Metal type flux-cored wire and method of manufacturing austenitic stainless steel structural part

A technology of austenitic stainless steel and flux-cored welding wire, applied in metal processing equipment, welding accessories, welding equipment, etc., can solve problems such as difficulty, high manufacturing cost, and prone to defects, etc., achieve high production efficiency and improve fatigue resistance Ability, the effect of reducing welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

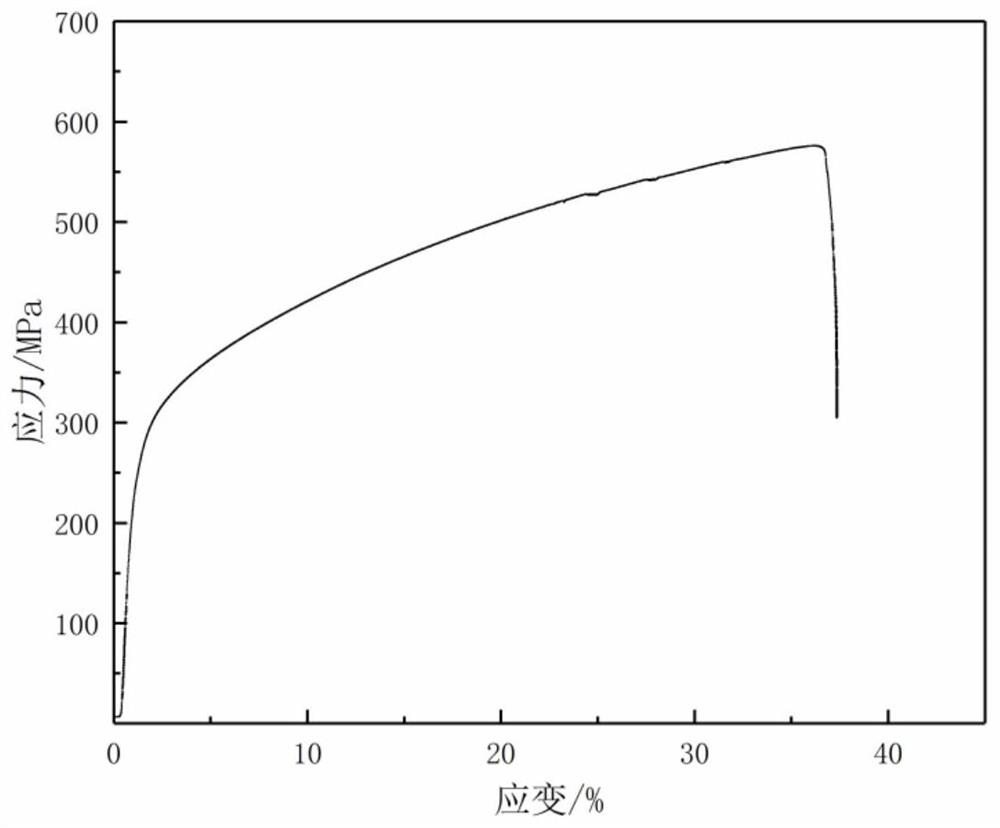

Embodiment 1

[0044]Step 1: Weigh 8% of ferrosilicon, 18% of manganese powder, 27% of nickel powder, 26% of chromium powder, 5% of molybdenum powder, 2.5% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder, 0.5% of lanthanum, 1% of niobium carbide, and the rest are iron powder. The sum of the percentages of the above components is 100%.

[0045] Step 2: Mix all the raw materials weighed in step 1 evenly and place them in a tube furnace, keep the temperature at 200° C. for 2 hours under the condition of continuously feeding argon.

[0046] Step 3: Place the low-carbon steel strip with a width of 7mm and a thickness of 0.3mm on the belt-releasing machine of the welding wire forming machine, and roll the low-carbon steel strip into a U-shaped groove through the pressure groove of the forming machine, and obtain in step 2 The drug core powder is put into the U-shaped groove, the filling rate of the drug core powder is controlled at 15wt%, and then the U-shaped groove is rolled a...

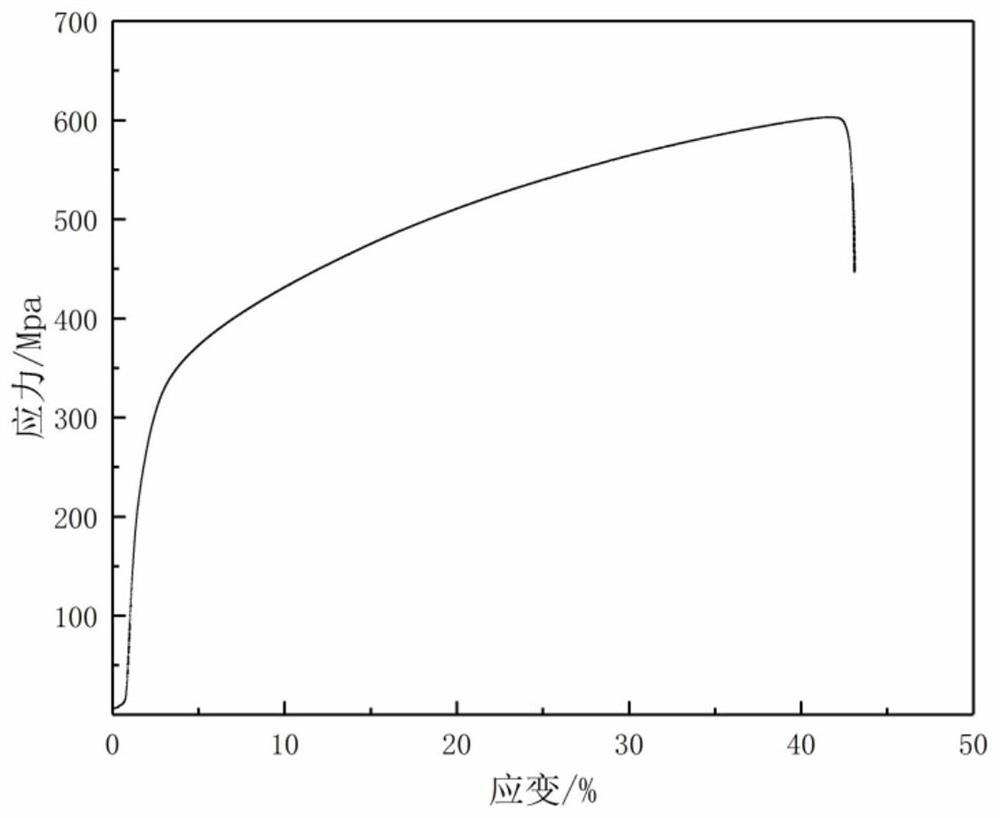

Embodiment 2

[0049] Step 1: Weigh ferrosilicon 8%, manganese powder 19%, nickel powder 27%, chromium powder 26%, molybdenum powder 7%, copper powder 2%, titanium powder 0.5%, aluminum powder 0.2%, oxide 0.5% of lanthanum, 1% of niobium carbide, and the rest is iron powder. The sum of the percentages of the above components is 100%.

[0050] Step 2: Mix all the raw materials weighed in step 1 evenly, place in a tube furnace, and keep warm at 230° C. for 3 hours under the condition of continuously feeding argon.

[0051] Step 3: Place the low-carbon steel strip with a width of 7mm and a thickness of 0.3mm on the belt-releasing machine of the welding wire forming machine, and roll the low-carbon steel strip into a U-shaped groove through the pressure groove of the forming machine, and obtain in step 2 The drug core powder is put into the U-shaped groove, the filling rate of the drug core powder is controlled at 15wt%, and then the U-shaped groove is rolled and closed with a molding machine, w...

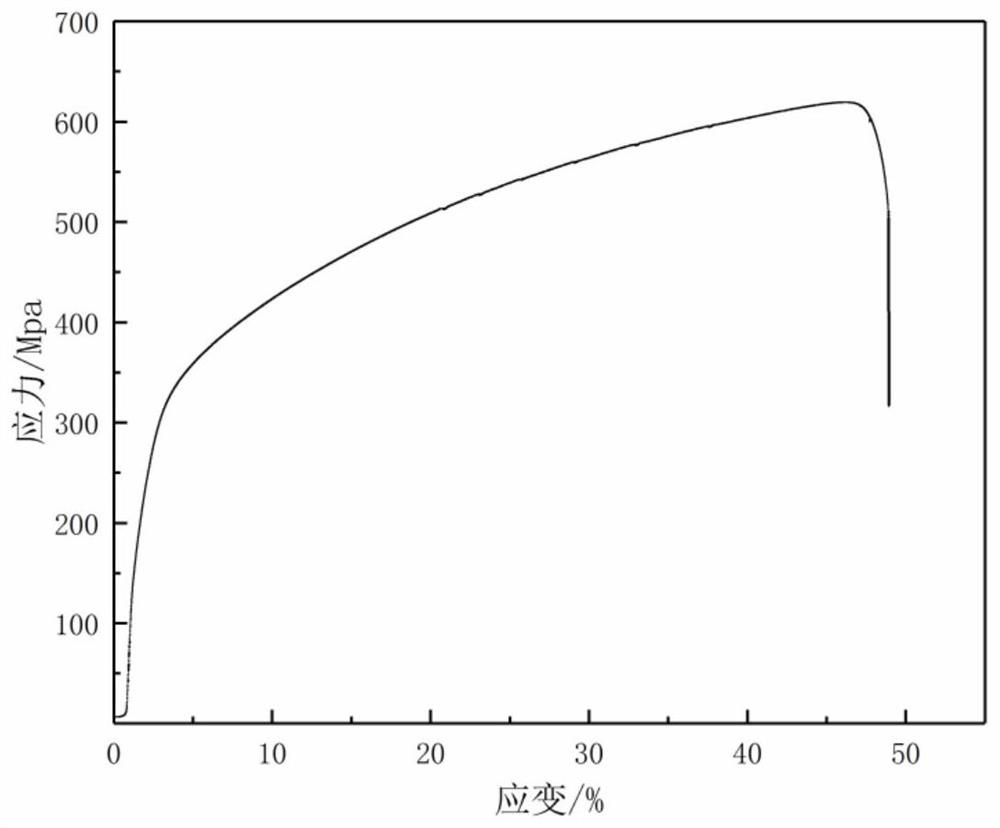

Embodiment 3

[0054] Step 1: Weigh 8% of ferrosilicon, 20% of manganese powder, 27% of nickel powder, 26% of chromium powder, 4% of molybdenum powder, 1.5% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder, and 0.5% of lanthanum, 1% of niobium carbide, and the rest are iron powder. The sum of the percentages of the above components is 100%.

[0055] Step 2: Mix all the raw materials weighed in step 1 evenly, place in a tube furnace, and keep warm at 250° C. for 2.5 hours under the condition of continuously feeding argon.

[0056] Step 3: Place the low-carbon steel strip with a width of 7mm and a thickness of 0.3mm on the belt-releasing machine of the welding wire forming machine, and roll the low-carbon steel strip into a U-shaped groove through the pressure groove of the forming machine, and obtain in step 2 The drug core powder is put into the U-shaped groove, the filling rate of the drug core powder is controlled at 15wt%, and then the U-shaped groove is rolled and close...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com