Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Ensure concentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

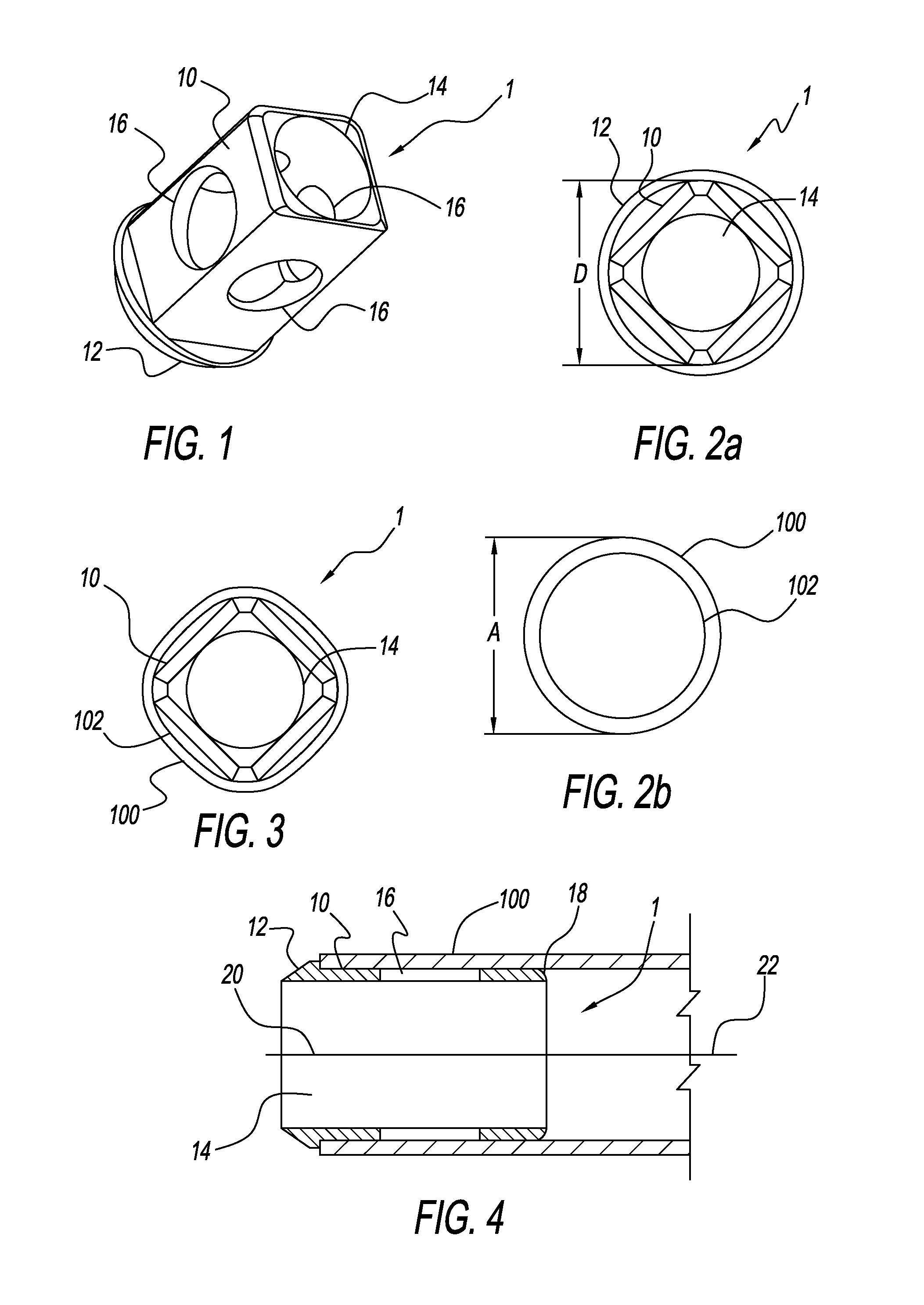

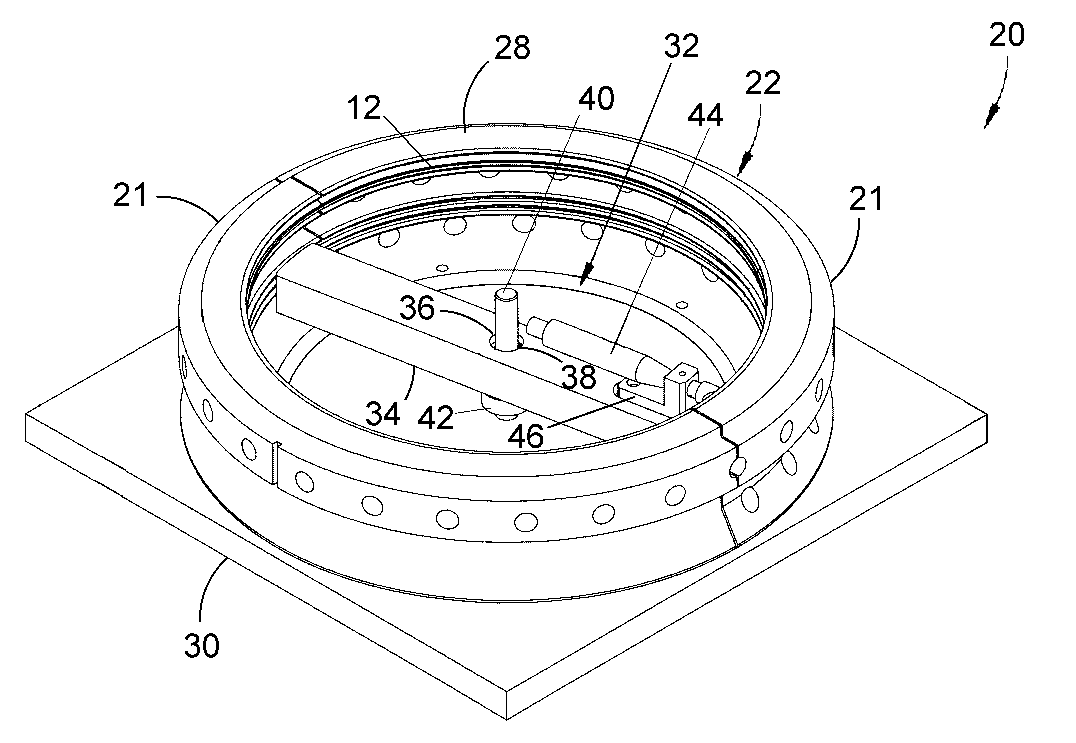

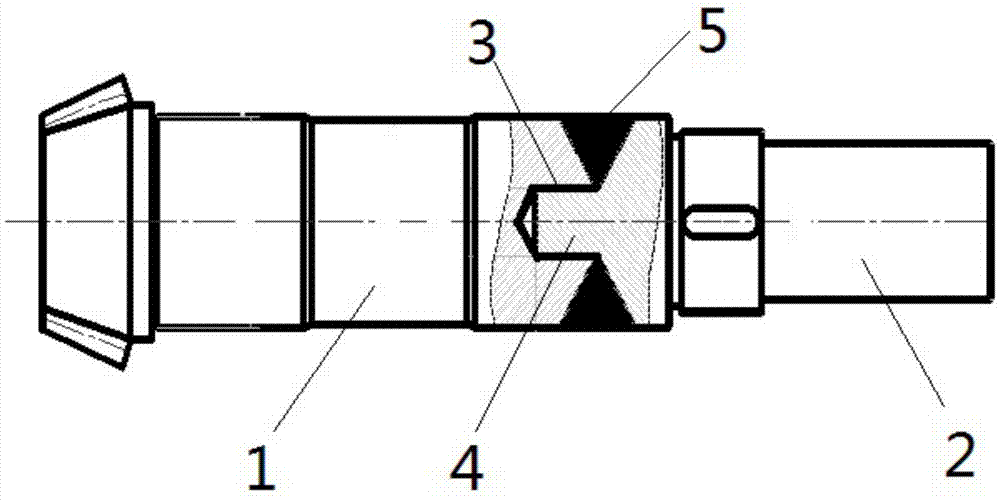

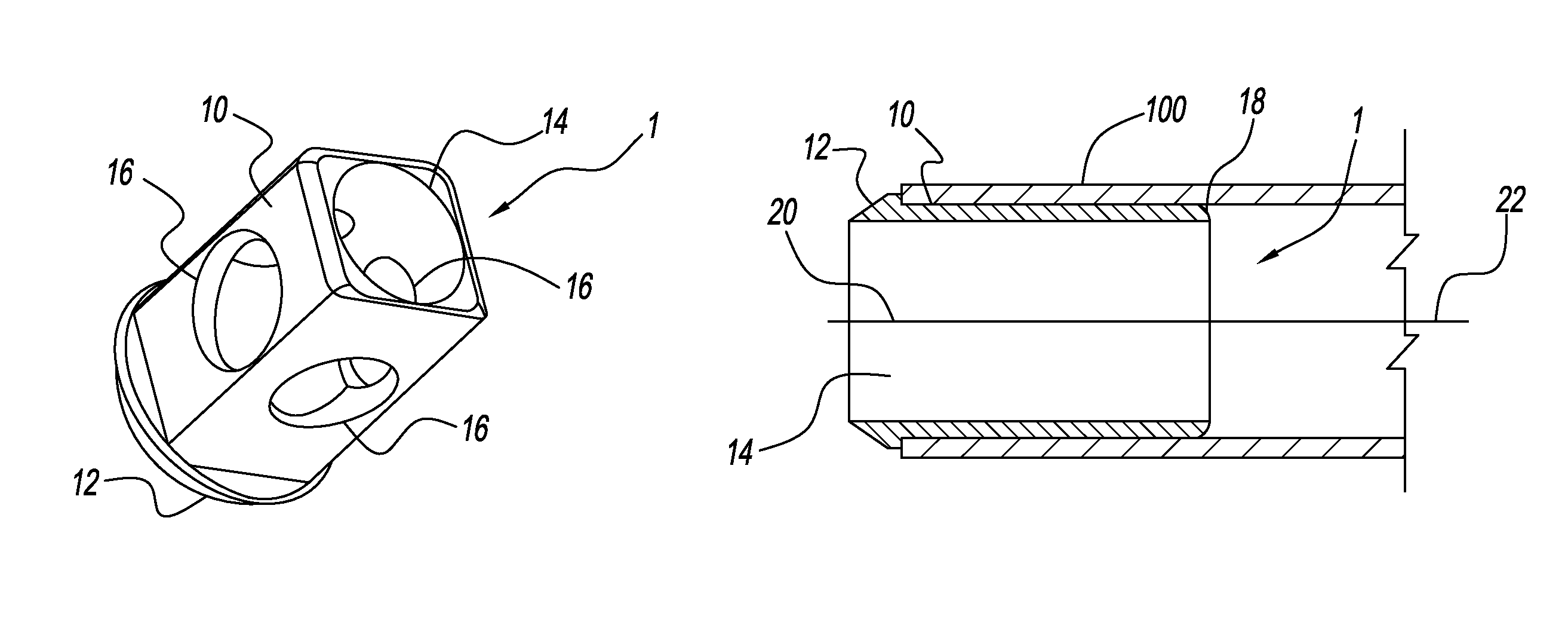

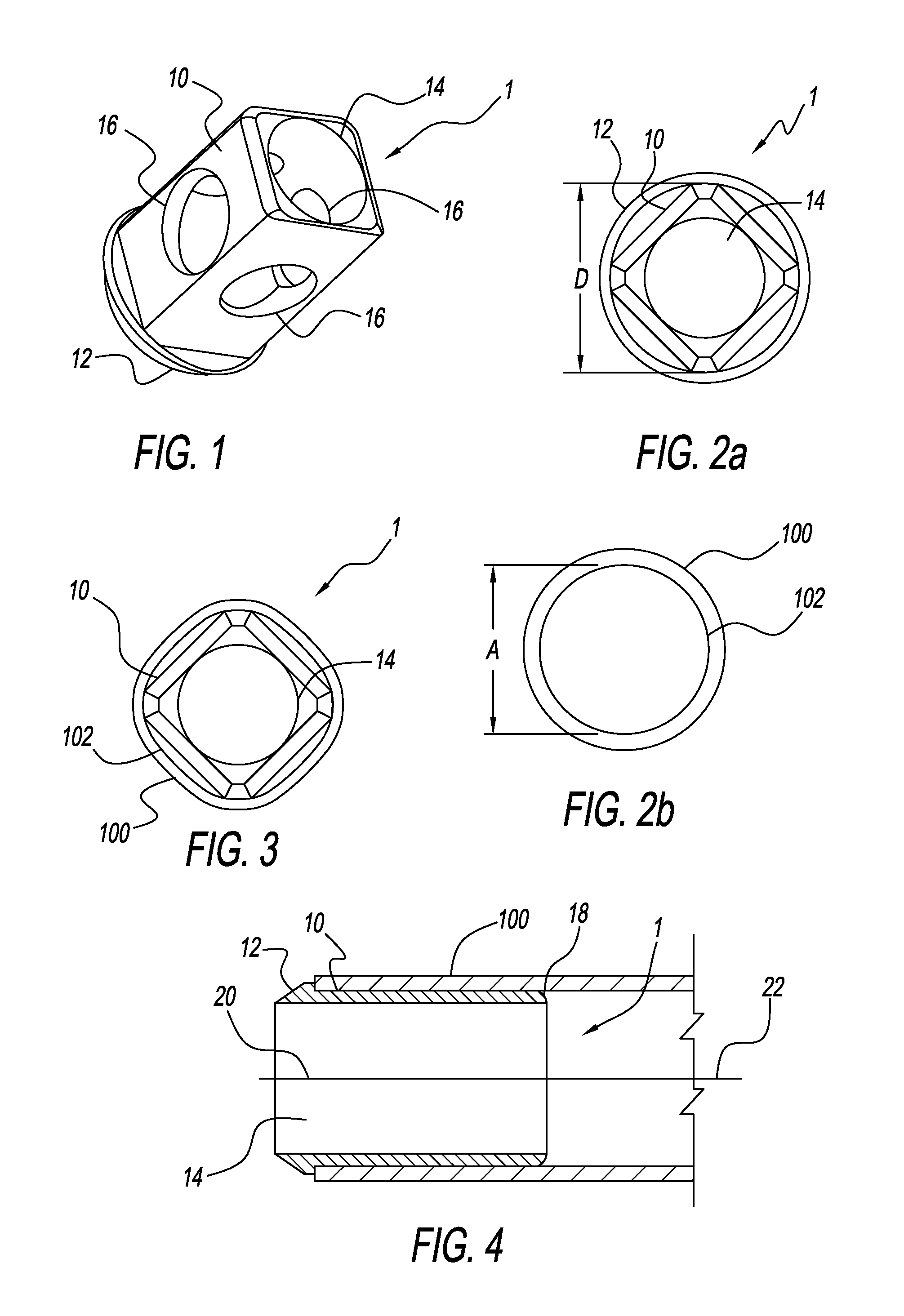

Nock bushing

A improved nock bushing preferably includes a non-round body and a stop flange. The non-round body preferably has a square shape. A nock hole is formed through at least substantially all of a length of the non-round body to receive a projection from an arrow nock. A plurality of lightening openings are preferably formed through the non-round body. The stop flange extends from one end of the non-round body. A distance across the largest cross-section dimension of the non-round body is preferably greater than a diameter of a bushing hole in an arrow shaft. In use, the non-round body is inserted into a nock end of an arrow shaft, which flexes the nock end. The arrow shaft will want to return back to its original round shape and thus applies force to an outer surface of the non-round body.

Owner:HUANG DORGE O

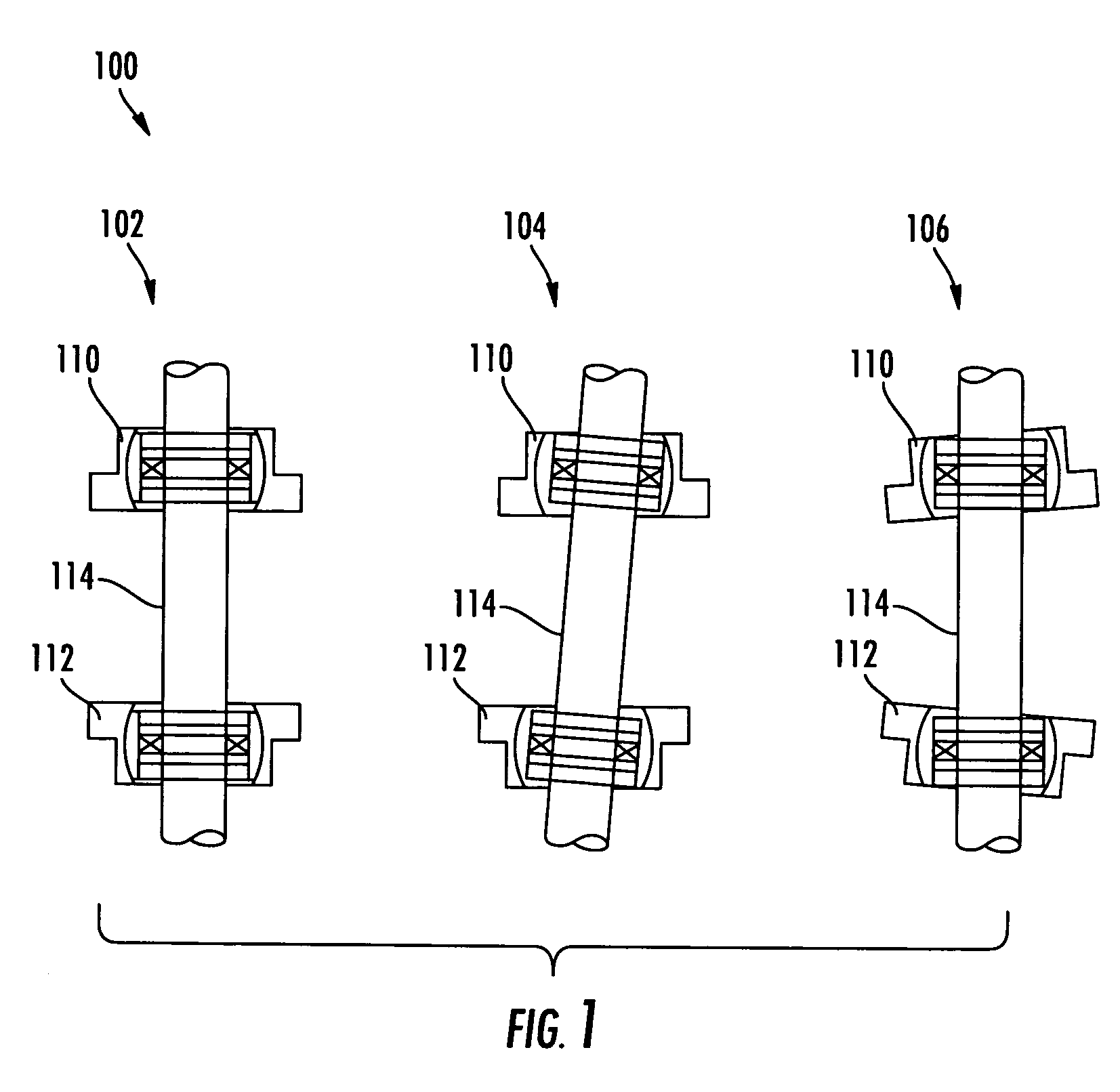

Self aligning bearing and seal assembly

ActiveUS20100135606A1Reduce frictionExtended seal lifeBall bearingsSliding contact bearingsEngineeringMechanical engineering

A self aligning bearing and seal assembly including a bearing housing operable to mount to a surface, a bearing unit seated within the bearing housing and having an outer race, an inner race, and at least one ball intermediate the outer and inner race. The self aligning bearing and seal assembly also includes a pivot assembly having a shaft sleeve operable for receiving and maintaining a rotatable shaft and being disposed in the bearing housing and in operational contact with the inner race of the bearing unit. The pivot assembly allows for a degree of angular misalignment between the surface and the shaft greater than three degrees.

Owner:RELADYNE RELIABILITY SERVICES INC

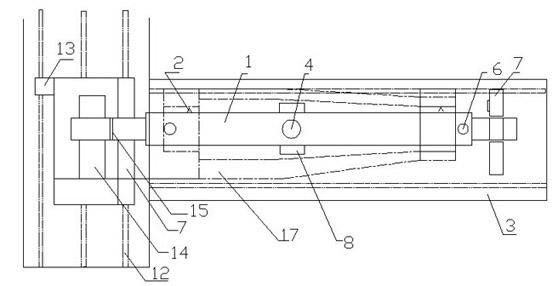

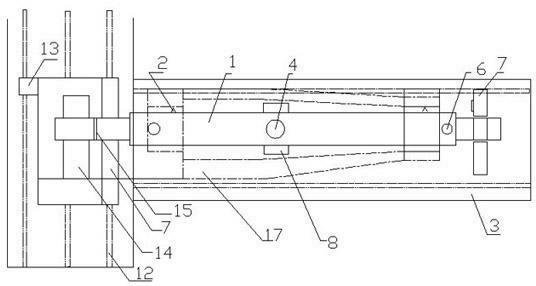

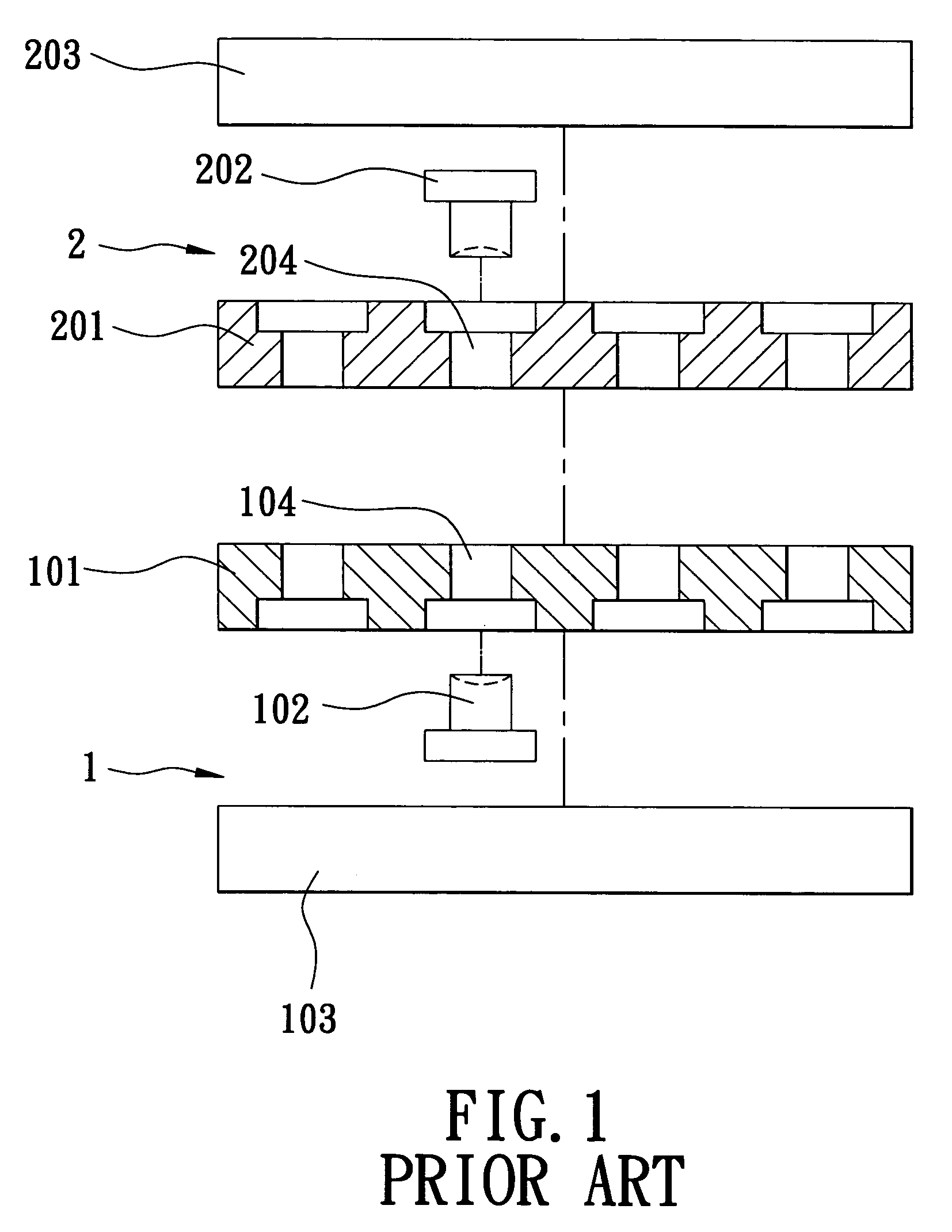

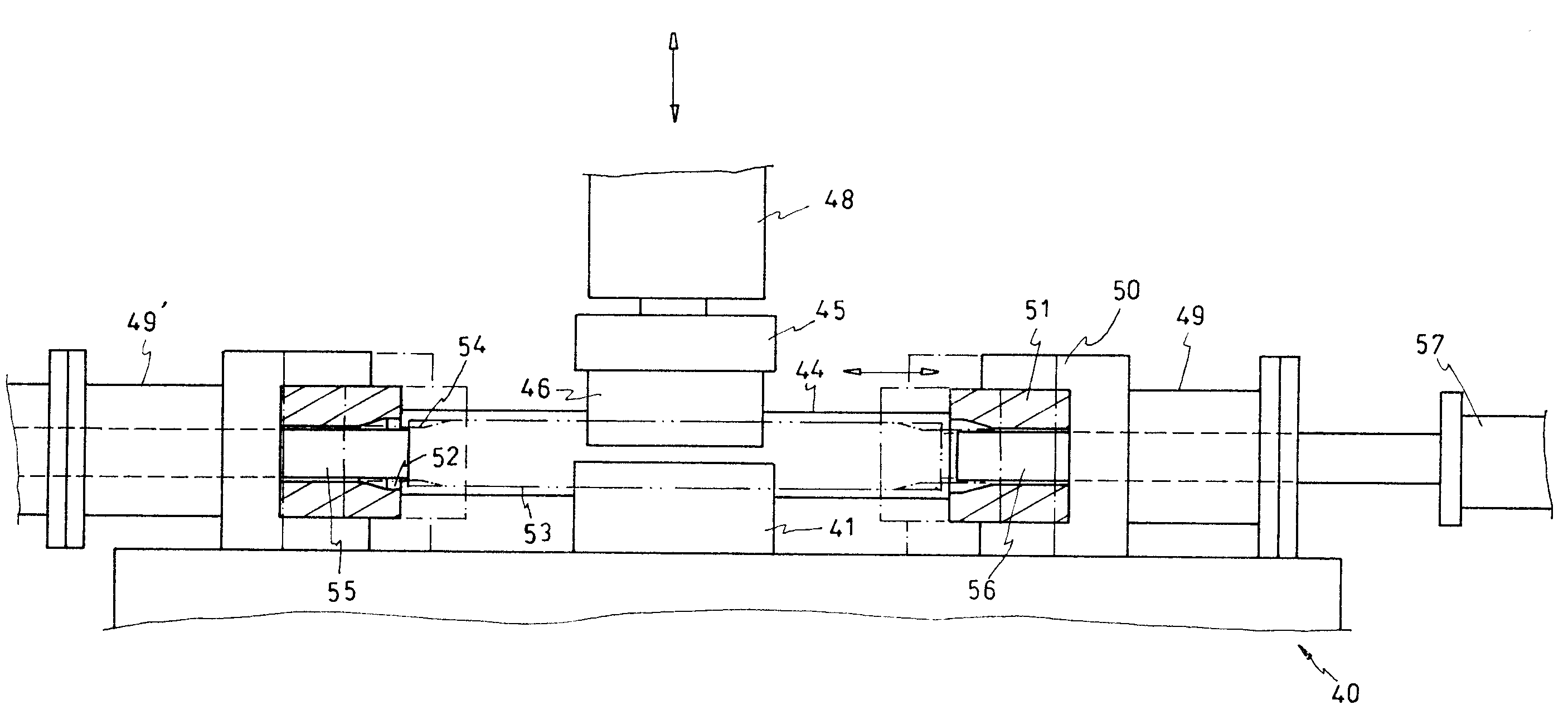

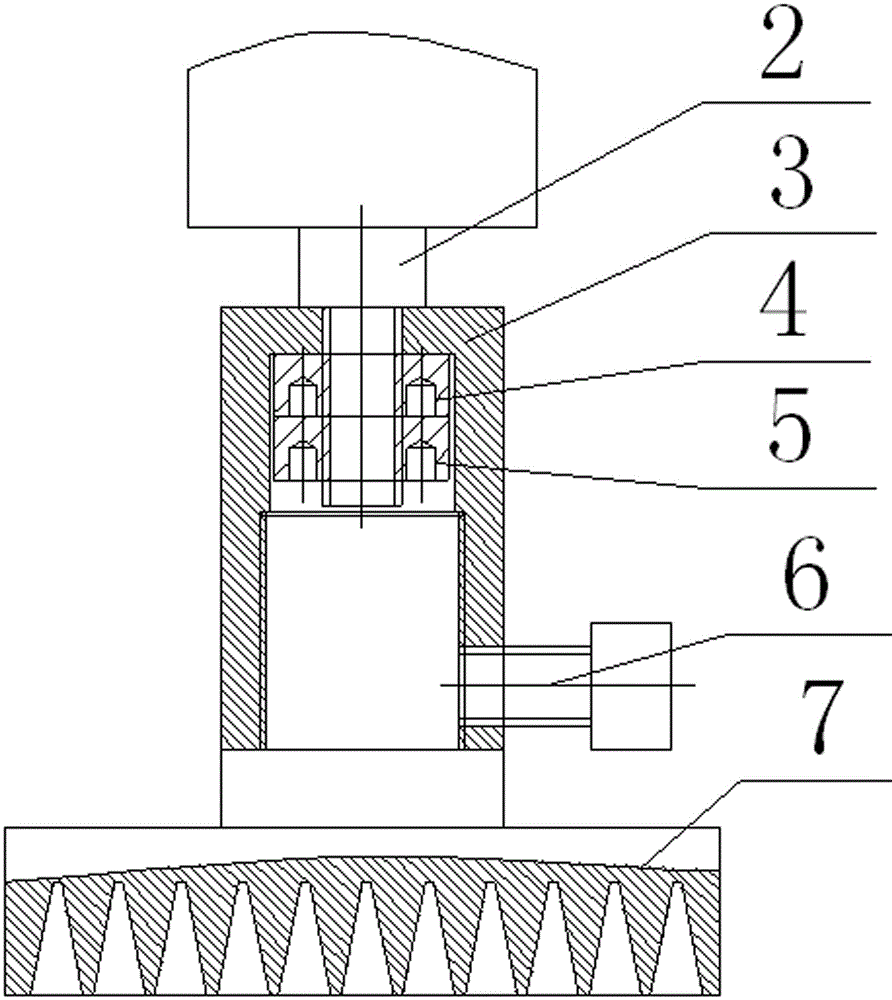

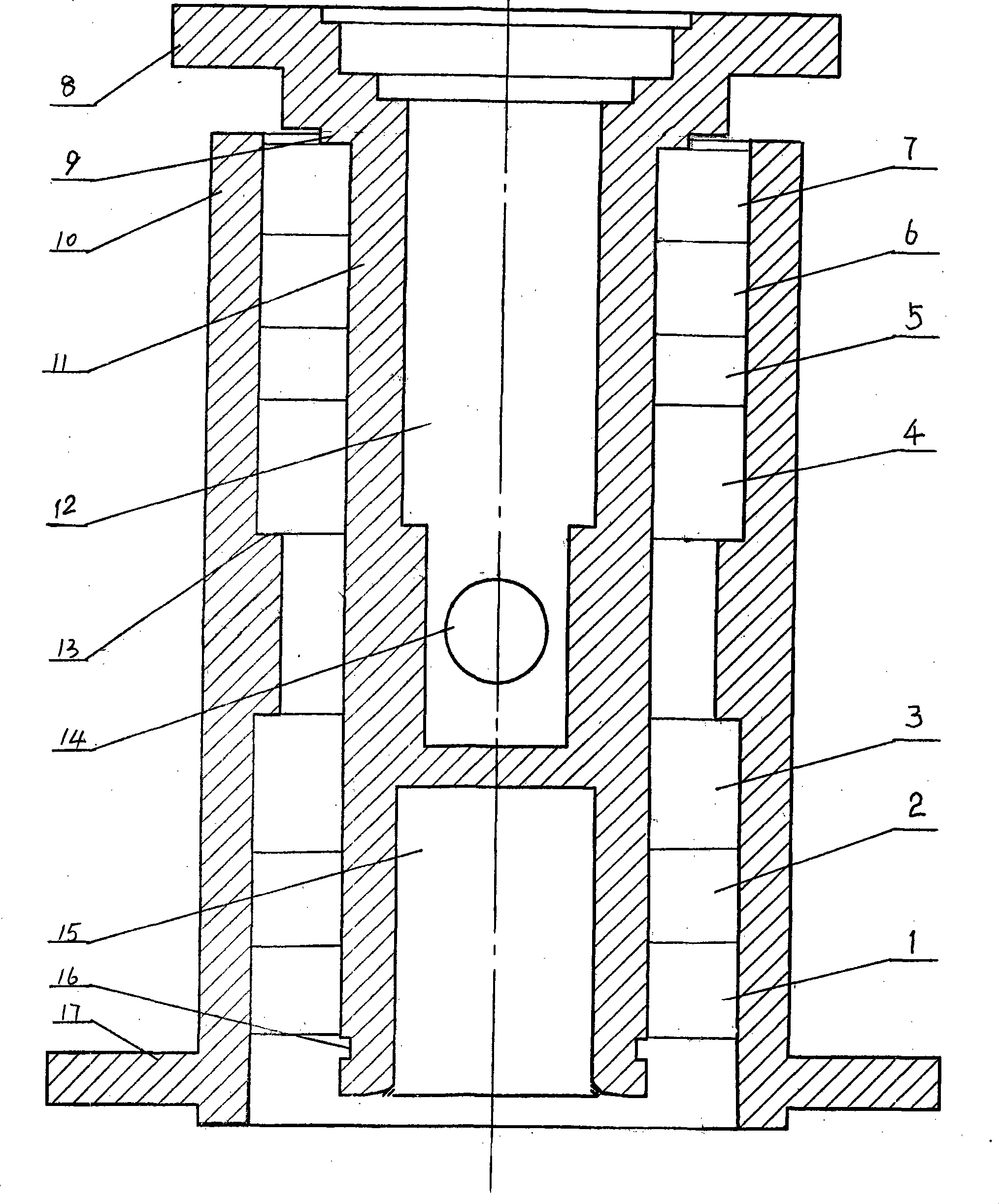

Porous boring machine for combined boring bar

InactiveCN102615309APrecise adjustment of deformationSolve the problem of difficult to control deflection deformationBoring barsTool holdersEngineeringMechanical engineering

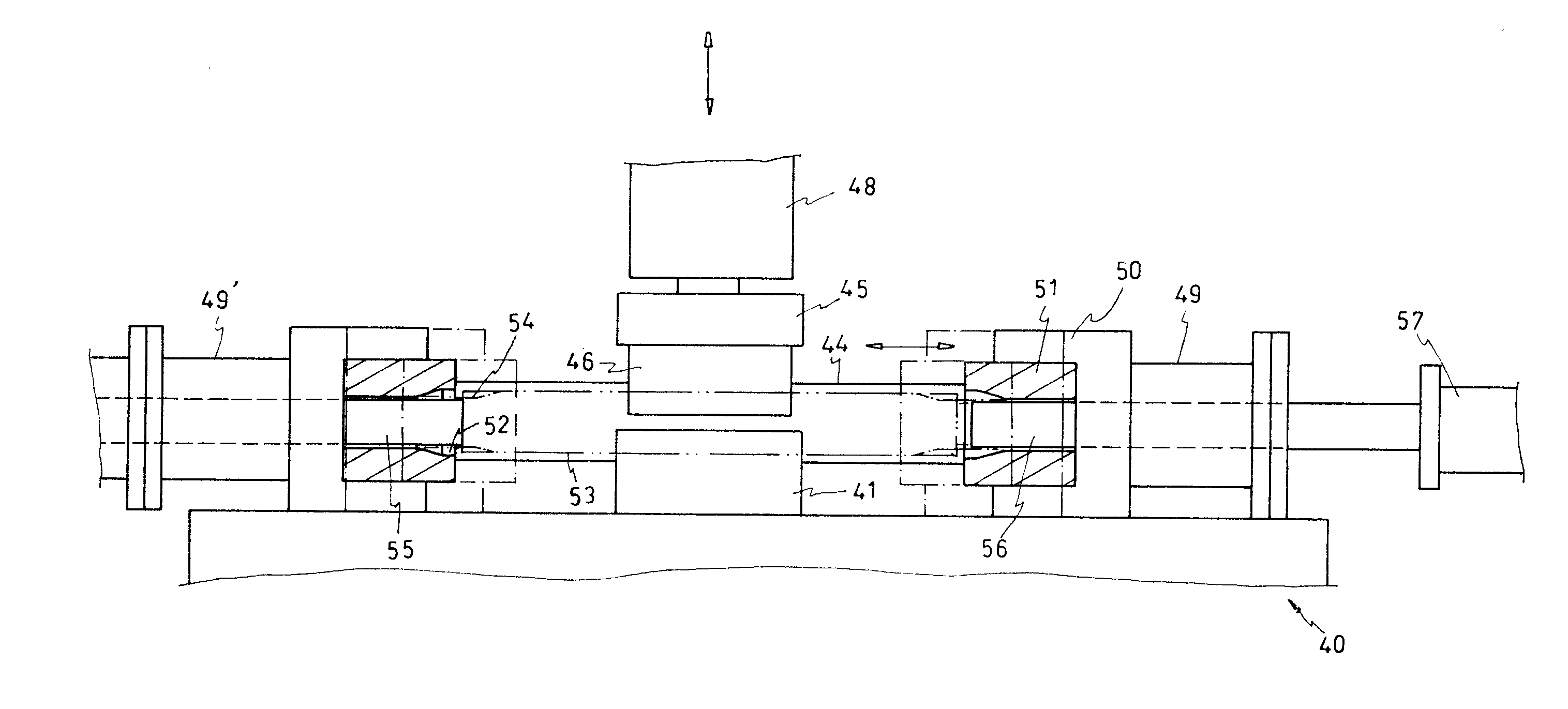

The invention discloses a porous boring machine for a combined boring bar. The porous boring machine comprises a drive device, a boring bar, boring cutters, a boring platform, a deflection fine adjusting mechanism and a boring cutter adjusting mechanism, wherein the boring bar is driven by the drive device; the boring cutters are arranged on the boring bar; the deflection fine adjusting mechanism is used for adjusting the deflection of the boring bar; the boring cutter adjusting mechanism is used for adjusting the telescopic length of the boring cutters; the two boring cutters are arranged in the boring cutter mounting holes in the boring bar respectively; the boring bar is provided with deflection test holes; both ends of the boring bar are connected to movable support seats respectively; the deflection fine adjusting mechanism is positioned between the two movable support seats and is connected with the boring bar; the boring cutter adjusting mechanism is arranged in the boring cutter mounting holes and is connected with the boring cutters; and the movable support seats and the deflection fine adjusting mechanism are arranged on the boring platform. According to the porous boring machine, the combined boring bar is adopted, the problem that the deflection and the deformation of the super-long boring bar are difficult to control is solved, the deformation amount of the boring bar can be accurately adjusted, and the concentricity and other machining accuracy of machined workpieces are ensured.

Owner:SICHUAN BAISHICHANG HEAVY MACHINERY

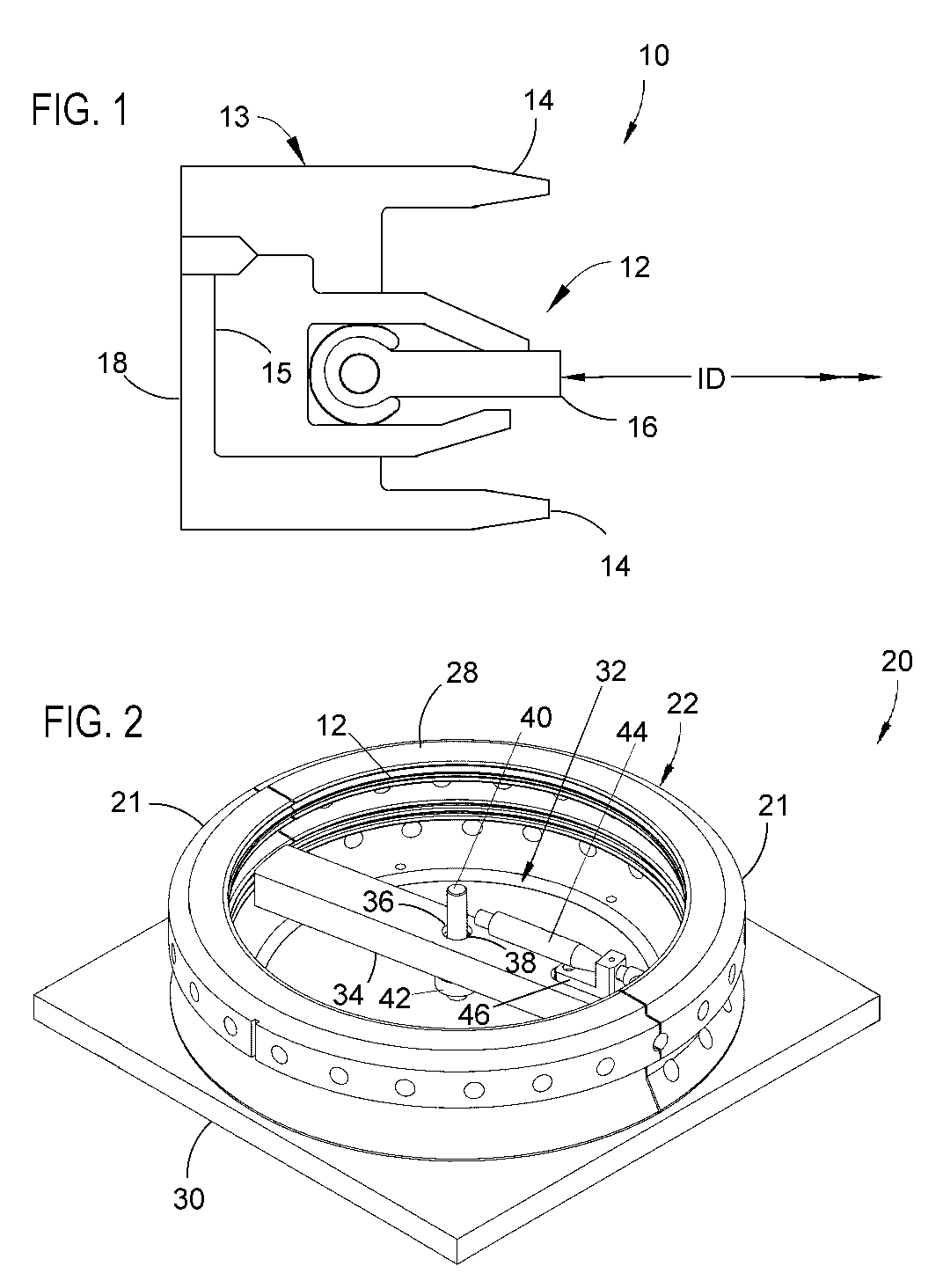

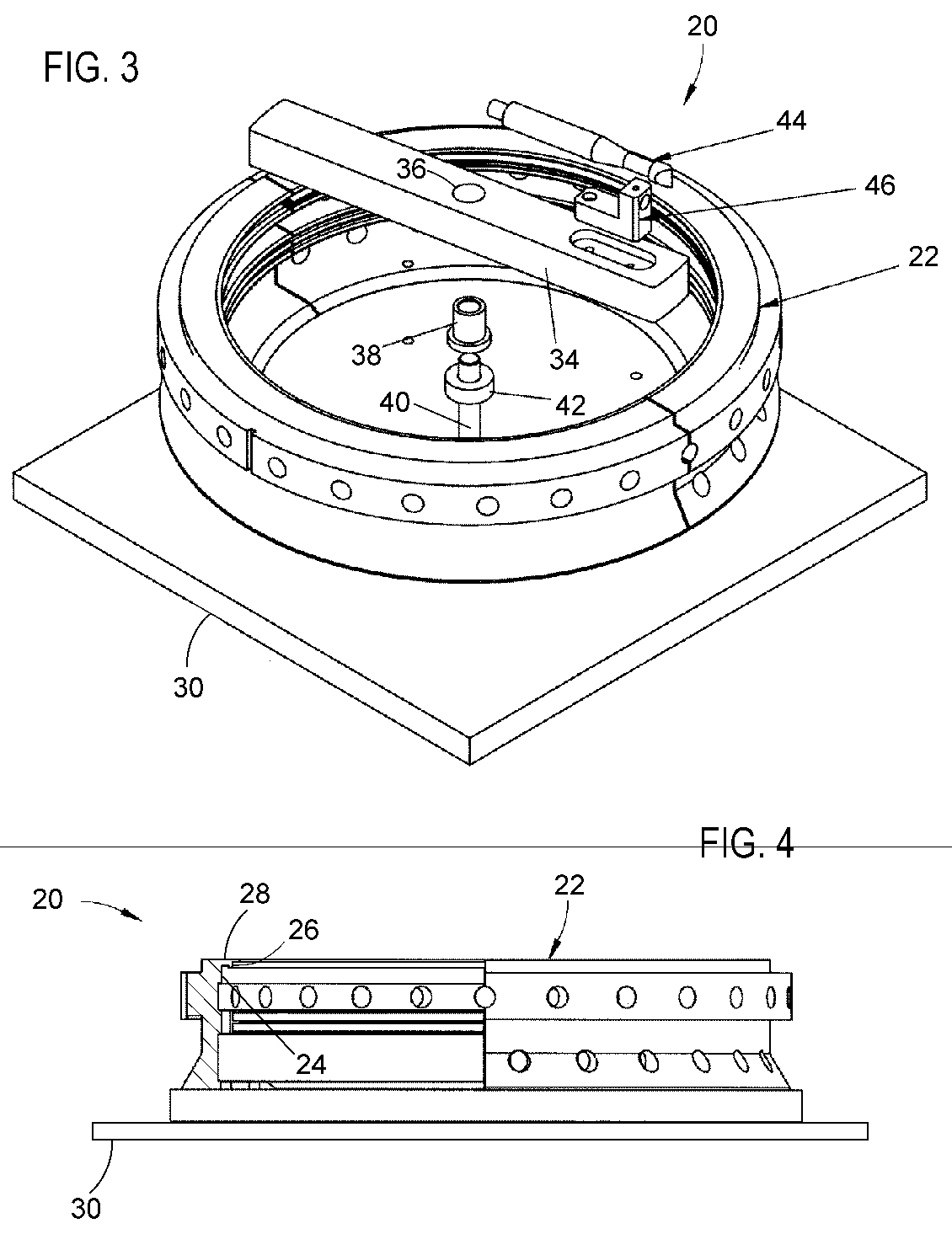

Fixture and inspection method for an annular seal

InactiveUS20070119042A1Ensure concentricityEngine sealsMechanical diameter measurementsEngineeringMechanical engineering

A fixture assembly and inspection method by which the internal diameter and / or concentricity of a segmented annular seal can be readily inspected and optionally measured prior to final installation. The fixture assembly has at least two fixture segments supported on a base, by which an annular fixture housing is defined having an outer rim and a groove with a cross-sectional shape corresponding to a cross-sectional shape of the annular seal. The fixture assembly further includes a device or apparatus for assessing at least one dimensional characteristic of the annular seal when installed in the groove of the fixture housing and as the assessing device / apparatus travels along the interior circumference of the fixture housing.

Owner:GENERAL ELECTRIC CO

Processing method for piston rod assembly

The invention provides a processing method for a piston rod assembly. When an annular groove of a piston is processed, a 4 mm groove cutter is used for performing rough turning firstly, then a 2mm small-sized groove cutter is used for slowly turning a groove bottom excircle through cutting for two times to eliminate chatter marks, the groove is narrowed properly under the premise that the hardness is guaranteed, so that the transverse deformation of the groove subjected to carburization and quenching is still within the common difference required; 0.4-0.5 mm allowance of the total is taken out and is subjected to completely turning firstly, then an upper grinder is assembled, so as to control the concentricity, and guarantee the overall precision; chamfers and bottom diameter dimension of the excircle required when threads are subjected to thread rolling are subjected to completely turning on a numerically controlled lathe firstly, then threads are rolled, so as to guarantee the linear type of threads while ensuring concentricity; a piston and a piston rod are assembled by a spanner, so as to guarantee that the centers of the piston and the piston rod are positioned on the same operating horizontal plane; the torque is adjusted to guarantee the torque force, and the piston and the piston rod are tightly screwed; after the piston rod assembly is completely assembled, the bending deformation during grinding is remarkably reduced when the upper grinder is subjected to overall grinding, so that the straightness and concentricity during the grinding of the integral piston rod assembly are well guaranteed.

Owner:上海沪东造船油嘴油泵有限公司

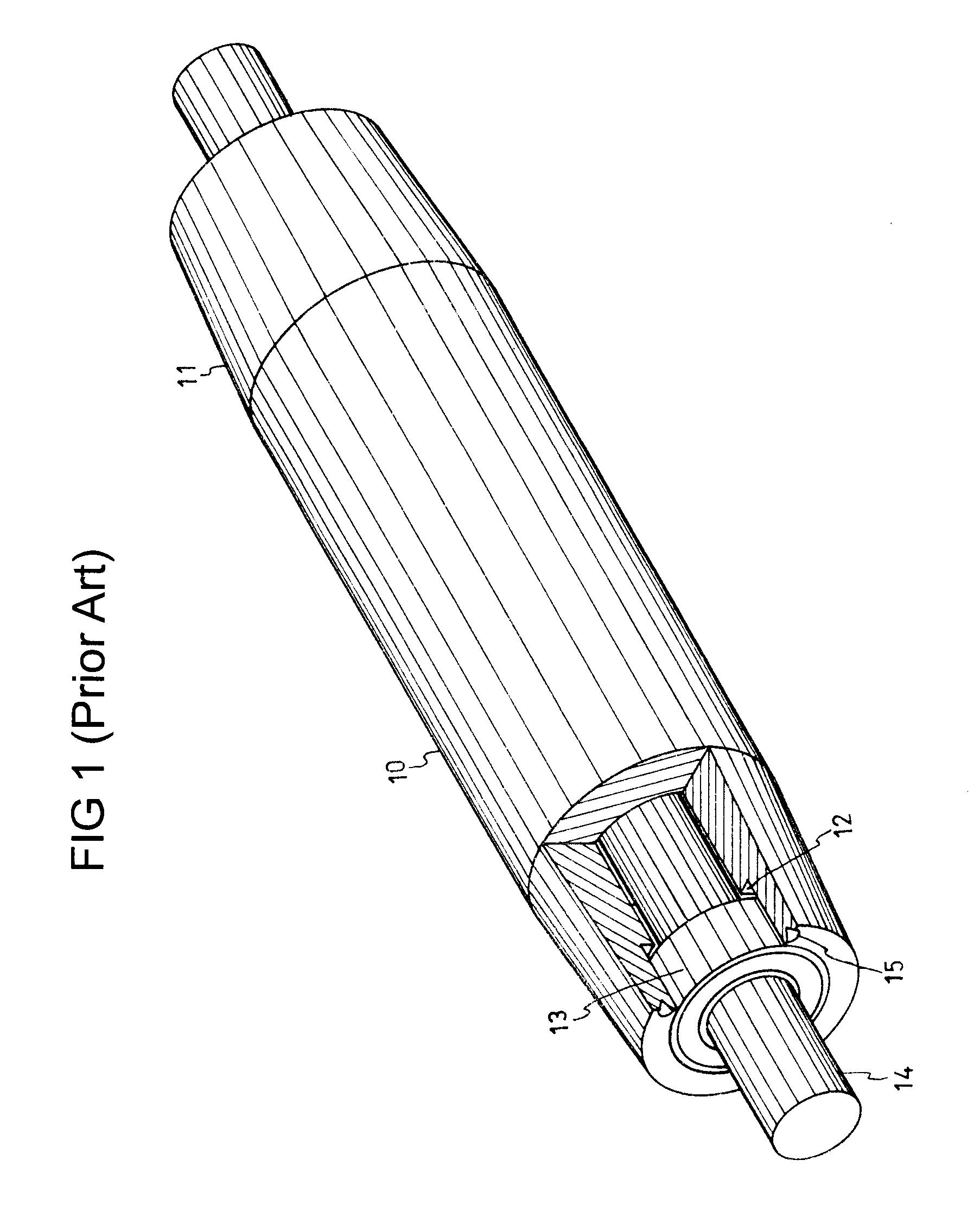

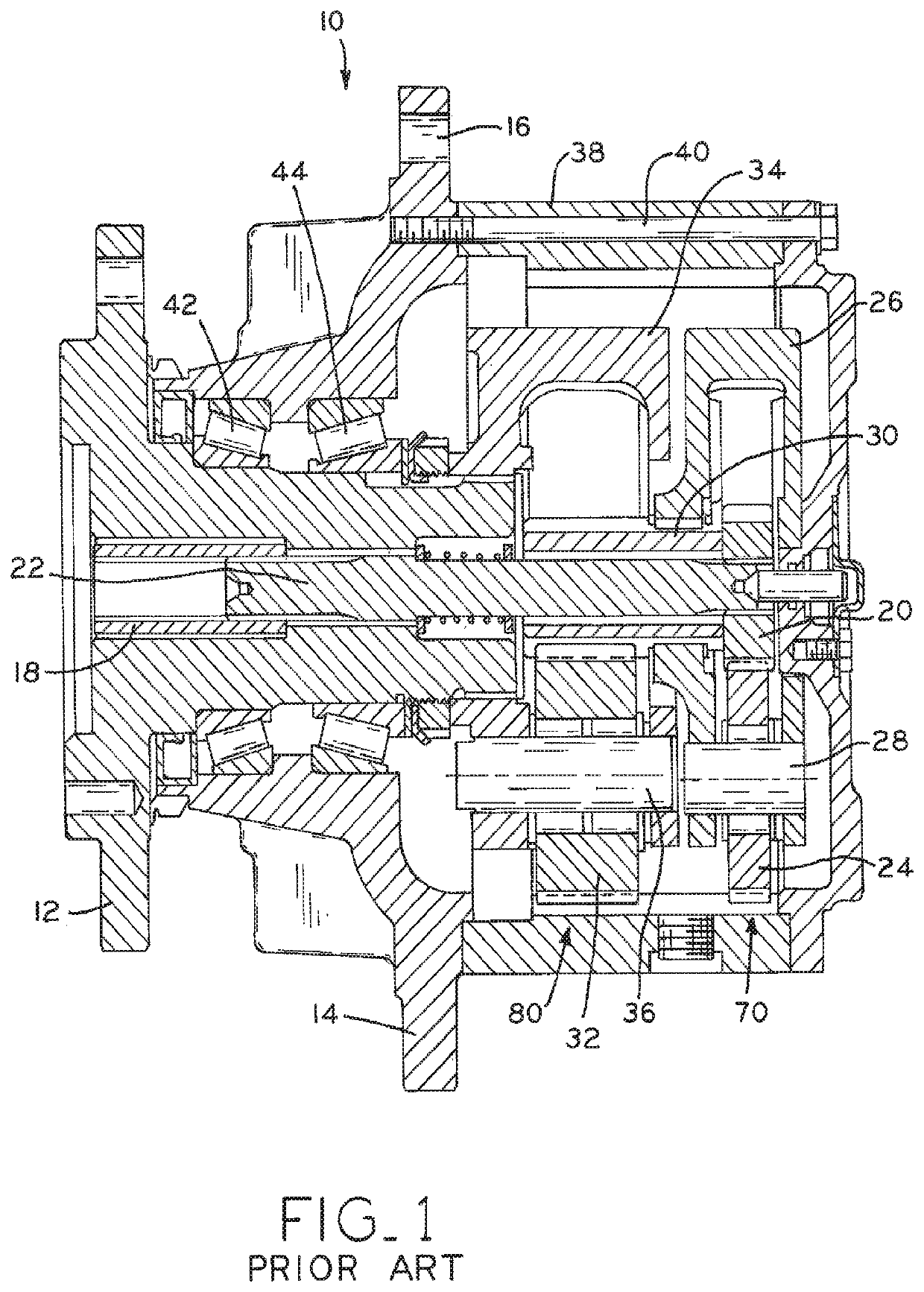

Concentric machining device for a roller

InactiveUS20070243280A1Production rate can be promotedAccurate concentricityShaping toolsCeramic shaping apparatusHydraulic cylinderMachining

A concentric machining device for a roller includes a movable upper base, a stationary lower base, two movable mold seats, two slide rods and four first hydraulic cylinders. Each of the mold seats has a forming mold inside, the forming mold has a fitting hole with an enlarged conical opening at the front side thereof, a locating shaft is received in the forming mold of the first mold seat and penetrates the fitting hole thereof and the first cylinder member, a clamping shaft is received in the forming mold of the second mold seat and penetrates the fitting hole thereof and the second hydraulic cylinder to connect with the fourth hydraulic cylinder. The roller is held by the bases and the shafts via two of the hydraulic cylinders and both ends of the roller are machined by the forming molds in the mold seats to provide squeezed and shrunk shapes once the mold seats are actuated by the other two hydraulic cylinders.

Owner:HUANG TE LI

Self aligning bearing and seal assembly

ActiveUS8398310B2Easy to installEliminate needBall bearingsSliding contact bearingsEngineeringMechanical engineering

Owner:RELADYNE RELIABILITY SERVICES INC

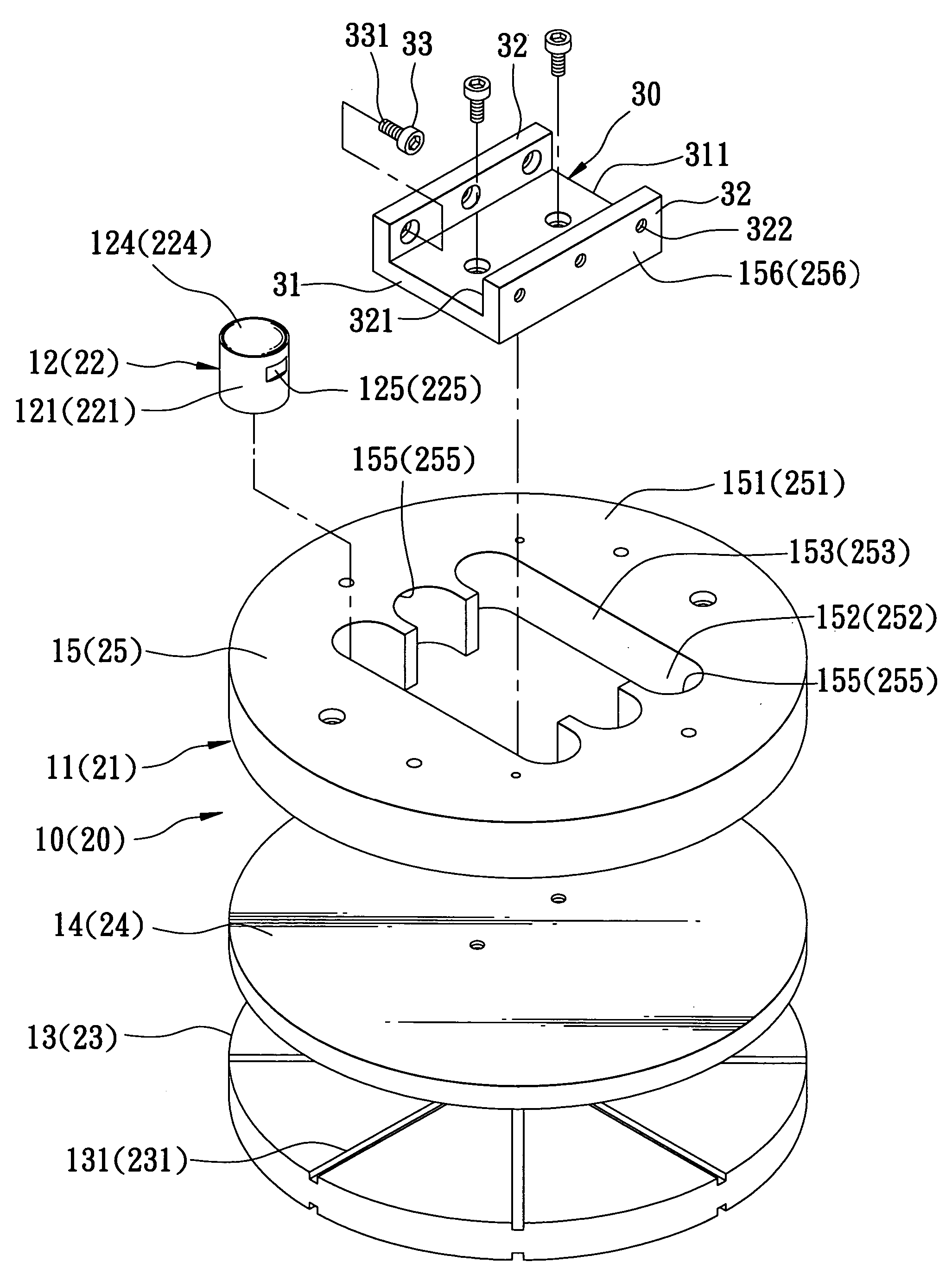

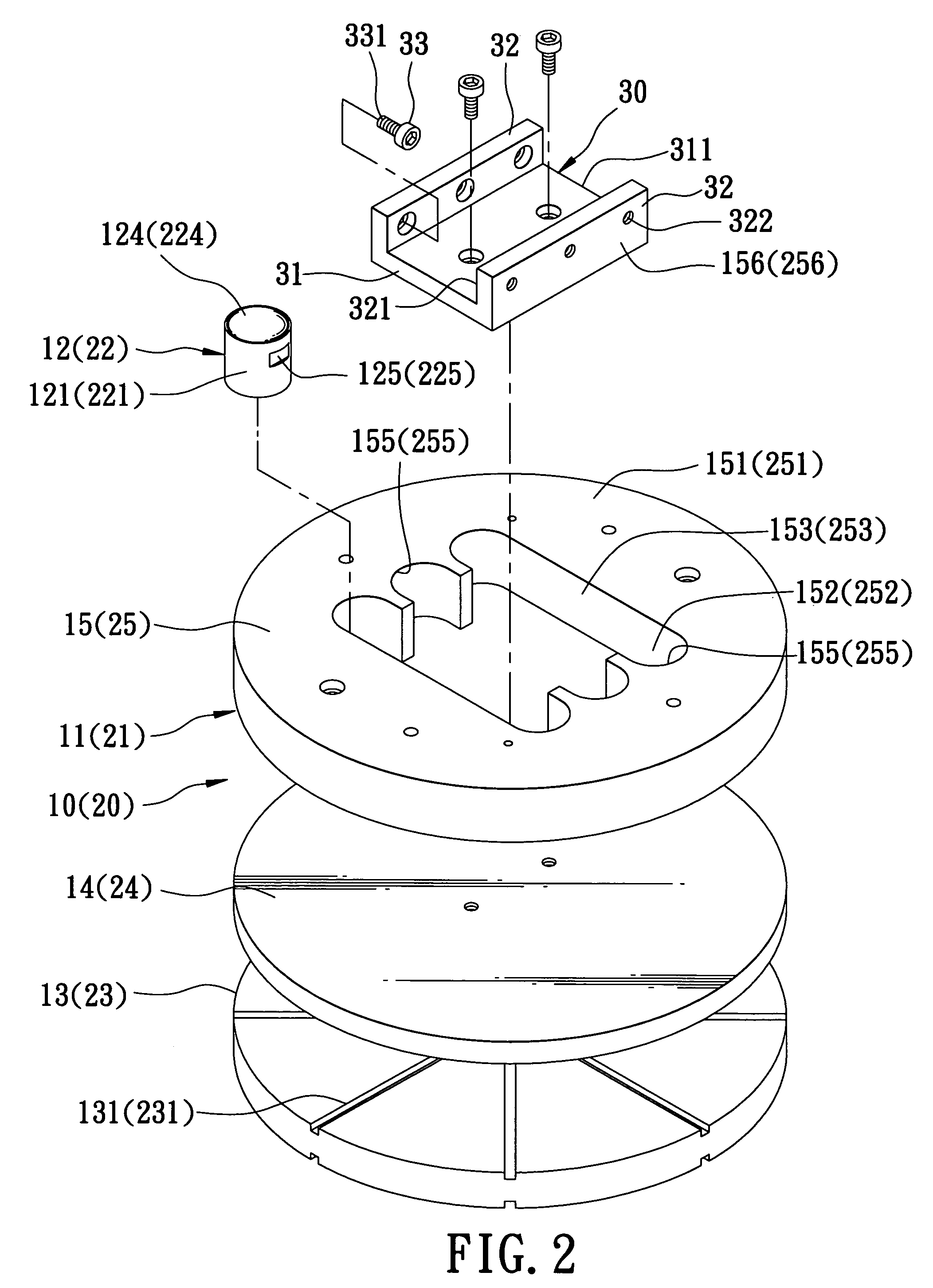

Molding apparatus with removable mold cores

InactiveUS7008212B2Quick changeIncrease productivityMould separation apparatusConfectioneryShell moldingCavity wall

A molding apparatus for lenses includes first and second molding units, each of which has a mold core holder, a plurality of mold cores disposed in the mold core holder, and a clamp unit provided within the mold core holder. The mold core holder has an abutment surface, and a plurality of cavities extending inwardly from the abutment surface and receiving respectively the mold cores. The cavities include cavity walls, respectively. The clamp unit includes a plurality of clamp elements attached to the clamp unit to clamp respectively the mold cores against the cavity walls. Individual removal of the mold cores of the molding units for replacement is permitted by operating the clamp elements.

Owner:ASIA OPTICAL INT LTD

Fixture and inspection method for an annular seal

InactiveUS7752726B2Ensure concentricityEngine sealsMechanical diameter measurementsEngineeringMechanical engineering

Owner:GENERAL ELECTRIC CO

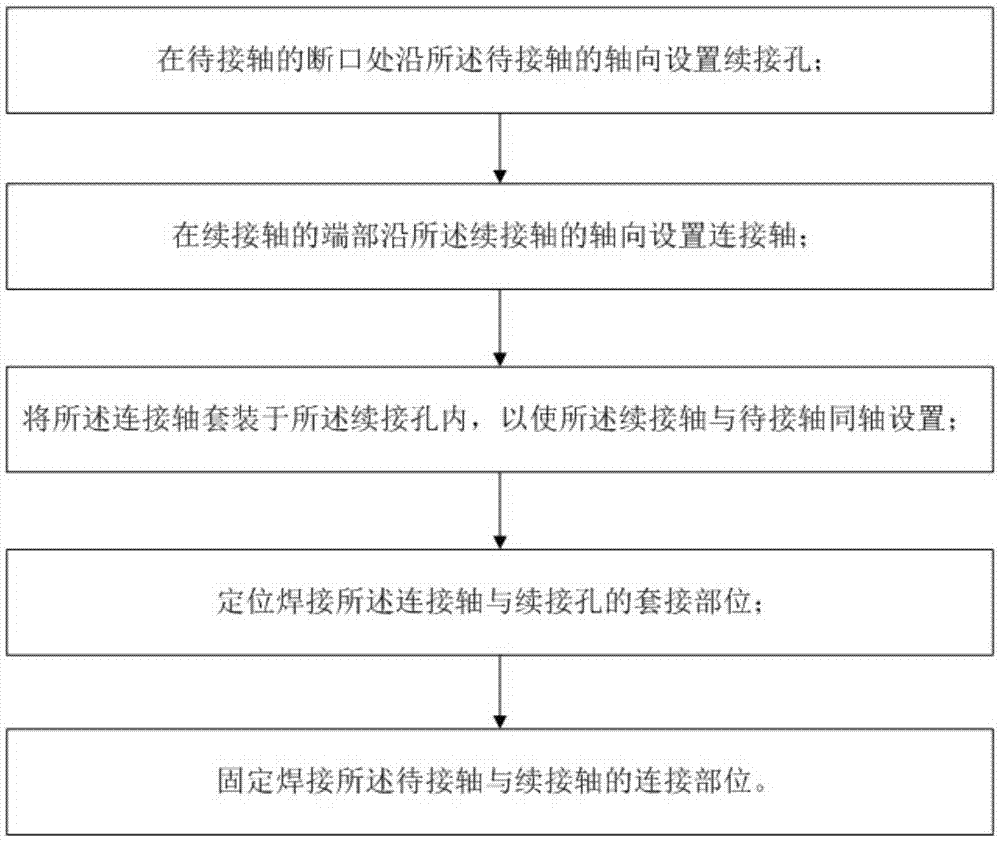

Shaft mechanism emergency maintenance method and structure

ActiveCN107127524AEnsure strengthEnsure concentricityWelding/cutting auxillary devicesAuxillary welding devicesUltimate tensile strengthCoal

The invention relates to the technical field of coal machine emergency maintenance, in particular to a shaft mechanism emergency maintenance method and structure. The shaft mechanism emergency maintenance method and structure are characterized in that a continuing hole is formed in a fracture of a to-be-connected shaft in the axial direction of the to-be-connected shaft, a connecting shaft is arranged at the end of a continuing shaft in the axial direction of the continuing shaft, the connecting shaft is sleeved with the continuing hole, and therefore it is guaranteed that the continuing shaft and the to-be-connected shaft are coaxial; the continuing shaft is coaxially welded to the fracture of the to-be-connected shaft through two times of welding, it is guaranteed that the to-be-connected shaft obtained after emergency maintenance can quickly restore to normally work, the strength and the coaxiality of maintained shaft mechanisms can be effectively guaranteed, quick maintenance of broken shafts is achieved, the equipment halt time is shortened, and it is guaranteed that a coal mine restores to normally produce as soon as possible; and meanwhile, reusing of the waste shaft mechanisms is achieved, cost is saved, and unnecessary economic losses are reduced.

Owner:INNER MONGOLIA YITAI COAL

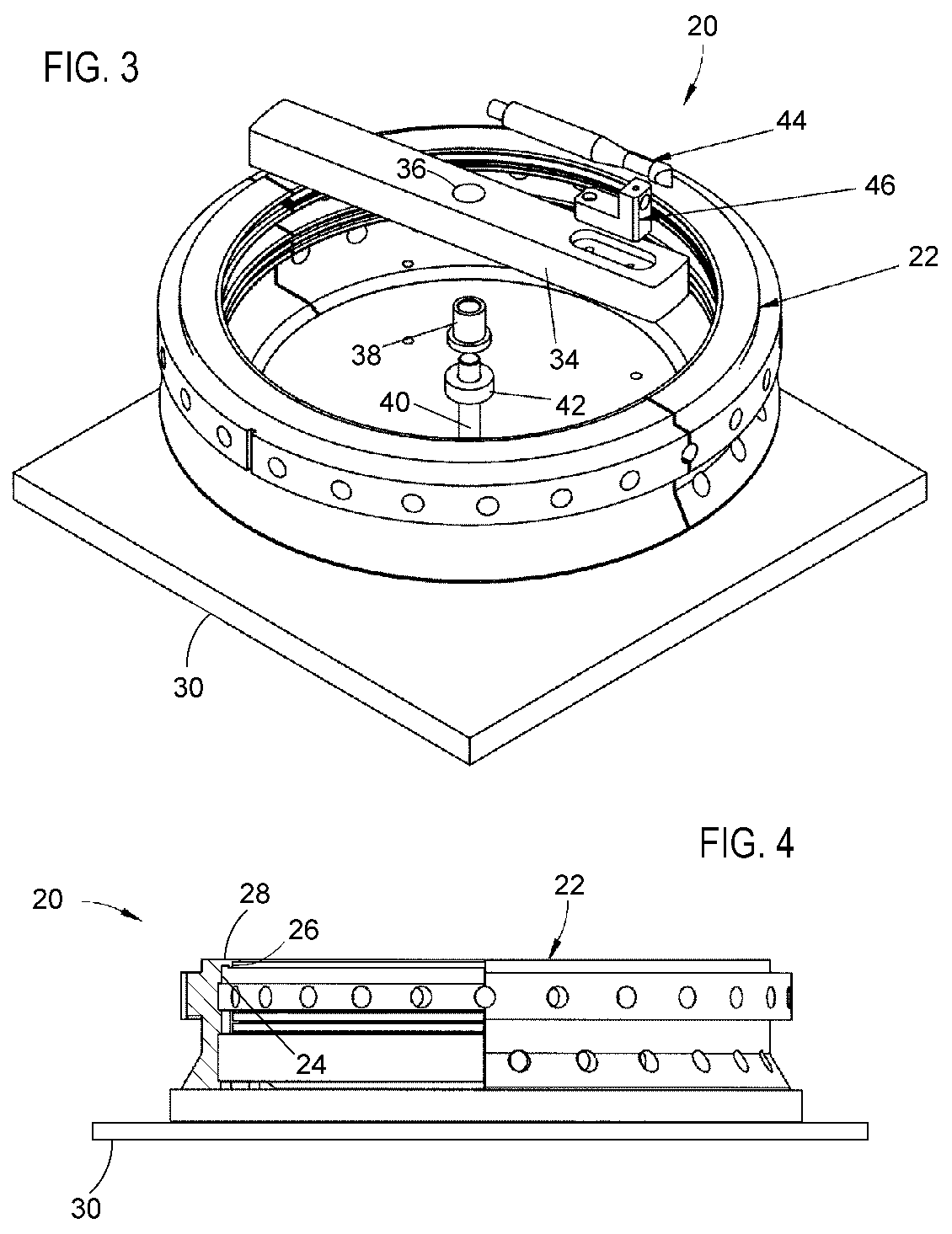

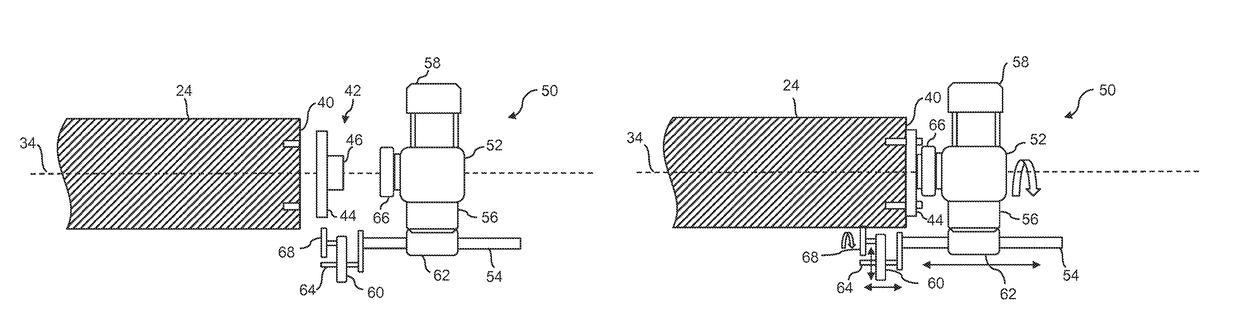

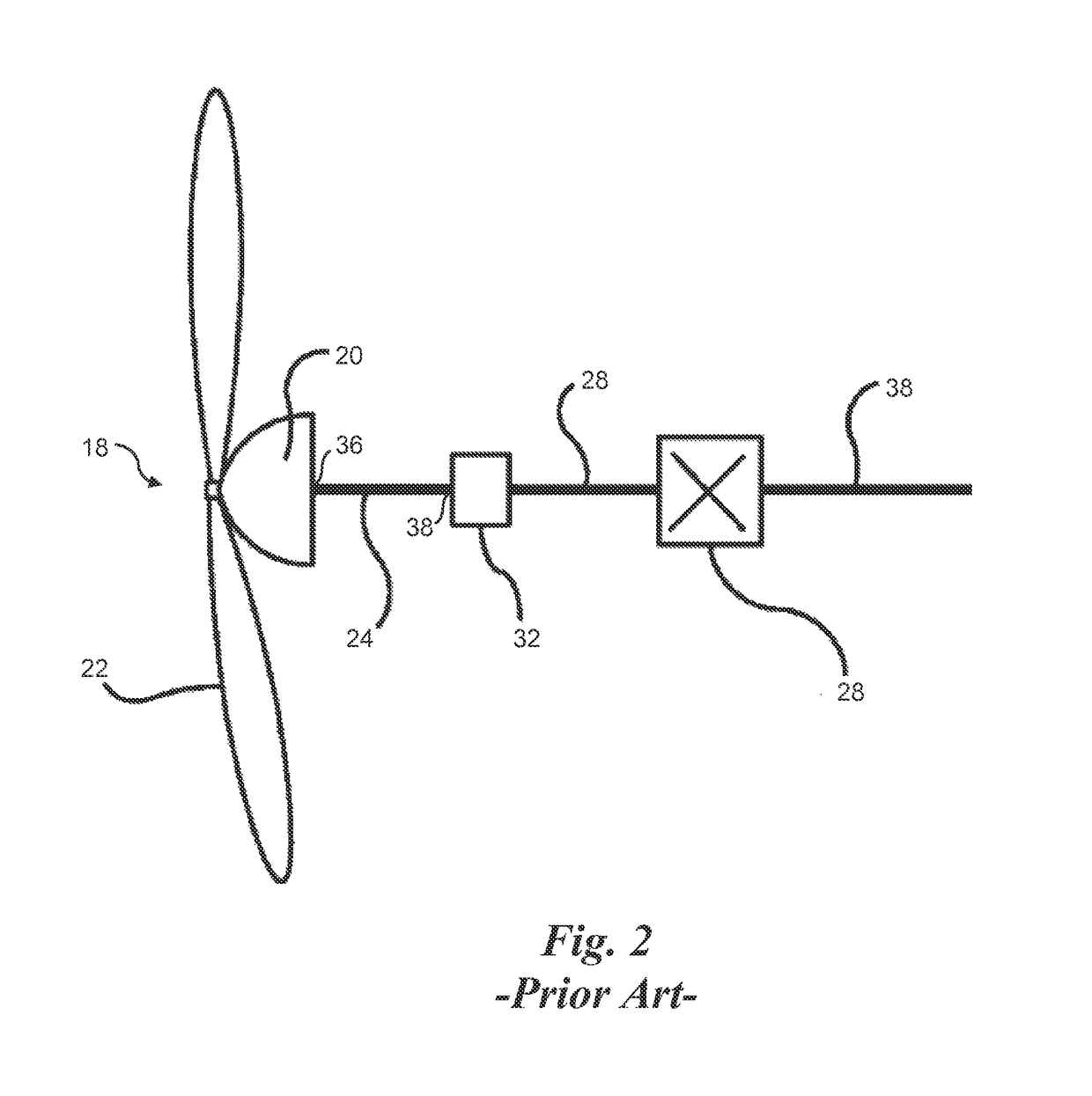

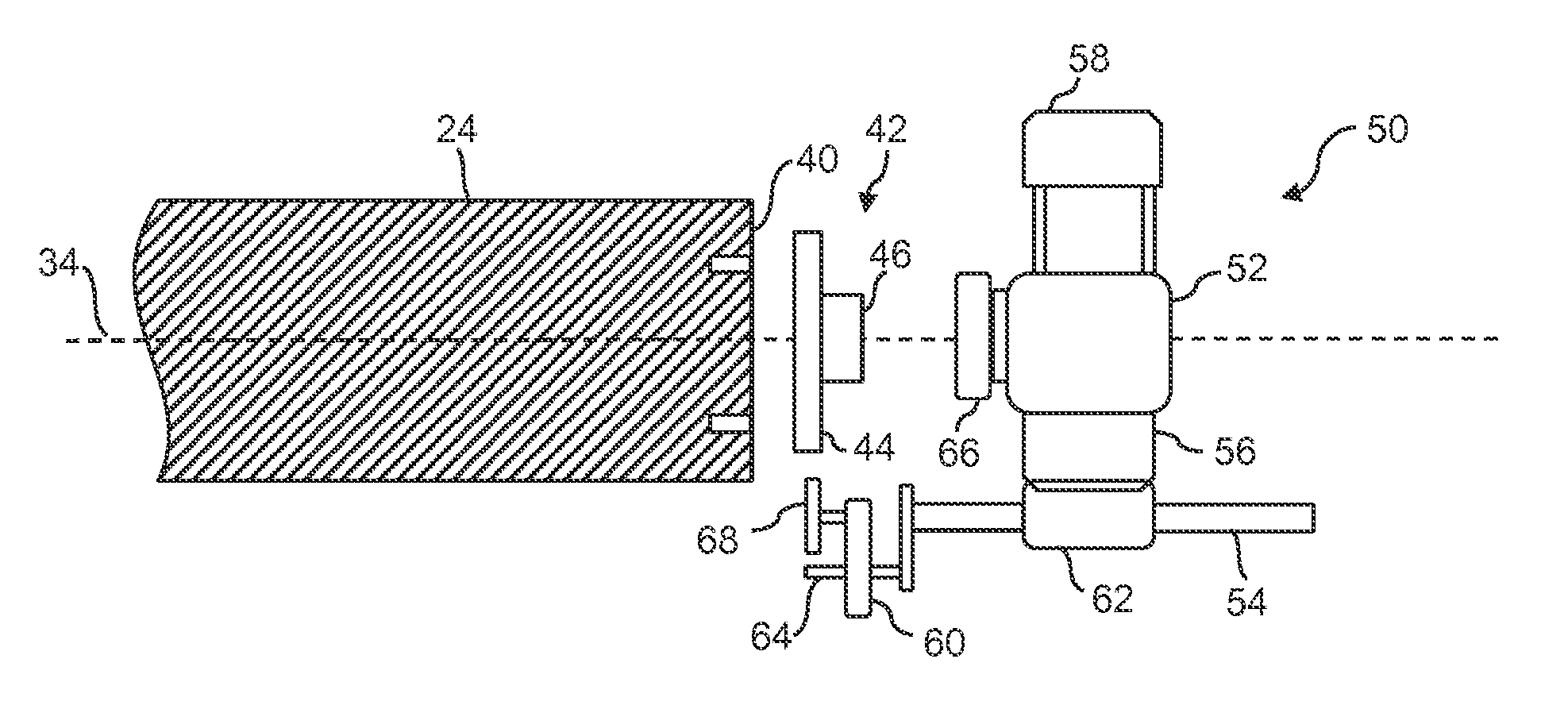

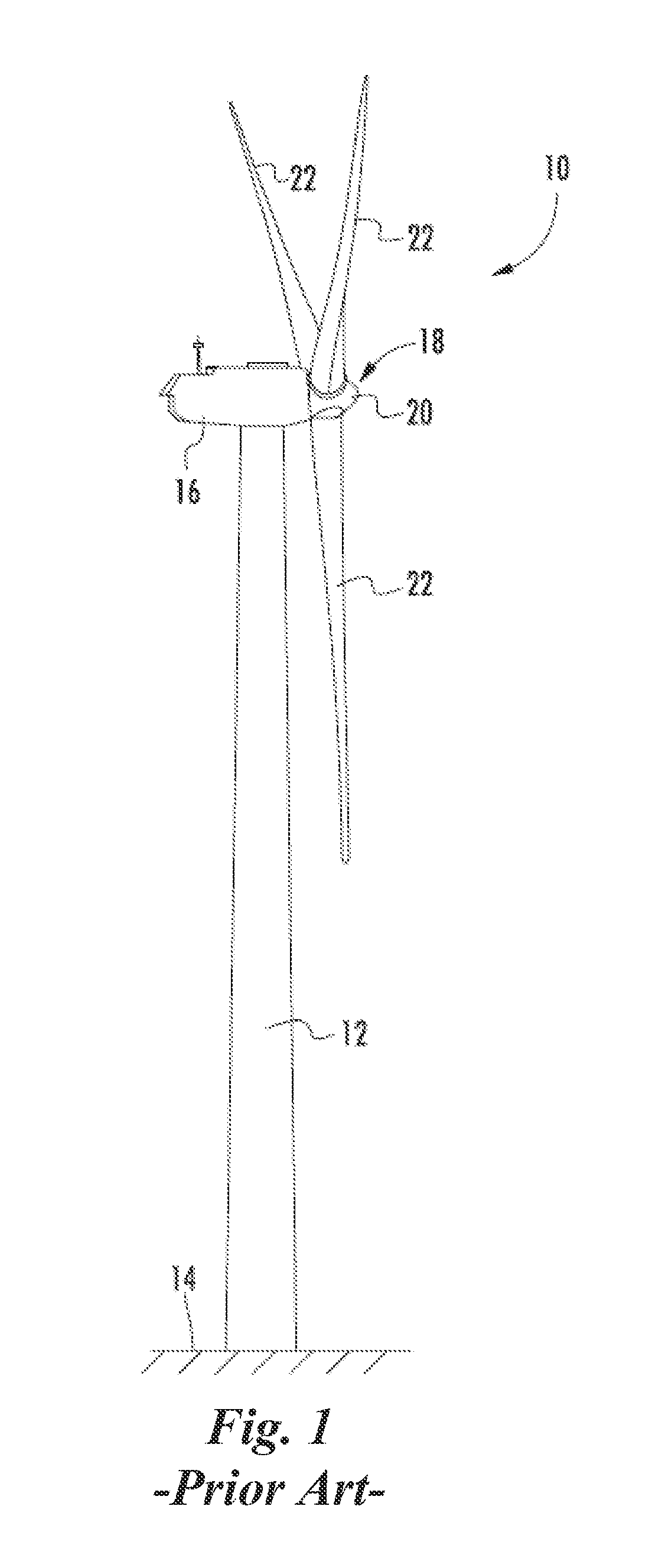

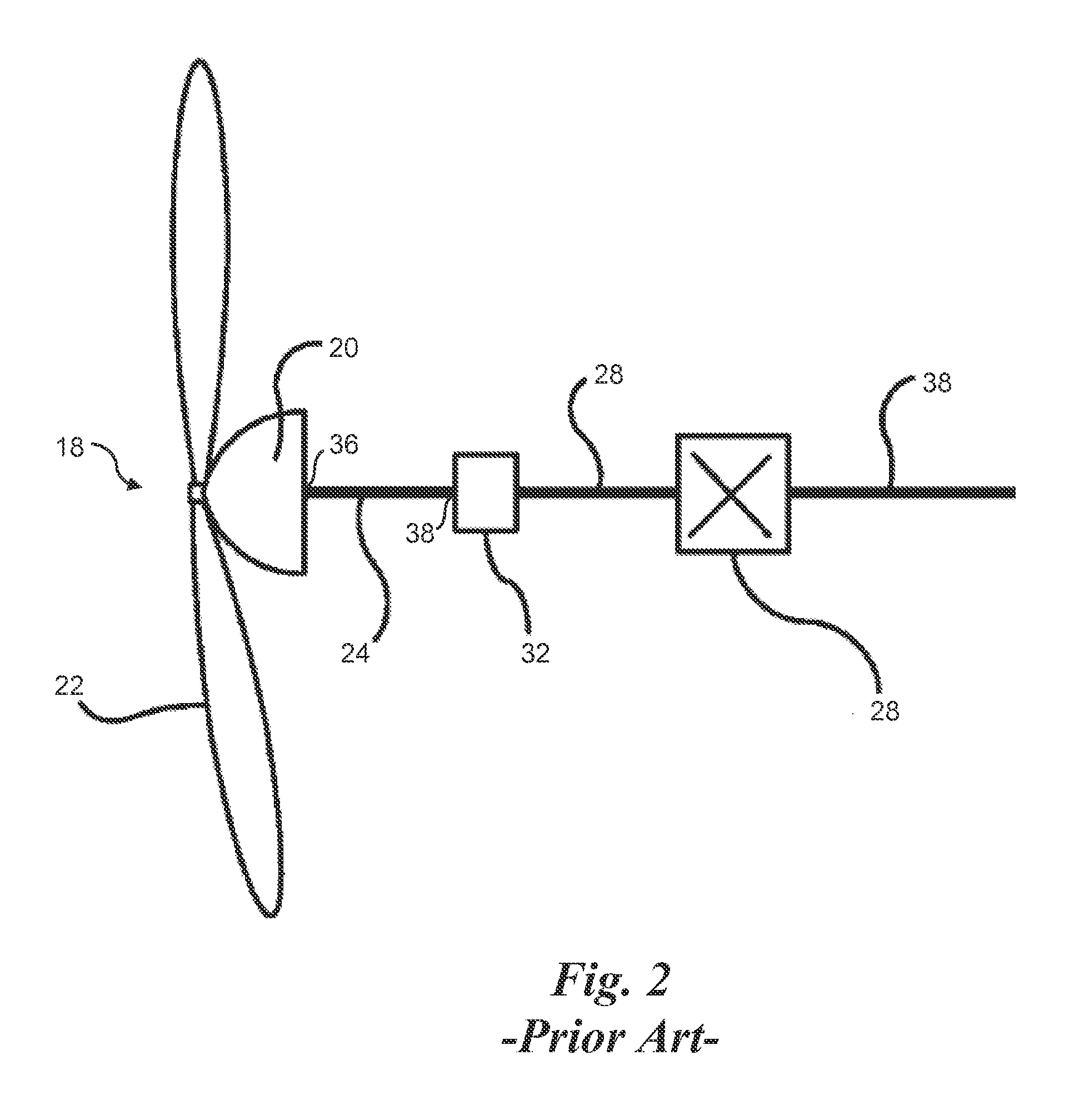

System and method for in-situ resurfacing of a wind turbine main rotor shaft

ActiveUS9757821B2Ensure concentricityWind motor assemblyWind motor combinationsRotational axisNacelle

A method is provided for in-situ resurfacing of a main rotor shaft of a wind turbine, wherein in an operational state, the main rotor shaft is coupled at a first end to a rotor hub and at the opposite second end to a gearbox or directly to a generator within a nacelle. The method includes uncoupling the rotor shaft from the gearbox or generator so as to expose an end face of the second end of the rotor shaft. A fixture is attached to the exposed end face concentric with the rotational axis of the rotor shaft. A lathe system in then attached to the fixture. The rotor shaft surface adjacent to the exposed end is machined with the lathe system such that the resurfaced portion of the rotor shaft surface is brought to a round state concentric with the rotational axis of the rotor shaft. The method is conducted within the nacelle with the first end of the rotor shaft remaining coupled to the rotor.

Owner:GE INFRASTRUCTURE TECH INT LLC

Concentric machining device for a roller

InactiveUS7549312B2Ensure concentricityPromote productionShaping toolsCeramic shaping apparatusHydraulic cylinderEngineering

A concentric machining device for a roller includes a movable upper base, a stationary lower base, two movable mold seats, two slide rods and four first hydraulic cylinders. Each of the mold seats has a forming mold inside, the forming mold has a fitting hole with an enlarged conical opening at the front side thereof, a locating shaft is received in the forming mold of the first mold seat and penetrates the fitting hole thereof and the first cylinder member, a clamping shaft is received in the forming mold of the second mold seat and penetrates the fitting hole thereof and the second hydraulic cylinder to connect with the fourth hydraulic cylinder. The roller is held by the bases and the shafts via two of the hydraulic cylinders and both ends of the roller are machined by the forming molds in the mold seats to provide squeezed and shrunk shapes once the mold seats are actuated by the other two hydraulic cylinders.

Owner:HUANG TE LI

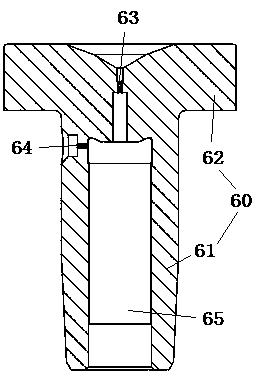

Nock bushing

An improved nock bushing preferably includes a bushing body and a stop flange. The bushing body preferably has a non-round body. An undercut is preferably formed under the stop flange. A nock hole is formed through at least substantially all of a length of the non-round body to receive a projection from an arrow nock. A plurality of lightening openings are preferably formed through the bushing body. The stop flange extends from one end of the bushing body. A distance across the largest cross-section dimension of the bushing body is preferably greater than a diameter of a bushing hole in an arrow shaft. In use, the non-round body is inserted into a nock end of an arrow shaft, which flexes the nock end. The arrow shaft will want to return back to its original round shape and thus applies force to an outer surface of the bushing body.

Owner:HUANG DORGE O

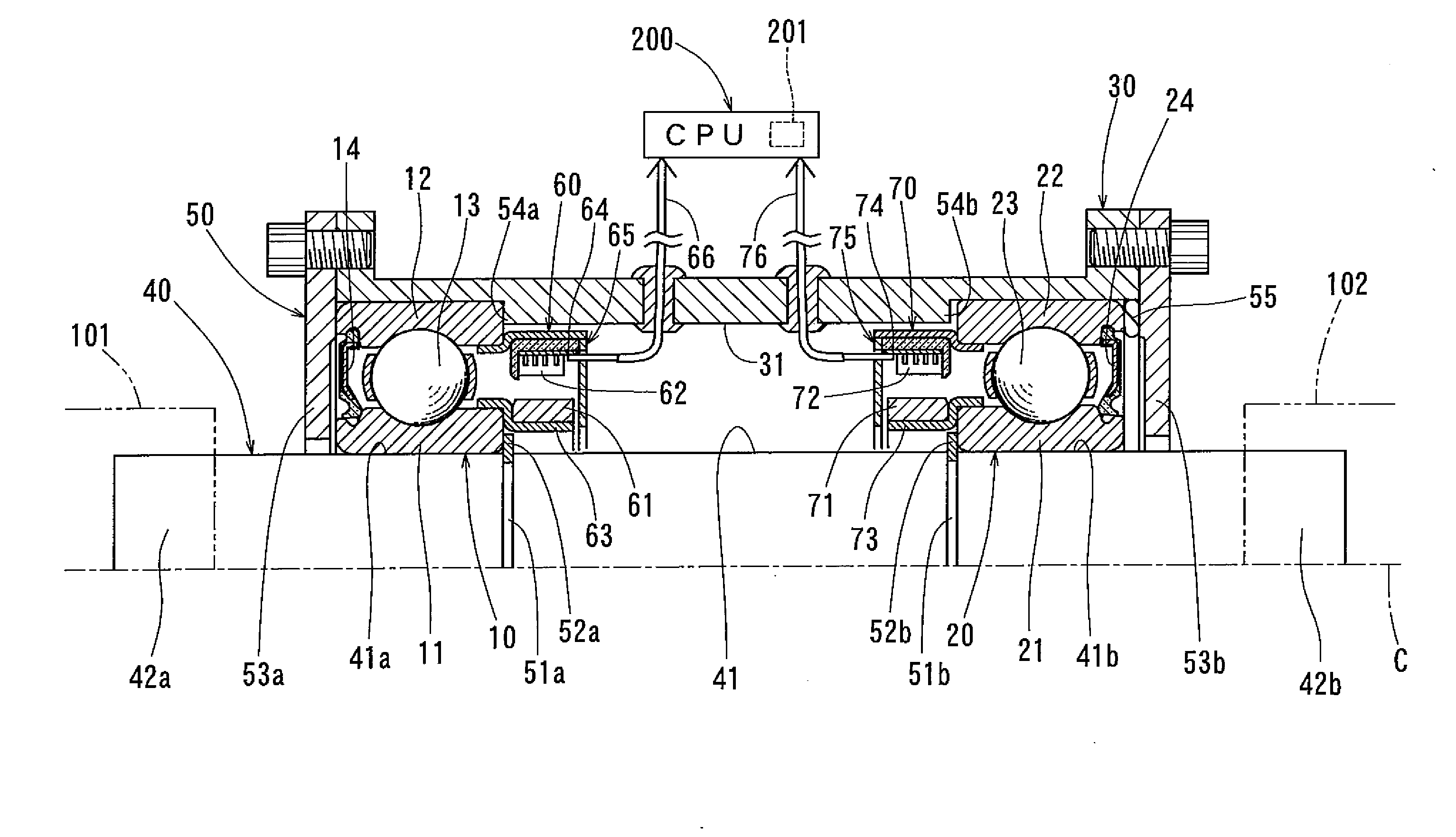

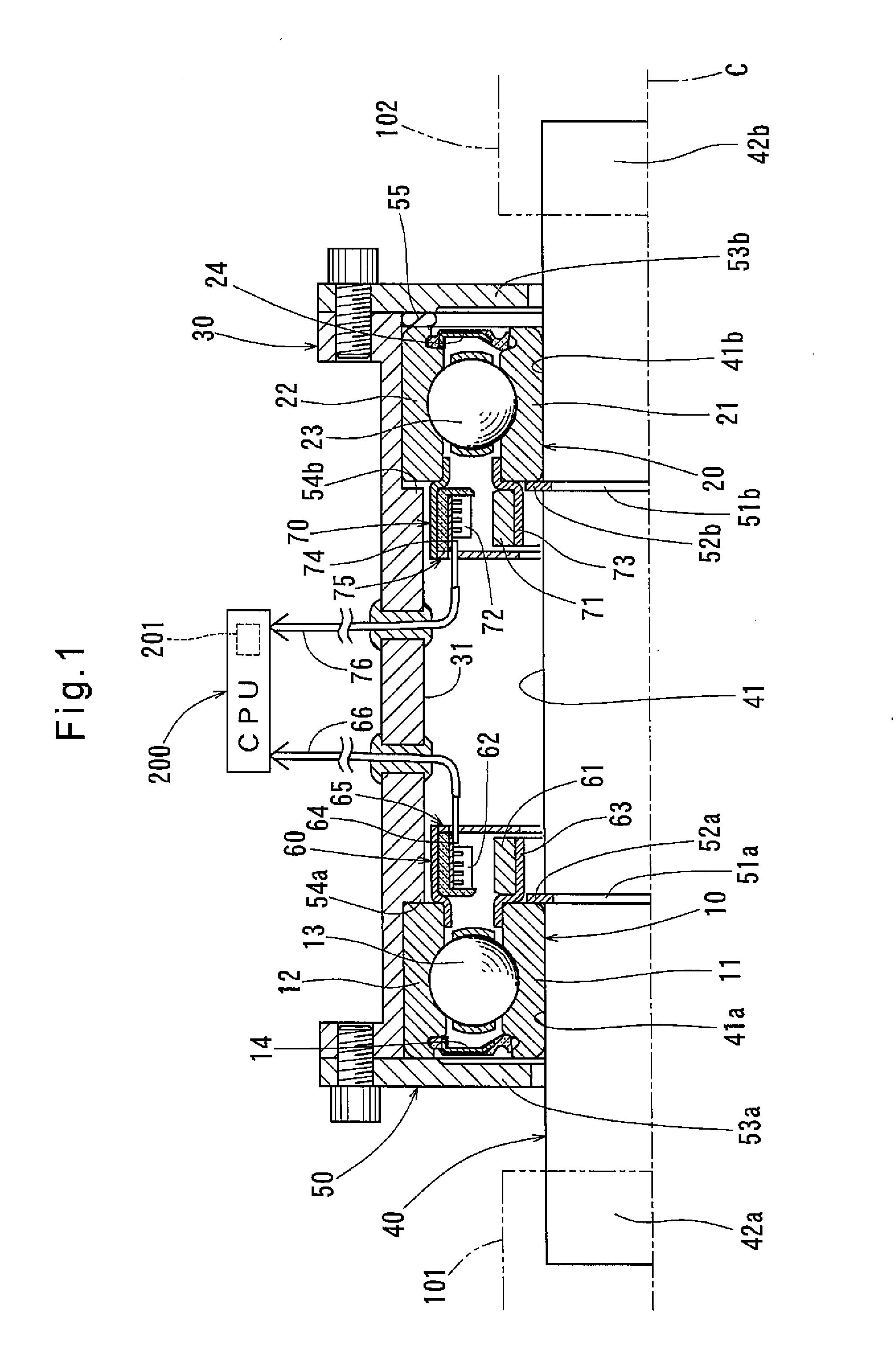

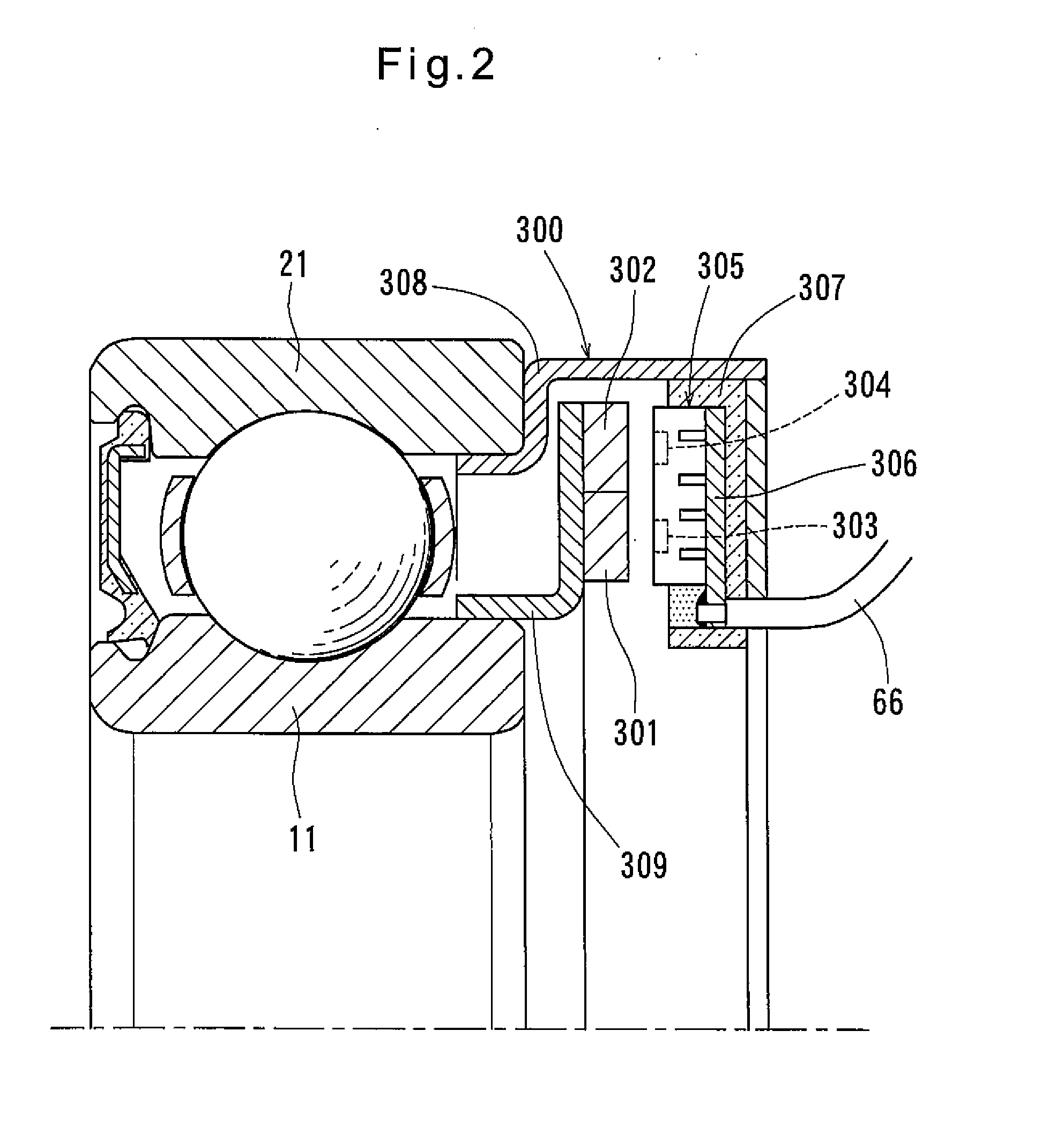

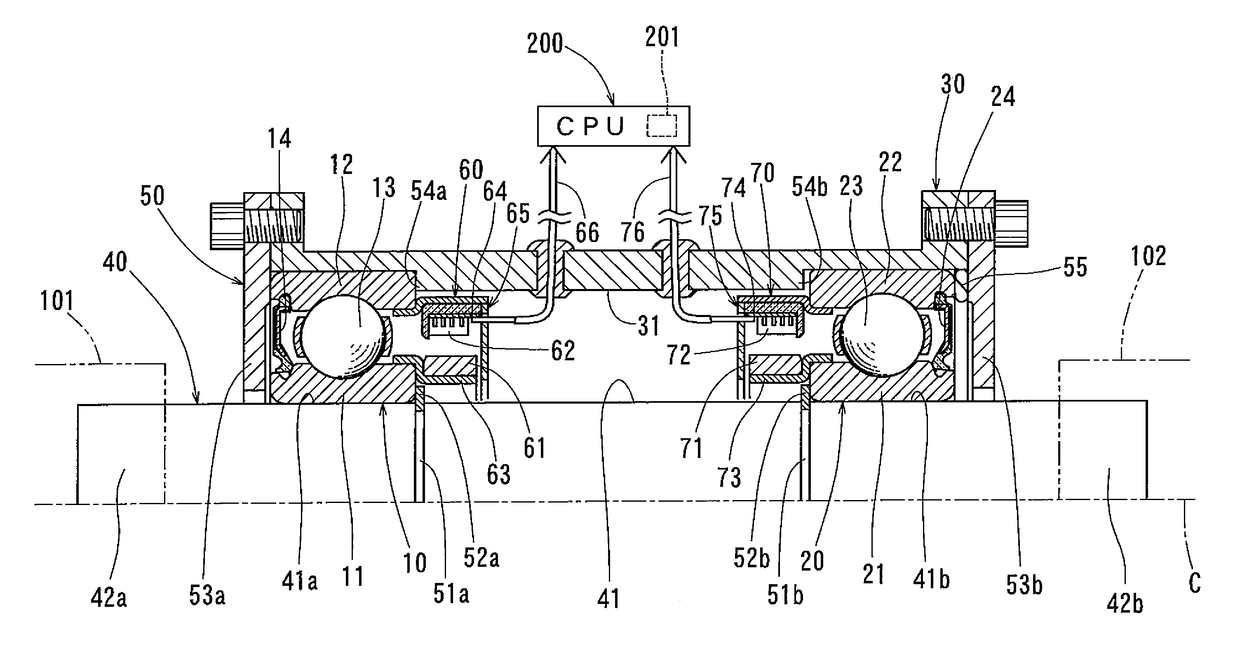

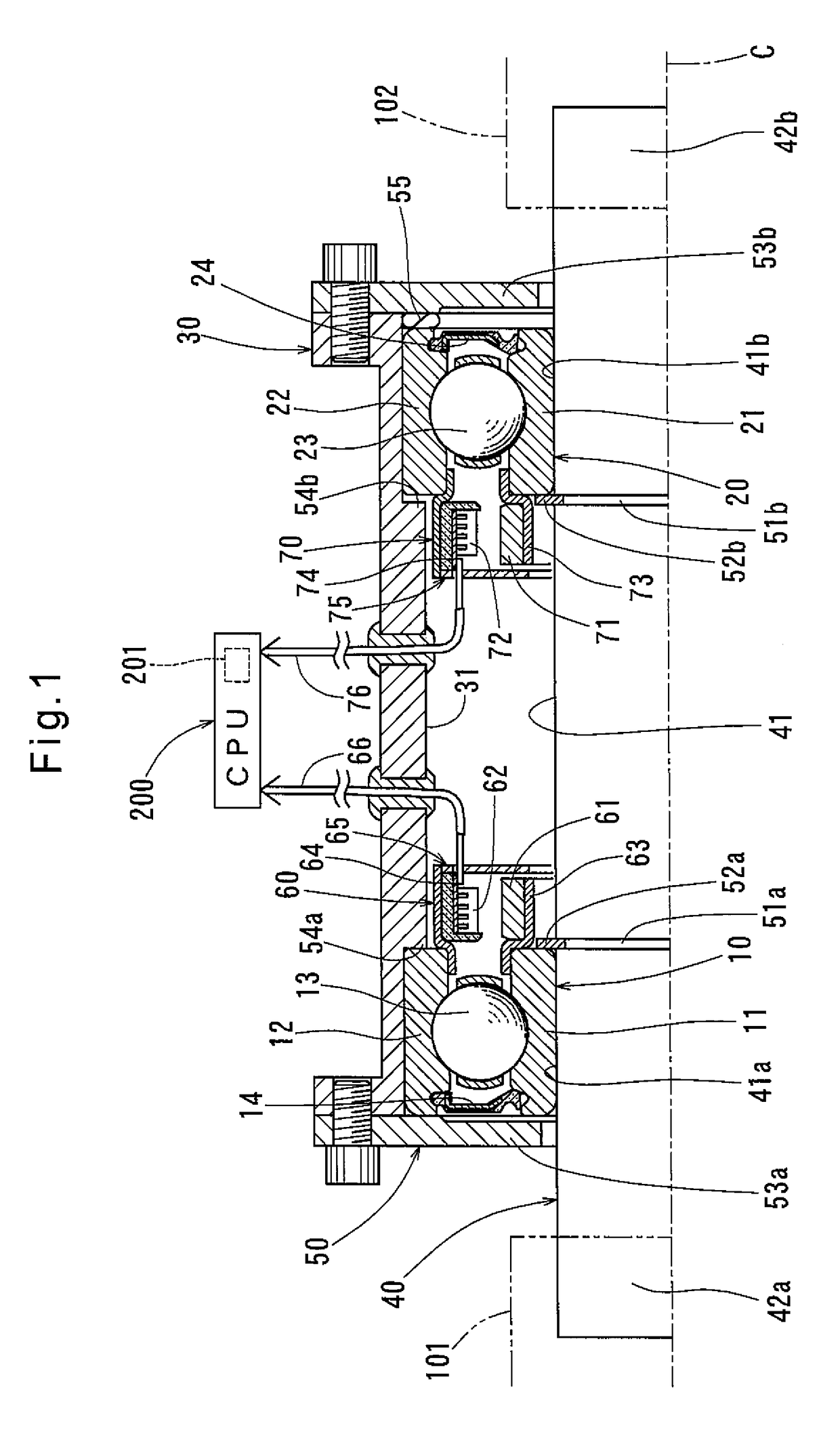

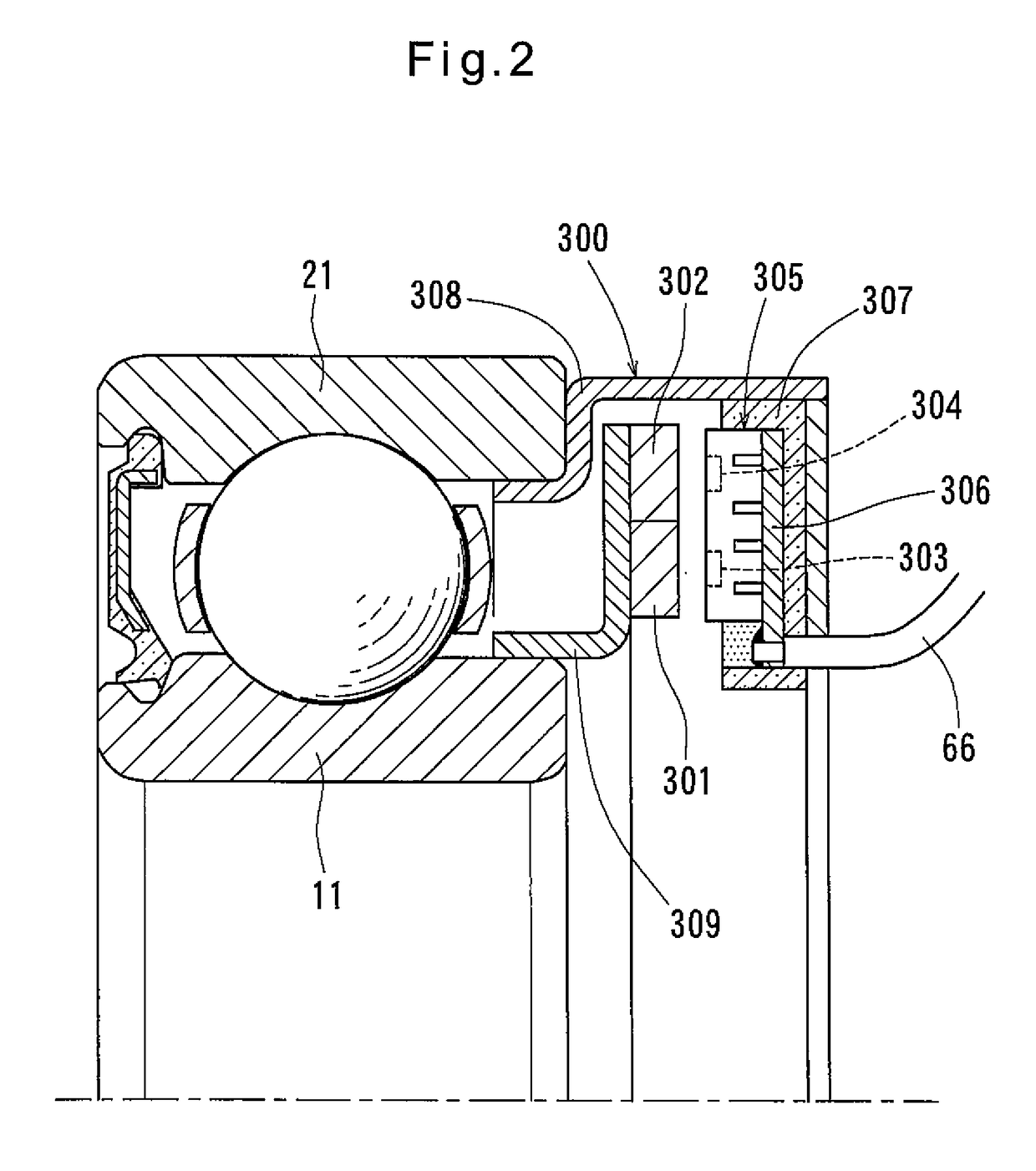

Torque sensor unit

InactiveUS20160216168A1Precise positioningPrevents reduction in mounting accuracyBearing assemblyShaftsAbsolute rotationEngineering

A torque sensor unit includes two magnetic angle sensors capable of detecting absolute rotation angles of a shaft member which indicate a twist angle of the shaft member when the shaft member is twisted. The shaft member has two end portions exposed to outside so that the shaft member can be connected at the two end portions to shaft-forming parts of a device.

Owner:NTN CORP

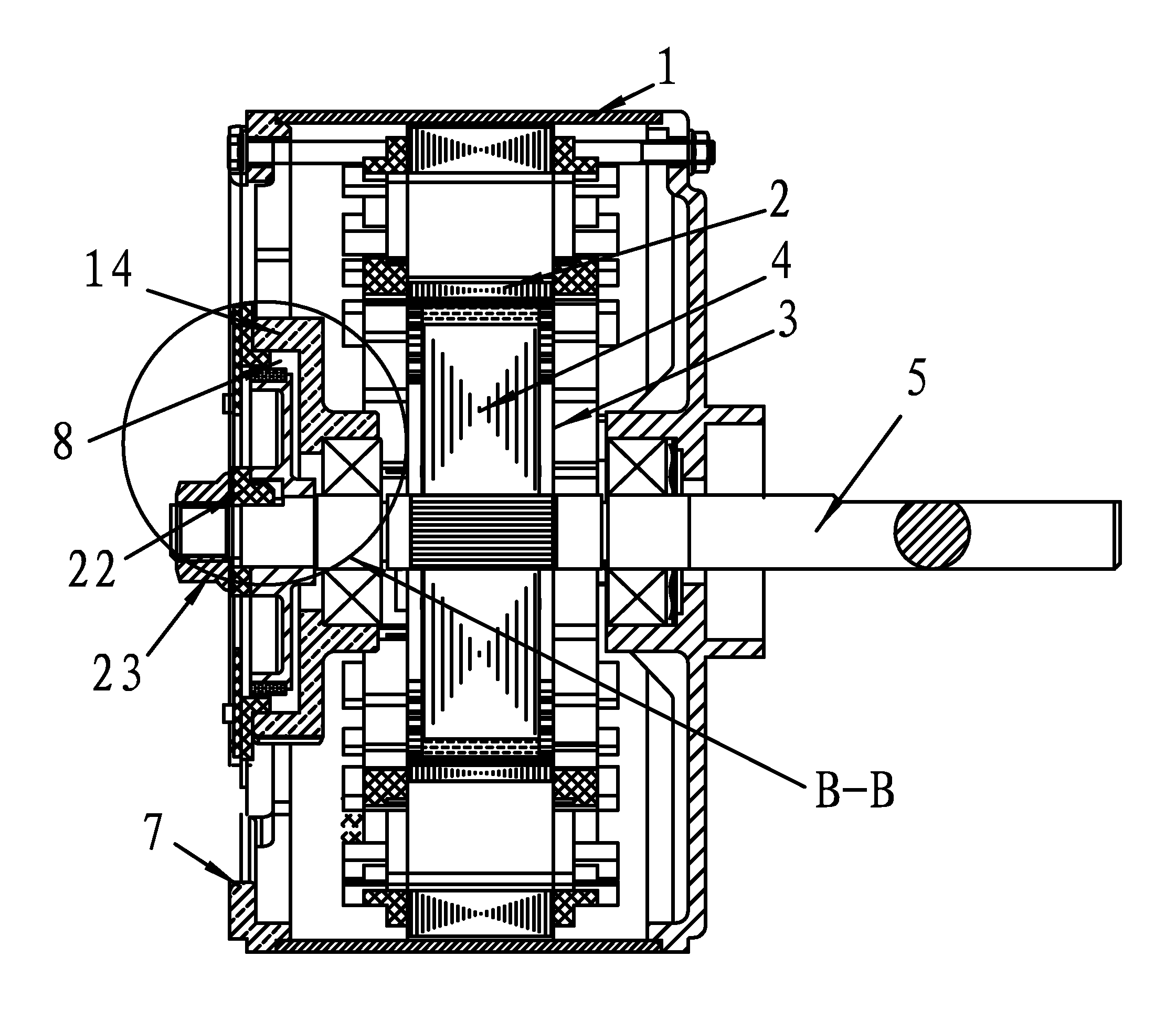

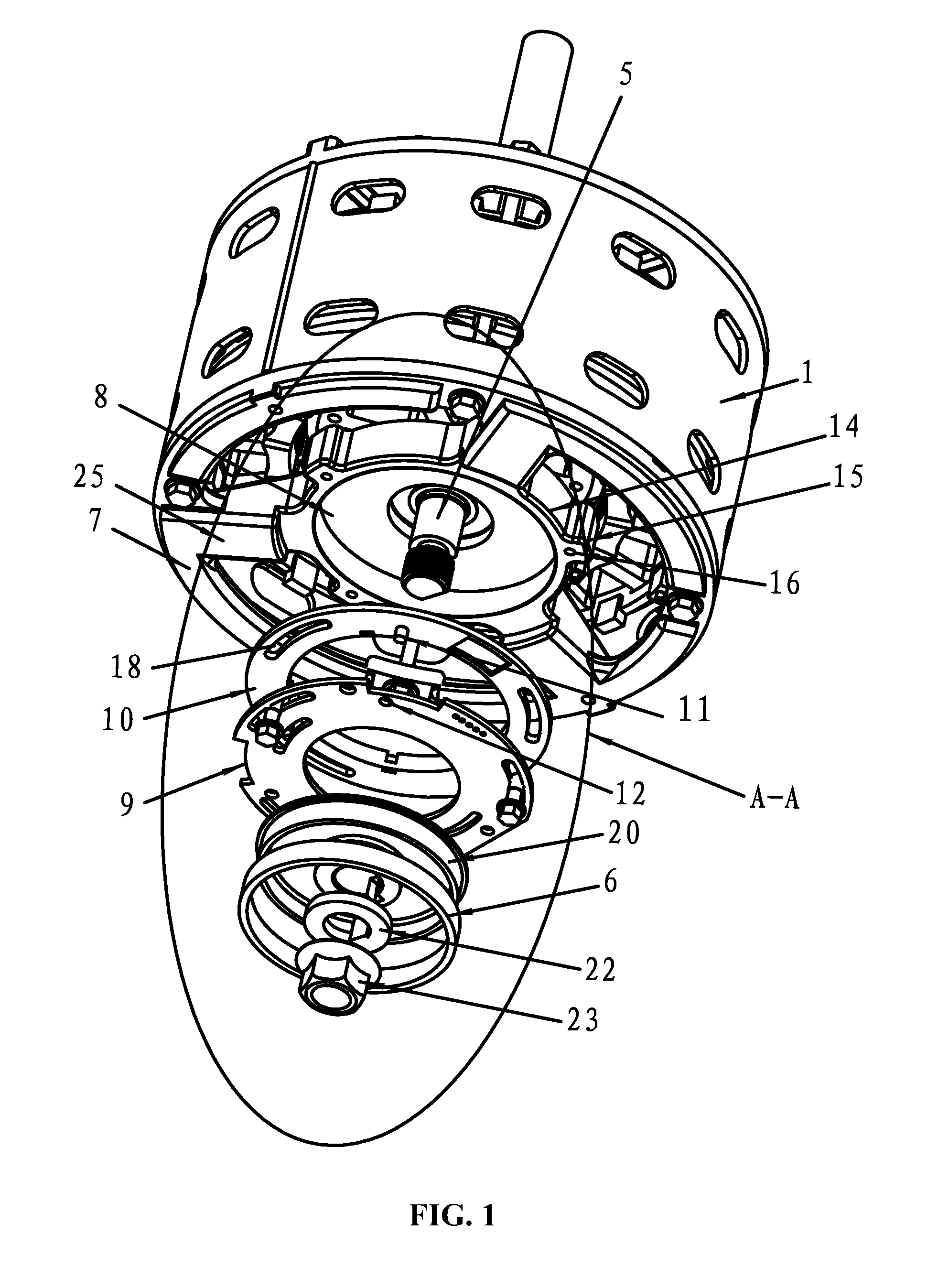

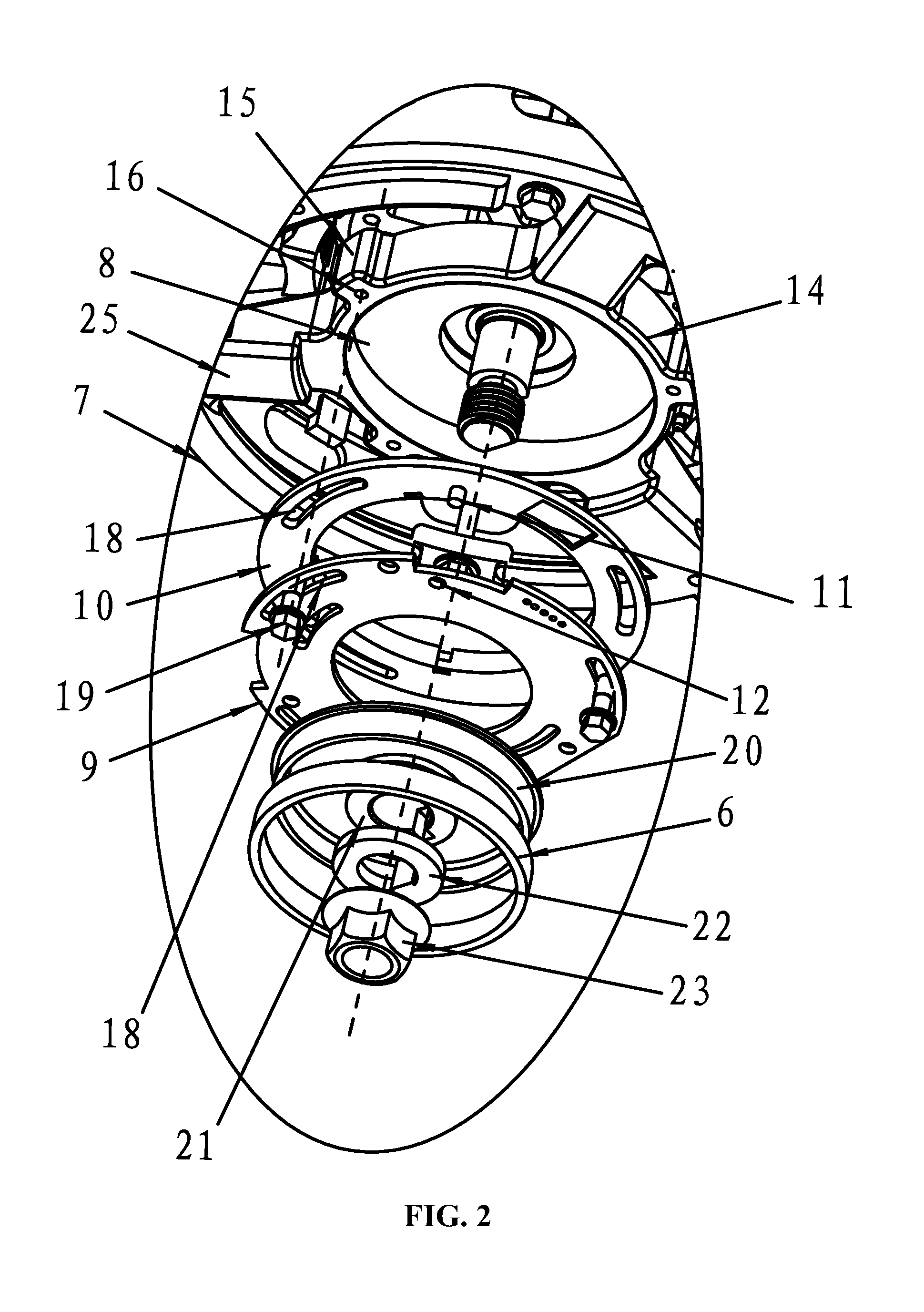

Wheel drive transmission

ActiveUS10766361B2Produced efficiently and inexpensivelyEnsure concentricityToothed gearingsCouplings for rigid shaftsGear wheelEngineering

A multistage wheel drive includes primary and secondary planetary stages, in which the ring gear of the primary (i.e., input-side) planetary stage is formed from a single machined part which also includes the planet gear carrier of the secondary (i.e., output-side) planetary stage. This dual-function “combination” component includes a splined exterior surface which interfaces with a correspondingly splined interior surface on the spindle in order to rotationally fix the combination component to the spindle. This arrangement ensures concentricity between the primary and secondary planetary stages, while allowing a desired amount of radial tolerance between the spindle, the combination component, and the hub of the wheel drive. In addition, the present arrangement can be produced efficiently and inexpensively.

Owner:AUBURN GEAR

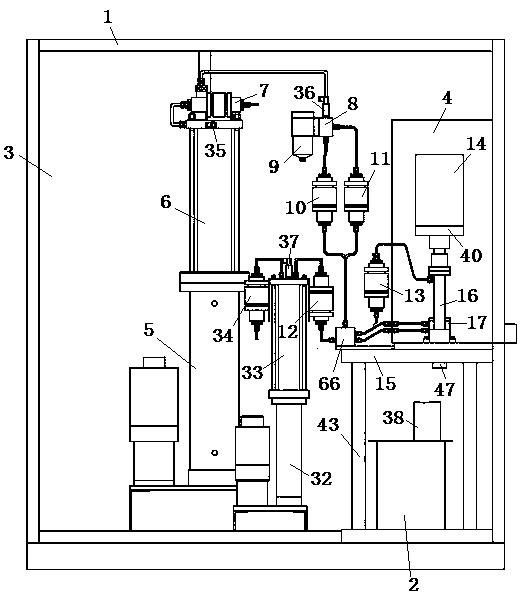

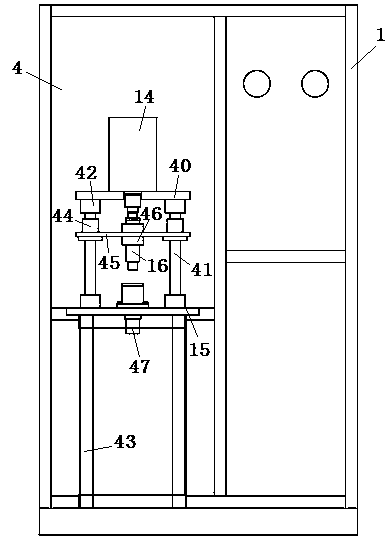

Microporous extrusion grinding machine tool

ActiveCN109732468AImprove work efficiencyGuaranteed orifice sizeEdge grinding machinesGrinding machine componentsSolenoid valveFilter system

The invention discloses a microporous extrusion grinding machine tool. The microporous extrusion grinding machine tool comprises a frame, an abrasive barrel, a suction system, a filtering system, an oil switching system and a clamp assembly, wherein the frame comprises a power part and an operating part; one side of the power part is provided with a door; one side of the operating part is providedwith an opening; the suction system comprises a large servo electric cylinder, a suction cylinder and a solenoid valve VI; the large servo electric cylinder is installed in the power part; the top end portion of a piston rod of the large servo electric cylinder is fixedly connected to a piston; the suction cylinder is fixedly connected to the top of the large servo electric cylinder; a sealing member is arranged between the suction cylinder and the large servo electric cylinder; the piston of the end portion of the large servo electric cylinder is slidably connected to the inner wall of the suction cylinder; the solenoid valve VI is fixedly connected to the suction cylinder; and the solenoid valve VI is connected to an inner cavity of the suction cylinder through a pipe. BY means of the microporous extrusion grinding machine tool, two micro holes can be machined on one device at the same time, and with no need of changing multiple devices, so that the time and labor are saved, and thework efficiency is greatly improved.

Owner:SUQIAN DINGCHENG MACHINERY MFG

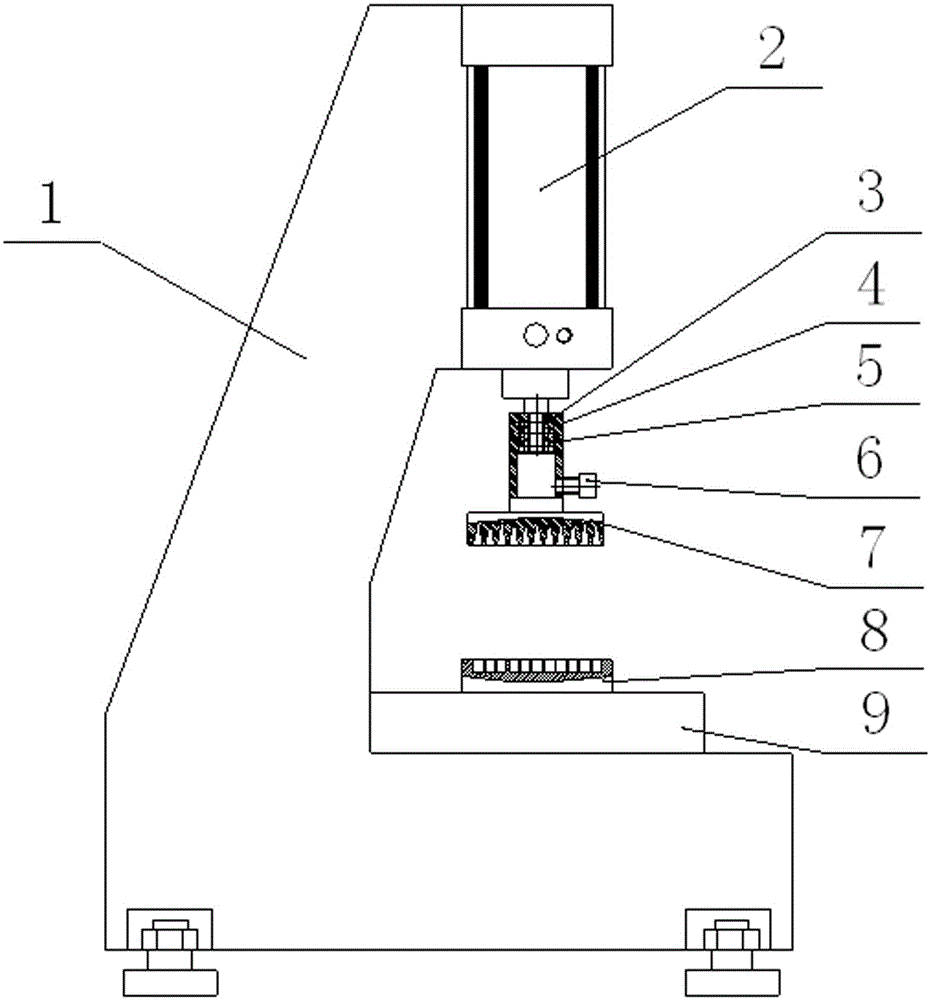

Closing device of connector jack

InactiveCN105119123AMeet the performance requirementsEnsure concentricityLine/current collector detailsSet screwOperational performance

The present invention relates to a closing device of a connector jack, comprising a body, a pneumatic actuator, a fixing sleeve, set screws, a closing dish, a positioning fixture and a workbench. The workbench is arranged on the body, the pneumatic actuator correspondingly located above the workbench is connected with the body, and the fixing sleeve is connected with the pneumatic actuator; the closing dish is penetrated into and connected within the fixing sleeve, the set screws are penetrated into and connected with the side wall of the fixing sleeve and are configured to compress the closing dish located within the fixing sleeve, and a plurality of conical bores are uniformly distributed with respect to the set of the connector jacks at the lower end surface of the closing dish; and the positioning fixture is arranged on the workbench with respect to the closing dish. The closing device of the connector jack provided by the invention has advantages of convenient operation, high overall closing concentricity and high precision, and is able to effectively ensure the concentric performance and the plugging performance of the corresponding pins and satisfy the operational performance requirement of the electric connector.

Owner:TAIXING SPACE APPLIANCE

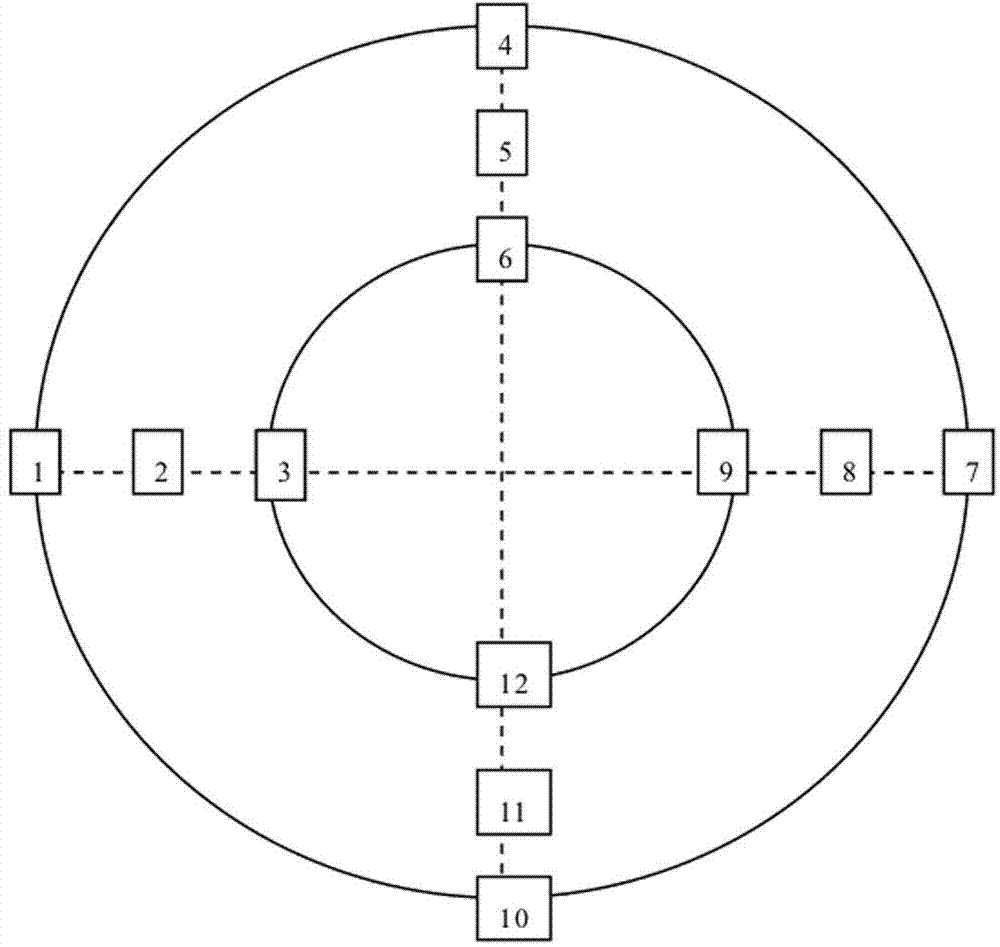

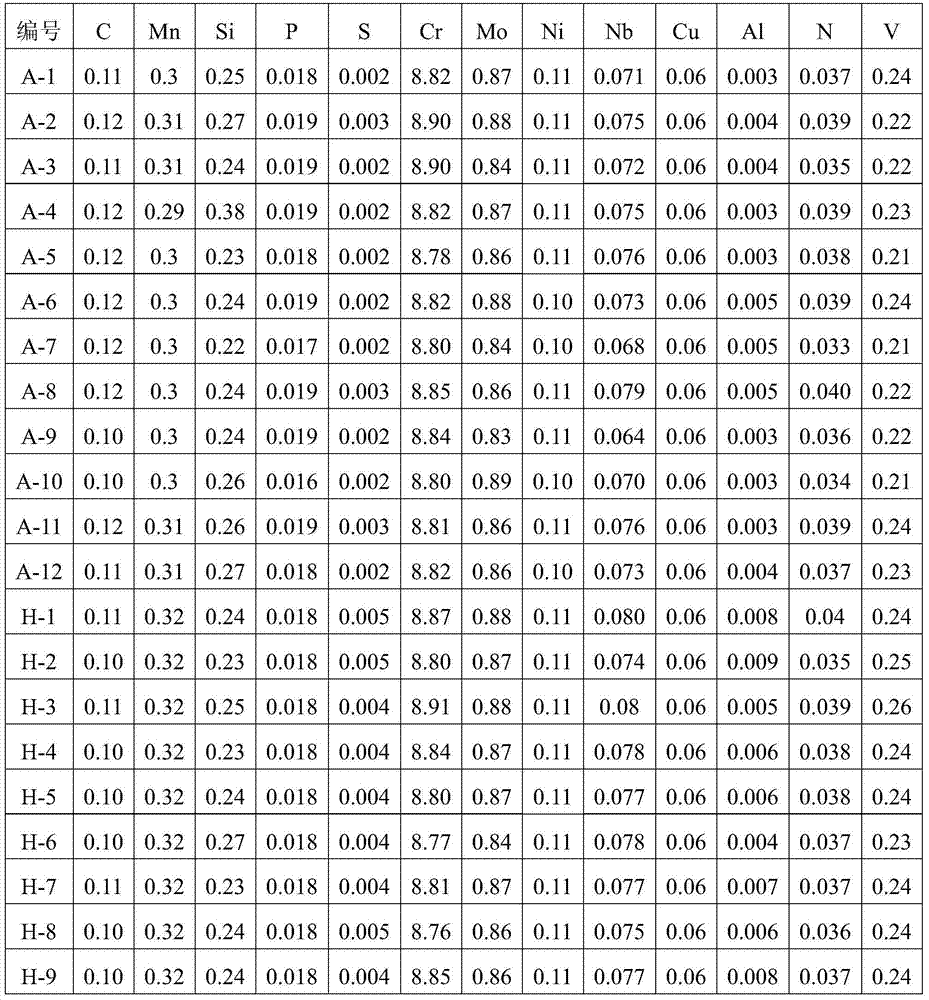

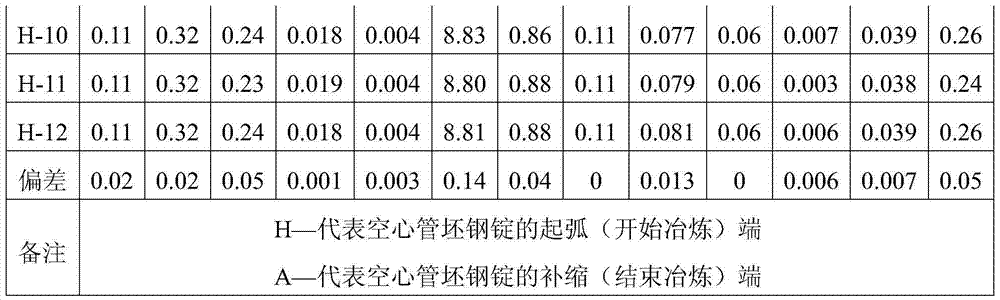

Method for smelting hollow billet steel ingot by using ingot stripping type electroslag furnace

The invention discloses a method for smelting a hollow billet steel ingot by using an ingot stripping type electroslag furnace. An outer crystallizer, an inner crystallizer and a bottom water tank are arranged in the ingot stripping type electroslag furnace, and an annular electrode bar is arranged between the outer crystallizer and the inner crystallizer; liquid slag charge is added into the ingot stripping type electroslag furnace, and arc striking is performed for smelting; the normal smelting current is controlled to be 21,000-25,000 A, the normal smelting voltage is controlled to be 78-88 V, and the smelting speed of the annular electrode bar is controlled to be 14-22 kg / min; and when a smelt liquid steel level formed by smelting is located in the position of 1 / 2-2 / 3 of the height of a section used for solidifying liquid steel in the inner crystallizer, the bottom water tank is controlled to drive a steel ingot to move downwards for ingot stripping, the ingot stripping speed is controlled to be 3-16 mm / min, the downward friction force suffered by the inner crystallizer is controlled to be smaller than 40% of the minimum deformation force which can be borne by the inner crystallizer, and the hollow billet steel ingot is obtained after the steel ingot is completely stripped. The method can smelt the qualified hollow billet steel ingot, and the quality and the production efficiency of a pipe fitting are improved greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Torque sensor unit

InactiveUS9739672B2Precise positioningImprove accuracyBearing assemblySteering linkagesAbsolute rotationControl theory

A torque sensor unit includes two magnetic angle sensors capable of detecting absolute rotation angles of a shaft member which indicate a twist angle of the shaft member when the shaft member is twisted. The shaft member has two end portions exposed to outside so that the shaft member can be connected at the two end portions to shaft-forming parts of a device.

Owner:NTN CORP

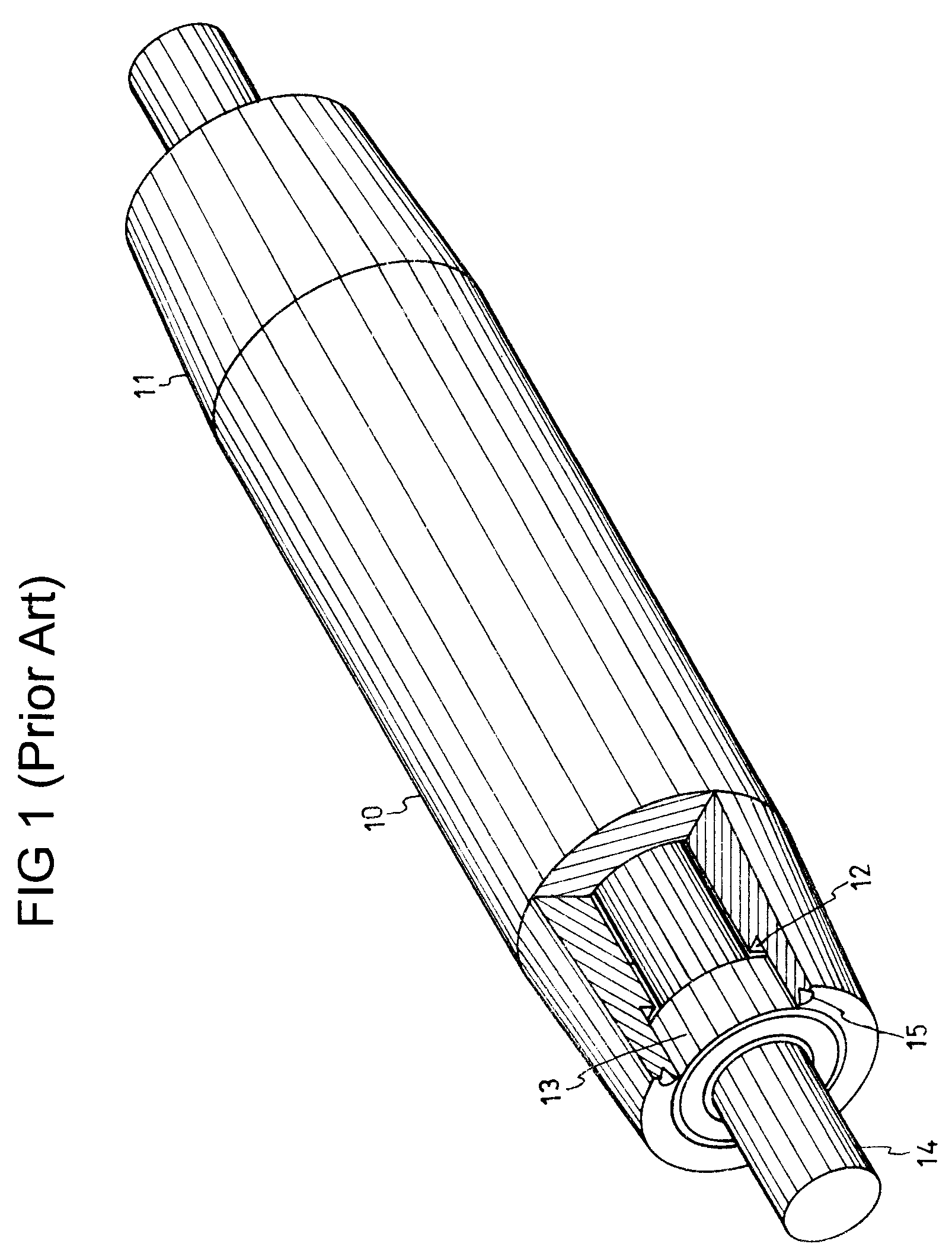

Downhole drill head

The invention relates to a downhole drill head comprising a speed reducer, a drill rod seat used for installing a drill rod of a downhole drill, a sleeve barrel (10) and a transmission shaft (11), wherein the rear end of the sleeve barrel (10) is fixedly connected to the speed reducer, and the transmission shaft (11) is installed in the sleeve barrel (10) by a bearing and a sealing ring; a connecting hole (15) used for installing an output shaft of the speed reducer is disposed at the rear end of the transmission shaft (11), and the front end is provided with a flange (8) which can be connected with the drill rod seat; a hollow aeration passage (12) is arranged on the transmission shaft (11), the front end of the aeration passage (12) is opened, and the rear end is closed; and the middle parts of the sleeve barrel (10) and the transmission shaft (11) are respectively provided with an air hole communicated with the aeration passage (12). The transmission shaft of the downhole drill head and the output shaft of the speed reducer adopt the spilt structure, thereby preventing the original structure from impacting and damaging internal gear wheels of the speed reducer.

Owner:迟利民

Low-frequency detector

InactiveCN110632648AEnsure concentricityEnsure location accuracySeismic signal receiversVibration measurementEngineering

The invention relates to a low-frequency detector and aims at solving the technical problems that an existing mechanical vibration-type low-frequency detector is relatively large in size and weight, high in construction cost, inconvenient to construct and transport and very easy to damage. The low-frequency detector comprises a shell, wherein a coil skeleton, an upper yoke and a lower yoke are arranged in the shell; the upper end of the coil skeleton is connected with the upper yoke through at least two upper leaf springs; and the lower end of the coil skeleton is connected with the lower yokethrough at least two lower leaf springs. The low-frequency detector can be applied to the technical field of exploration and engineering vibration measurement.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

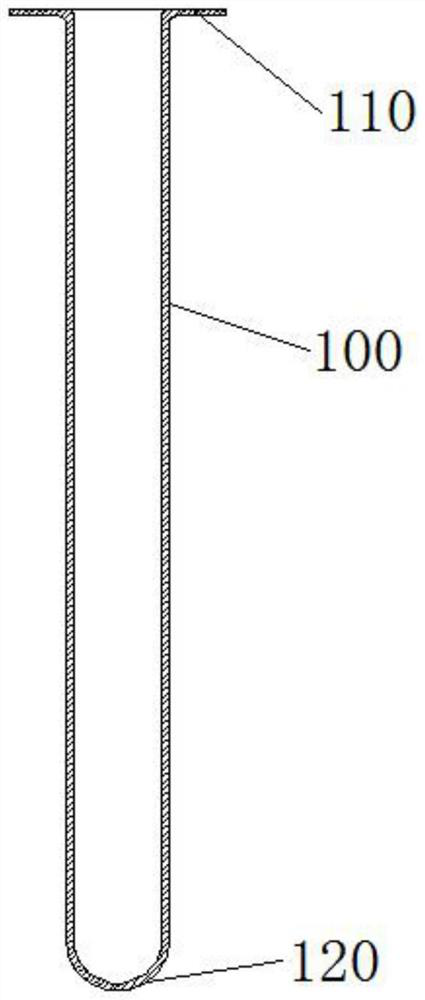

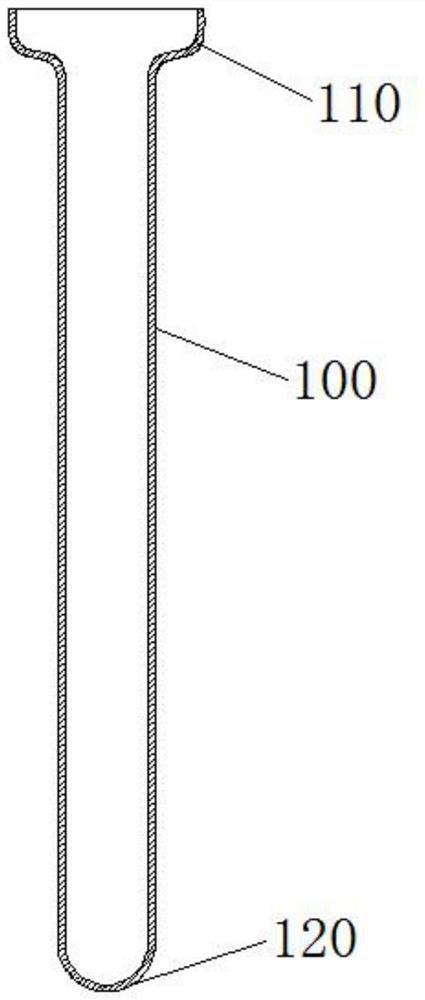

Stainless steel tube structure of heating rod of electronic thermostat and forming process of stainless steel tube structure

PendingCN114760722ASolve the problem of inconsistencySimple processOhmic-resistance heating detailsHeating element shapesHeater RodSS - Stainless steel

The invention provides an electronic thermostat heating rod stainless steel pipe structure and a forming process thereof. The electronic thermostat heating rod stainless steel pipe structure comprises a pipe body, and one end of the pipe body is stamped through a die to form an outward flange; and the other end of the pipe body is stamped by a die to form a sealed back cover. According to the process, a pipe or a plate is placed in a stamping die to be integrally stamped to form a hollow pipe body with one end in a flanging horn mouth shape and the other end being a sealed bottom. The pipe or the plate is made of stainless steel. The stainless steel pipe is integrally stamped to form the hollow pipe body with one end in the shape of the outwards-turned horn mouth flange and the other end in the shape of the sealed bottom, the machining process is simplified, the production efficiency is improved, the production cost is saved, and the problem that the flange and the stainless steel pipe cannot be concentric in the traditional welding process is solved; concentricity of the two parts is ensured, sealing-off and the like are avoided, and follow-up installation and use of products are not affected.

Owner:温州海得利电气有限公司

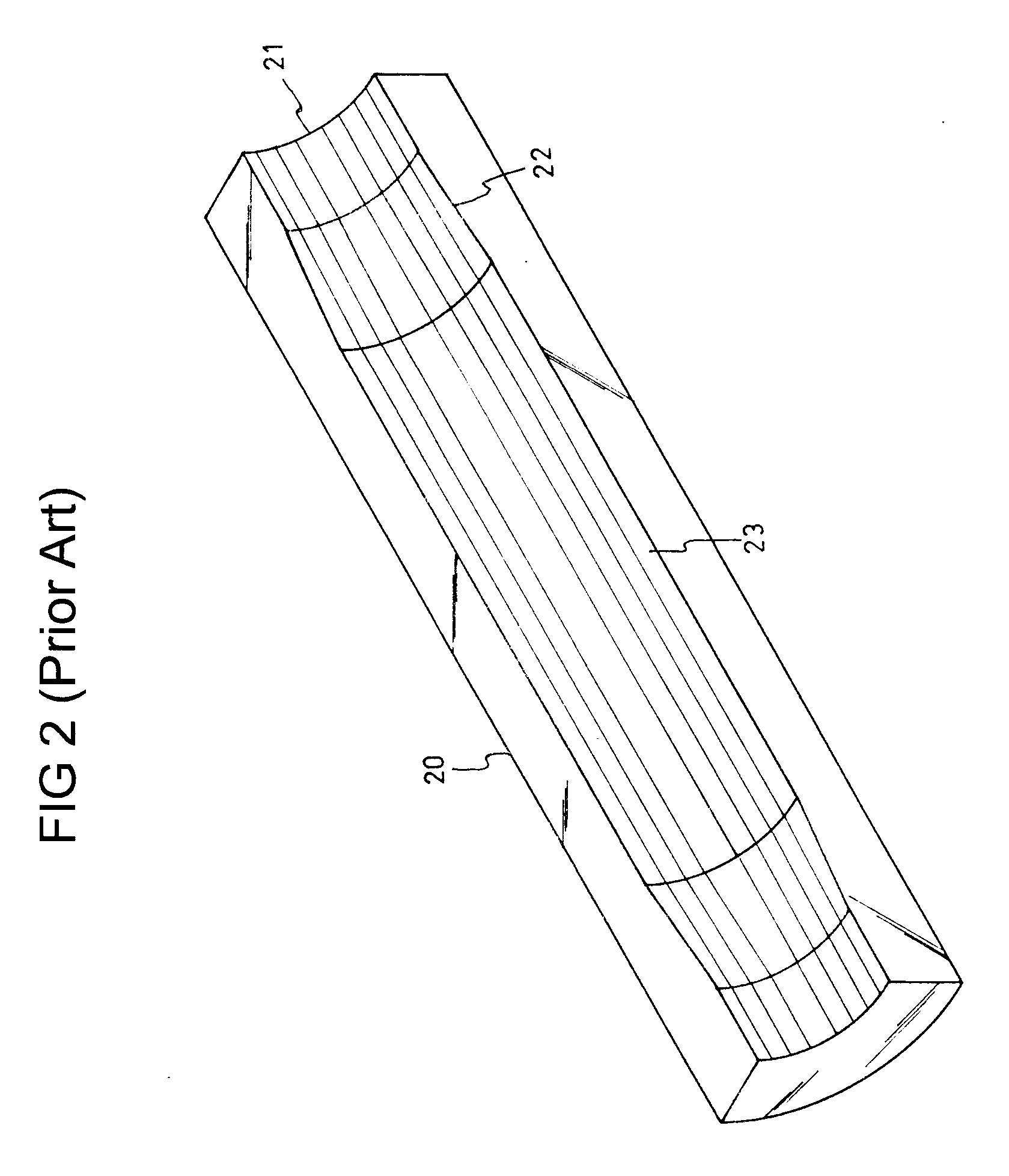

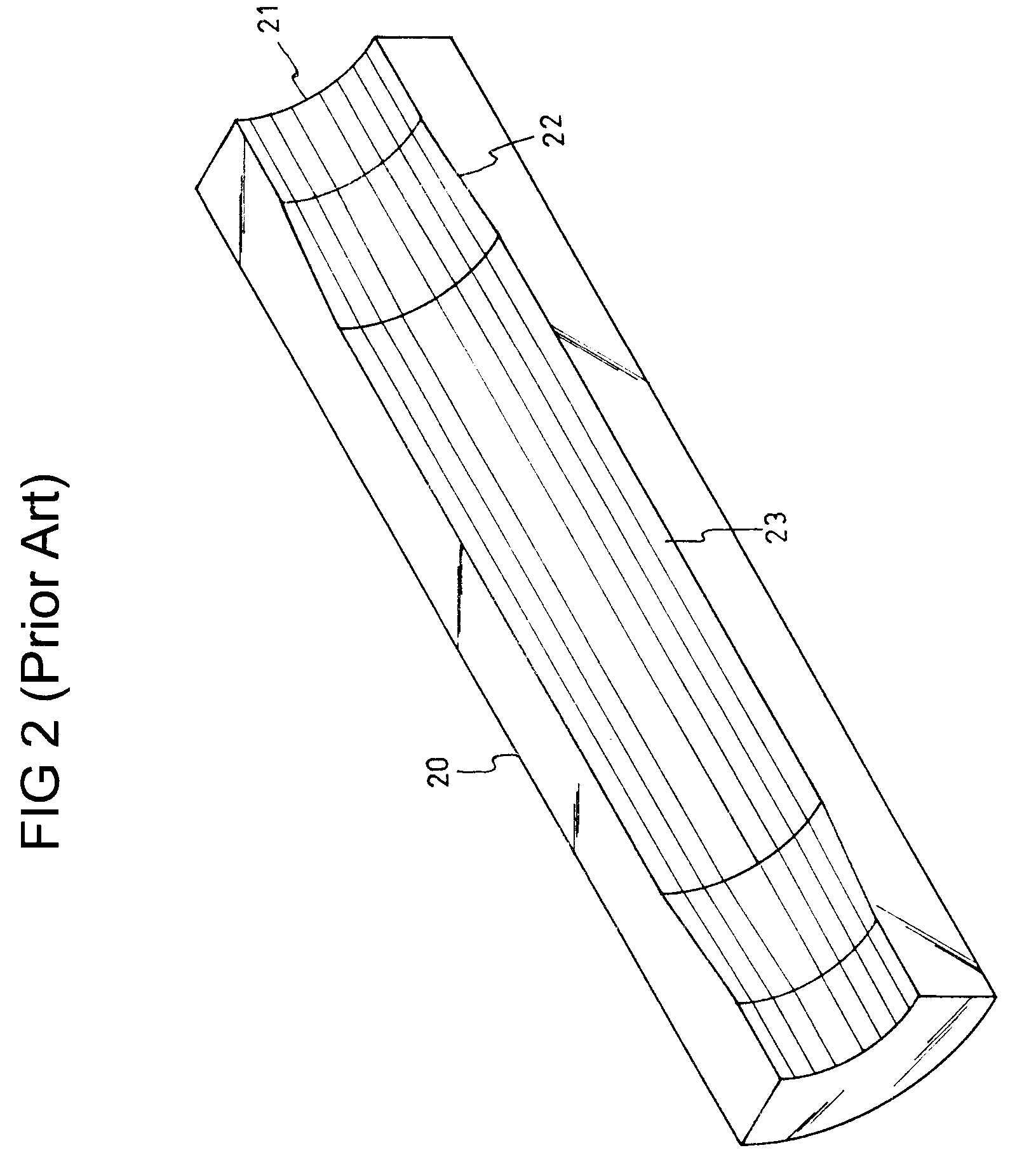

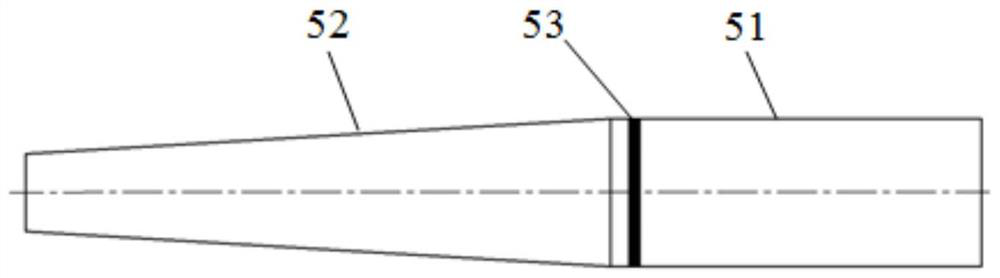

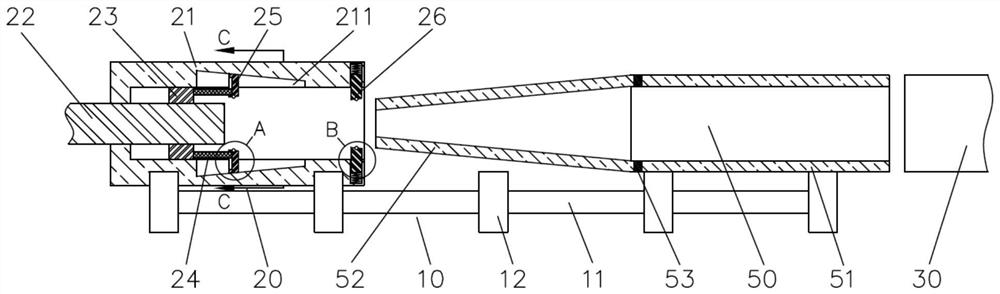

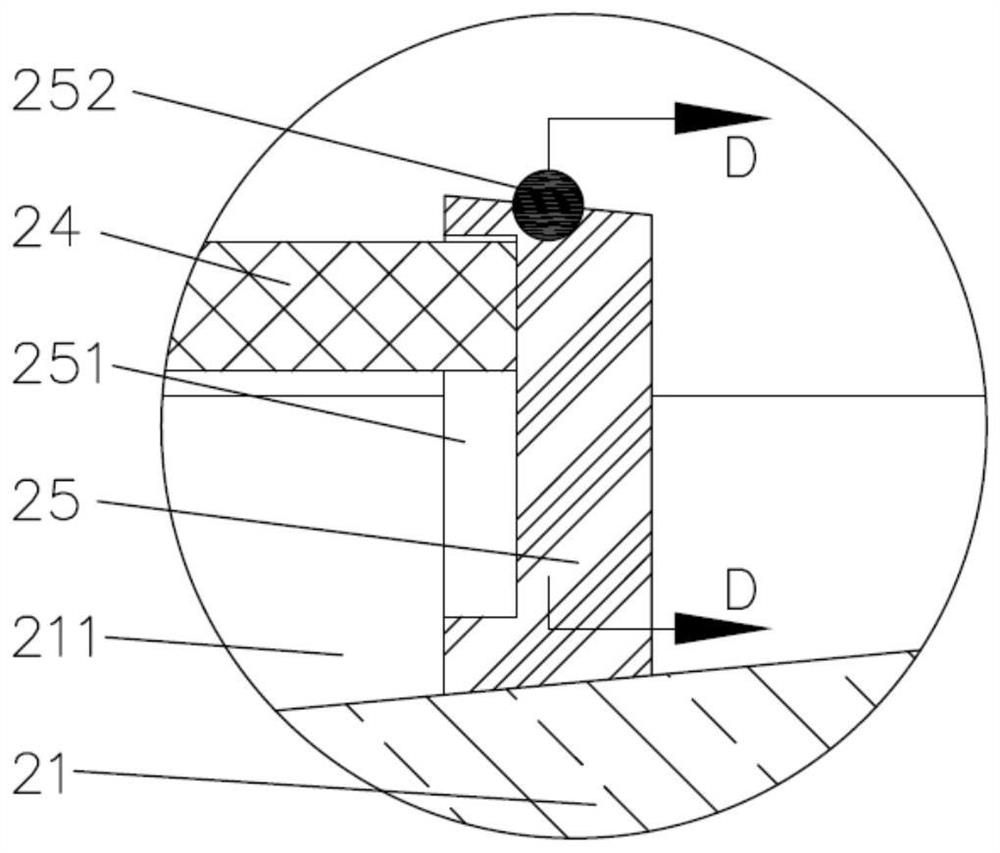

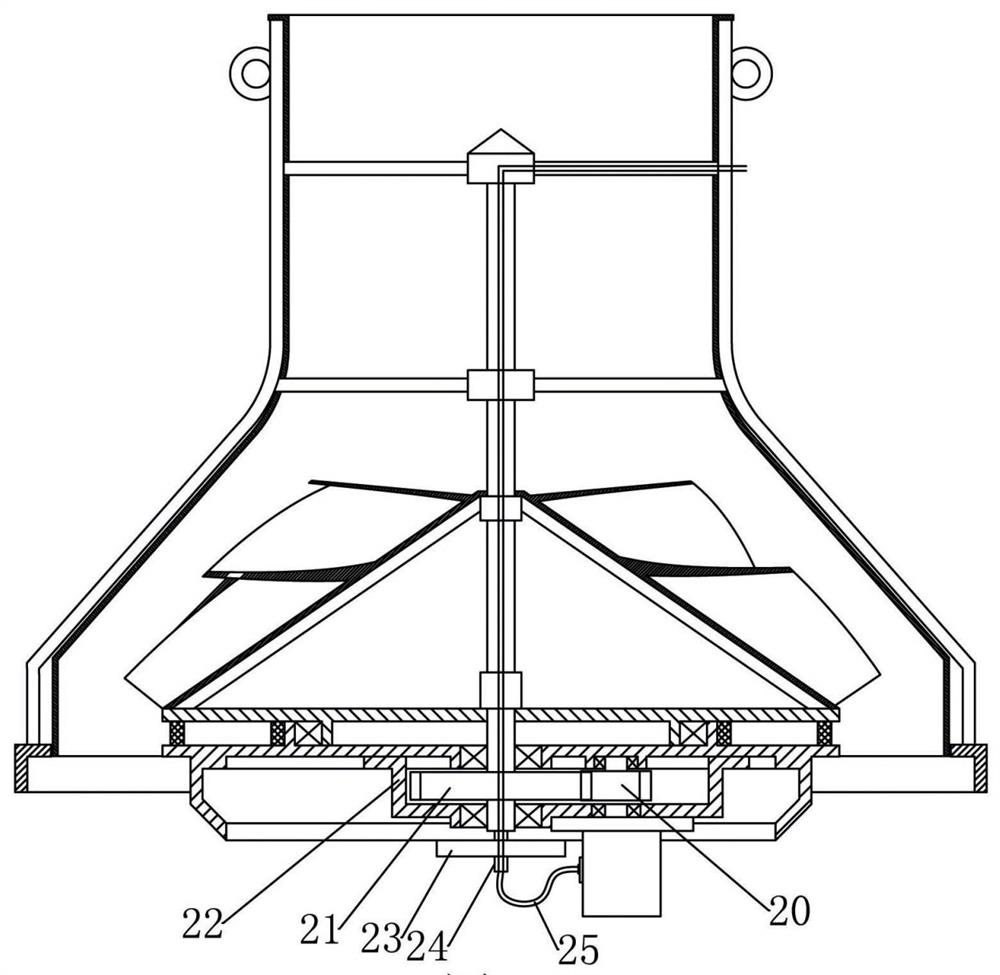

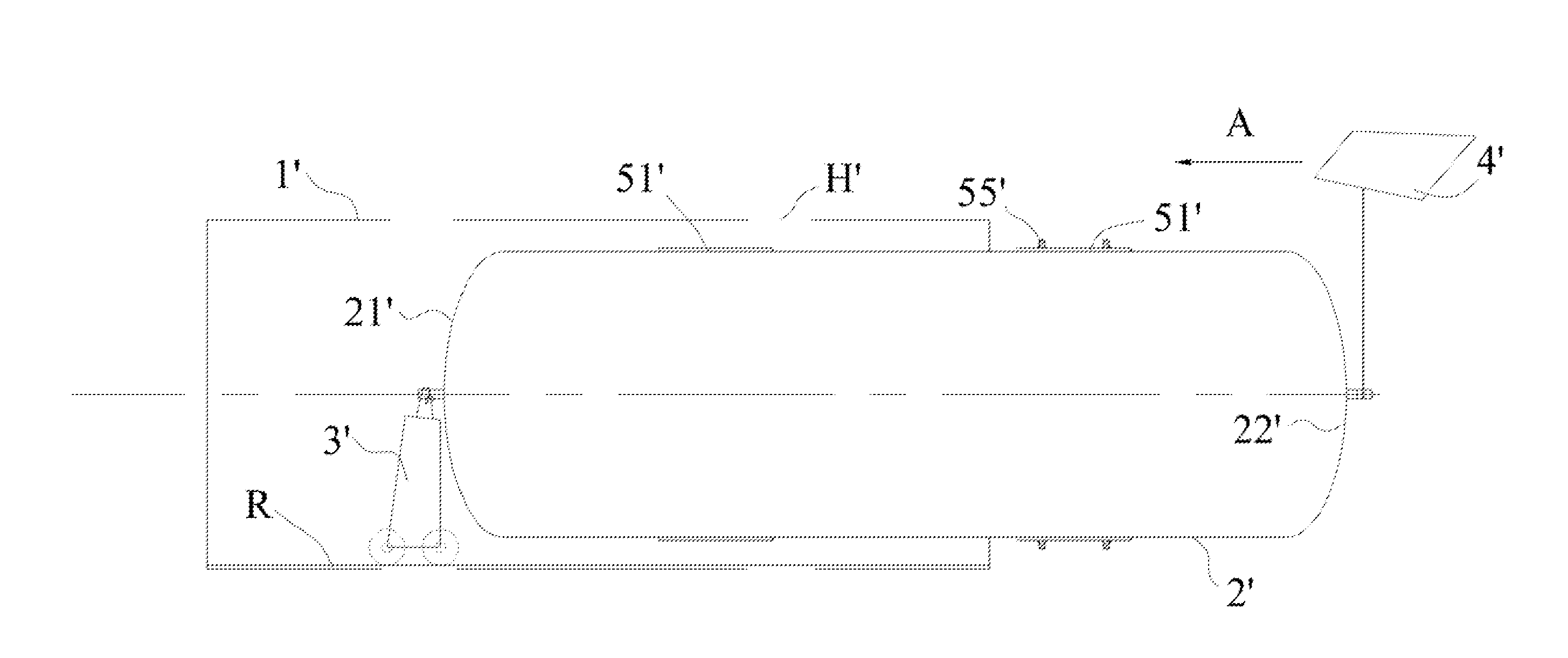

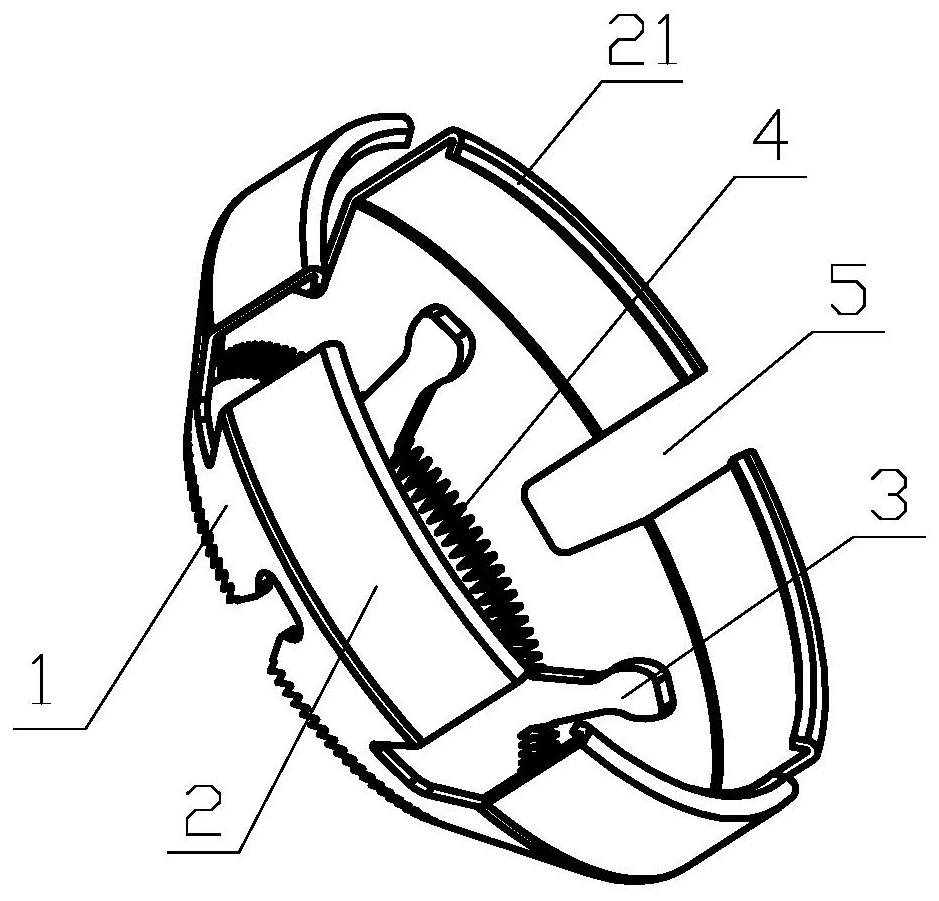

Automatic detection method for friction welding head of conical component with large length-diameter ratio

ActiveCN114062494AEnsure flatnessEnsure concentricityAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationFriction weldingWater immersion

The invention provides an automatic detection method for a friction welding head of a conical component with a large length-diameter ratio. The automatic detection method comprises the following steps: a, placing the conical component; b, carrying out water immersion ultrasonic detection; and c, screening qualified parts. According to the invention, an automatic detection system is adopted for detection, and the automatic detection system comprises an equipment water tank, a guide rail assembly (10), a profiling positioning tool (20), a first push rod (30), a clamping, assembling and disassembling tool (40) and water immersion ultrasonic C scanning equipment. The profiling positioning tool (20) comprises a tool body (21), a second push rod (22), a sliding sleeve (23), a connecting rod (24), a first clamping jaw (25), a second clamping jaw (26) and a compression spring (260). According to the method, the flatness and the coaxiality of the conical component with the large length-diameter ratio on the ultrasonic C scanning water tank guide rail can be effectively ensured, so that the detection accuracy is ensured; and meanwhile, the method can realize rapid and automatic loading and unloading, saves labor productivity, is high in detection efficiency, and can realize large-scale detection.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

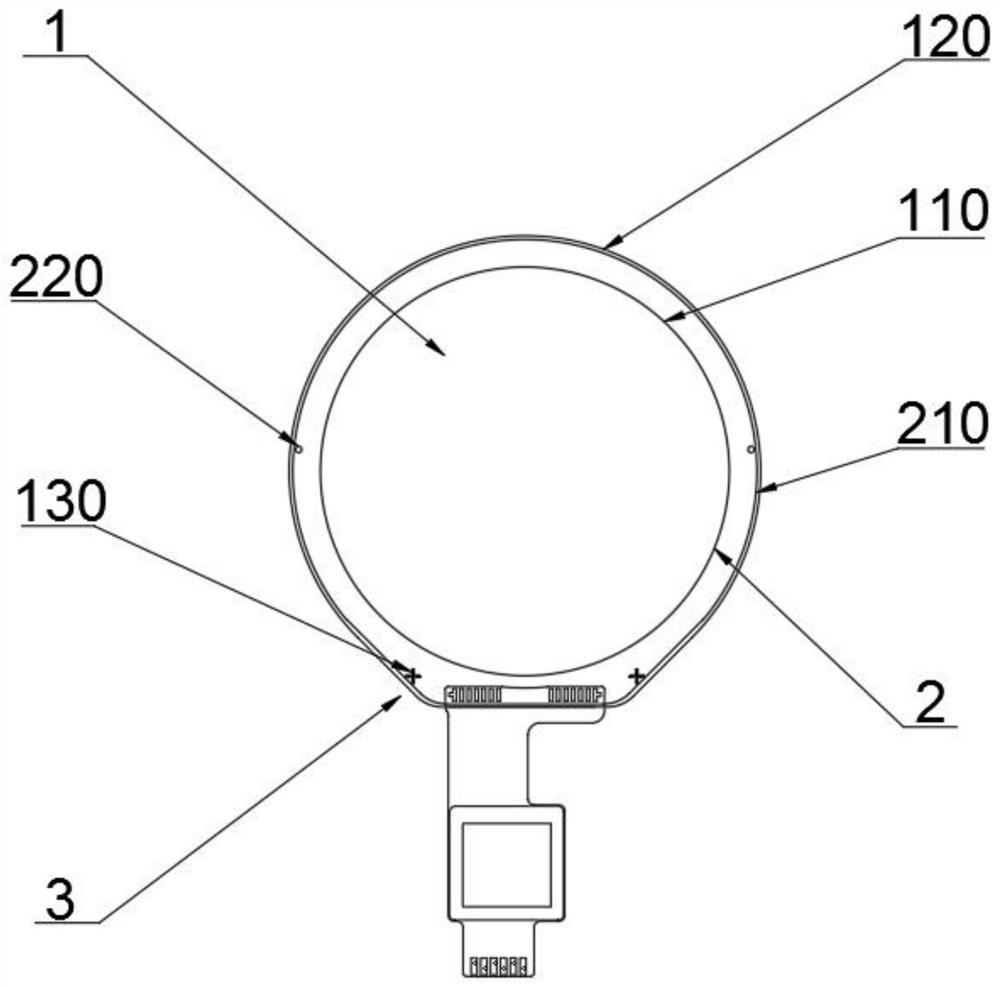

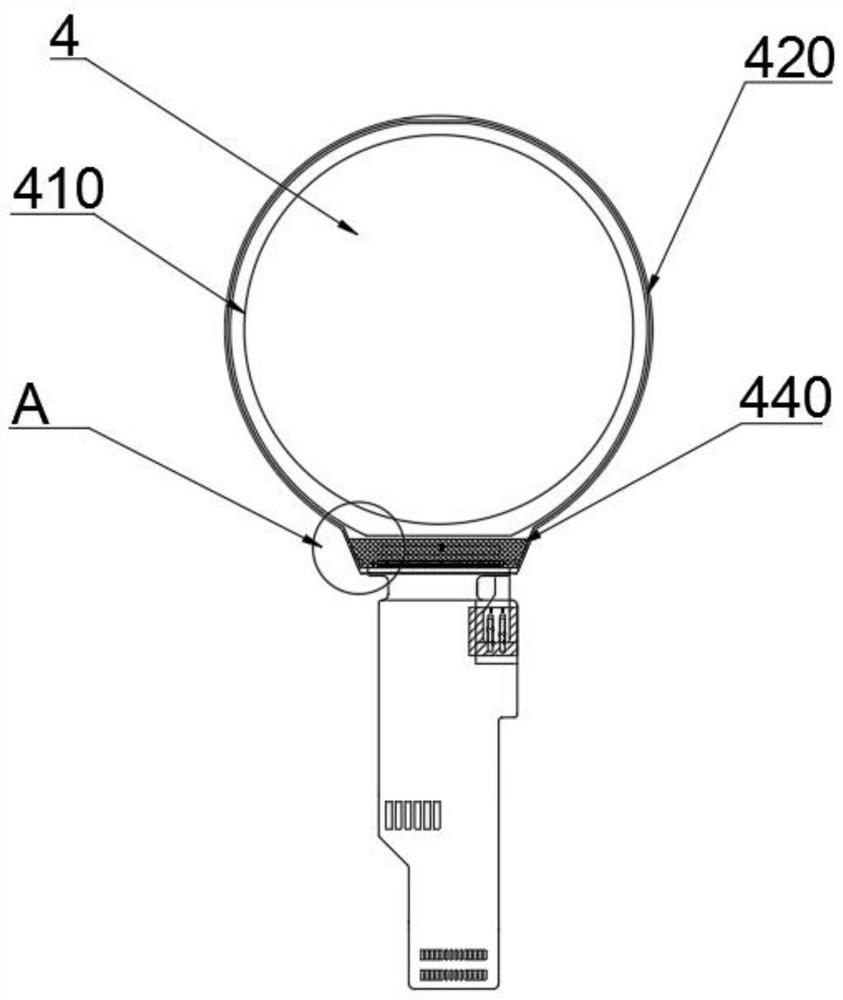

Fitting method and fitting device for circular wearable touch display module

PendingCN111930257AEnsure concentricityMake sure the deflection angleDetails for portable computersInput/output processes for data processingSilver pasteEngineering

The invention discloses a fitting method and a fitting device for a circular wearable touch display module. The fitting method comprises the following steps: fitting a circular wearable touch displaymodule on a substrate; the method comprises the steps that a circular touch cover plate is grabbed, a circular touch screen functional part is grabbed, the circular touch cover plate and the circulartouch screen functional part are attached to form a circular touch screen, a circular display screen is grabbed, the circular touch screen is grabbed, and the circular display screen and the circulartouch screen are attached. According to the invention, the circular inner frame of the faying surface of the circular touch screen cover plate is grabbed through the CCD; and the concentricity and thedeflection angle of the circular touch screen cover plate and the circular touch screen functional sheet are ensured through calculation of the two symmetrical white alignment targets on the bindingsurface of the circular touch screen cover plate, the circular shape of the circular touch screen functional sheet and the two symmetrical solid silver paste circular targets on the circular touch screen functional sheet.

Owner:SHENZHEN GREAT PROSPECT OPTOELECTRONICS CO LTD

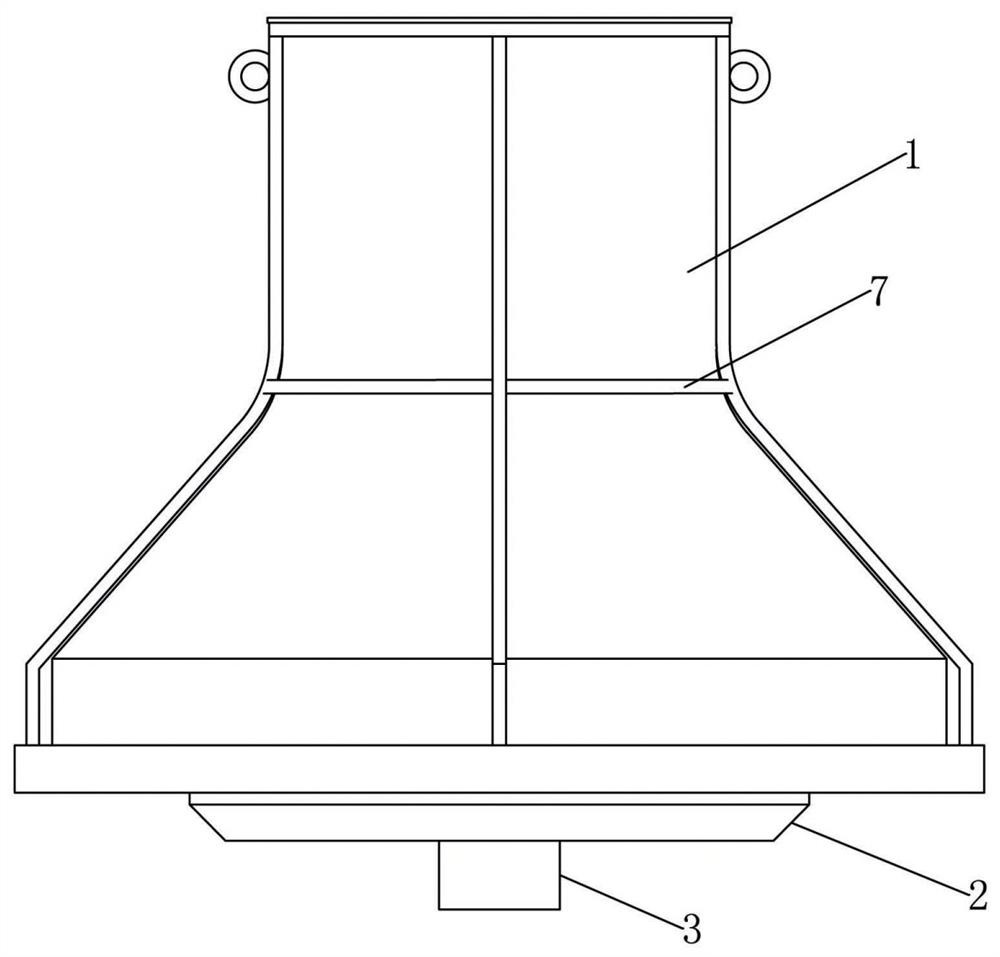

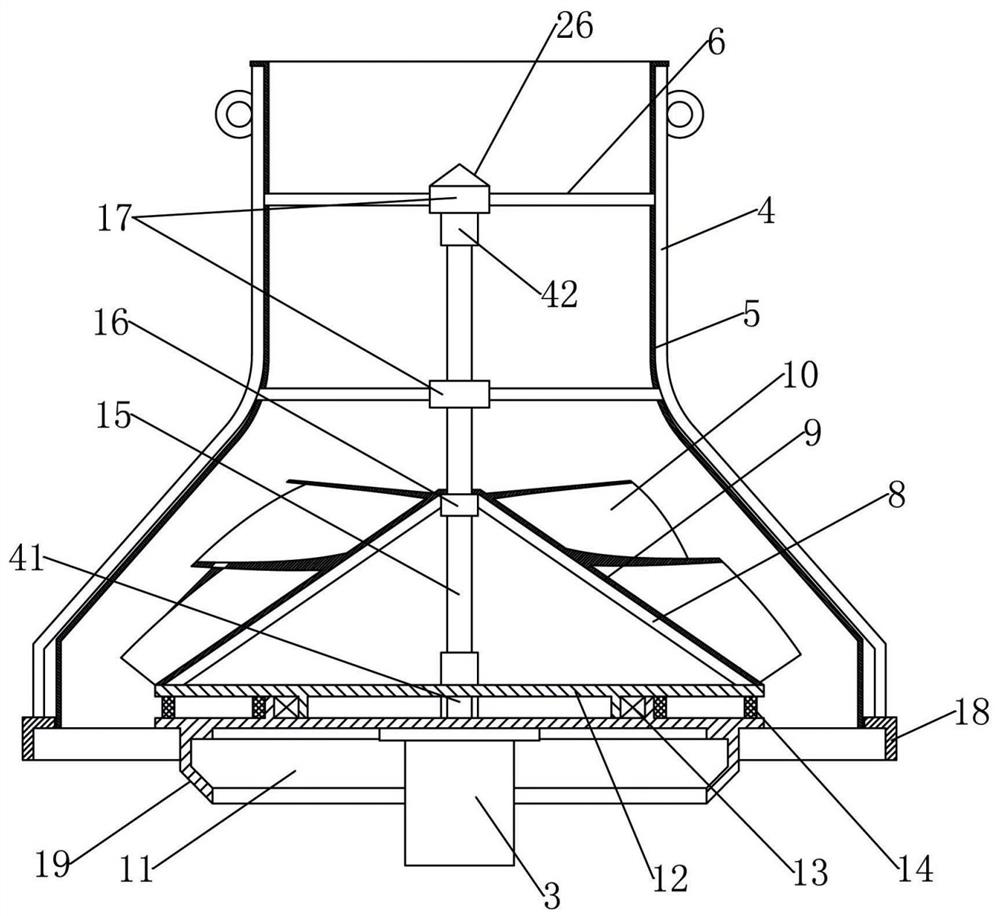

Automatic vibration-free self-compacting uniform blanking device for prestressed concrete cylinder pipe

PendingCN114274337AEvenly distributedPrevent left and right skew problemsFeeding arrangmentsAuxillary shaping apparatusElectric machineryDrive motor

The invention discloses an automatic vibration-free self-compacting uniform blanking device for a prestressed concrete cylinder pipe, which mainly comprises an outer conical cover body assembly and an inner conical cover body assembly, the outer conical cover body assembly comprises an upper cylindrical section and a lower conical section, the inner conical cover body assembly is a cone, and the outer conical cover body assembly comprises an upper cylindrical section and a lower conical section. The outer cone cover body assembly and the inner cone cover body assembly are sleeved together and are connected through the middle shaft. After sleeving, a conical cavity exists between the rotating body and the cone, one of the rotating body and the cone is driven by a driving motor to rotate, spiral pushing plates are evenly distributed on the inner wall, located on one side of the conical cavity, of the rotating body, the width of the adjacent spiral pushing plates at the cone top is smaller than that of the cone bottom, and the height of each spiral pushing plate at the cone top is larger than that of the cone bottom. According to the application of the concrete blanking device, concrete blanking distribution is more uniform, and some embodiments adopt an automatic compaction function, so that the concrete blanking device can be suitable for ordinary concrete and self-compacting concrete.

Owner:河南省富臣管业有限公司

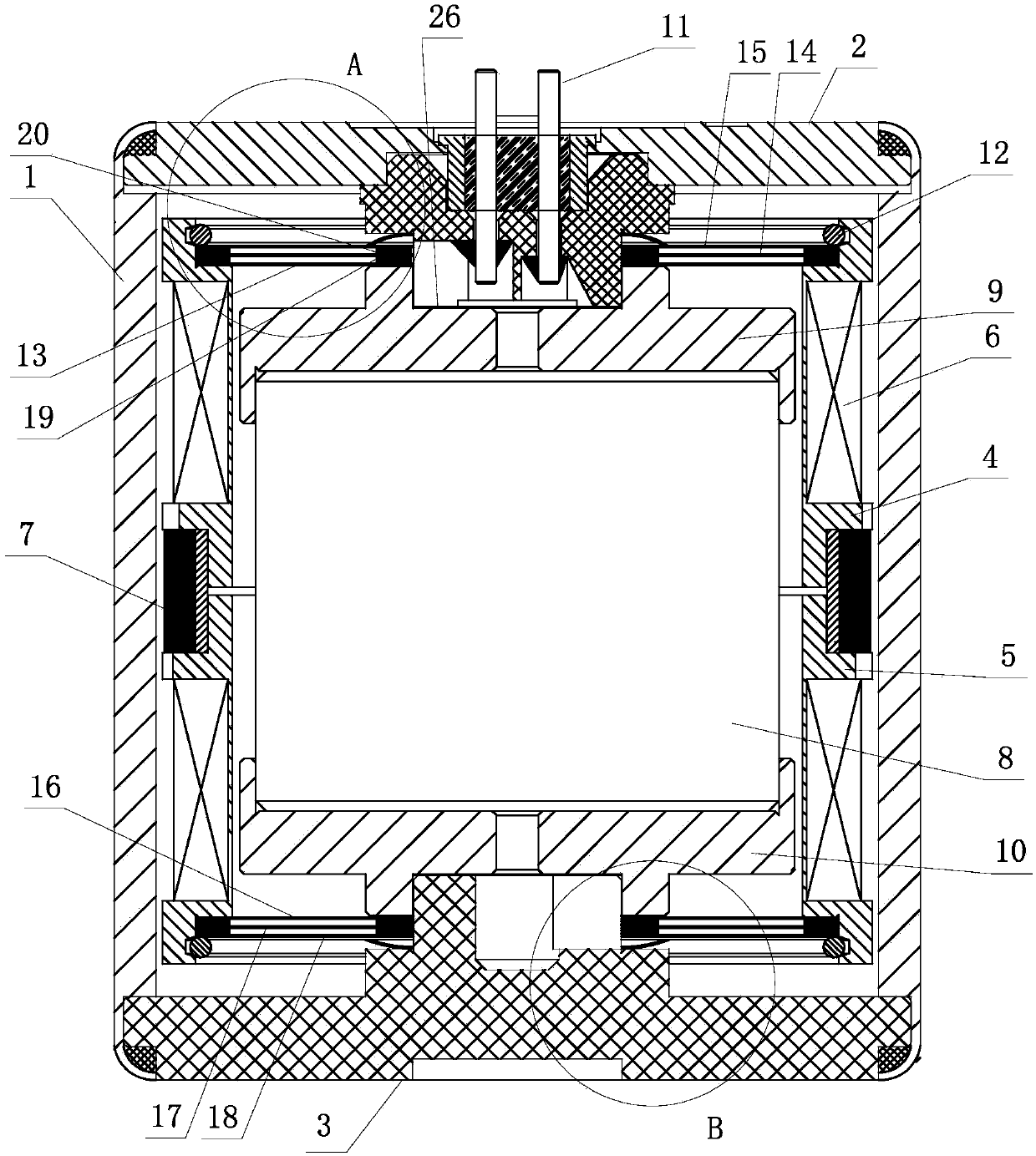

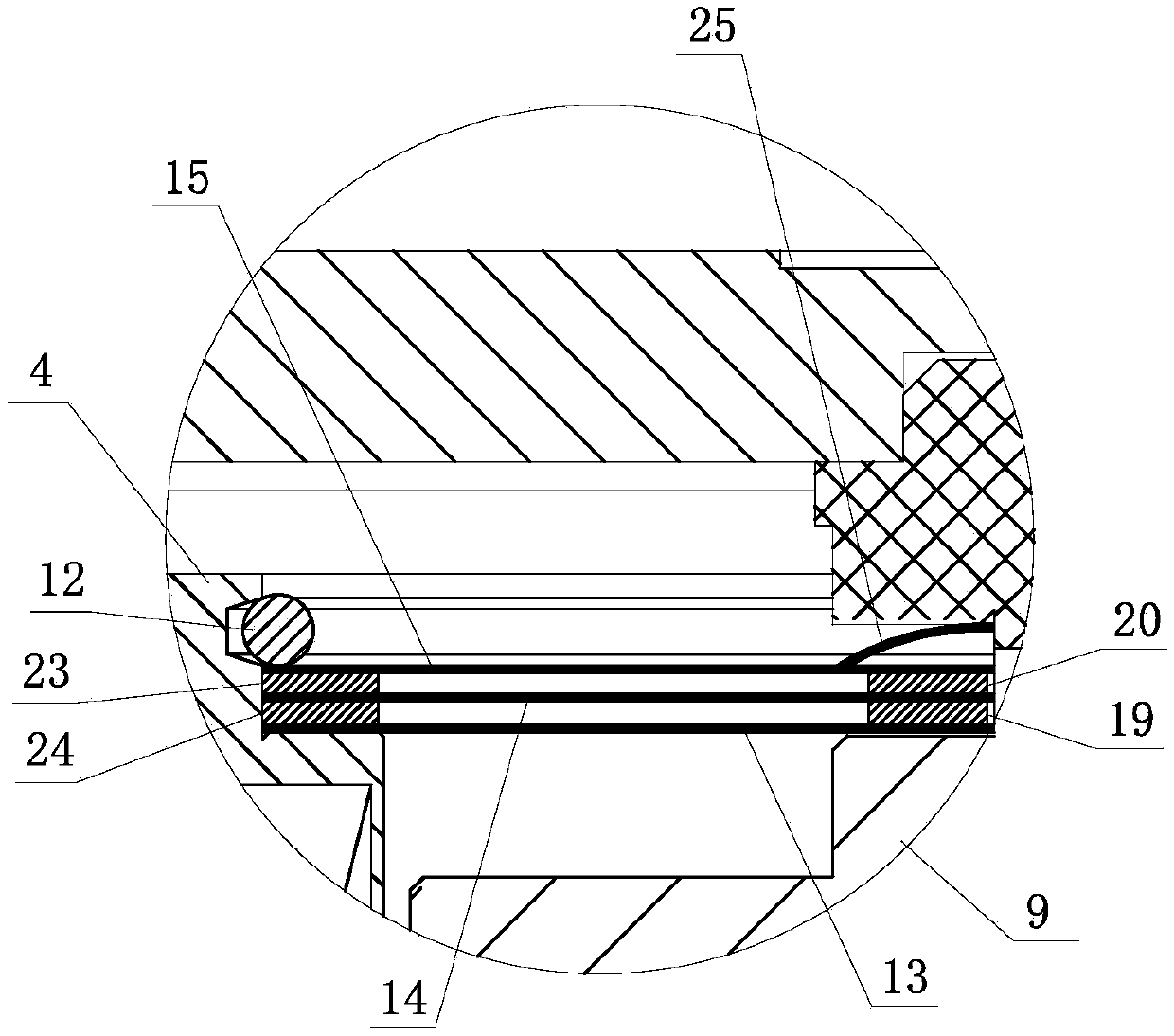

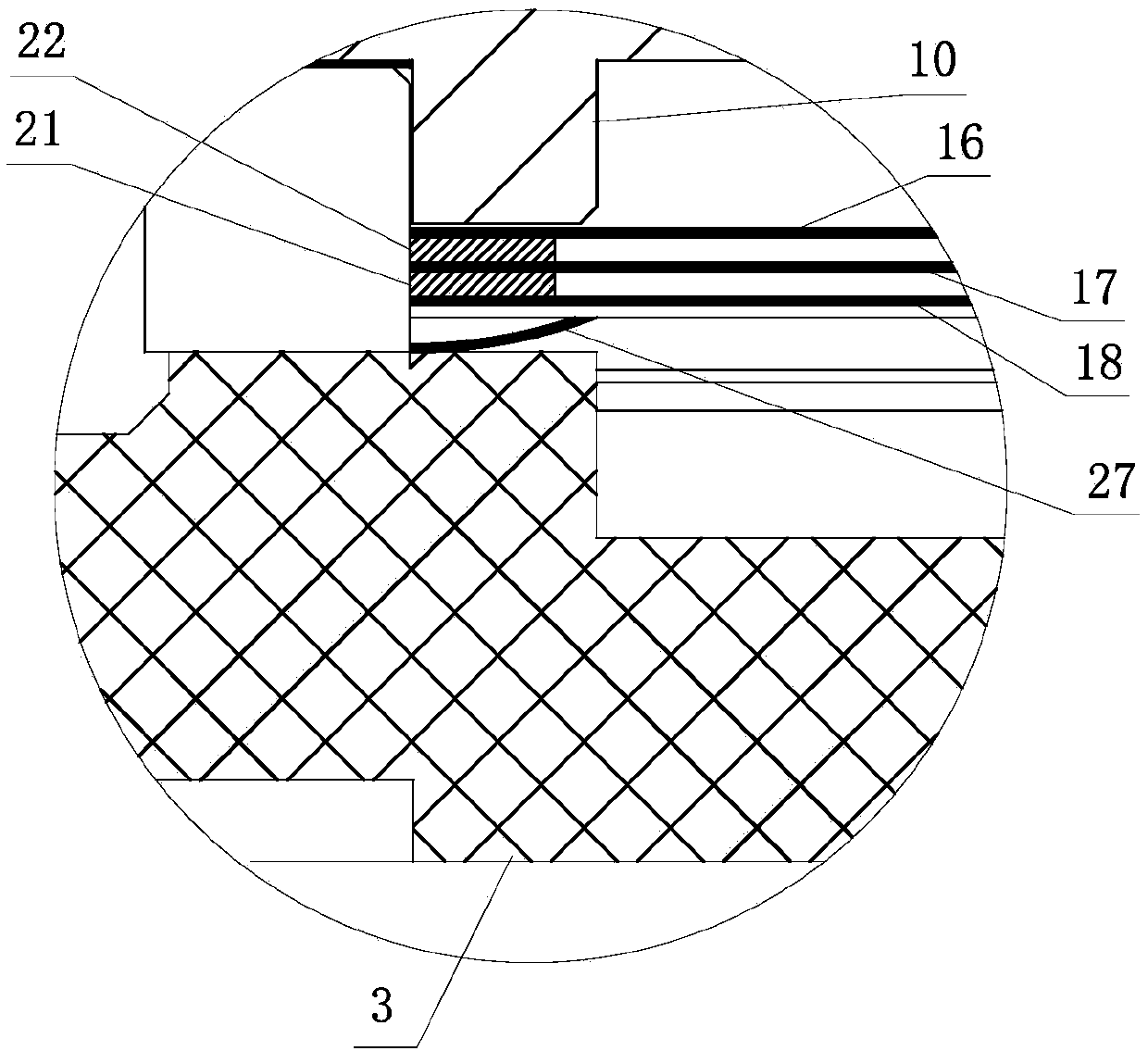

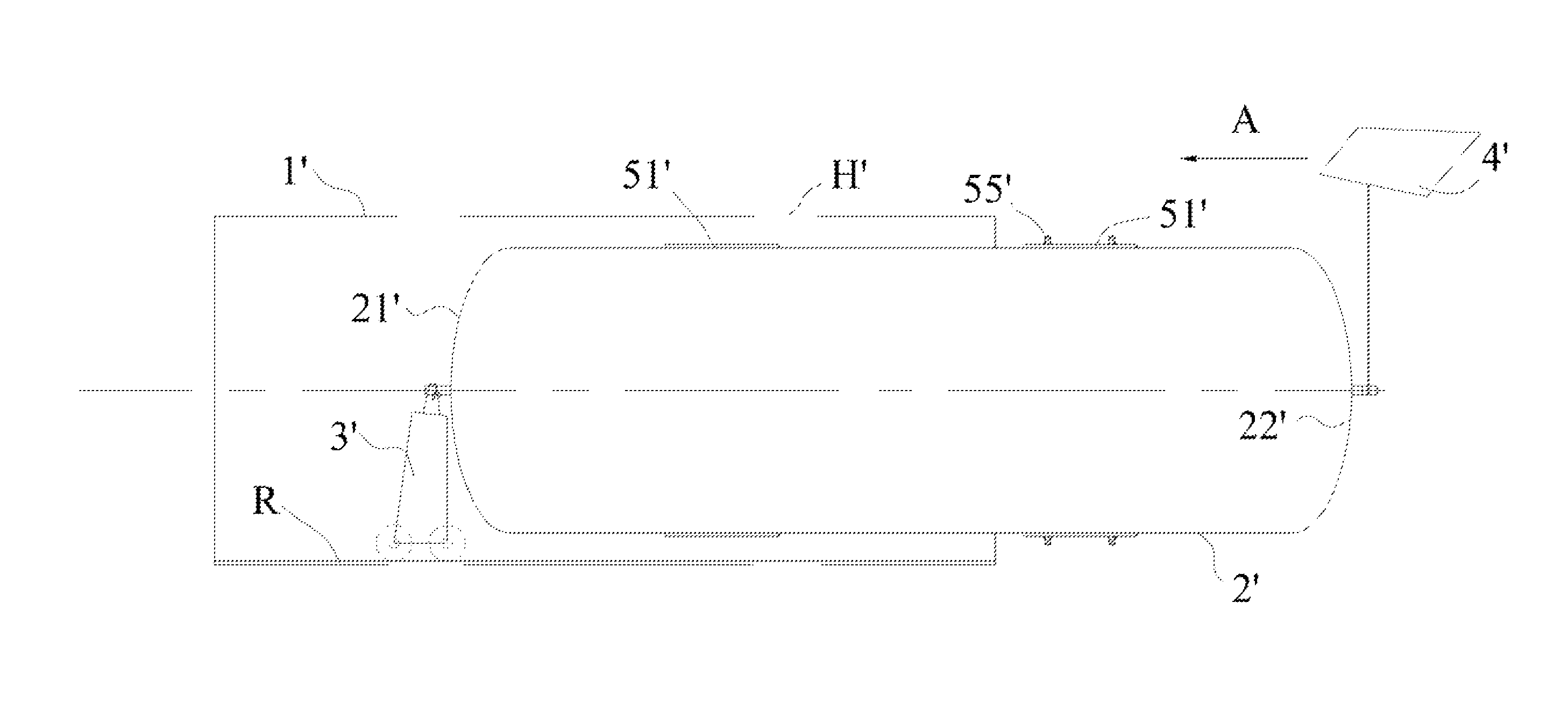

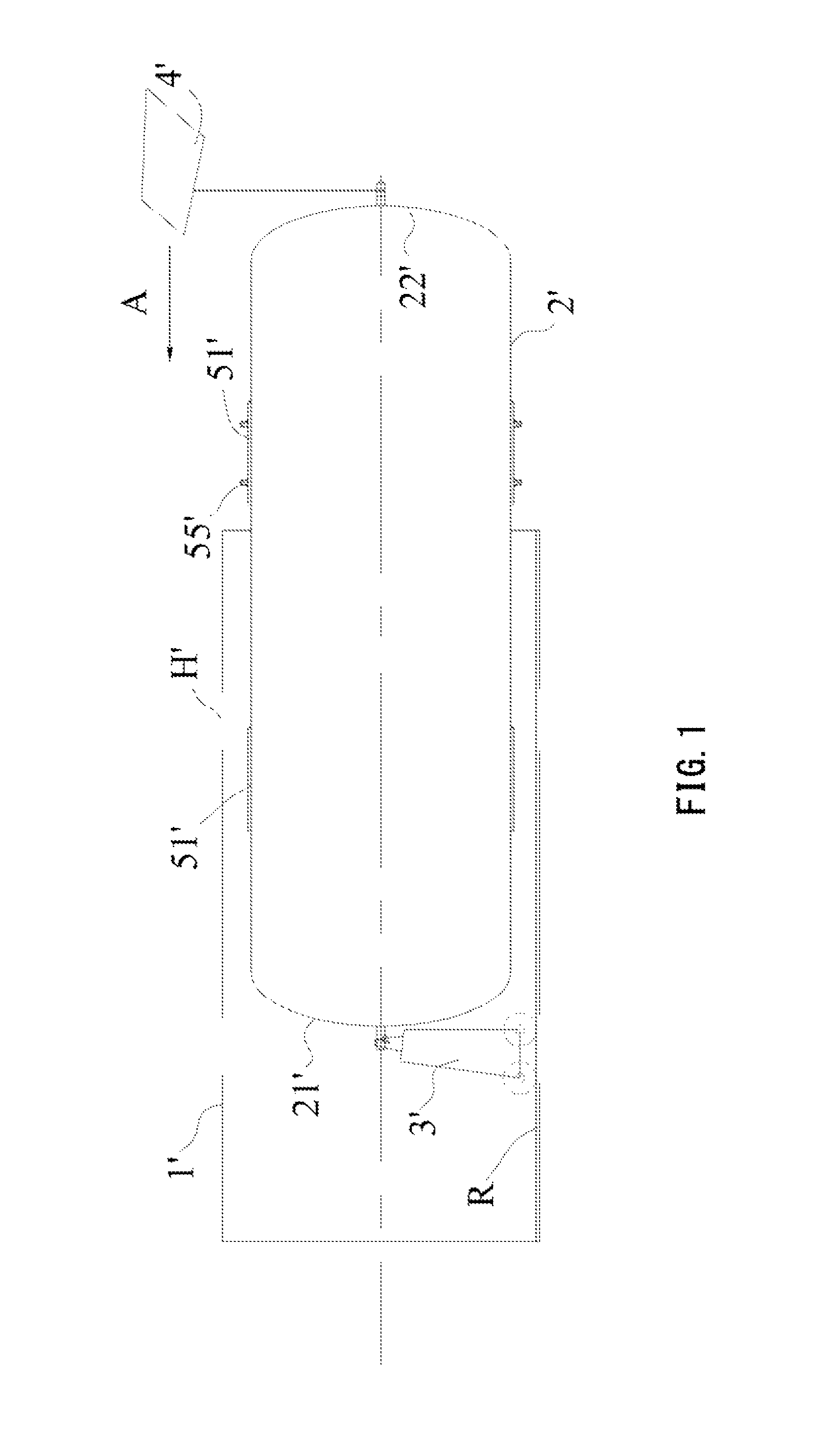

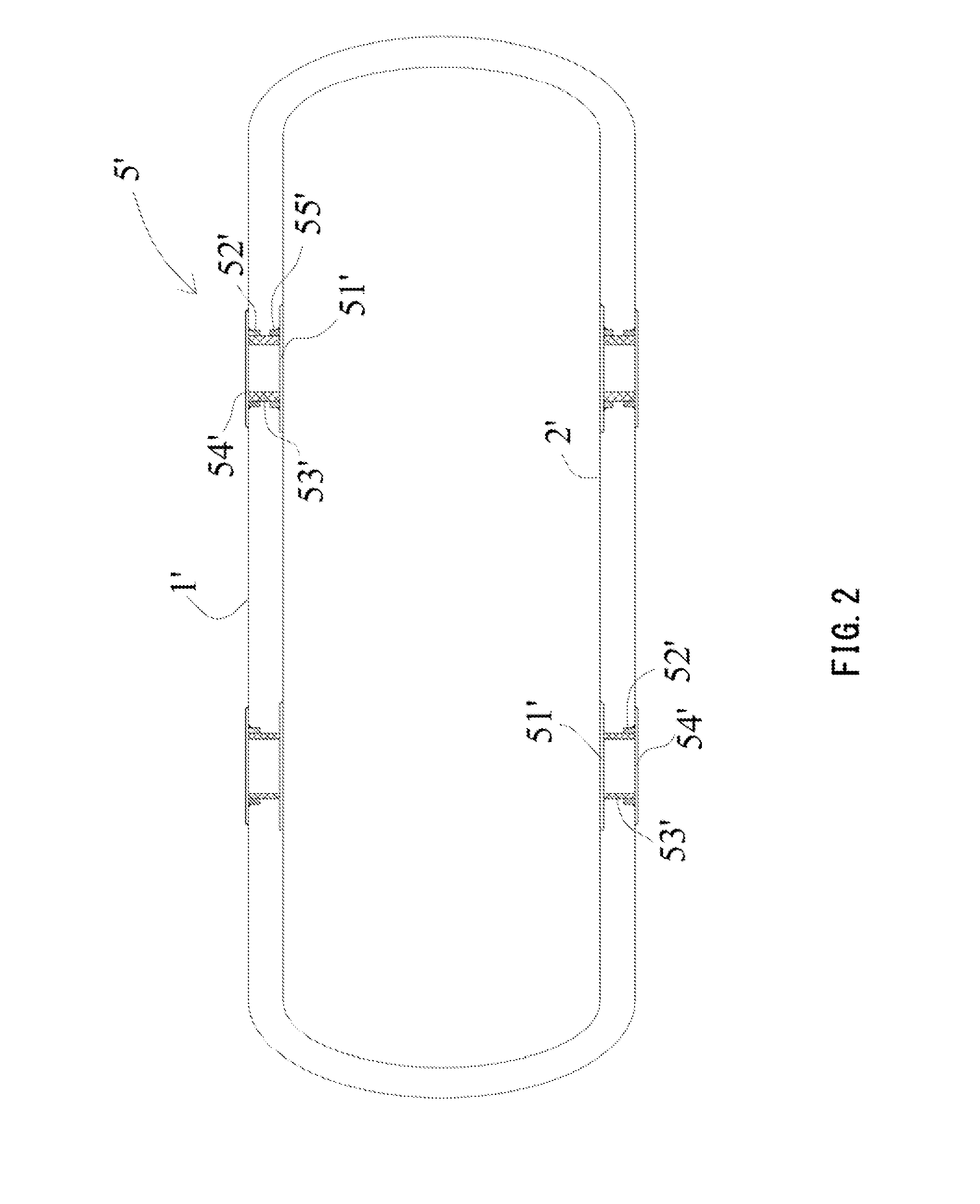

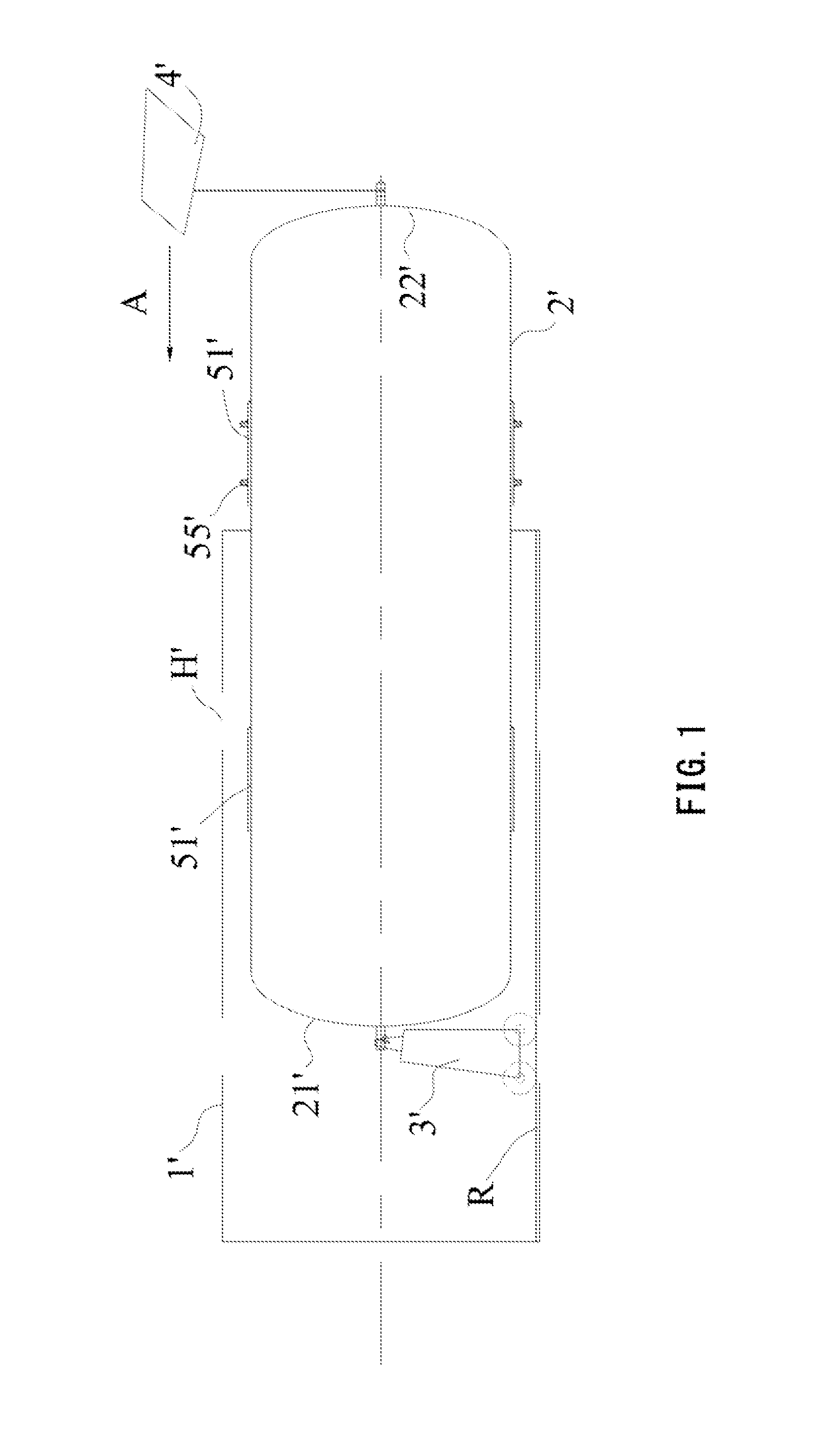

High vacuum container and adjusting device

ActiveUS8800805B2Reduced concentricity requirementsEnsure concentricityContainer filling methodsLarge containersEngineeringMechanical engineering

A high vacuum container includes an inner container body, an outer container body, a first group of supporting devices and a second group of supporting devices. Each group of supporting devices includes four supporting assemblies, and two supporting assemblies are disposed at the upper portion of the high vacuum container, and the other two are disposed at the lower portion of the high vacuum container. Each supporting assembly includes a base plate welded at outer surface of the inner container body and a heat insulating pipe extending along a radial direction of the high vacuum container, one end of the heat insulating pipe abutting against the base plate. Each supporting assembly at the lower portion further includes a fixing element, and each fixing element partly is partly inserted into the outer container body through the opening on the outer container body. Each fixing element has a top plate and a bending portion, and each bending portion bends vertically from the edge of the top plate and towards the inner part of the high vacuum container, and sleeves onto outside of the heat insulating pipe, and outer surface of the bending portion is welded to the outer container body at the opening. The high vacuum container and an adjusting device for adjusting the concentricity of the high vacuum container would be beneficial to high concentricity.

Owner:ZHANGJIAGANG CIMC SANCTUM CRYOGENIC EQUIP +1

Brushless DC motor having structures for mounting a hall element and a magnetic ring outside a motor casing

ActiveUS8803386B2Reasonable structureCost-effectiveUsing electrical meansDC commutatorHall elementEngineering

Owner:ZHONGSHAN BROAD OCEAN

High Vacuum Container and Adjusting Device

ActiveUS20130228489A1Reduce the impactEnsure concentricityLarge containersPackaging under vacuum/special atmosphereEngineeringMechanical engineering

A high vacuum container includes an inner container body, an outer container body, a first group of supporting devices and a second group of supporting devices. Each group of supporting devices includes four supporting assemblies, and two supporting assemblies are disposed at the upper portion of the high vacuum container, and the other two are disposed at the lower portion of the high vacuum container. Each supporting assembly includes a base plate welded at outer surface of the inner container body and a heat insulating pipe extending along a radial direction of the high vacuum container, one end of the heat insulating pipe abutting against the base plate. Each supporting assembly at the lower portion further includes a fixing element, and each fixing element partly is partly inserted into the outer container body through the opening on the outer container body. Each fixing element has a top plate and a bending portion, and each bending portion bends vertically from the edge of the top plate and towards the inner part of the high vacuum container, and sleeves onto outside of the heat insulating pipe, and outer surface of the bending portion is welded to the outer container body at the opening. The high vacuum container and an adjusting device for adjusting the concentricity of the high vacuum container would be beneficial to high concentricity.

Owner:ZHANGJIAGANG CIMC SANCTUM CRYOGENIC EQUIP +1

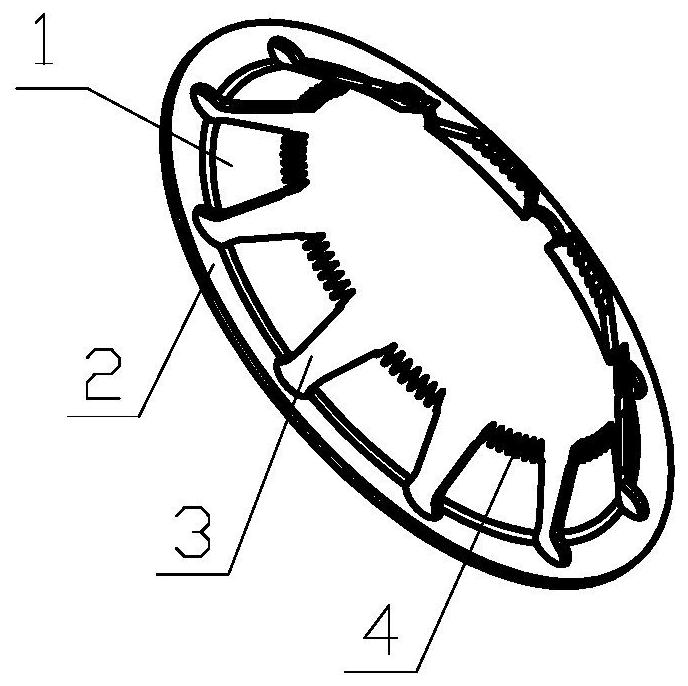

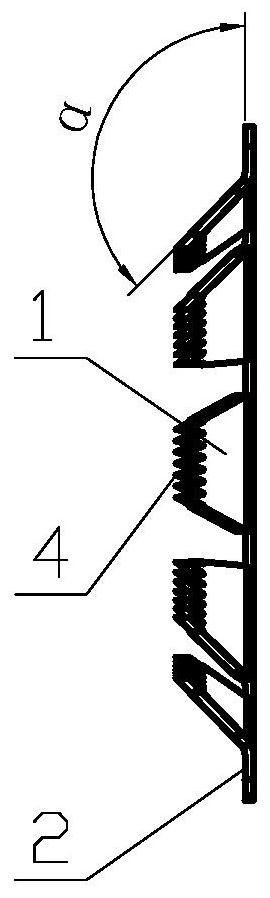

Locking disc spring for pipeline joint

PendingCN111853400ANot easy to release under pressureGuaranteed concentricityCouplingsSharp toothPhysics

The invention discloses a locking disc spring for a pipeline joint. The disc spring is provided with an annular locating edge, wherein a plurality of locking toothed discs extending toward the centerare arranged on the inner side of the locating edge; sharp teeth are arranged on the head parts of the locking toothed discs; the locking toothed discs form conical arrangement; and alternate disc grooves are formed between the locking toothed discs. The locking disc spring for the pipeline joint provided by the invention is better in elasticity, higher in fatigue resistance, and not easy to loseefficacy; the locating edge clings to the inner wall of a main body, so that the concentricity of the toothed disc spring and a pipe is ensured; and the sharp teeth on the sleeve type toothed disc spring are deepened into the pipe after the pipe is inserted into the joint, so that the pipeline is not easy to separate under stress and is safer to use since the disc spring can be deepened into the pipe compared with the prior art that no sharp teeth exist.

Owner:邱强生

System and method for in-situ resurfacing of a wind turbine main rotor shaft

ActiveUS20170002790A1Ensure concentricityWind motor assemblyWind motor combinationsRotational axisNacelle

A method is provided for in-situ resurfacing of a main rotor shaft of a wind turbine, wherein in an operational state, the main rotor shaft is coupled at a first end to a rotor hub and at the opposite second end to a gearbox or directly to a generator within a nacelle. The method includes uncoupling the rotor shaft from the gearbox or generator so as to expose an end face of the second end of the rotor shaft. A fixture is attached to the exposed end face concentric with the rotational axis of the rotor shaft. A lathe system in then attached to the fixture. The rotor shaft surface adjacent to the exposed end is machined with the lathe system such that the resurfaced portion of the rotor shaft surface is brought to a round state concentric with the rotational axis of the rotor shaft. The method is conducted within the nacelle with the first end of the rotor shaft remaining coupled to the rotor.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com