Method for preparing oil-absorbing wave-absorbing composite material from wood fiber powder

A technology of wood fiber powder and composite material, applied in the field of wood fiber powder, can solve the problems of high density, inability to absorb oil, narrow absorption frequency band, etc., and achieve the effects of increasing surface area, enhancing wave absorption performance, and enhancing magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

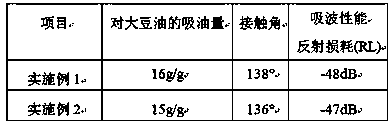

Embodiment 1

[0029] A method for preparing an oil-absorbing wave-absorbing composite material with wood fiber powder, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0030] (1) Hydrothermal treatment method of wood fiber powder:

[0031] Add deionized water to 10 parts of hydrophobic wood fiber powder at a ratio of 1:40, seal it in the reactor, heat to 165°C, and react with hydrothermal treatment for 70 minutes, then cool, filter, wash with water for 3 times, and freeze-dry to obtain hydrothermally treated oil-absorbing wood fiber powder. fiber powder;

[0032] Among them, the preparation of hydrophobic wood fiber powder: mix 30 parts of ethyl orthosilicate, 50 parts of n-butanol and 130 parts of distilled water, add dropwise 22 parts of ammonia water with a concentration of 25% and stir until transparent, add 2 parts of wood fiber powder and stir for 4 hours Afterwards, wash with water, filter 3 times, and dry t...

Embodiment 2

[0040] A method for preparing an oil-absorbing wave-absorbing composite material with wood fiber powder, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0041] (1) Hydrothermal treatment method of wood fiber powder:

[0042] Add deionized water to 20 parts of hydrophobic lignocellulosic powder at a ratio of 1:40, seal it in the reactor, heat to 175°C, react with hydrothermal treatment for 50 minutes, cool, filter, wash with water for 3 times, freeze-dry to obtain hydrothermally treated oil-absorbing wood fiber powder;

[0043] Among them, the preparation of hydrophobic wood fiber powder: mix 35 parts of ethyl orthosilicate, 60 parts of n-butanol and 150 parts of distilled water, add dropwise 25 parts of ammonia water with a concentration of 25% and stir until transparent, add 4 parts of wood fiber powder and stir for 5 hours Afterwards, wash with water, filter 5 times, and dry to obtain lignocellulos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com