A method for reducing iron scale of hot-rolled strip steel based on reduction pretreatment process

A technology for hot-rolled strip steel and iron oxide scale, applied in the field of metallurgy, can solve problems such as low reduction efficiency of galvanized sheet, and achieve the effect of improving reduction reaction efficiency and reducing hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

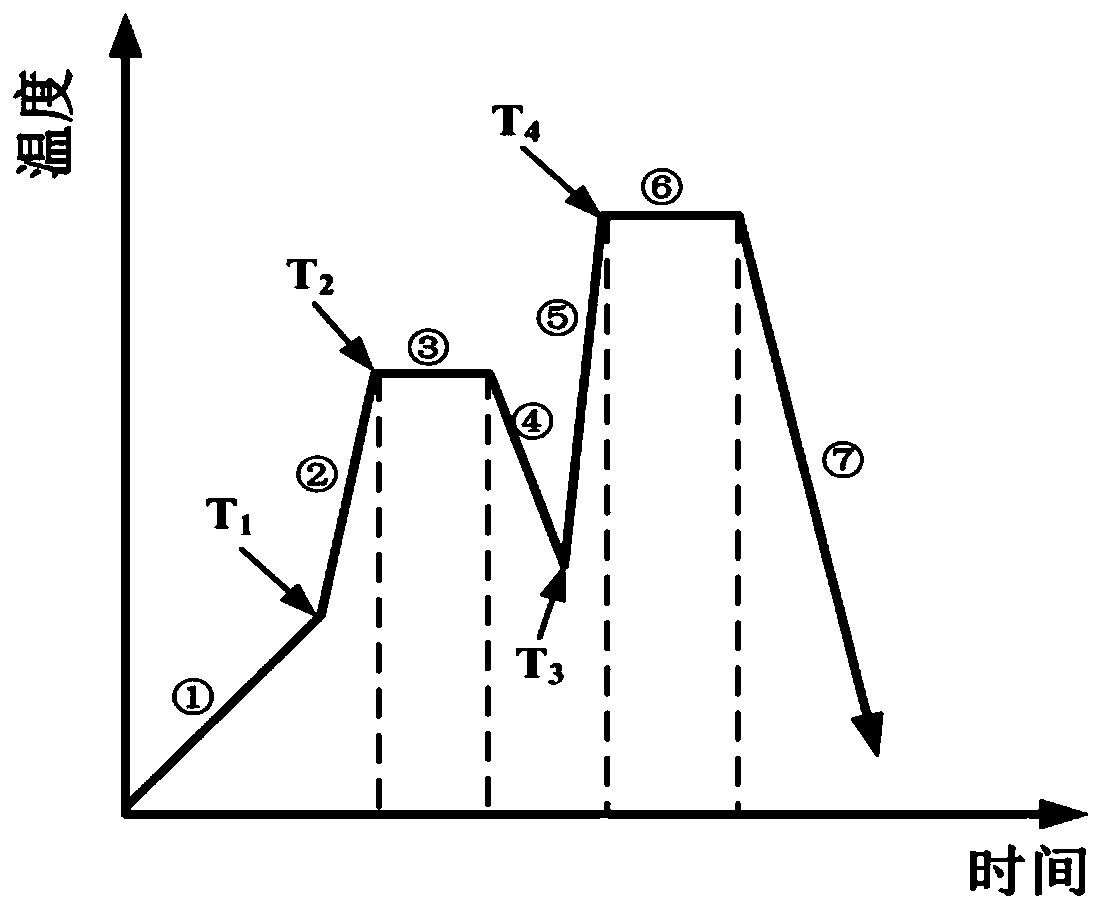

[0071] A method for reducing scale of hot-rolled strip steel based on the reduction pretreatment process, the process diagram is as follows image 3 shown, including the following steps:

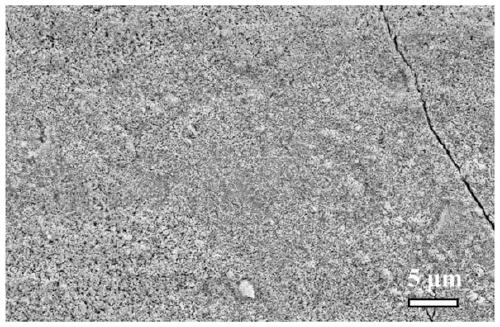

[0072] (1) Get hot-rolled steel strip, heat up to 200 ℃ with 30 ℃ / s, carry out preheating, wherein, the composition of hot-rolled steel strip contains C: 0.03%, Si: 0.04%, Mn: 0.15% by weight percentage, S: 0.015%, P: 0.019%, Cr: 0.2%, Als: 0.015%, and the rest are Fe and unavoidable impurities during smelting. The thickness of the hot-rolled steel strip is 1.3 mm, and the microscopic appearance of the cross-section of the oxide scale is as follows: Figure 4 As shown, the thickness of the iron oxide scale is 6 μm, and the lamellar eutectoid Fe in the iron oxide scale 3 o 4 The ratio of / α-Fe is 95%;

[0073] (2) The rapid heating reduction pretreatment section rapidly heats up to 550°C at 150°C / s, and the H 2 The volume concentration is 50%, and the isothermal reduction is 30s. The sur...

Embodiment 2

[0077] A method for reducing scale of hot-rolled strip steel based on reduction pretreatment process, comprising the following steps:

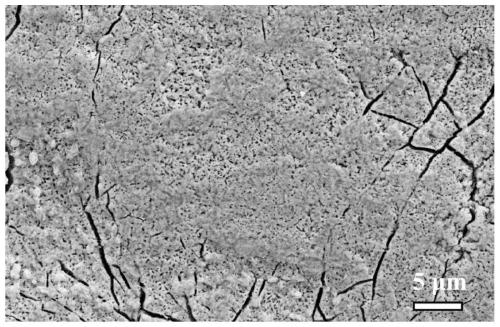

[0078] (1) Get hot-rolled steel strip, heat up to 300 ℃ with 60 ℃ / s, carry out preheating, wherein: the composition of hot-rolled steel strip contains C: 0.10%, Si: 0.60%, Mn: 1.0% by weight percentage, S: 0.015%, P: 0.019%, Cr: 0.5%, Als: 0.045%, Ti: 0.08%, and the rest are Fe and unavoidable impurities during smelting. The thickness of the hot-rolled steel strip is 1.5 mm, and the microscopic appearance of the cross-section of the oxide scale is as follows: Figure 8 As shown, the thickness of the iron oxide scale is 6 μm, and the lamellar eutectoid Fe in the iron oxide scale 3 o 4 The ratio of / α-Fe is 60%;

[0079] (2) The rapid heating reduction pretreatment section rapidly heats up to 500°C at 100°C / s, H 2 The volume concentration is 30%, and the isothermal reduction is 60s;

[0080] (3) After strip reduction pretreatment, the tempe...

Embodiment 3

[0083] A method for reducing scale of hot-rolled strip steel based on reduction pretreatment process, comprising the following steps:

[0084] (1) Get hot-rolled steel strip, heat up to 300 ℃ with 45 ℃ / s, carry out preheating, wherein: the composition of hot-rolled steel strip contains C: 0.05%, Si: 0.30%, Mn: 0.5% by weight percentage, S: 0.009%, P: 0.010%, Cr: 1.0%, Als: 0.045%, Ti: 0.045%, Nb: 0.08%, and the rest are Fe and unavoidable impurities during smelting. The thickness of the hot-rolled strip steel is 2.0mm, the thickness of the iron oxide scale is 6.5μm, and the lamellar eutectoid structure Fe in the iron oxide scale is 3 o 4 The ratio of / α-Fe is 70%;

[0085] (2) The rapid heating reduction pretreatment section rapidly heats up to 450°C at 80°C / s, and the H 2 The volume concentration is 5%, and the isothermal reduction is 600s;

[0086] (3) After strip reduction pretreatment, the temperature is dropped by 50°C at a cooling rate of 10°C / s;

[0087] (4) In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com