogen permeable composition having a porous ceramic substrate, and a two part membrane adhered thereto. The two part membrane has a metal powder part and a ceramic oxide part, with the metal powder part being Ni, Pd, Pd alloys, Nb, Ta, Zr, V or mixtures thereof. The oxide part is yttria stabilized zirconia, shrinkable alumina, suitably doped cerates, titanate, zirconates of barium or strontium or mixtures thereof, and the hydrogen flux is at least 20 cm3 per minute-cm2 at 500° C. in a 100% hydrogen atmosphere. A paste method of forming the composition is disclosed. A method of extracting hydrogen from a gas is also disclosed.

Owner:CHICAGO UNIV OF +1

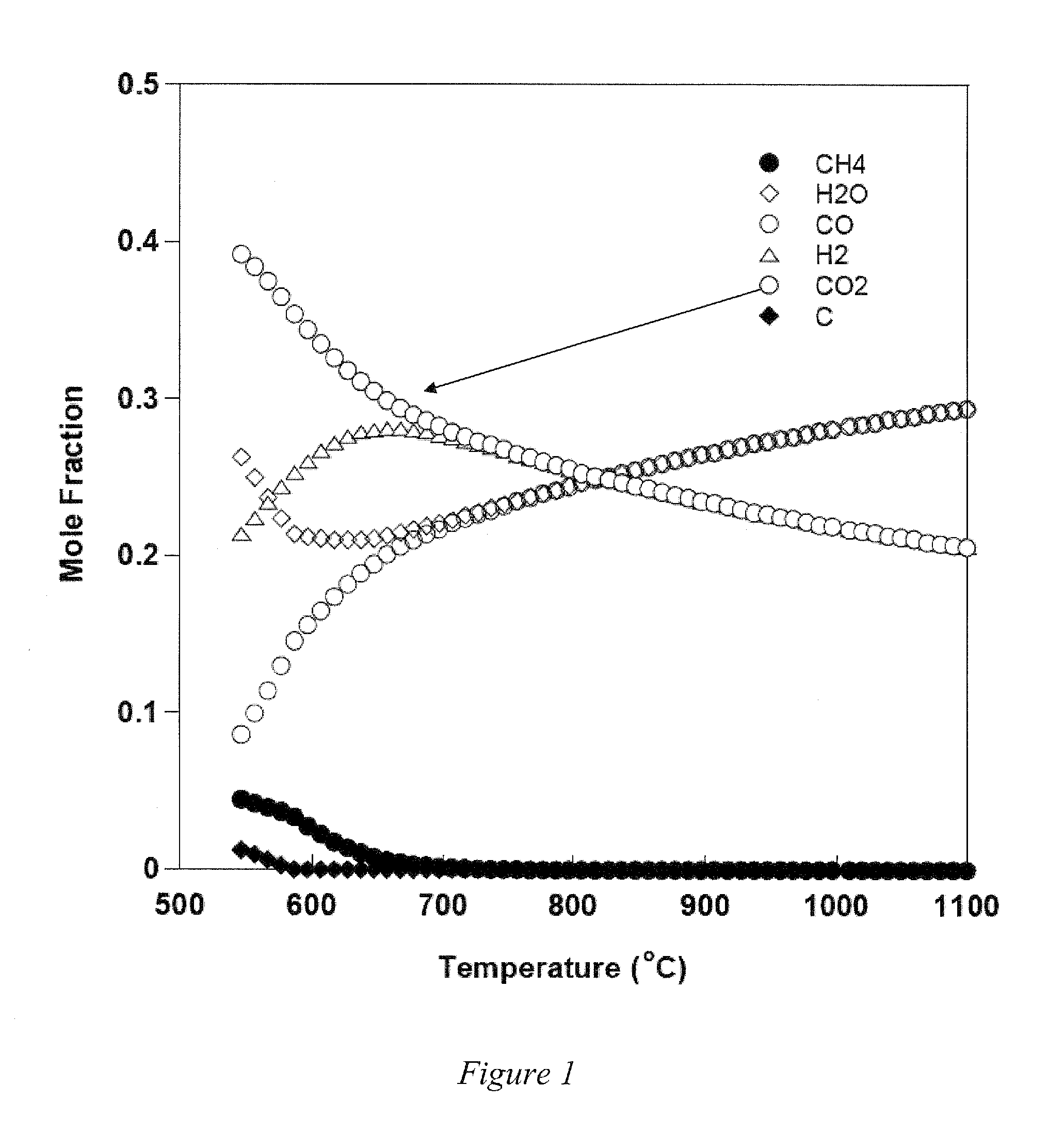

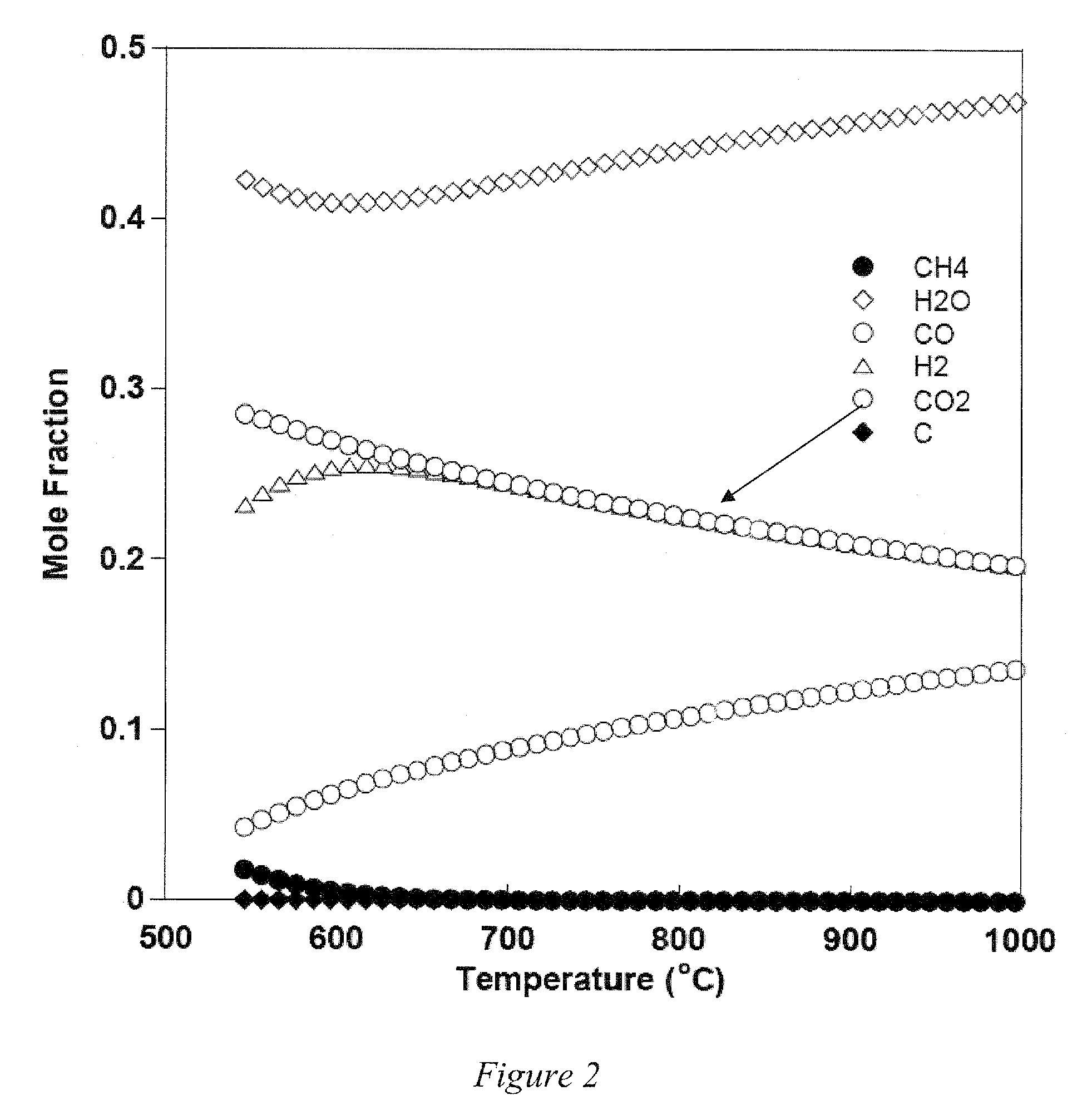

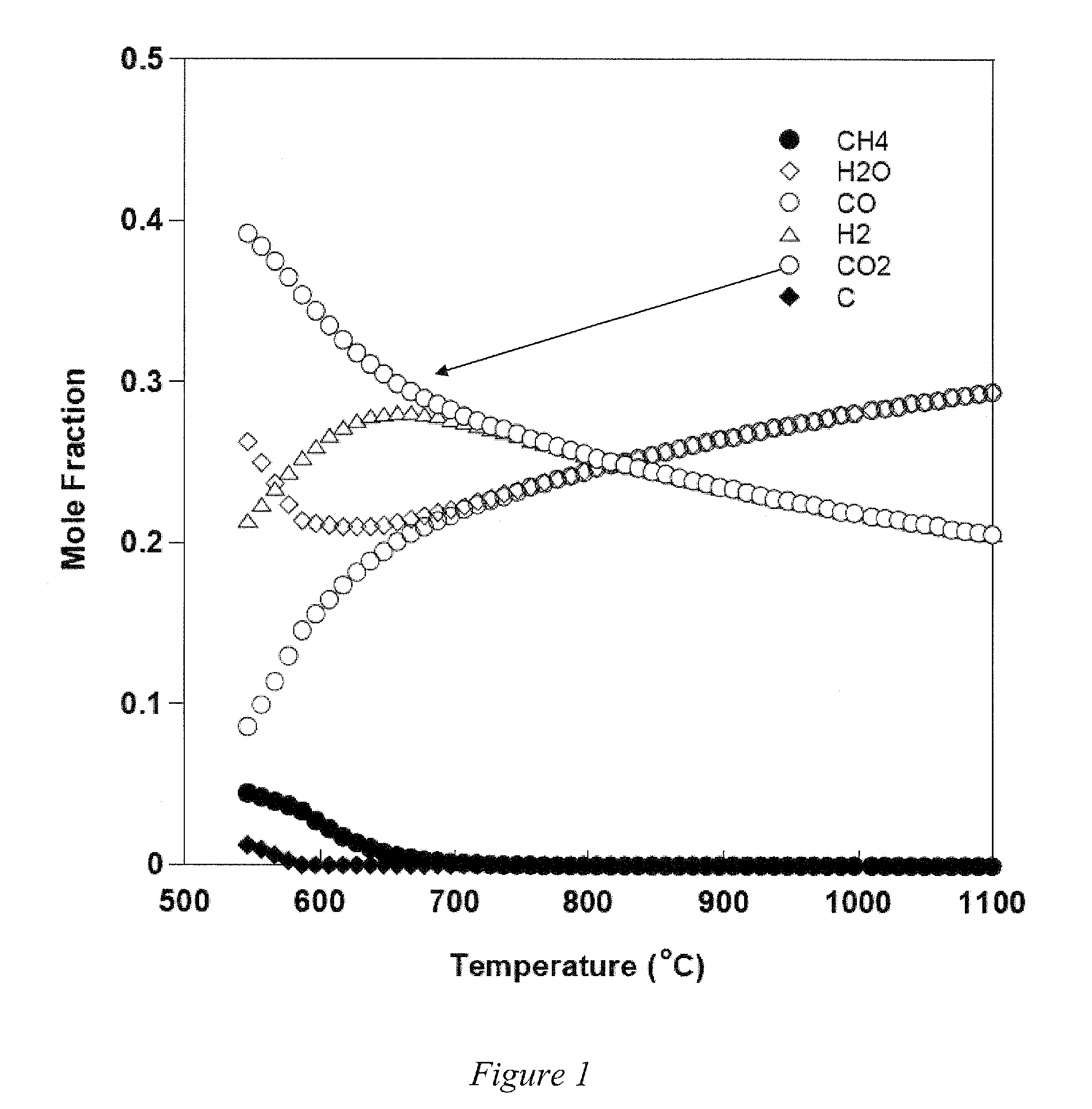

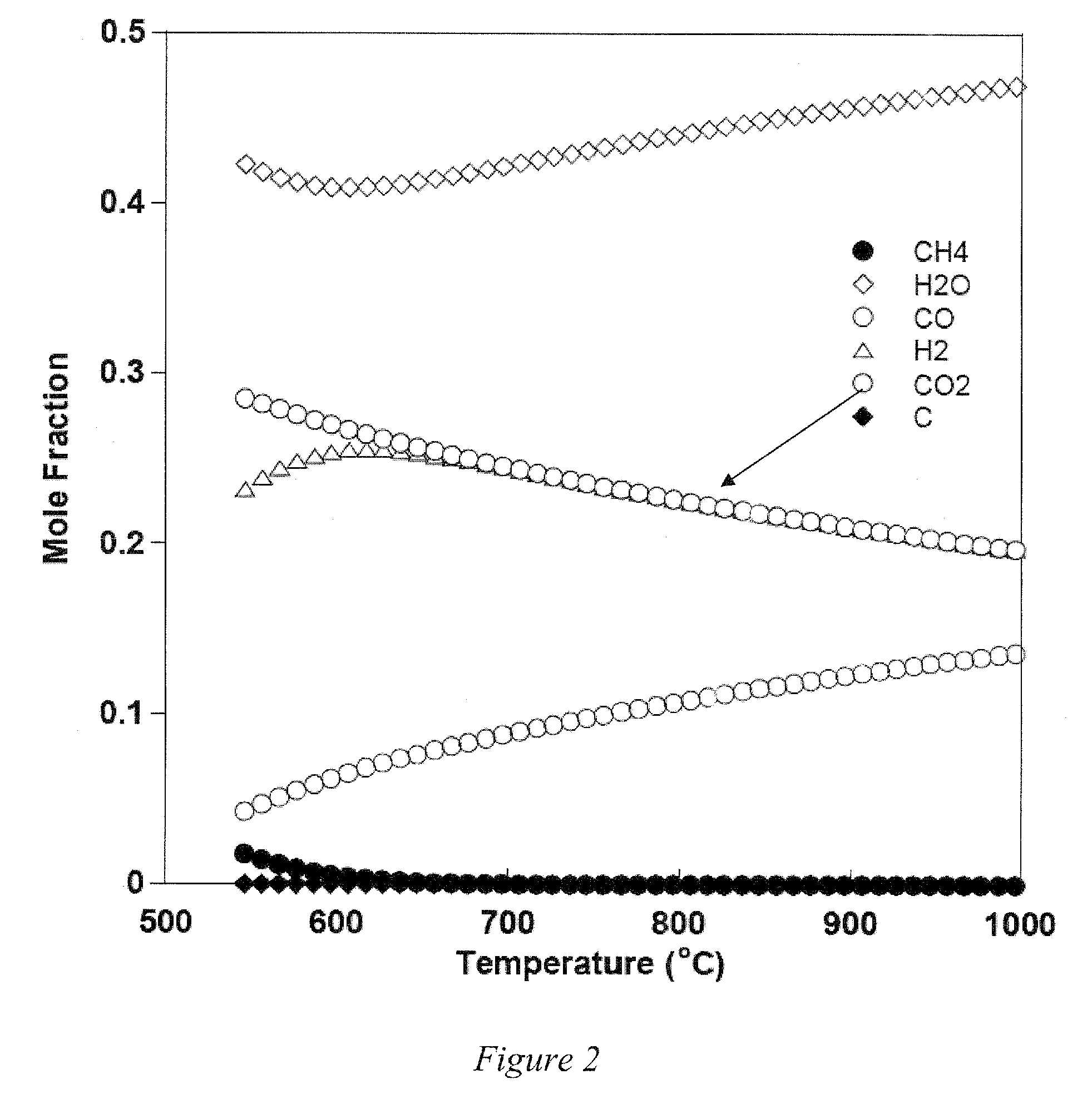

Proton conducting membranes for hydrogen production and separation

ActiveUS20110084237A1Improve stabilityIncreased hydrogen permeationLayered productsPretreated surfacesMulliteAlloy

In one embodiment, a membrane of proton-electron conducting ceramics that is useful for the conversion of a hydrocarbon and steam to hydrogen has a porous support of M′-Sr1-z′M″z′Ce1-x′-y′Zrx′M′″y′O3-δ, Al2O3, mullite, ZrO2, CeO2 or any mixtures thereof where: M′ is Ni, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, W, Zn, Pt, Ru, Rh, Pd, alloys thereof or mixtures thereof; M″ is Ba, Ca, Mg, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, or Yb; M′″ is Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, W, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, or Yb; z′ is 0 to about 0.5; x′ is 0 to about 0.5; y′ is 0 to about 0.5; and x′+y′>0; for example, Ni—SrCe1-x′Zrx′O3-δ, where x′ is about 0.1 to about 0.3. The porous support is coated with a film of a Perovskite-type oxide of the formula SrCe1-x-yZrxMyO3-δ where M is at least one of Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, W, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, and Yb, x is 0 to about 0.15 and y is about 0.1 to about 0.3. By including the Zr and M in the oxide in place of Ce, the stability can be improved while maintaining sufficient hydrogen flux for efficient generation of hydrogen. In this manner, the conversion can be carried out by performing steam methane reforming (SMR) and / or water-gas shift reactions (WGS) at high temperature, where the conversion of CO to CO2 and H2 is driven by the removal of H2 to give high conversions. Methods of preparing the membrane cells and a system for use of the membrane cells to prepare hydrogen are presented. A method for sequestering CO2 by reaction with methane or other hydrocarbon catalyzed by the novel membrane to form a syngas is also presented.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

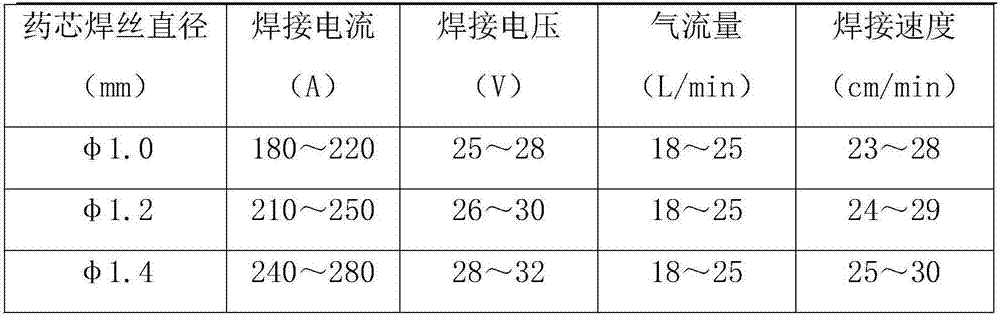

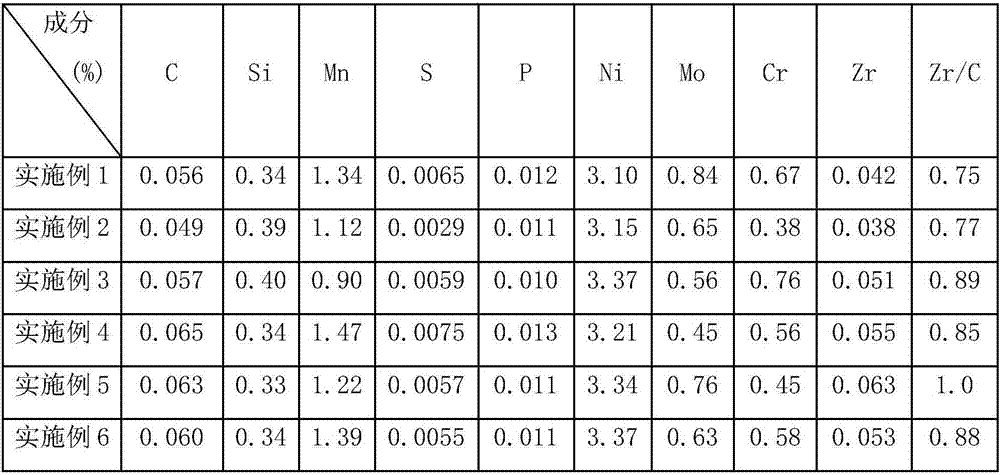

1000 MPa-level high-strength all-position ultra-low hydrogen flux-cored wire and welding method thereof

ActiveCN107052617AReduce moisture contentLow diffusible hydrogen contentArc welding apparatusWelding/cutting media/materialsCarbon steelMolten slag

The invention provides a 1000 MPa-level high-strength all-position ultra-low hydrogen flux-cored wire which comprises a carbon steel sheath and a flux core. The flux core comprises the ingredients of, in percentage by mass, 2-4% of SrCO3, 3-6% of CaF2, 25-35% of TiO2, 3-10% of feldspar, 2-5% of Si-Fe; 2-5% of Mg, 0.2-0.5% of C, 0.4-1.0% of Zr-Fe, 8-15% of Mn, 3-6% of Cr, 18-20% of Ni, 3-7% of Mo, 1.5-3% of Fe3O4 and the balance Fe of the total amount of the flux core. A titanium alkali type slag system is adopted for the flux-cored wire, a slagging constituent and an arc stabilizing substance are added into the flux core, molten slag can completely cover weld metal, the tensile strength Rm of the deposited metal is larger than or equal to 980 MPa, the elongation rate A is larger than or equal to 13%, the deposited metal charpy impact KV2 (-60 DEG C) is larger than or equal to 34 J, and the 1000 MPa-level high-strength all-position ultra-low hydrogen flux-cored wire is suitable for all-position welding.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

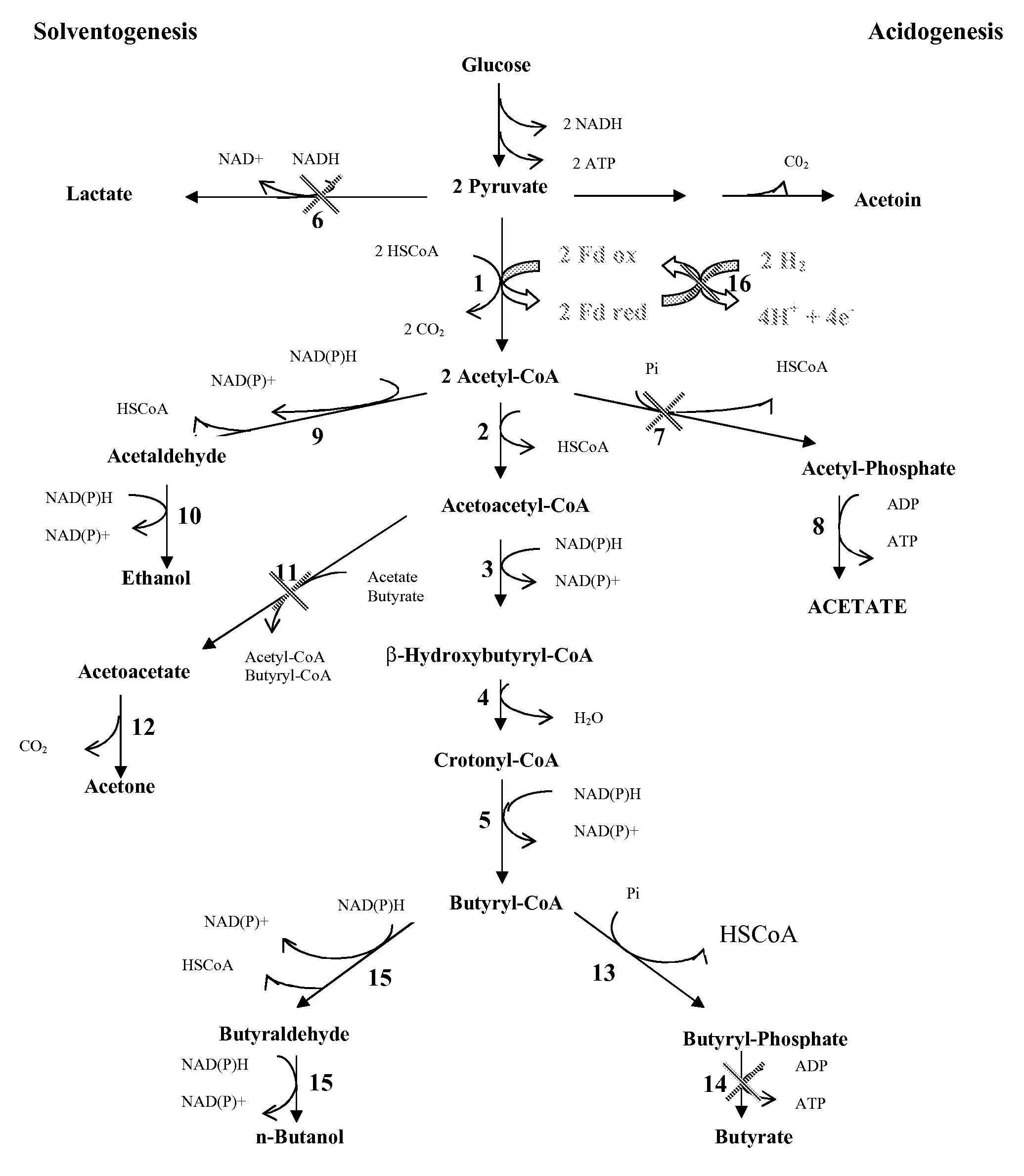

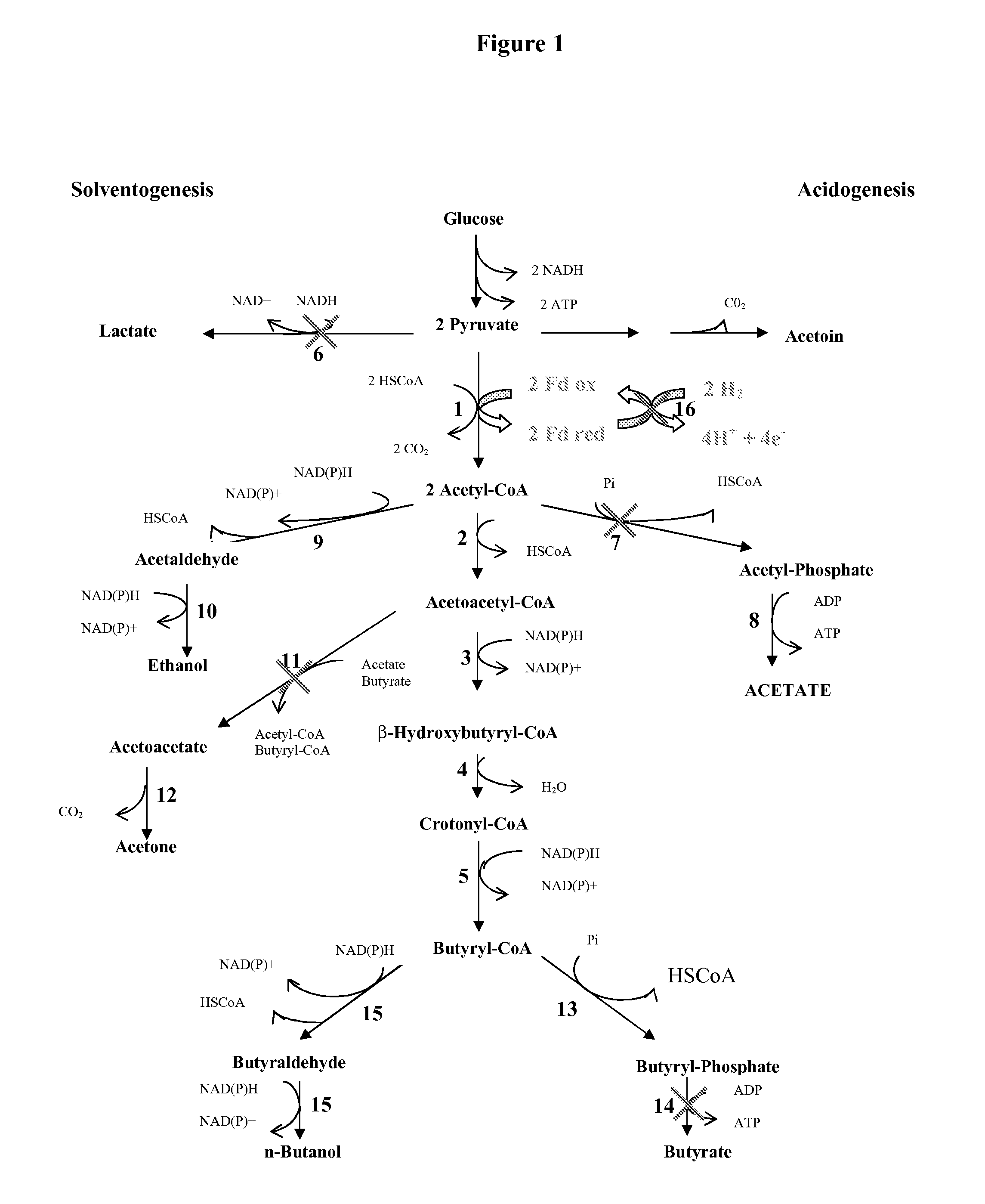

PROCESS FOR THE BIOLOGICAL PRODUCTION OF n-BUTANOL WITH HIGH YIELD

The present invention provides a method for the biological production of n-butanol at high yield from a fermentable carbon source. In one aspect of the present invention, a process for the conversion of glucose to n-butanol is achieved by the use of a recombinant organism comprising a host C. acetobutilicum transformed i) to eliminate the butyrate pathway ii) to eliminate the acetone pathway iii) to eliminate the lactate pathway and iv) to eliminate the acetate pathway. In another aspect of the present invention, the hydrogen flux is decreased and the reducing power redirected to n-butanol production by attenuating the expression of the hydrogenase gene. Optionally the n-butanol produced can be eliminated during the fermentation by gas striping and further purified by distillation.

Owner:METABOLIC EXPLORER

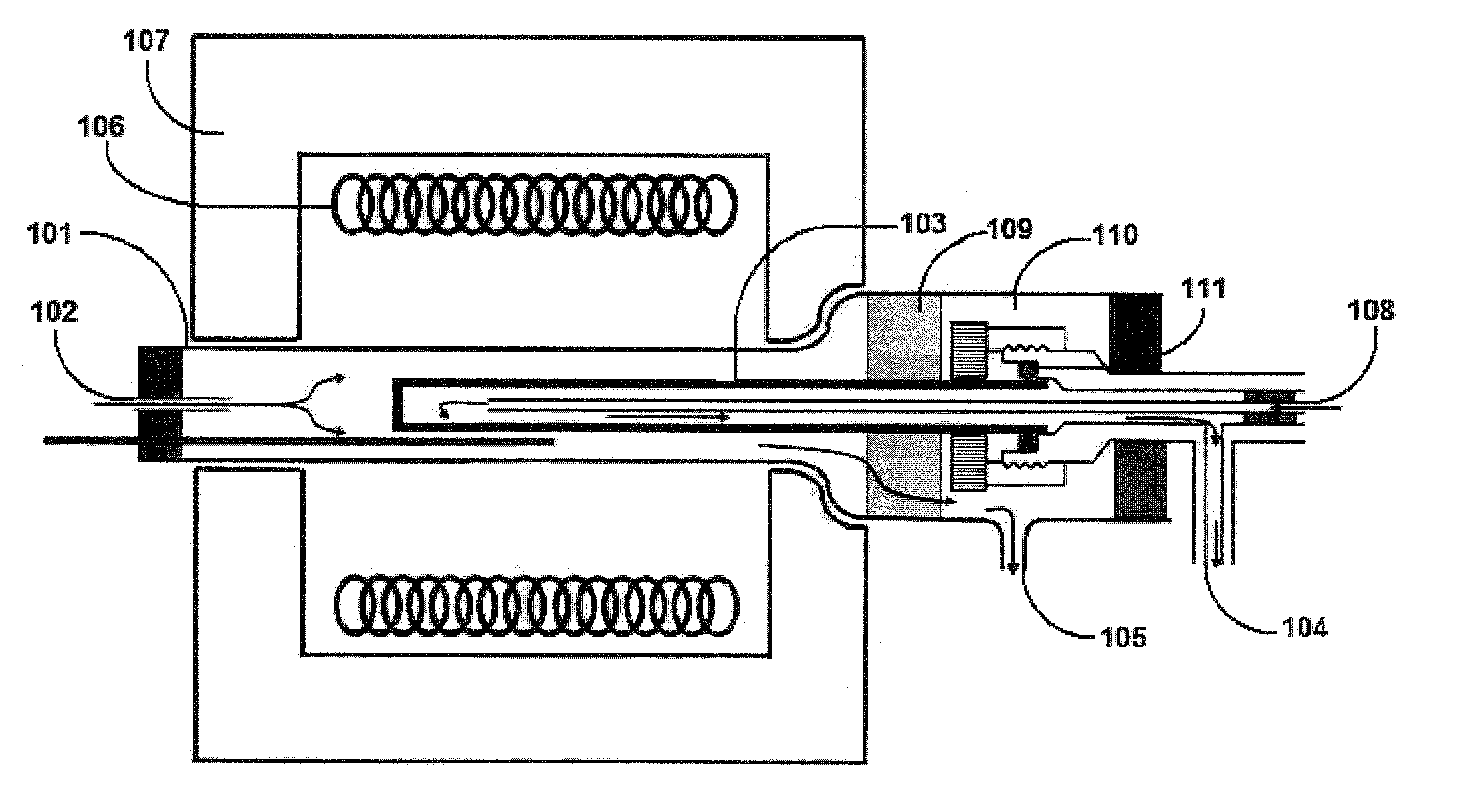

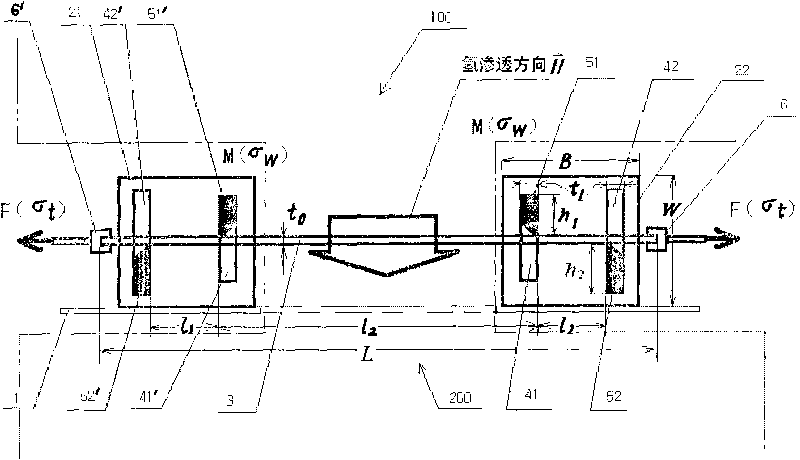

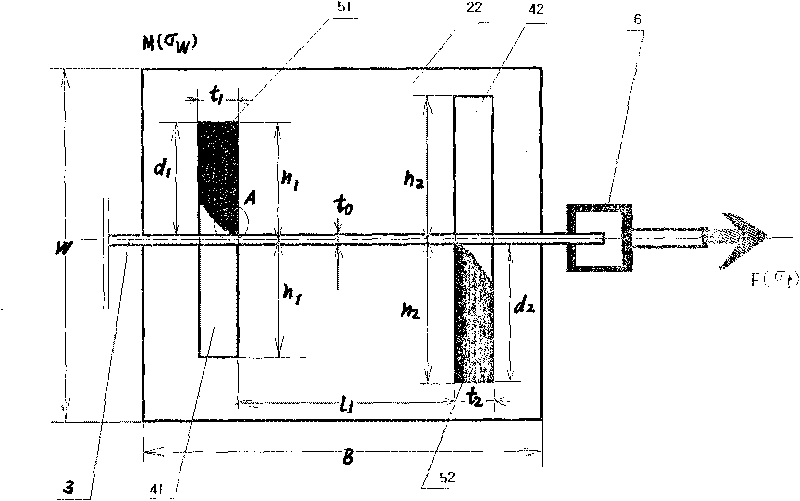

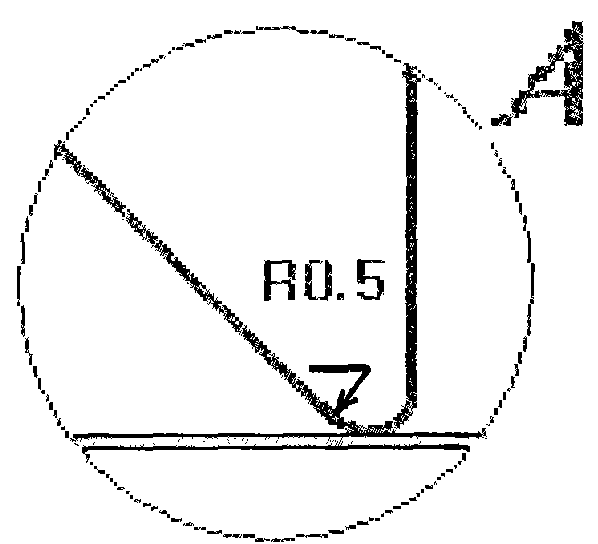

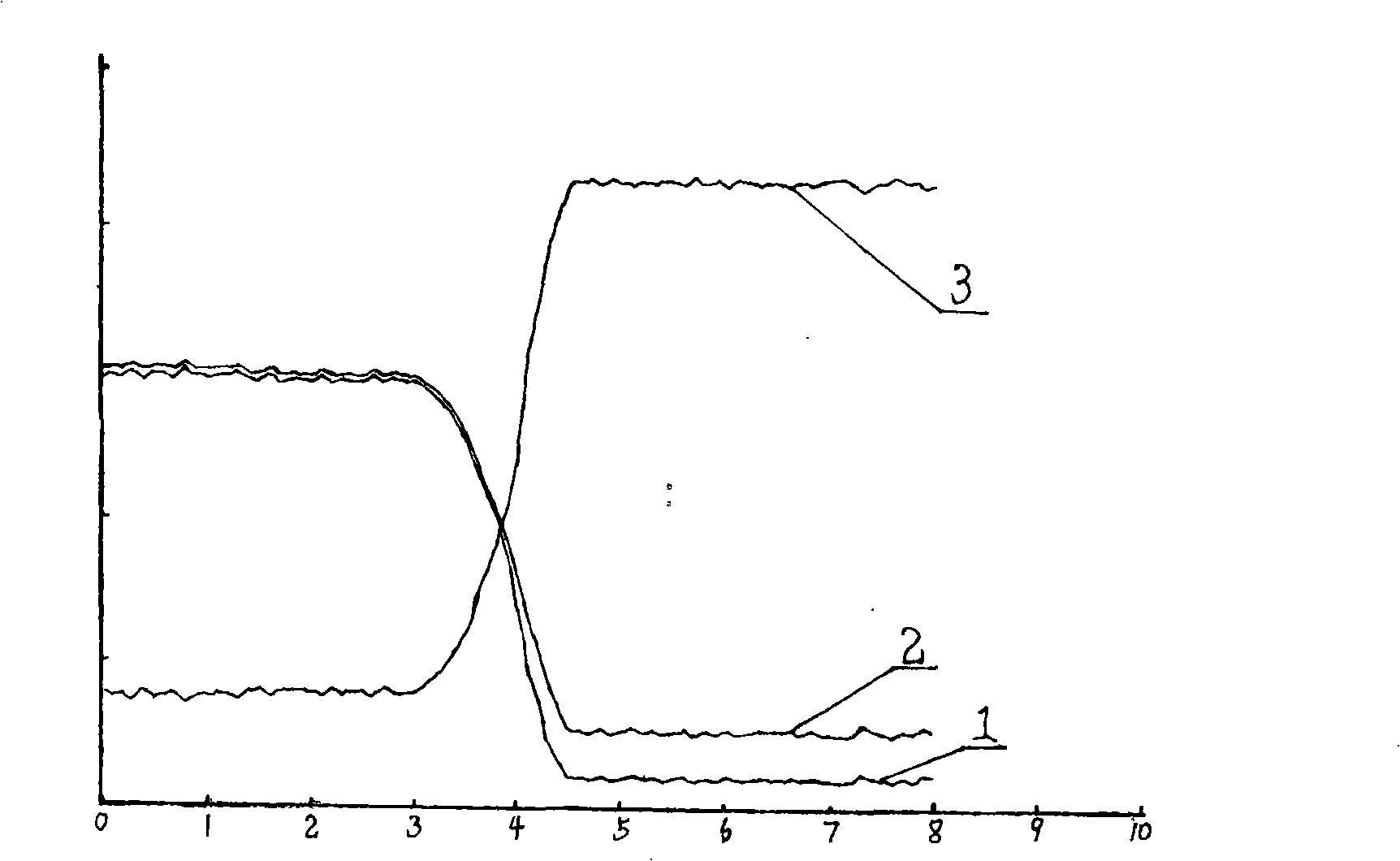

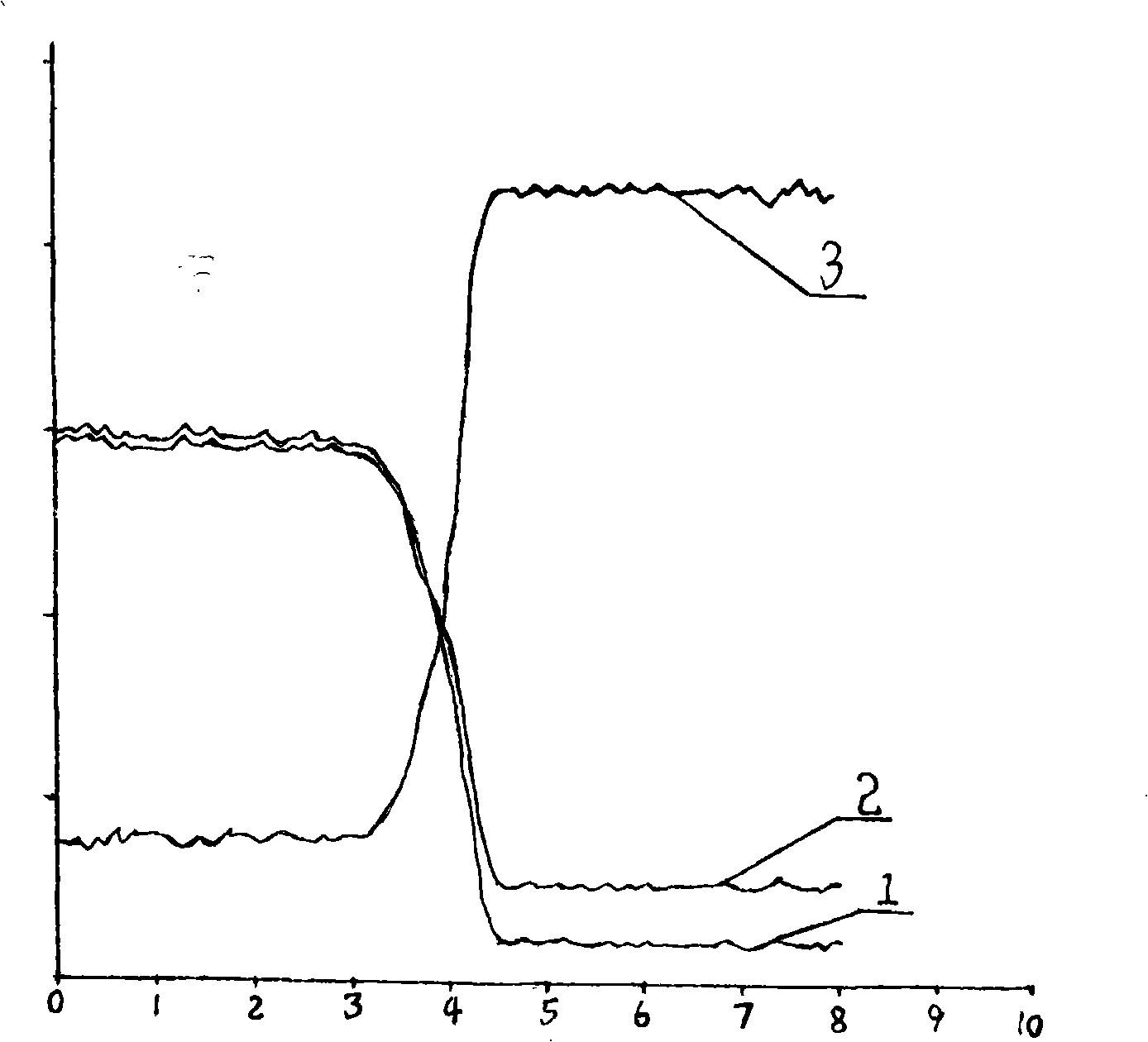

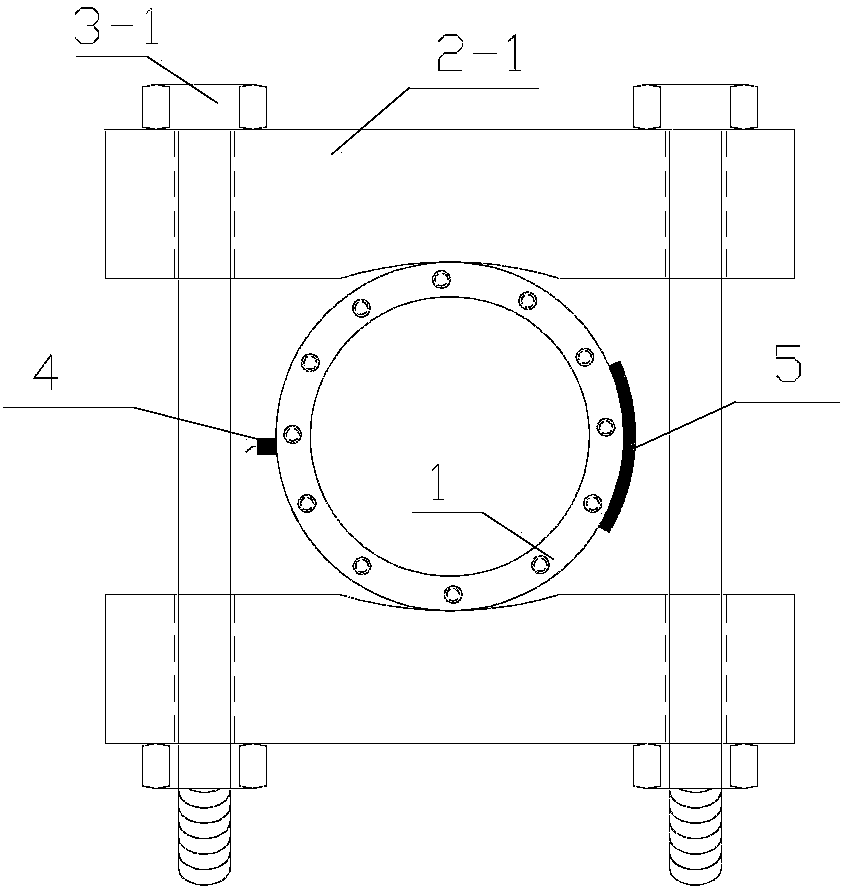

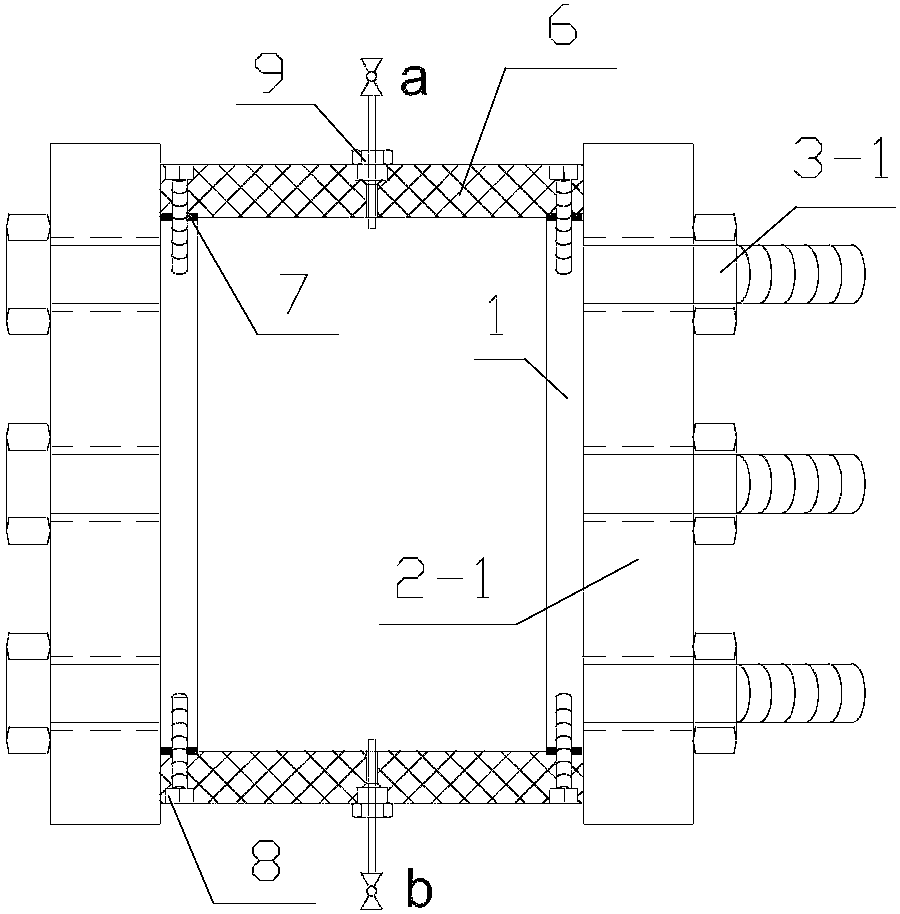

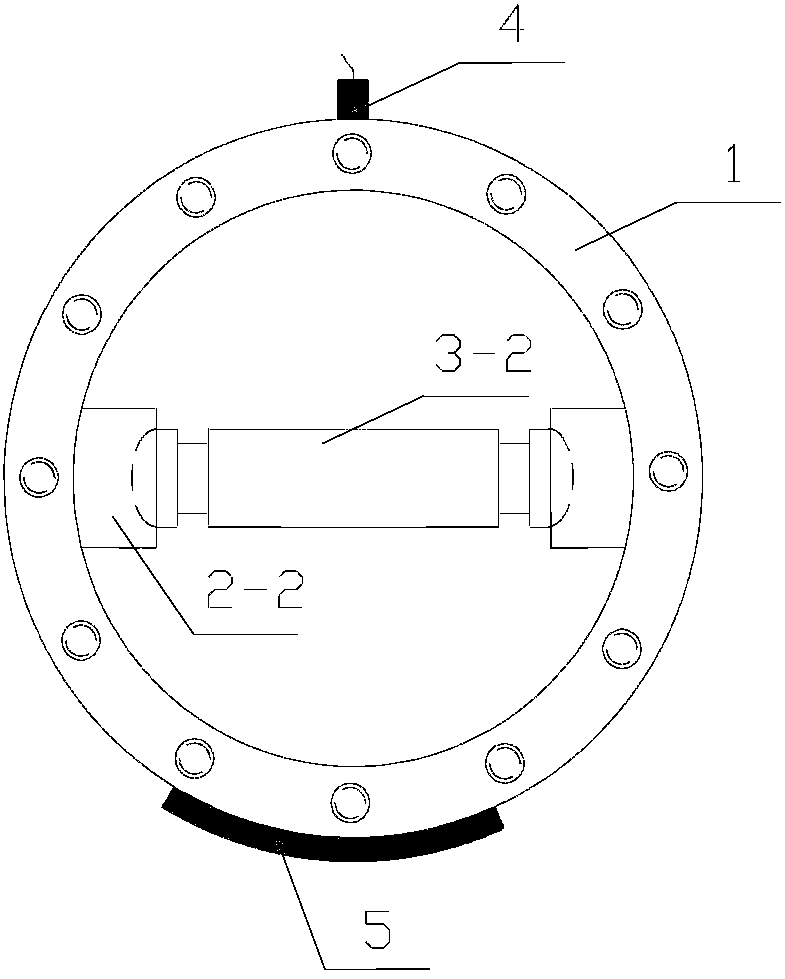

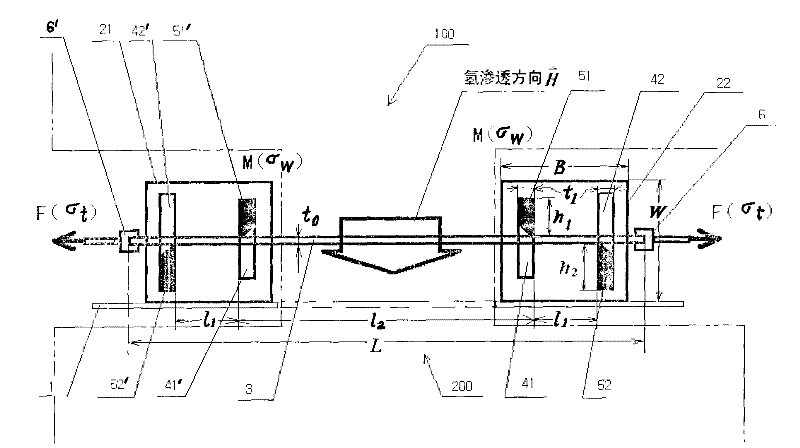

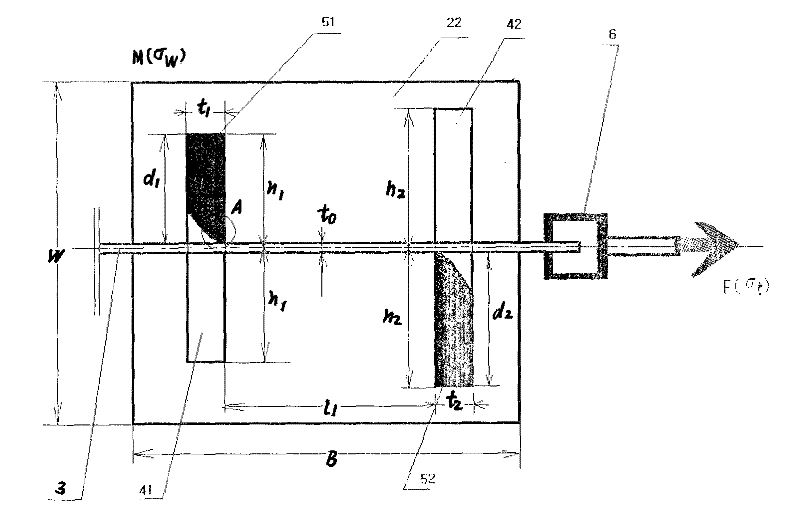

Loading device and loading mode for use in measurement of hydrogen diffusion in stress field

InactiveCN101706409AEffective assessmentReduce biasWeather/light/corrosion resistanceDynamic fieldEngineering

The invention relates to a loading device and a loading mode for use in the measurement of hydrogen diffusion in a stress field. In the loading device and the loading mode, a loading frame and a loading strip apply a load 1 and / or an axially loading platform applies a load 2 and a hydrogen permeation double electrolytic cell is adopted at the same time so as to realize the random change of a dynamic field in the direction of hydrogen permeation in a thin film within a certain range, namely the change of the size, direction and gradient of the stress field to change conditions for hydrogen diffusion and simulate the conditions of hydrogen diffusion in an actual material. The loading device and the loading mode are widely used in the measurement of the metal hydrogen flux and hydrogen diffusion coefficient of a specified stress field, so an advanced technical means is provided for testing the hydrogen corrosion, hydrogen permeation and hydrogen brittleness sensibility of steel and titanium alloy and other materials used in petroleum and natural gas drilling and transmission equipment, hydrogenation reactors, oil and gas transmission equipment, marine fixed structures, submerged pipelines and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

Extension method of material for low forward voltage drop Schottky diode

ActiveCN101295638AControl and optimize heating timeLower forward voltage dropSemiconductor/solid-state device manufacturingPositive pressurePressure reduction

The invention discloses an extension method for a material used for a lower positive pressure reduction schottky diode. The invention controls and optimizes the temperature rising time of each step by adjusting the program of temperature rising and the careful cooperation of hydrogen flux to lead the impurities of a wafer from an underlay to be expanded outwards during a heat treatment process and finally lead the transition area of a silicon epitaxial wafer to reach the range of 1.2 to 1.3 micron by expelling the air by hydrogen. The resistance rate uniformity in the wafer is less than 3 percent by adopting the method of the invention, thereby leading the transition area of the wafer to be controlled between 1.0 and 1.3 micron and leading the resistance rate uniformity in a furnace to be less than 5 percent; besides, the repetitiveness and the reproducibility of the resistance rate and the thickness between furnaces are good; the repetitiveness in the furnace and the transition area of the wafer is good; the uniformity and the consistency of the positive pressure reduction and negative pressure reduction of the schottky diode manufactured by the material are good.

Owner:HEBEI POSHING ELECTRONICS TECH

Atomic hydrogen as a surfactant in production of highly strained InGaAs, InGaAsN, InGaAsNSb, and/or GaAsNSb quantum wells

InactiveUS6858519B2Avoid phase separationSimple materialLaser detailsSemiconductor/solid-state device manufacturingIndiumQuantum well

Atomic hydrogen flux impinging on the surface of a growing layer of III-V compounds during VCSEL processing can prevent three-dimensional growth and related misfit dislocations. Use of hydrogen during semiconductor processing can allow, for example, more indium in InGaAs quantum wells grown on GaAs. Atomic hydrogen use can also promote good quality growth at lower temperatures, which makes nitrogen incorporated in a non-segregated fashion producing better material. Quantum wells and associated barriers layers can be grown to include nitrogen (N), aluminum (Al), antimony (Sb), and / or indium (In) placed within or about a typical GaAs substrate to achieve long wavelength VCSEL performance, e.g., within the 1260 to 1650 nm range.

Owner:II VI DELAWARE INC

Proton conducting membranes for hydrogen production and separation

ActiveUS8845768B2Improve stabilityIncreased hydrogen permeationLayered productsIsotope separationElectronHydrogen production

In one embodiment, a membrane of proton-electron conducting ceramics that is useful for the conversion of a hydrocarbon and steam to hydrogen has a porous support of M′-Sr1-z′M″z′Ce1-x′-y′Zrx′M′″y′O3-δ, Al2O3, mullite, ZrO2, CeO2 or any mixtures thereof where: M′ is Ni, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, W, Zn, Pt, Ru, Rh, Pd, alloys thereof or mixtures thereof; M″ is Ba, Ca, Mg, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, or Yb; M′″ is Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, W, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, or Yb; z′ is 0 to about 0.5; x′ is 0 to about 0.5; y′ is 0 to about 0.5; and x′+y′>0; for example, Ni—SrCe1-x′Zrx′O3-δ, where x′ is about 0.1 to about 0.3. The porous support is coated with a film of a Perovskite-type oxide of the formula SrCe1-x-yZrxMyO3-δ where M is at least one of Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, W, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, and Yb, x is 0 to about 0.15 and y is about 0.1 to about 0.3. By including the Zr and M in the oxide in place of Ce, the stability can be improved while maintaining sufficient hydrogen flux for efficient generation of hydrogen. In this manner, the conversion can be carried out by performing steam methane reforming (SMR) and / or water-gas shift reactions (WGS) at high temperature, where the conversion of CO to CO2 and H2 is driven by the removal of H2 to give high conversions. Methods of preparing the membrane cells and a system for use of the membrane cells to prepare hydrogen are presented. A method for sequestering CO2 by reaction with methane or other hydrocarbon catalyzed by the novel membrane to form a syngas is also presented.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Test device and method for evaluating anti-cracking sensitivity of pipeline steel in acid environment

PendingCN108267396AReliable evaluationComprehensive and reliable resistance to cracking susceptibilityWeather/light/corrosion resistanceWave detectionButt joint

The invention discloses a test device and method for evaluating the anti-cracking sensitivity of pipeline steel in acid environment. The test device comprises an annular pipe section loading assembly,a pipe end sealing assembly and a nondestructive examination assembly, wherein the loading assembly comprises an outer loading assembly and an inner loading assembly; the pipe end sealing assembly comprises a sealing cover and a sealing ring arranged at the two ends of the annular test pipe section; a pipe hole and a sealing element of the pipe hole are arranged on each of the two sealing covers;the nondestructive examination assembly comprises an ultrasonic wave detection instrument and a hydrogen flux measuring instrument. The goal of evaluating the anti-cracking sensitivity of pipeline steel in acid environment on the basis of not damaging the pipe self inner stress and maintaining the original surface state can be realized; more quantized data than that of small-dimension sample evaluation can be obtained; the anti-cracking sensitivity of pipeline steel in acid environment can be more comprehensively and reliably evaluated. In addition, the evaluation on a pipe body, a pipe making welding seam and a butt joint welding seam can be simultaneously completed by one annular tested pipe section.

Owner:CHINA PETROLEUM ENG & CONSTR +1

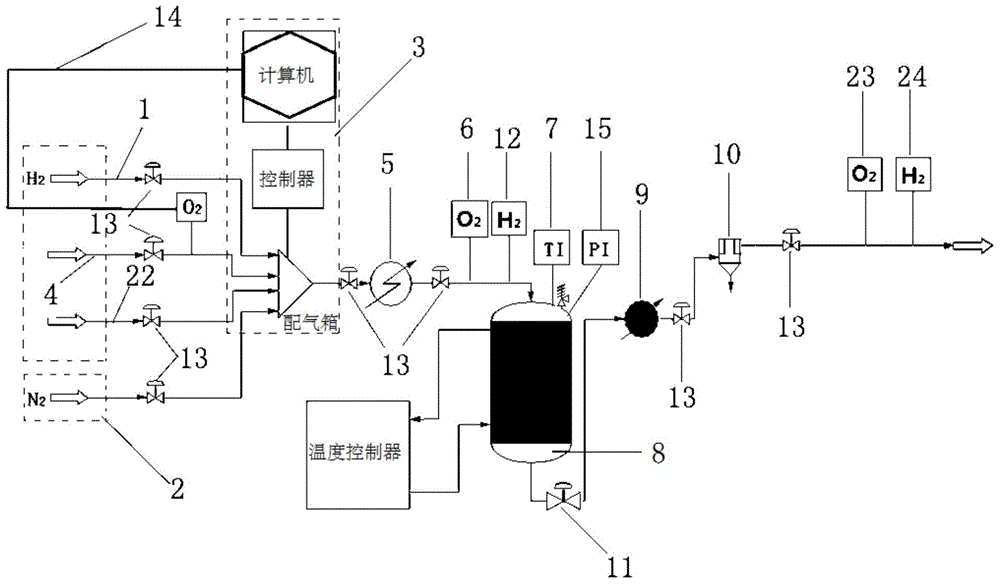

Hydrogenation catalytic deoxidation device and method for testing performance of hydrogenation deoxidation catalyst

ActiveCN105087053AGuaranteed removal rateThe reaction ratio is reasonableMaterial analysisRefining to eliminate hetero atomsTest performanceOxygen content

The invention discloses a method for testing performance of a hydrogenation deoxidation catalyst. According to the method, an online monitoring and interlocking system is arranged on a hydrogenation catalytic deoxidation device to monitor the change of oxygen content in real time, and the hydrogen flux is changed according to the change of the oxygen content, so that the reaction proportion of hydrogen and oxygen is reasonable; and meanwhile, after the reaction is finished, by monitoring the change of the oxygen content, the performance of the hydrogenation deoxidation catalyst can be evaluated.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

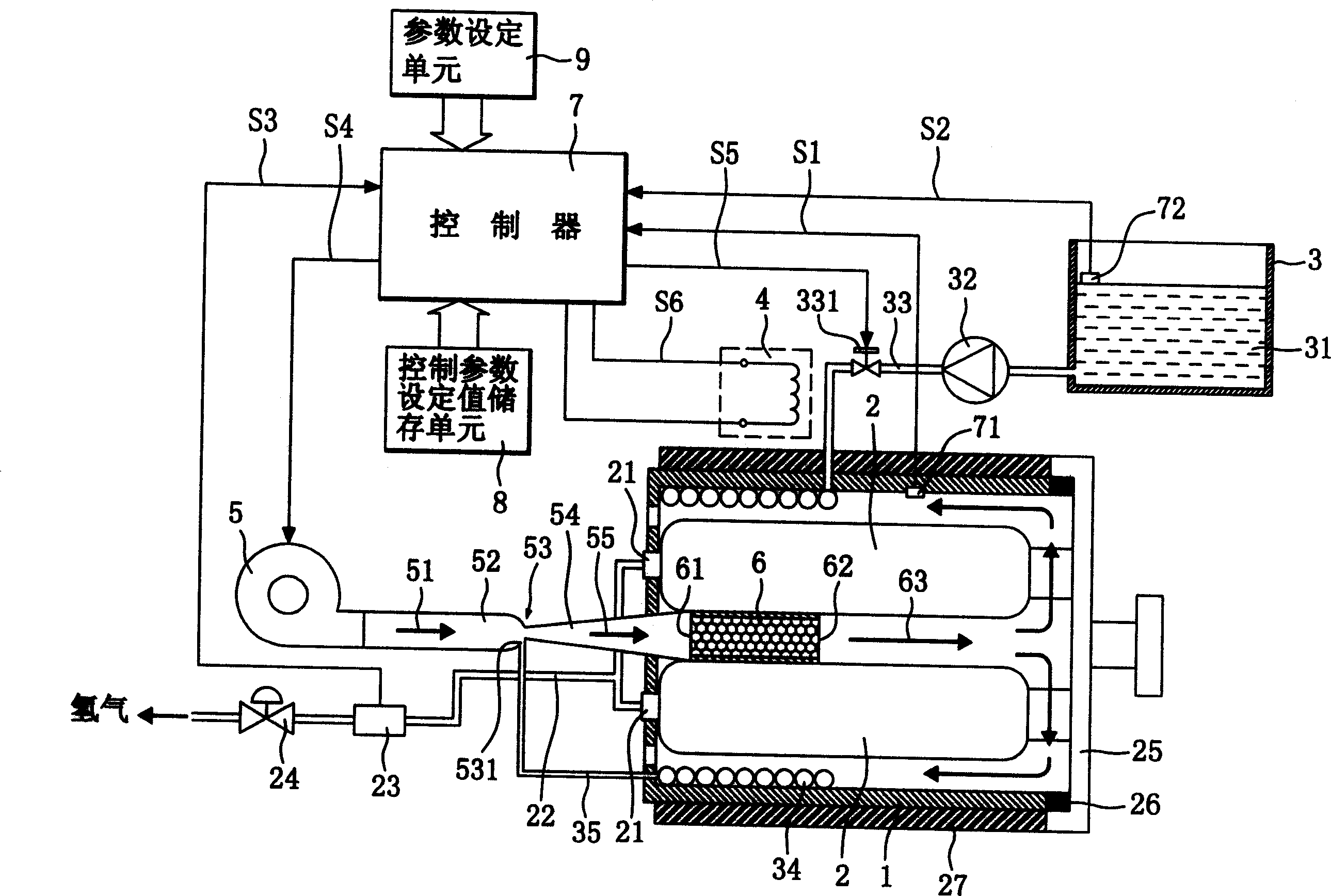

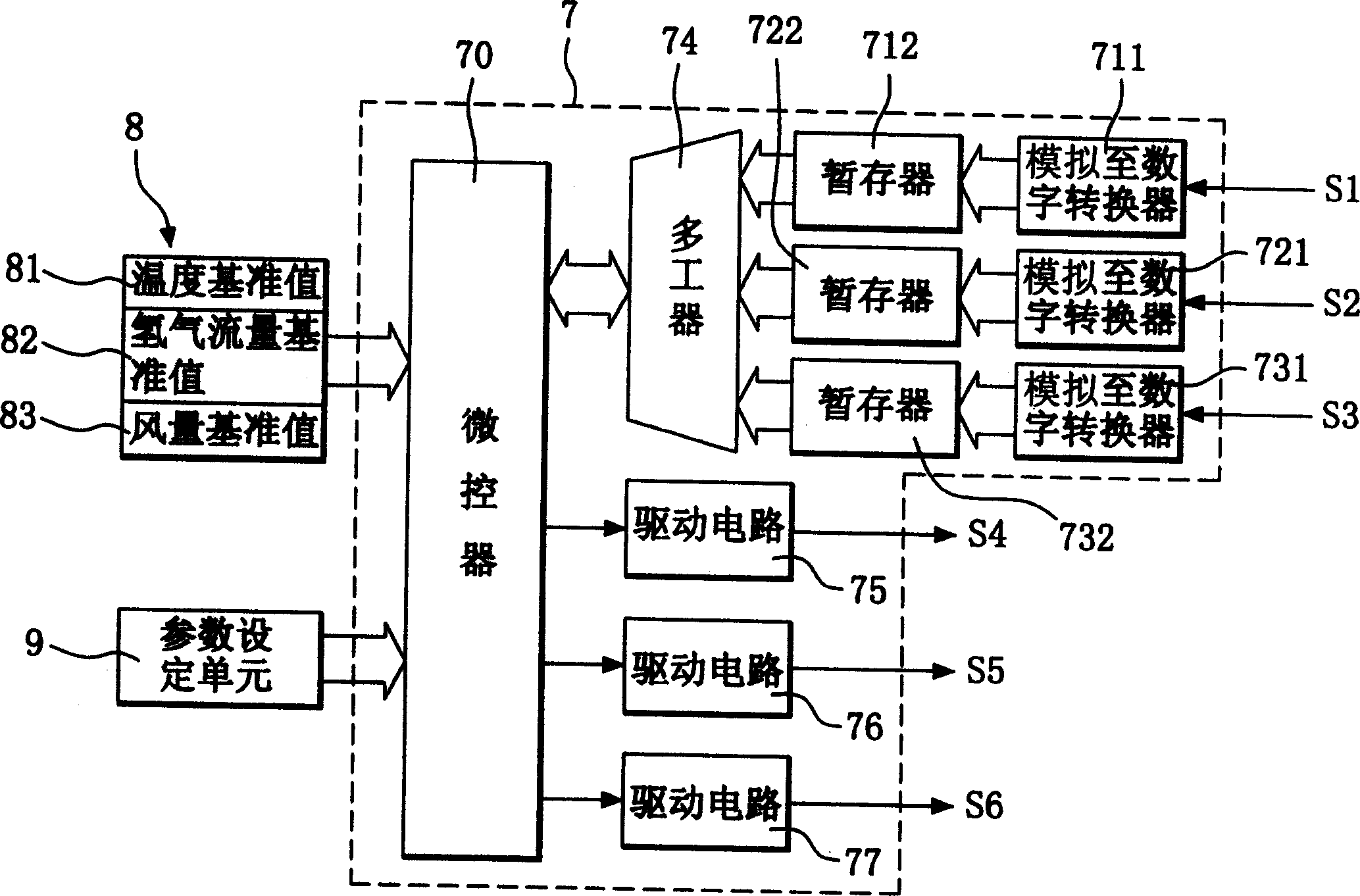

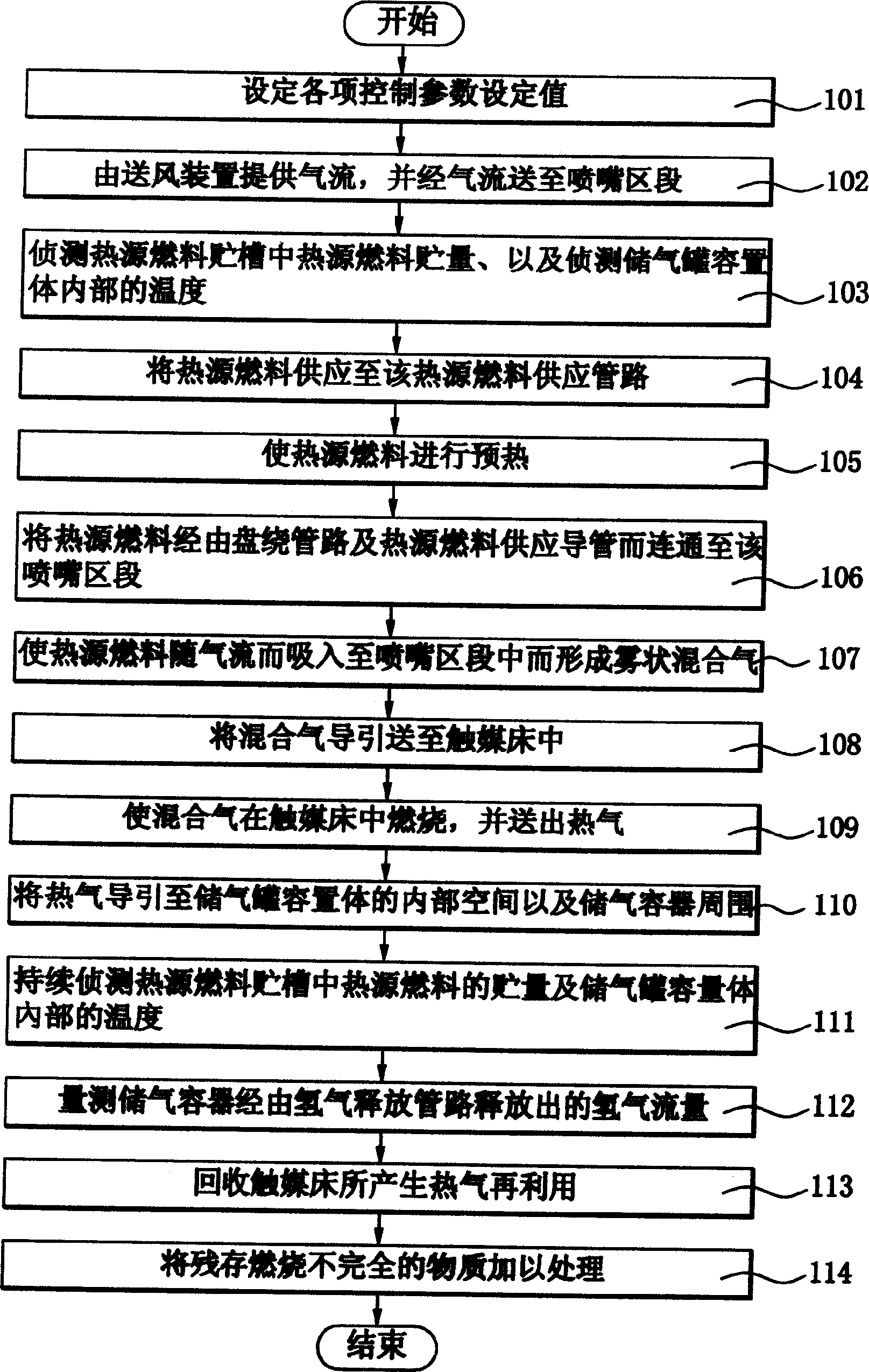

Hydrogen flow control apparatus for hydrogen storage container

InactiveCN1595700AEasy to controlContainer filling methodsGas handling applicationsExecution controlProcess engineering

A hydrogen flux control device for hydrogen storage container, used for control flux of the hydrogen storage container by control the temperature. The invention includes a heating device which is linked to a heat source fuel storage plot by a transmitting pipeline, and a catalyst bed where heat source fuel is sent, for heating the hydrogen storage jar, a purger for sending air to the hydrogen storage jar, and a controller which controls the heating device and purger according to the temperature signal received, by these to control the temperature and hydrogen flux in hydrogen storage container, the controller has linkage a parameter setup unit for designing and storing each control parameter in the working course of controller.

Owner:ASIA PACIFIC FUEL CELL TECH

Process for the biological production of n-butanol with high yield

The present invention provides a method for the biological production of n-butanol at high yield from a fermentable carbon source. In one aspect of the present invention, a process for the conversion of glucose to n-butanol is achieved by the use of a recombinant organism comprising a host C. acetobutylicum transformed i) to eliminate the acetate pathway ii) to eliminate the butyrate pathway iii) to eliminate the lactate pathway and iv) to eliminate the acetone pathway. In another aspect of the present invention, the hydrogen flux is decreased and the reducing power redirected to n-butanol production by interrupting the expression of the hydrogenase gene. Optionally the n-butanol produced can be eliminated during the fermentation by gas striping and further purified by distillation.

Owner:METABOLIC EXPLORER

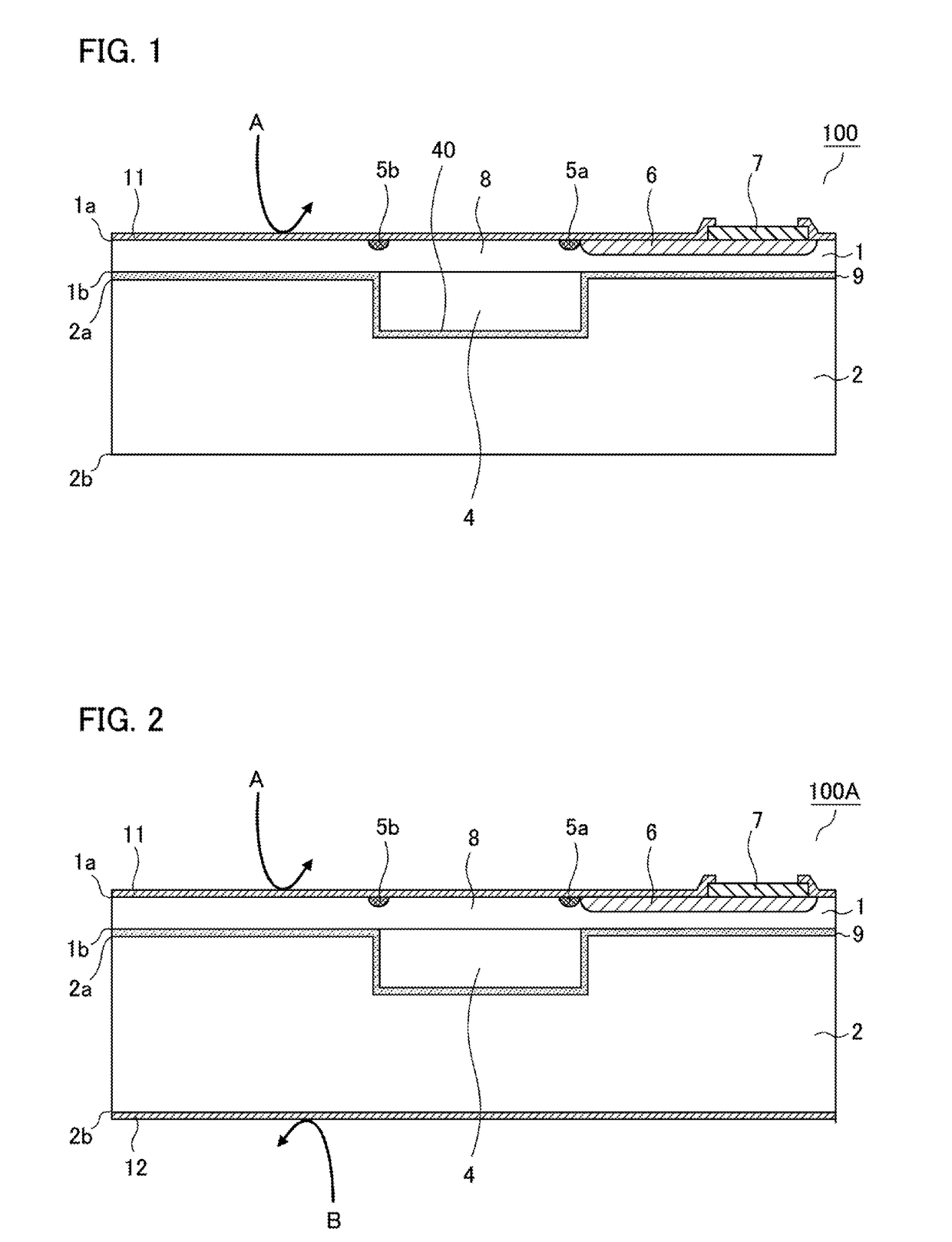

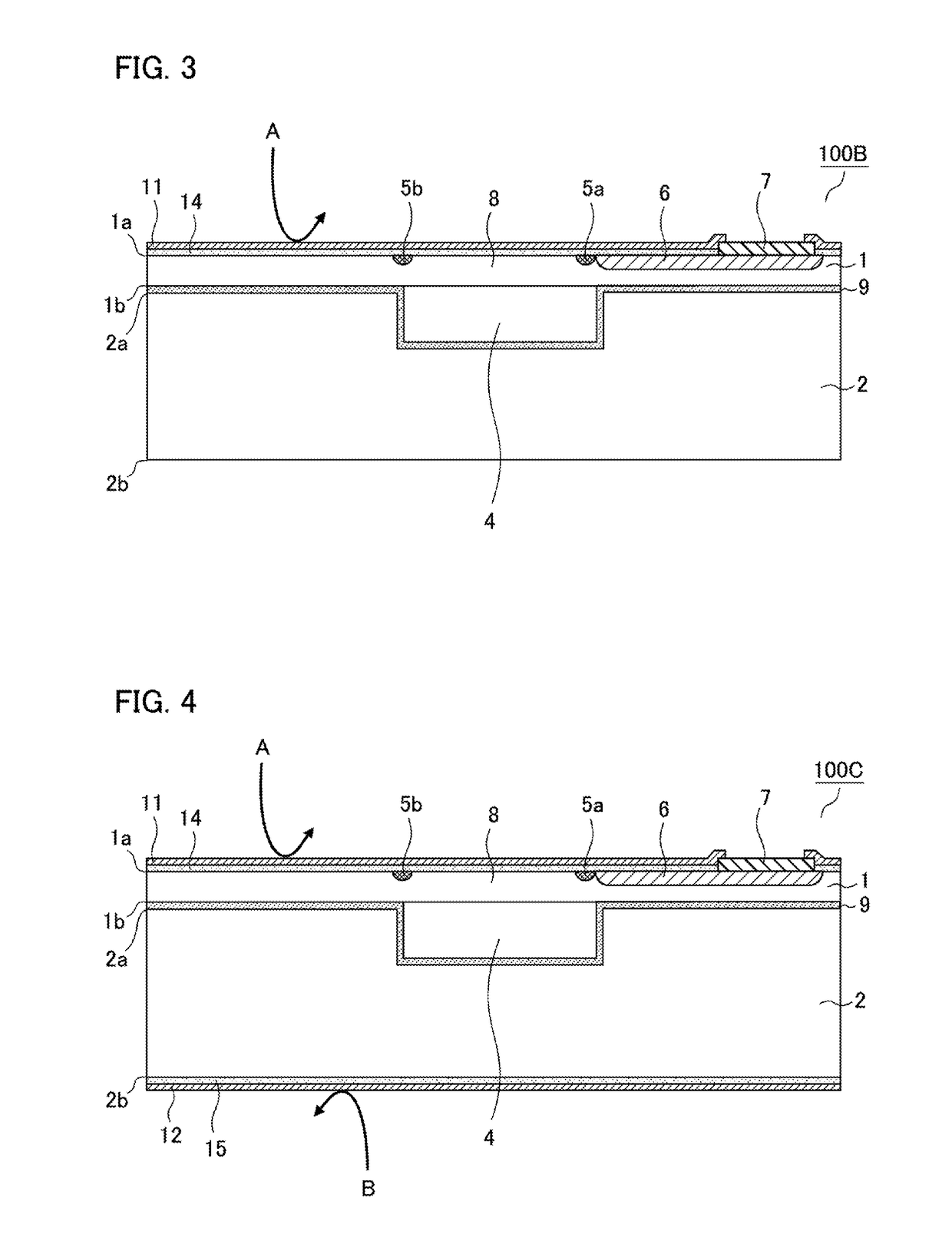

Semiconductor pressure sensor

ActiveUS20170113917A1Improve accuracyPrevent intrusionFluid pressure measurement by electric/magnetic elementsPiezoelectric/electrostrictive devicesHydrogen permeationSemiconductor

In a semiconductor pressure sensor element, a first hydrogen permeation protection film is provided on a principal surface side of a first silicon substrate, and a second hydrogen permeation protection film is provided on a principal surface side of a second silicon substrate. The permeation paths of the hydrogen fluxes shown by the arrows A and B in FIG. 9 are blocked by the films. Also, a trench surrounding a reference pressure chamber is provided, and the first hydrogen permeation protection film and a third hydrogen permeation protection film are joined at the bottom portion of the trench, thereby blocking the permeation path of the hydrogen flux shown by the arrow C in FIG. 9. Furthermore, by providing a hydrogen storage chamber, hydrogen is trapped before the hydrogen reaches the reference pressure chamber.

Owner:MITSUBISHI ELECTRIC CORP

High-strength and ultra-low-hydrogen flux-cored wire

ActiveCN105562958ALow diffusible hydrogen contentHigh strengthWelding/cutting media/materialsSoldering mediaPotassium fluorideYttrium

The invention discloses a high-strength and ultra-low-hydrogen flux-cored wire which is composed of a carbon steel wrapper and inner flux-cored powder. The high-strength and ultra-low-hydrogen flux-cored wire comprises, by weight percentage, 5-15% of nickel powder, 5-10% of ferromanganese powder, 0.5-2.5% of ferromolybdenum powder, 0.5-3.0% of ferrotitanium powder, 5-10% of iron-yttrium powder, 0.5-2.5% of iron-silicon powder, 2-10% of potassium fluoride, 3-8% of feldspar, 0.1-1.5% of quartz, 0.5-2.0% of fluorite, 0.1-1.0% of sodium carbonate, 0.1-1.0% of potassium oxide and the balance iron powder. According to submerged-arc welding weld metal manufactured through the flux-cored wire, the content of diffusible hydrogen is smaller than or equal to 3 ml / 100 g, the tensile strength is larger than or equal to 700 MPa, and the impact toughness at minus 40 DEG C is larger than or equal to 50 J.

Owner:HAINING RUIAO METAL TECH CO LTD

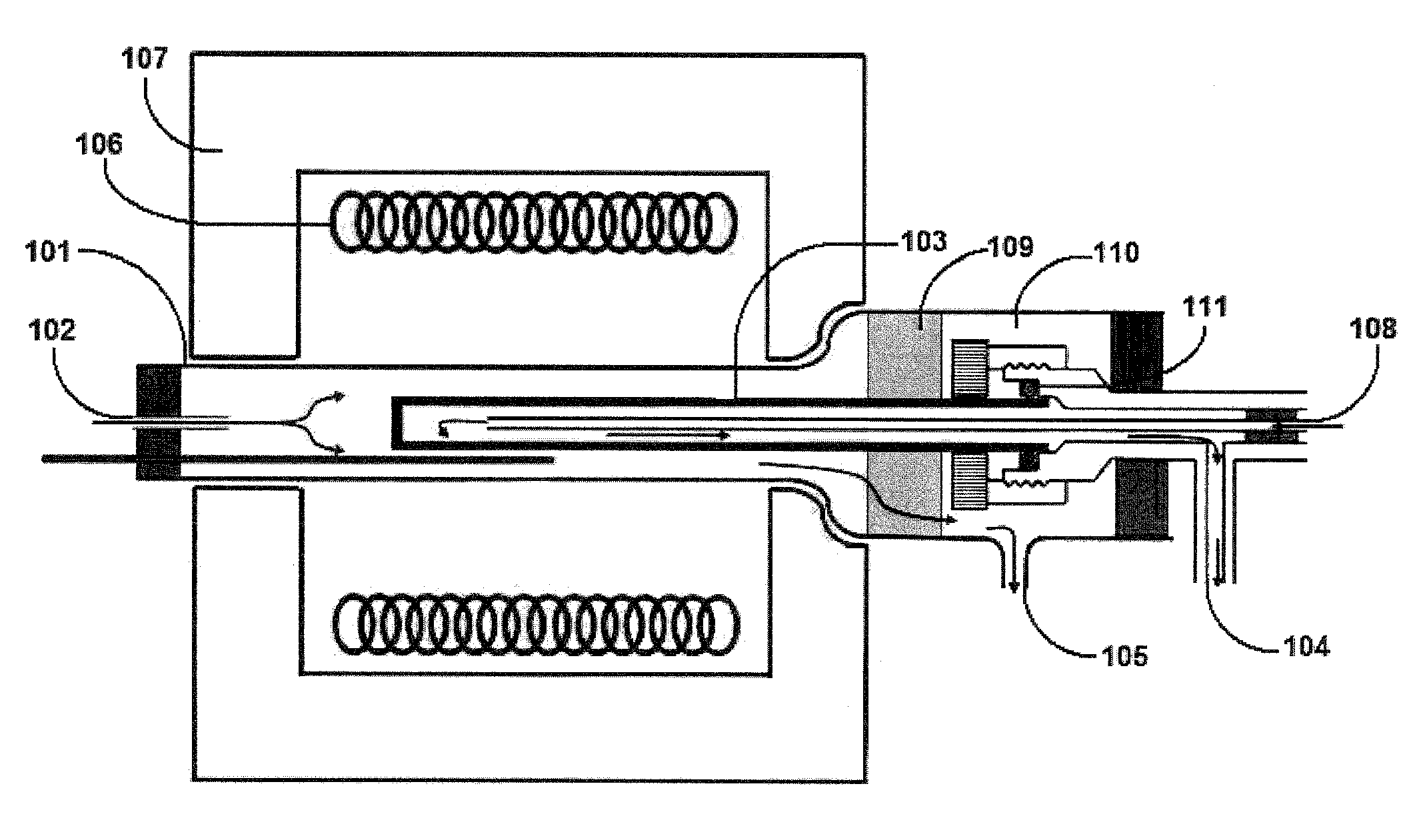

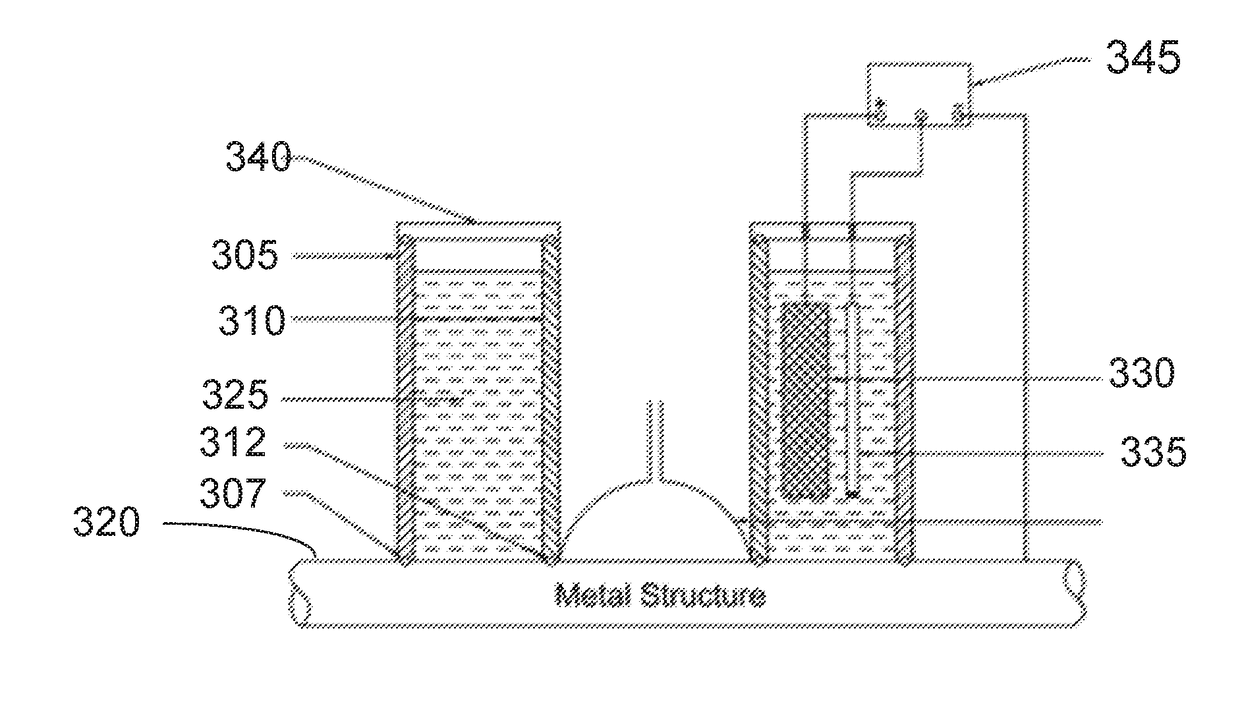

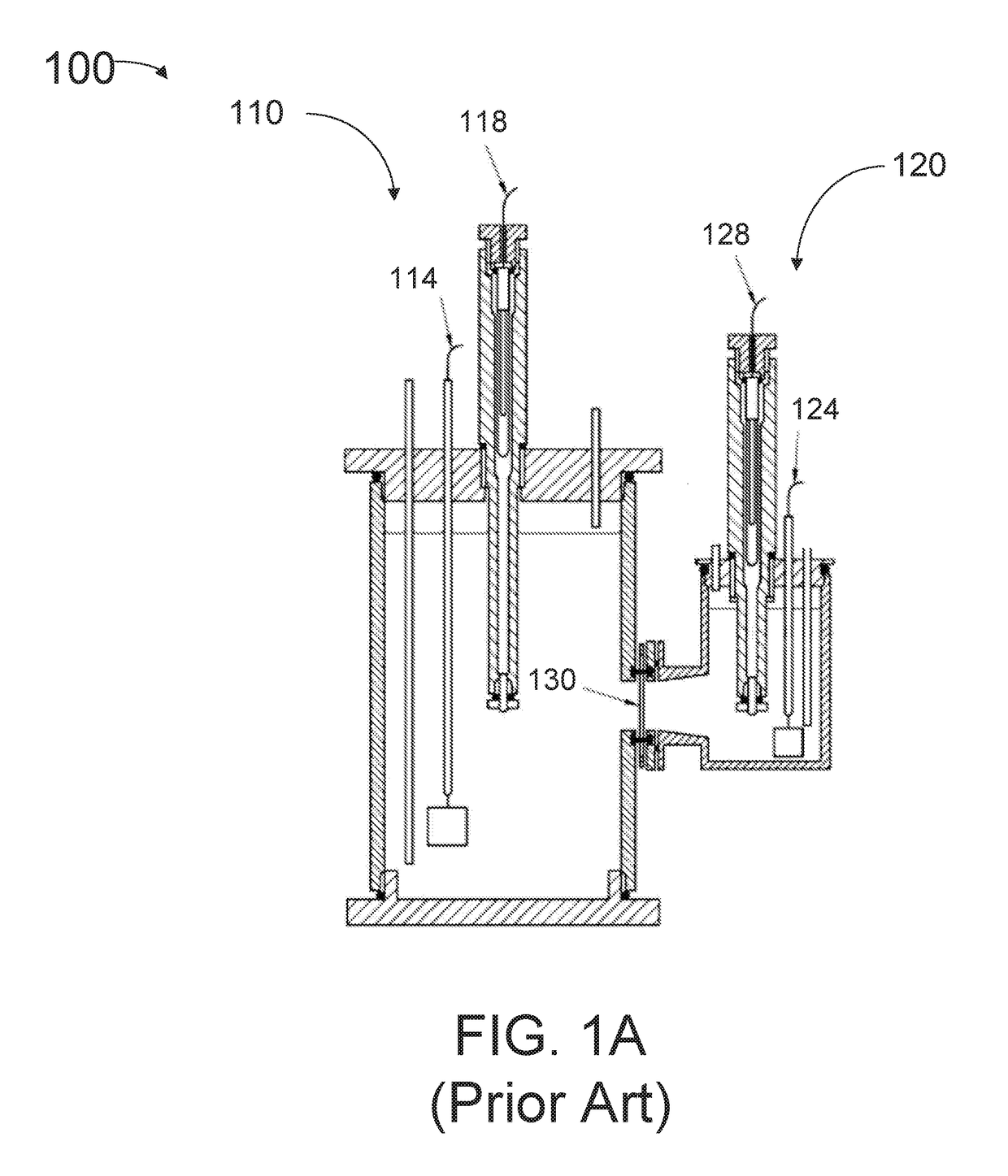

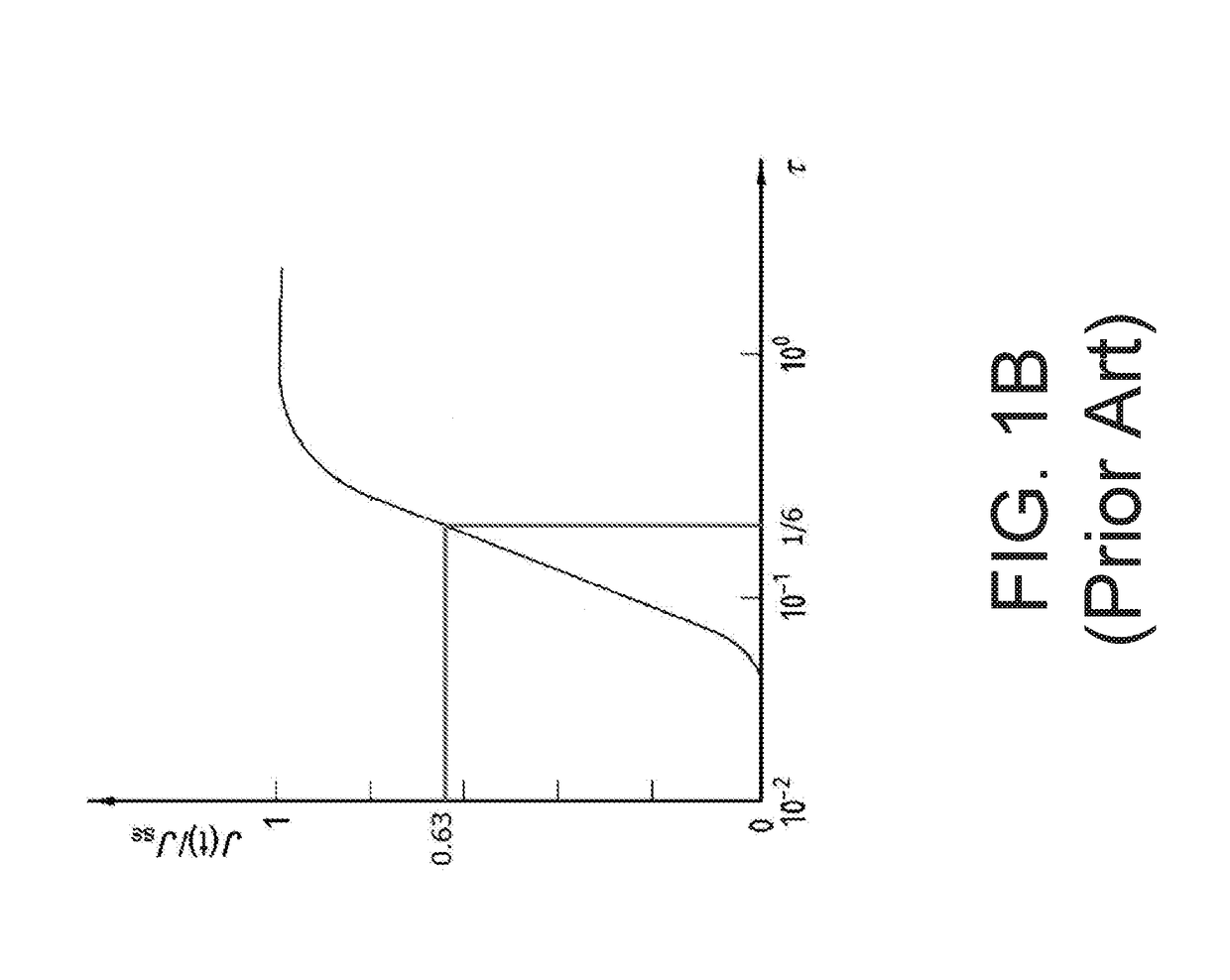

Apparatus and method for the non-destructive measurement of hydrogen diffusivity

ActiveUS20180313779A1Ensure concentricityPrevent leakageFluid pressure measurement using elastically-deformable gaugesMaterial analysis by electric/magnetic meansNon destructiveMetal

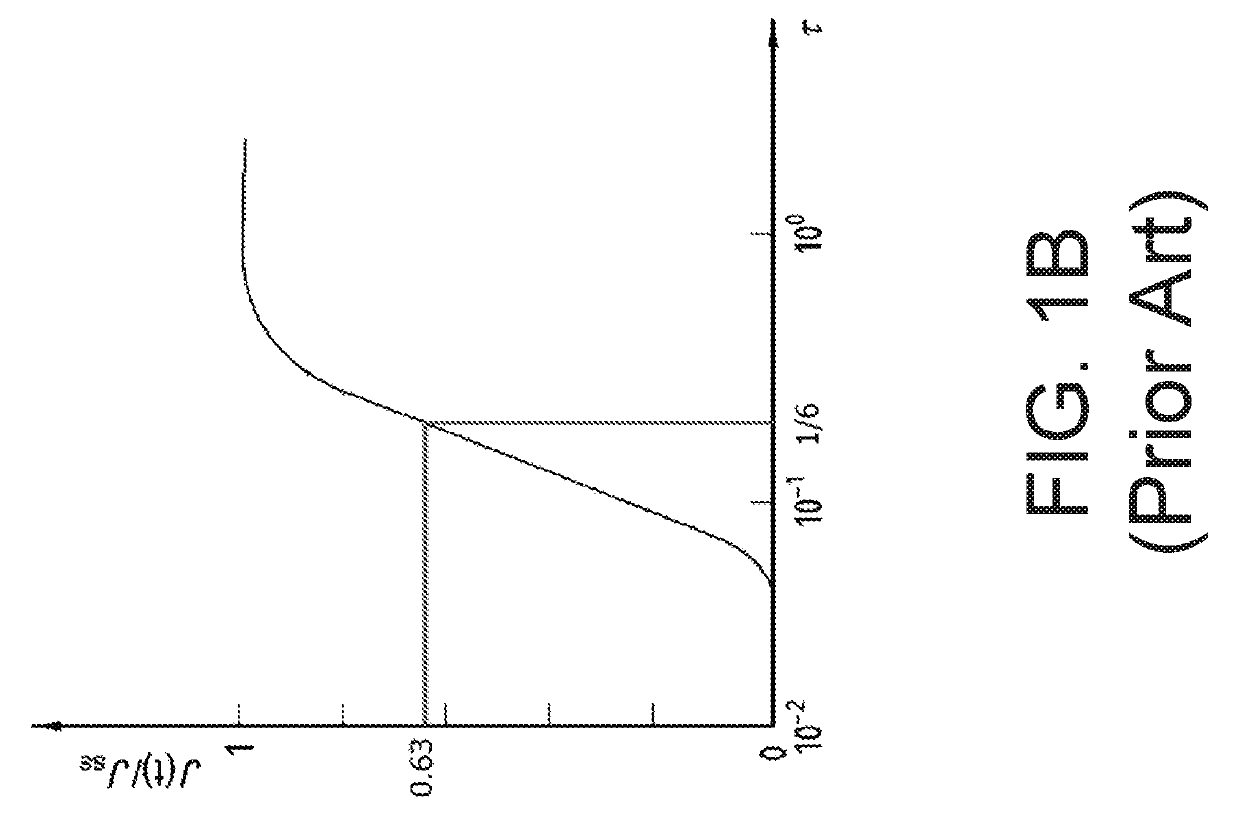

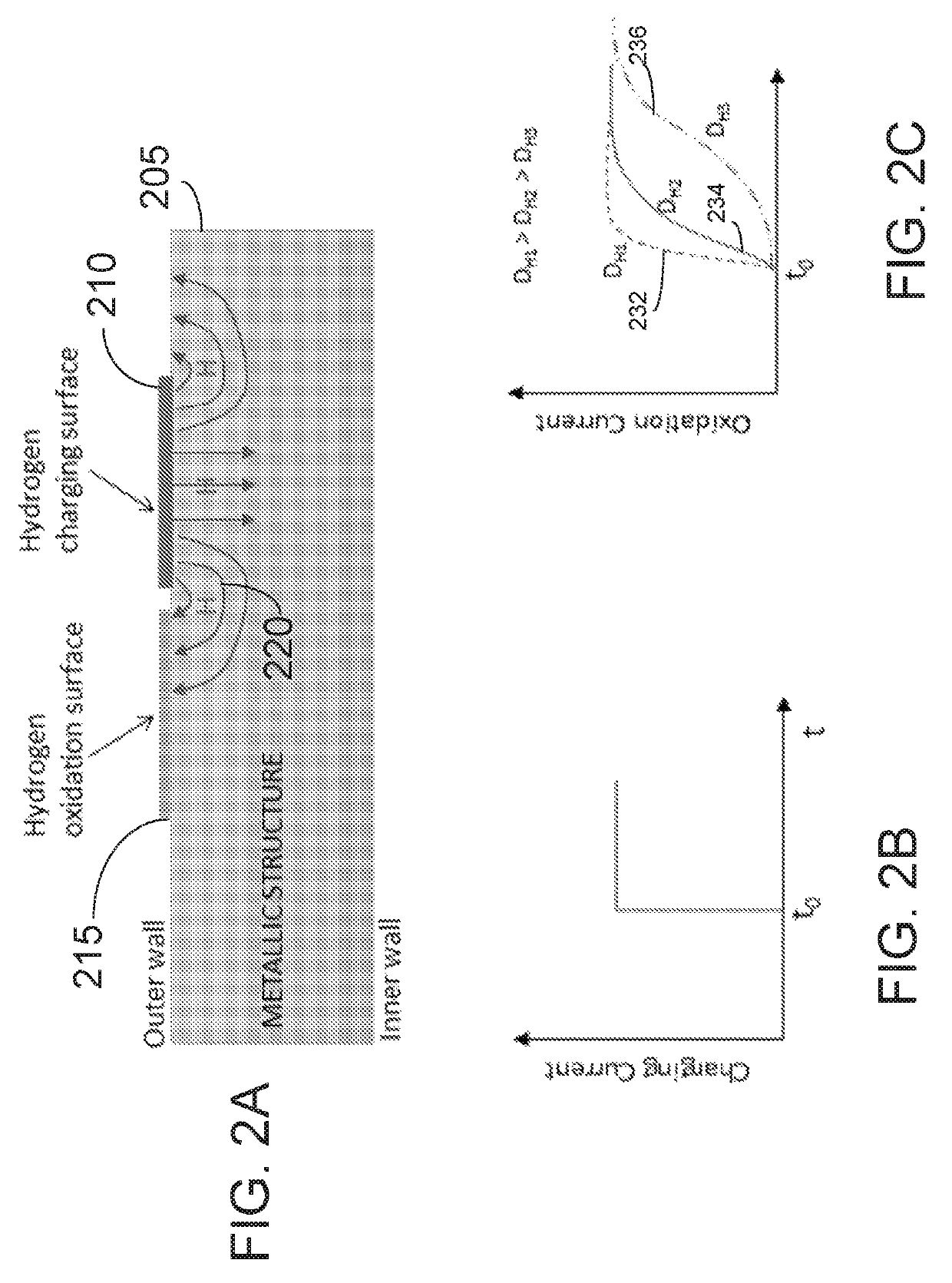

A method of measuring a hydrogen diffusivity of a metal structure is provided. The method includes providing a hydrogen charging surface at a first location on an external surface of the structure, and a hydrogen oxidation surface at a second location adjacent to the first location on the external surface of the structure. A hydrogen flux is generated and directed into the metal surface at the charging surface. At least a portion of the hydrogen flux generated by the charging surface and diverted back toward the surface is detected, and a transient of the diverted hydrogen flux is measured. The hydrogen diffusivity of the metal structure is then determined based on the measured transient.

Owner:SAUDI ARABIAN OIL CO

A fuel cell engine system

ActiveCN103474686BReduce energy consumptionReduce volumeFuel cell auxillariesFuel cell detailsCirculator pumpEngineering

The invention discloses a fuel cell engine system, comprising a fuel cell stack, a distribution assembly, a hydrogen supply unit, an air supply unit, a cooling unit and a heat exchanger, wherein a humidifier of the air supply unit is omitted; the hydrogen supply unit comprises a hydrogen reflux part; the hot end of the heat exchanger is air fluid while the cold end of the heat exchanger is provided with two independent fluids, namely a hydrogen fluid and a cooling cycle fluid; the hot end inlet of the heat exchanger is connected with a vent of an air compressor while the hot end outlet is connected with an air inlet of the fuel cell stack; the two fluid inlets of the cold end of the heat exchange are respectively connected with a control valve outlet of a hydrogen storage tank outlet and a cooling cycle pump outlet; the two fluid outlets of the cold end of the heat exchanger are respectively connected with the fuel cell stack hydrogen inlet and cooling cycle pump inlet. The fuel cell engine system has the beneficial effects that the air cooler and the hydrogen preheater are combined, and hydrogen flux is used for replacing the air side humidifier, thus simplifying the system, reducing the size and weight of the parts, and reducing the system energy consumption.

Owner:SUNRISE POWER CO LTD

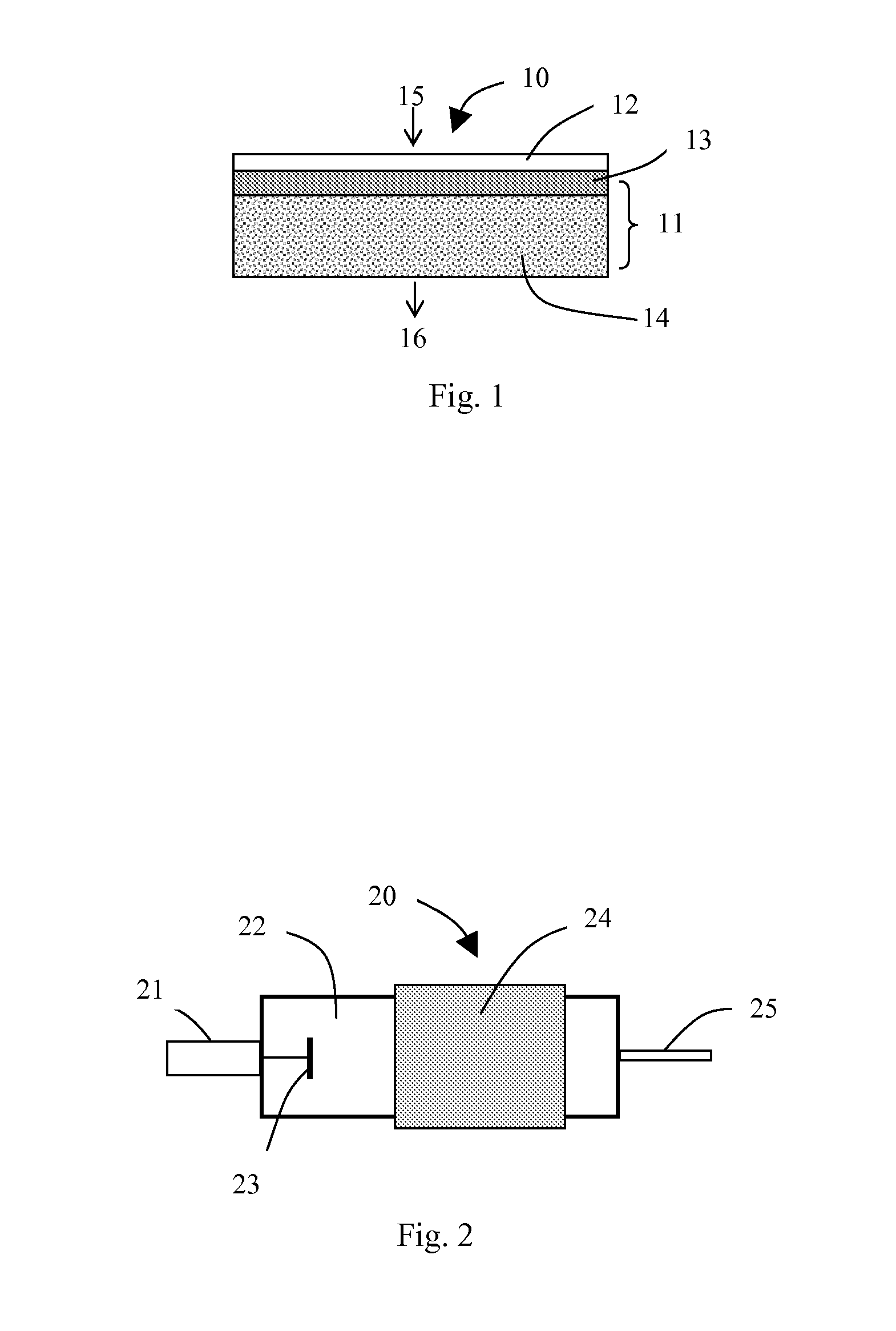

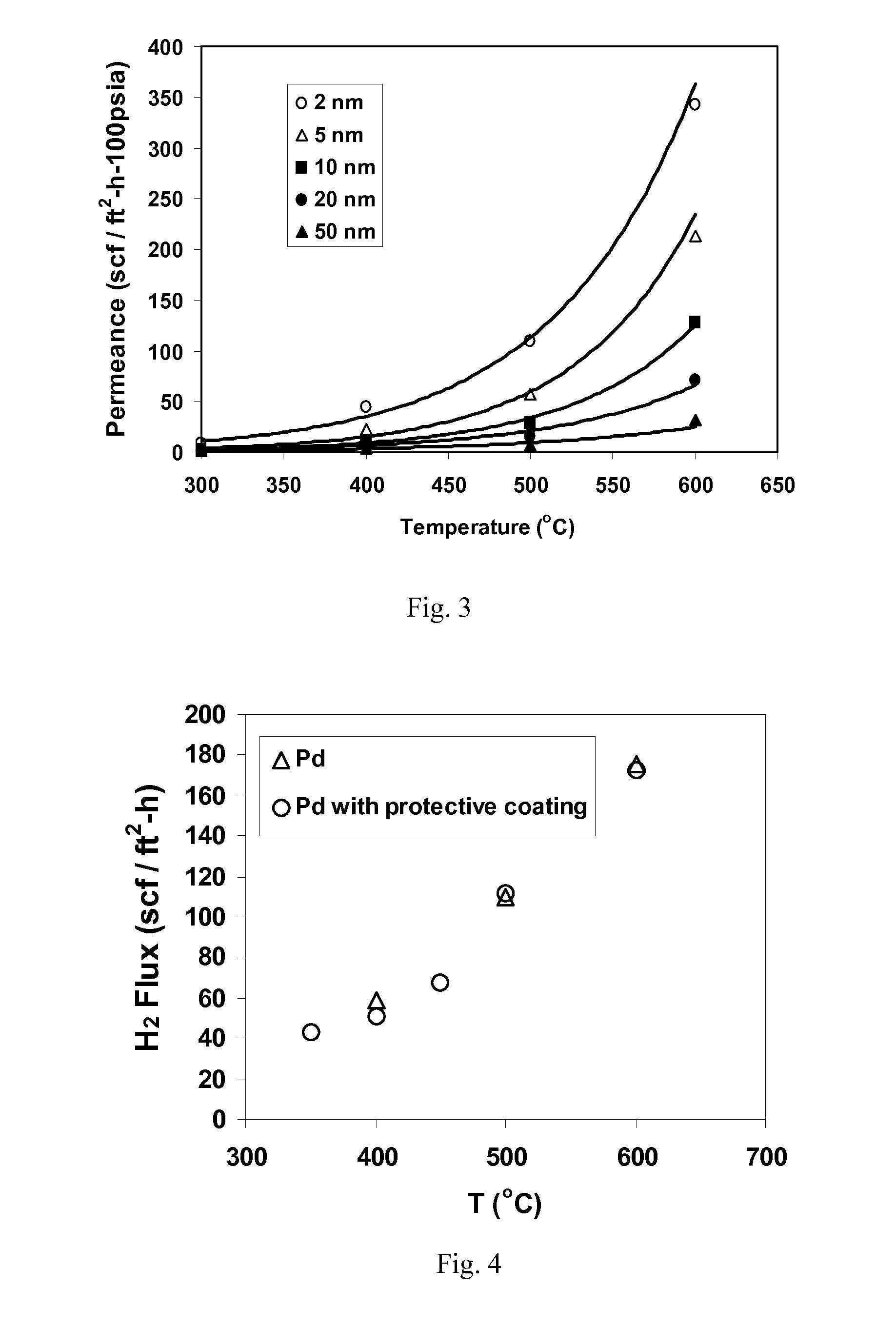

Hydrogen selective protective coating, coated article and method

Hydrogen selective coatings, coated articles and methods for their formation and for hydrogen separation or purification. The coatings are formed by atomic layer deposition of suitable metal oxides with desirable hydrogen activation energy or hydrogen flux, e.g., silicon dioxide, and can be borne on a nonporous, thin-film metal or cermet substrate, e.g., a palladium sheet or layer. The coated substrate may include a porous support for the sheet or layer. The coated article may be used as a purification membrane and the coating can protect the metal layer from contaminants in the gas or process stream from which hydrogen is being purified. In some embodiments, the coated article can provide such protection at elevated temperatures in excess of 300° C.; and in other embodiments, can provide protection at temperatures in excess of 600° C. and even in excess of 800° C.

Owner:T3 SCI

PROCESS FOR THE BIOLOGICAL PRODUCTION OF n-BUTANOL WITH HIGH YIELD

The present invention provides a method for the biological production of n-butanol at high yield from a fermentable carbon source. In one aspect of the present invention, a process for the conversion of glucose to n-butanol is achieved by the use of a recombinant organism comprising a host C. acetobutilicum transformed i) to eliminate the butyrate pathway ii) to eliminate the acetone pathway iii) to eliminate the lactate pathway and iv) to eliminate the acetate pathway. In another aspect of the present invention, the hydrogen flux is decreased and the reducing power redirected to n-butanol production by attenuating the expression of the hydrogenase gene. Optionally the n-butanol produced can be eliminated during the fermentation by gas striping and further purified by distillation.

Owner:METABOLIC EXPLORER

Low-hydrogen flux-cored wire suitable for high-strength steel and preparation method thereof

ActiveCN110340567AImprove performanceStable arc burningWelding/cutting media/materialsSoldering mediaCombustionHydrogen content

The invention relates to a low-hydrogen flux-cored wire suitable for high-strength steel, and belongs to the preparation field of flux-cored wires. The flux-cored wire is formed by a skin and a core,wherein the skin is a nickel strap; and the core is prepared from the components in percentage by mass: 40 to 65 percent of CaF2, 2 to 10 percent of K2ZrF6, 5 to 15 percent of LiF, 7 to 14 percent ofAl, 5 to 10 percent of Mn, 2 to 5 percent of Cr, 5 to 10 percent of Mg, 0.5 to 5 percent of Si, 0.5 to 5 percent of B, 0.5 to 5 percent of RE2O3, 2 to 7 percent of TiO, 2 to 5 percent of CaO, and thebalance Fe. The flux-cored wire prepared through the invention is excellent in processing property and stable in electric arc combustion, the hydrogen content of deposited metal is low, the quality ofthe welded high-strength steel is stable, and a welding performance of the high-strength steel is greatly improved.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

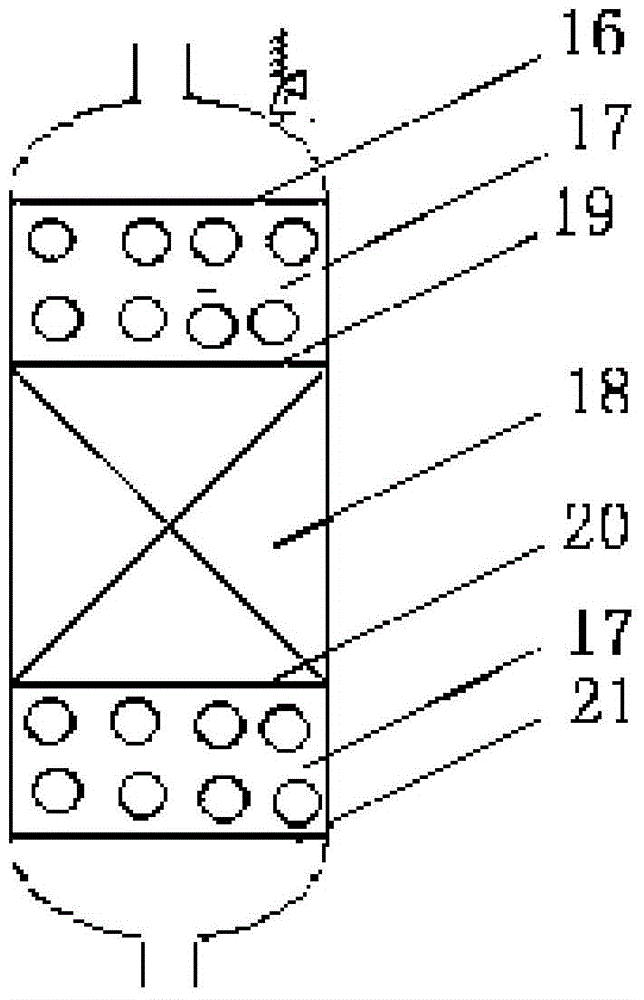

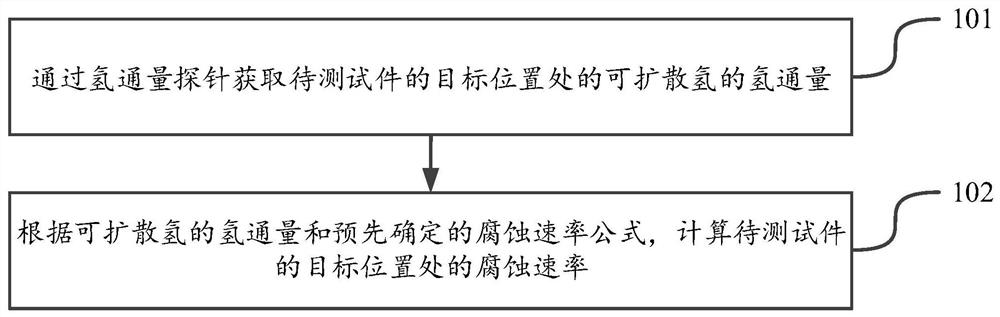

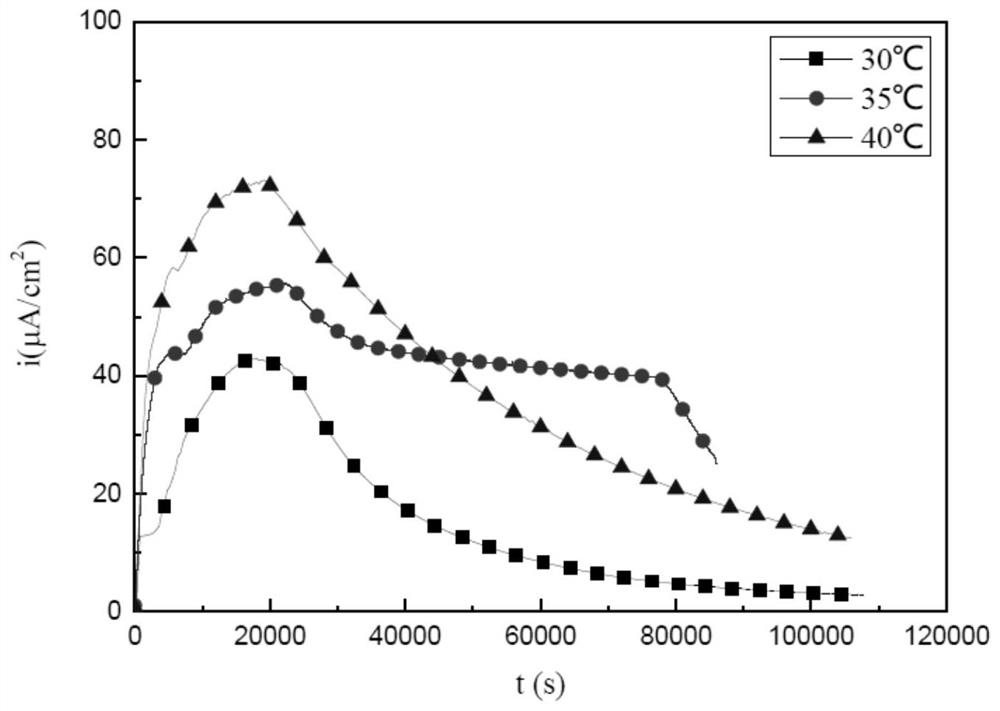

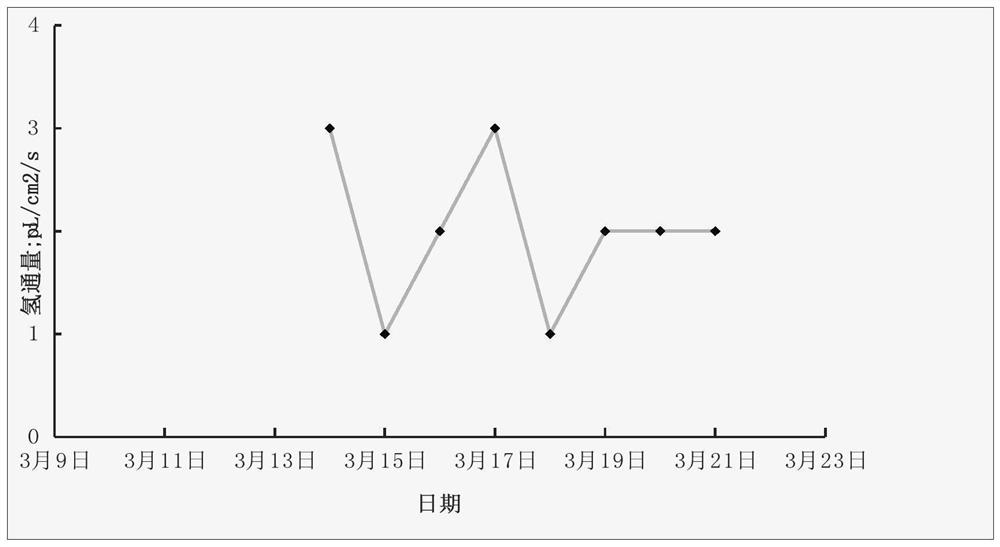

Method for determining corrosion rate and D-S double-electrolytic-tank experimental device

PendingCN114720363AShort timeWeather/light/corrosion resistanceCorrosion monitoringElectrolytic cell

The invention relates to a method for determining a corrosion rate and a D-S double-electrolytic-tank experimental device, and belongs to the technical field of corrosion rate testing. The method comprises the following steps: acquiring the hydrogen flux of diffusible hydrogen at a target position of a test piece to be tested through a hydrogen flux probe; and according to the hydrogen flux of the diffusible hydrogen and a predetermined corrosion rate formula, calculating the corrosion rate of the target position of the test piece to be tested. By adopting the method, the corrosion rate can be determined without using a weight loss method, the method is simple and convenient, and the consumed time is short. Moreover, compared with a weightlessness method, the method does not need to cut a to-be-tested piece for a coupon test, and the method is a nondestructive corrosion monitoring method.

Owner:PETROCHINA CO LTD

Loading device and loading mode for use in measurement of hydrogen diffusion in stress field

InactiveCN101706409BEffective assessmentReduce biasWeather/light/corrosion resistanceDynamic fieldEngineering

The invention relates to a loading device and a loading mode for use in the measurement of hydrogen diffusion in a stress field. In the loading device and the loading mode, a loading frame and a loading strip apply a load 1 and / or an axially loading platform applies a load 2 and a hydrogen permeation double electrolytic cell is adopted at the same time so as to realize the random change of a dynamic field in the direction of hydrogen permeation in a thin film within a certain range, namely the change of the size, direction and gradient of the stress field to change conditions for hydrogen diffusion and simulate the conditions of hydrogen diffusion in an actual material. The loading device and the loading mode are widely used in the measurement of the metal hydrogen flux and hydrogen diffusion coefficient of a specified stress field, so an advanced technical means is provided for testing the hydrogen corrosion, hydrogen permeation and hydrogen brittleness sensibility of steel and titanium alloy and other materials used in petroleum and natural gas drilling and transmission equipment, hydrogenation reactors, oil and gas transmission equipment, marine fixed structures, submerged pipelines and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

A low-hydrogen flux-cored welding wire suitable for high-strength steel and its preparation method

ActiveCN110340567BImprove performanceStable arc burningWelding/cutting media/materialsSoldering mediaHydrogen contentMetal

The invention relates to a low-hydrogen flux-cored wire suitable for high-strength steel, and belongs to the preparation field of flux-cored wires. The flux-cored wire is formed by a skin and a core,wherein the skin is a nickel strap; and the core is prepared from the components in percentage by mass: 40 to 65 percent of CaF2, 2 to 10 percent of K2ZrF6, 5 to 15 percent of LiF, 7 to 14 percent ofAl, 5 to 10 percent of Mn, 2 to 5 percent of Cr, 5 to 10 percent of Mg, 0.5 to 5 percent of Si, 0.5 to 5 percent of B, 0.5 to 5 percent of RE2O3, 2 to 7 percent of TiO, 2 to 5 percent of CaO, and thebalance Fe. The flux-cored wire prepared through the invention is excellent in processing property and stable in electric arc combustion, the hydrogen content of deposited metal is low, the quality ofthe welded high-strength steel is stable, and a welding performance of the high-strength steel is greatly improved.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN100494322CStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

Apparatus and method for the non-destructive measurement of hydrogen diffusivity

ActiveUS10436741B2Fluid pressure measurement using elastically-deformable gaugesMaterial analysis by electric/magnetic meansNon destructiveMetal

A method of measuring a hydrogen diffusivity of a metal structure is provided. The method includes providing a hydrogen charging surface at a first location on an external surface of the structure, and a hydrogen oxidation surface at a second location adjacent to the first location on the external surface of the structure. A hydrogen flux is generated and directed into the metal surface at the charging surface. At least a portion of the hydrogen flux generated by the charging surface and diverted back toward the surface is detected, and a transient of the diverted hydrogen flux is measured. The hydrogen diffusivity of the metal structure is then determined based on the measured transient.

Owner:SAUDI ARABIAN OIL CO

A kind of production method of ultra-low hydrogen flux-cored welding wire

ActiveCN111347194BImprove rust resistanceGood wire feeding performanceWelding/cutting media/materialsSoldering mediaRoll formingFlux-cored arc welding

The invention provides a production method of ultra-low hydrogen flux-cored welding wire, which sequentially includes the processes of powder filling, rolling forming, wire thinning, annealing, coating drawing, and layer winding; wherein, in the annealing process, the heating temperature is 500-600 ℃; in the annealing device, the running speed of the welding wire is less than or equal to 8m / s, the actual length of the heating section is 800-1000mm, and the heating current is less than or equal to 300A. After passing through the water cooling tank in the device, the welding wire is cooled. After cooling for 2-5 seconds, Lower to 80-150°C; the coating drawing process is carried out in the coating drawing die, which contains hydrogen-free anti-rust oil, and the temperature of the anti-rust oil is 60-80°C. The production method described in the invention has flexible and controllable technology and strong adaptability, can produce ultra-low hydrogen flux-cored welding wires of various types and specifications, and has continuous production process and high efficiency.

Owner:TIANJIN YONGCHANG WELDING WIRES

Anti-corrosion detection technology for petroleum mechanical device

InactiveCN109211758AExtended service lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationUltrasonic thickness measurementThinning

The invention discloses an anti-corrosion detection technology for a petroleum mechanical device. The corrosion degree of the mechanical device is reduced through application of technical means, global thinning is performed on a globally corroded device, and global processing of the device is performed through modes of visual inspection or ultrasonic thickness measurement etc.; local thinning is performed on a locally corroded device, local corrosion phenomena usually comprise crevice corrosion and pitting corrosion, and the corrosion can be effectively processed through potential detection orfluorescent powder detection; the petroleum mechanical device also has a phenomenon of sensitization or hydrogen embrittlement which can be detected through a sampling analysis, and conventional monitoring equipment comprises hydrogen flux measurement and eddy-current test devices; and most corrosion problems in the device are stripping and blistering, and the detection efficiency can be improvedby employing modes of radiographic testing and ultrasonic angle beam testing etc. Through the above technical scheme, a certain assistance effect for staff can be produced during detection.

Owner:久裕电子科技(江苏)有限公司

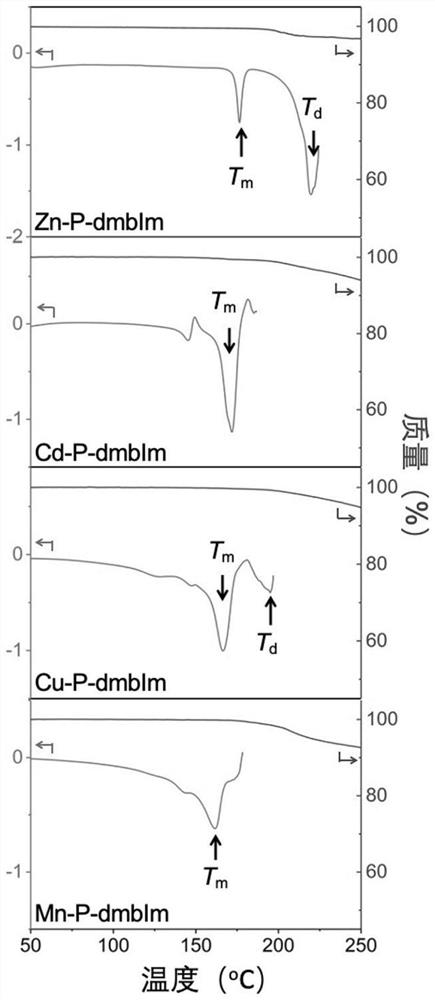

A class of glassy MOF membrane material with hydrogen separation properties and preparation method thereof

A class of glassy MOF membrane materials with hydrogen separation properties of the present invention is obtained by pressing the obtained MOFs powder material into tablets-melting-cooling or hot pressing on a substrate to prepare a glassy MOF with hydrogen separation properties The membrane material method is characterized in that: the steps are as follows: MOFs powder material preparation method: mix the materials in 2 or 3, add ethanol to grind, wash and dry the solid to obtain the target product, this kind of glassy MOFs membrane material It is synthesized by melting-cooling method for MOFs materials with glass transition behavior. This method is universal, easy to operate, low in raw material cost, large-scale processability, and different selectivities can be obtained by adjusting different metal salts The separation membrane material, the prepared glass MOF membrane H 2 / CO 2 The highest separation ratio can reach 92.7, and it has a hydrogen flux of 230.4 Barrer.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of ultra-low hydrogen ceramic flux for chromium-molybdenum heat-resistant steel and its preparation method

ActiveCN103934594BLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

Ultralow hydrogen ceramic welding flux for chrome molybdenum heat resistant steel comprises the following components, by mass percent, 28%-35% of MgO, 6%-15% of CaO, 17%-22% of CaF2, 13%-20% of Al2O3, 5%-10% of SiO2, 1%-5% of K2O + NaO, 0.5%-3.5% of ferromanganese, 0.5%-2% of ferrosilicon, and 6%-8% of MgCO3. The ultralow hydrogen ceramic welding flux for the chrome molybdenum heat resistant steel contains magnesia, fluoride, silicate, carbonate, the ferromanganese and the ferrosilicon serving as reducing agents and quartz which improves slag detachability and appearance of welding seams. When the ultralow hydrogen ceramic welding flux for the chrome molybdenum heat resistant steel is used for welding, the electric arc is stable, the slag detachability in the welding seams is good, the appearance of the welding seams is attractive, and the surfaces of the welding seams are free of cracks, air holes, indentations and other welding defects.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com