Stainless steel tube structure of heating rod of electronic thermostat and forming process of stainless steel tube structure

A technology of stainless steel pipe and forming process, which is applied in the direction of ohmic resistance heating parts, heating element shape, etc., can solve the problems that the flange and the heating rod cannot be guaranteed, the flange and the heating rod are easy to desolder, and waste processing time, etc., to achieve The structure is simple, the processing is convenient, and the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

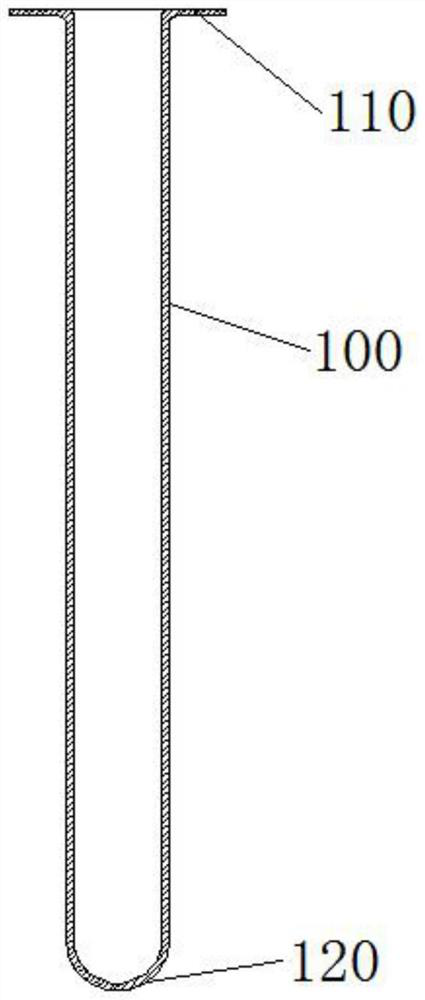

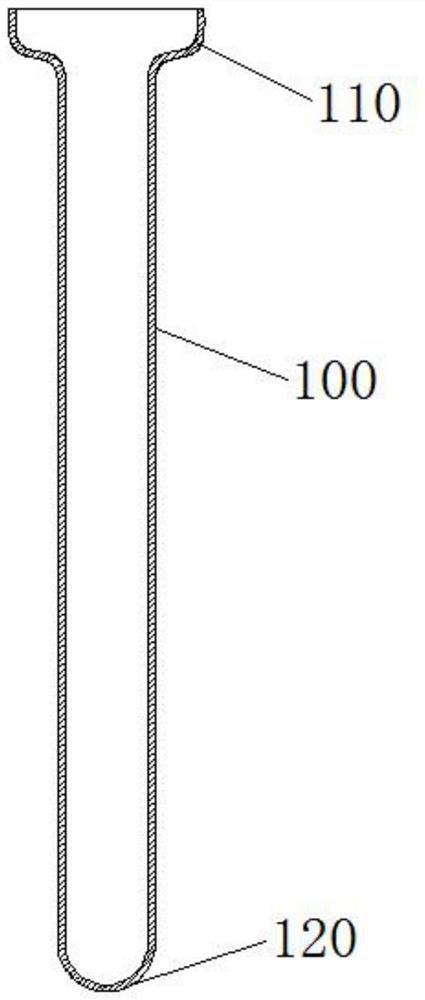

[0016] In the first embodiment, the other end of the tube body 100 is stamped by a die to form a sealed back cover 120 . In this embodiment, the other end of the tube body 100 is a sealed back cover 120 structure formed by die stamping, which can be combined with the tube body 100 and the tube body 100 . The flanging 110 structure is integrally stamped and formed, which greatly improves the processing efficiency.

Embodiment 2

[0017] The second embodiment, the difference between this embodiment and the first embodiment is that the other end of the pipe body 100 described in this embodiment is welded to form a sealed bottom cover 120, and the sealed bottom cover 120 of one end of the pipe body 100 is formed by welding, which can also be achieved. Same effect.

[0018] Among the above two embodiments, the first embodiment is preferably adopted, the processing procedure is simpler, the efficiency is higher, and the sealing performance is higher.

[0019] In this example figure 1 and figure 2 The pipe flanging structure shown is different in shape, but its function and the effect achieved are the same, all of which are used to replace the traditional flange structure.

[0020] The pipe body 100 and the flange 110 of the pipe body 100 are integrally stamped and formed by a stainless steel tube or a stainless steel plate. The everted bell mouth structure can be formed at the nozzle by lathe processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com